Professional Documents

Culture Documents

Lecture 4

Lecture 4

Uploaded by

fakhar mahtab0 ratings0% found this document useful (0 votes)

2 views10 pagesttt

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentttt

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views10 pagesLecture 4

Lecture 4

Uploaded by

fakhar mahtabttt

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 10

Health, Safety and Environment 1

DR. MUHAMMAD ZEESHAN MIRZA

LECTURE - 4

Department of Engineering Management (DEM) – NUST- CEME

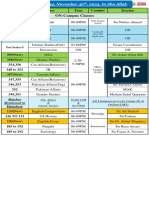

Course Information

Course Name Health, Safety and Environment

Course Code ME-424

Credit Hours 1

Email zeeshanmirza21@hotmail.com

Visiting Hours 2-4 pm (Tuesday & Wednesday)

Location Block-7, 1st Floor

Department of Engineering Management (DEM) – NUST- CEME

Accident Prevention

Prevention is the first or initial part of ‘control’

Accident control is a vital factor in every industry

Accident-prevention task requires, the short-term approach

(direct control of personal performance and environment)

And the long-term approach (instruction, training, and education)

Department of Engineering Management (DEM) – NUST- CEME

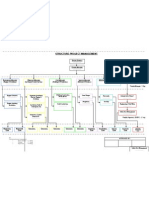

Principles of Accident Prevention

Department of Engineering Management (DEM) – NUST- CEME

Principles of Accident Prevention

Organization

The planned procedure that how safety programs is designed,

directed and controlled

Organization does not mean safety department only

All the members of the organization (including all departments) have

to contribute and play their role for safety

Top management, staff and every single person working for safety

Department of Engineering Management (DEM) – NUST- CEME

Principles of Accident Prevention

Fact Finding

The knowledge of probable or potential hazards (facts) is derived

from surveys, inspections, safety audits, observations, review or

records, inquiry, investigation, and judgment

Facts include past, present and future facts

Personal hazards (unsafe acts) are violations of commonly accepted

safety rules, practices, and procedures

Mechanical hazards (unsafe conditions) are of four groups: Static,

kinetic, electrical and chemical (including radioactive or nuclear)

Department of Engineering Management (DEM) – NUST- CEME

Principles of Accident Prevention

Fact Finding

Department of Engineering Management (DEM) – NUST- CEME

Principles of Accident Prevention

Hazard Analysis

Initially a hazard analysis (HAZAN) is undertaken so as to ascertain

the magnitude of the potential problem

Its potential for harm to the people, plant, process and the public

A subsequent risk analysis will then go on to examine the actual

consequences – worst possible case considerations – and express

them in quantifiable terms

Department of Engineering Management (DEM) – NUST- CEME

Principles of Accident Prevention

Selection of Remedy

What and Which measures to be selected to prevent accidents in

future

Application of Remedy

How the measures will be implemented at workplace

Department of Engineering Management (DEM) – NUST- CEME

Department of Engineering Management (DEM) – NUST- CEME

You might also like

- Hazard EvaluationDocument48 pagesHazard Evaluationanpuselvi125100% (1)

- 5S - The Five Pillars of An Effective Workplace PDFDocument4 pages5S - The Five Pillars of An Effective Workplace PDFamirq4No ratings yet

- Group 1 Safety EngineeringDocument103 pagesGroup 1 Safety EngineeringErnielle Rae Dela CruzNo ratings yet

- Safety Critical Element Methodology in Oil & GasDocument5 pagesSafety Critical Element Methodology in Oil & GasHedi Ben Mohamed100% (2)

- EPC Structure Project ManagementDocument1 pageEPC Structure Project ManagementArif Rachman100% (3)

- Risk Analysis, Assessment, ManagementDocument7 pagesRisk Analysis, Assessment, ManagementSadiq AkbarNo ratings yet

- Dhi-Ehs-Hsm-001 Ehs Risk Management Rev0Document22 pagesDhi-Ehs-Hsm-001 Ehs Risk Management Rev0khoahuyen_89No ratings yet

- CHE 534 Module 1Document37 pagesCHE 534 Module 1Precious JamesNo ratings yet

- Primarily For External Users Exclusively For Internal UsersDocument3 pagesPrimarily For External Users Exclusively For Internal UsersKim Taehyung100% (1)

- SMS CourseDocument271 pagesSMS CourseSherif AbbasNo ratings yet

- Safety Engineer Safety Engineering Is An Engineering Discipline Which Assures That Engineered SystemsDocument5 pagesSafety Engineer Safety Engineering Is An Engineering Discipline Which Assures That Engineered SystemsJohn Nate RiveraNo ratings yet

- Small Business An Entrepreneurs Plan Enhanced Canadian 7th Edition Knowles Solutions ManualDocument23 pagesSmall Business An Entrepreneurs Plan Enhanced Canadian 7th Edition Knowles Solutions ManualPennyRuizotspf100% (46)

- Process Safety Capability StudiesDocument35 pagesProcess Safety Capability Studiesdmrpanda9940100% (1)

- Market Research and AnalysisDocument6 pagesMarket Research and AnalysishasanulfiqryNo ratings yet

- Ladder Risk AssessmentDocument3 pagesLadder Risk Assessmentvasanth pugazhendhiNo ratings yet

- Risk Assessment at Sea Training CourseDocument32 pagesRisk Assessment at Sea Training CourseNikkolai Kirril Gementiza UguisNo ratings yet

- 2019 Caterpillar Mining Equipment Management Metrics Document - Version 4Document78 pages2019 Caterpillar Mining Equipment Management Metrics Document - Version 4mauricio100% (4)

- Introduction To Process Safety PrinciplesDocument9 pagesIntroduction To Process Safety PrinciplesWafa Habib100% (1)

- Overview of Safety & System Safety Process2Document22 pagesOverview of Safety & System Safety Process2Xerxa LinganNo ratings yet

- Safety and DisasterDocument69 pagesSafety and DisasterRaol12 ChaudharyNo ratings yet

- Introduction To Safety: Topic 1Document32 pagesIntroduction To Safety: Topic 1Nelvin Kaw Chee QingNo ratings yet

- Professional Ethics: Dr. Muhammad Zeeshan MirzaDocument20 pagesProfessional Ethics: Dr. Muhammad Zeeshan MirzaRaaz KhanNo ratings yet

- Lecture 7 Industrial Safety - BDocument22 pagesLecture 7 Industrial Safety - BRain bowNo ratings yet

- 2.3.2.1 Safety Management System NotesDocument9 pages2.3.2.1 Safety Management System Noteskit_mak_5No ratings yet

- Safety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaDocument11 pagesSafety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaSheila Marie CagadasNo ratings yet

- Ergonomic in MaintainabilityDocument4 pagesErgonomic in MaintainabilityDamigo DiegoNo ratings yet

- Safety Management SystemDocument37 pagesSafety Management SystemTapasya NathNo ratings yet

- System Theory Based Hazard Analysis For Construction Site SafetyDocument12 pagesSystem Theory Based Hazard Analysis For Construction Site SafetymusniraNo ratings yet

- Maharashtra State Board of Vocational Education Examination, Mumbai-51Document5 pagesMaharashtra State Board of Vocational Education Examination, Mumbai-51MithileshNo ratings yet

- ARAMIS Project - Event Prediction (General)Document19 pagesARAMIS Project - Event Prediction (General)Titania AlrayshaNo ratings yet

- Penerbit, 039Document11 pagesPenerbit, 039Harshini Silva KumarNo ratings yet

- Proactive Safety ArticleDocument6 pagesProactive Safety ArticleLUIS ALEJANDRO CUERVO GALVISNo ratings yet

- Ieeebeiac2012347 350Document5 pagesIeeebeiac2012347 350Manas Kumar SamalNo ratings yet

- Safety and RiskDocument35 pagesSafety and Riskpandiyarajan142611100% (1)

- UNIT-4 Safety and Risk: GE6075 - Professional Ethics in EngineeringDocument35 pagesUNIT-4 Safety and Risk: GE6075 - Professional Ethics in EngineeringjohnjicklerNo ratings yet

- Safety Engr'gDocument4 pagesSafety Engr'gJohn GenirNo ratings yet

- Chain-Of-Events ModelsDocument15 pagesChain-Of-Events ModelsEdward SmithNo ratings yet

- Reliability Engineering vs. System SafetyDocument15 pagesReliability Engineering vs. System SafetyEdward SmithNo ratings yet

- Hazards Risk Analysis N ScankDocument51 pagesHazards Risk Analysis N ScankpotatoteddyNo ratings yet

- Risk Assessment in Mining IndustryDocument14 pagesRisk Assessment in Mining IndustrynathansolaiNo ratings yet

- Training Request Form - Process Safey TrainingsDocument3 pagesTraining Request Form - Process Safey TrainingssheerazaliNo ratings yet

- Mper 2017 0006Document14 pagesMper 2017 0006Abde LazizeNo ratings yet

- MME30001 Minor Activity OHS With Suggested Answers PDFDocument5 pagesMME30001 Minor Activity OHS With Suggested Answers PDFMosesNo ratings yet

- Systems-Theoretic Accident Model andDocument42 pagesSystems-Theoretic Accident Model andatcosupportNo ratings yet

- Reference ACC HardwareDocument8 pagesReference ACC HardwareVenkat RaoNo ratings yet

- Introduction To Industrial Safety and HealthDocument3 pagesIntroduction To Industrial Safety and HealthRey Danielle Taray NaveaNo ratings yet

- An Inherent Safety-Based Incident Investigation Methodology: Attiq Goraya, Paul R. Amyotte, and Faisal I. KhanDocument9 pagesAn Inherent Safety-Based Incident Investigation Methodology: Attiq Goraya, Paul R. Amyotte, and Faisal I. KhanValmir Pereira ZutinNo ratings yet

- Chapter1-SafetyDocument52 pagesChapter1-SafetyDani elbannaNo ratings yet

- ChE 197 Introduction To Health Safety and Environment Syllabus 1st Sem 2014 2015 PDFDocument2 pagesChE 197 Introduction To Health Safety and Environment Syllabus 1st Sem 2014 2015 PDFKeith SmithNo ratings yet

- (99+) The Five Pitfalls in Managing Safety Critical Elements (Sce) - LinkedinDocument1 page(99+) The Five Pitfalls in Managing Safety Critical Elements (Sce) - LinkedinAsim Qureshi0% (1)

- SPE - DescriptionDocument5 pagesSPE - DescriptionJuan VelasquezNo ratings yet

- NMISHRAG AppendicesDocument48 pagesNMISHRAG Appendicesapi-3733731No ratings yet

- Safety (Unit-1)Document15 pagesSafety (Unit-1)aditya raajNo ratings yet

- Sms OverviewDocument30 pagesSms Overviewive23No ratings yet

- M1-Safety StandardsDocument9 pagesM1-Safety StandardscarlNo ratings yet

- Safety Management - Module1Document28 pagesSafety Management - Module1Atienza ArjayNo ratings yet

- Near-Miss A Tool For Integrated Safety Health EnviDocument18 pagesNear-Miss A Tool For Integrated Safety Health EnviAgung SanjayaNo ratings yet

- Mr. Christian S. Sol: Accredited DOLE-OSH Safety Consultant Accredited DENR Pollution Control OfficerDocument31 pagesMr. Christian S. Sol: Accredited DOLE-OSH Safety Consultant Accredited DENR Pollution Control OfficerSn CarbonelNo ratings yet

- On The Safety of Machine LearningDocument20 pagesOn The Safety of Machine Learningel_charlieNo ratings yet

- SOP Template 2008Document2 pagesSOP Template 2008Brijgopal YadavNo ratings yet

- Analysis of Technological Risk Assessment MethodsDocument12 pagesAnalysis of Technological Risk Assessment MethodsBesiNo ratings yet

- Safety Engineering: The Task of Safety EngineersDocument6 pagesSafety Engineering: The Task of Safety EngineersEvaline Faith Tacadena BlancoNo ratings yet

- Occupational Safety and Health (KAS3501) : Semester 6 2014/ 2015 Group 8 Presentation Date: 1 April 2015Document57 pagesOccupational Safety and Health (KAS3501) : Semester 6 2014/ 2015 Group 8 Presentation Date: 1 April 2015Tahir AbbasNo ratings yet

- Safety Critical ElementDocument1 pageSafety Critical ElementAnonymous cKdbnUHNo ratings yet

- Assessment and Risk Management of Potential Hazards by Failure Modes and Effect Analysis (FMEA) Method in Yazd Steel ComplexDocument11 pagesAssessment and Risk Management of Potential Hazards by Failure Modes and Effect Analysis (FMEA) Method in Yazd Steel ComplexDaniel ReyesNo ratings yet

- Security Risk Management SeminarDocument10 pagesSecurity Risk Management SeminarJordan PopovskiNo ratings yet

- AMethodologyfor Choosingan Emergency Shutdown SystemDocument8 pagesAMethodologyfor Choosingan Emergency Shutdown SystemvaraNo ratings yet

- Pakistan and India Nuclear Standoff and Nuclear Politics of South Asia NotesDocument3 pagesPakistan and India Nuclear Standoff and Nuclear Politics of South Asia Notesfakhar mahtabNo ratings yet

- Lecture 5 (2)Document19 pagesLecture 5 (2)fakhar mahtabNo ratings yet

- 2nd ocrDocument7 pages2nd ocrfakhar mahtabNo ratings yet

- ODVVDocument5 pagesODVVfakhar mahtabNo ratings yet

- Assignment 2 PMDocument10 pagesAssignment 2 PMfakhar mahtabNo ratings yet

- Ford Pinto PresentationDocument16 pagesFord Pinto Presentationfakhar mahtabNo ratings yet

- Essay-Feb(Final)-2024 (1)Document1 pageEssay-Feb(Final)-2024 (1)fakhar mahtabNo ratings yet

- 26-Aug-2023Document3 pages26-Aug-2023fakhar mahtabNo ratings yet

- PINTODocument4 pagesPINTOfakhar mahtabNo ratings yet

- Week 4Document26 pagesWeek 4fakhar mahtabNo ratings yet

- 19 Feb 2024Document2 pages19 Feb 2024fakhar mahtabNo ratings yet

- CamScanner 12-20-2023 13.39Document8 pagesCamScanner 12-20-2023 13.39fakhar mahtabNo ratings yet

- Branches Science List Their MeaningsDocument2 pagesBranches Science List Their Meaningsfakhar mahtabNo ratings yet

- Experiments - 03,04 & 05Document24 pagesExperiments - 03,04 & 05fakhar mahtabNo ratings yet

- ME-431 Lab GroupsDocument1 pageME-431 Lab Groupsfakhar mahtabNo ratings yet

- Ocr 3Document42 pagesOcr 3fakhar mahtabNo ratings yet

- Week 2Document50 pagesWeek 2fakhar mahtabNo ratings yet

- 24 Oct 2023Document2 pages24 Oct 2023fakhar mahtabNo ratings yet

- 30 Nov 2023Document3 pages30 Nov 2023fakhar mahtabNo ratings yet

- 30 Dec 2023Document3 pages30 Dec 2023fakhar mahtabNo ratings yet

- Lesser: CamscannerDocument19 pagesLesser: Camscannerfakhar mahtabNo ratings yet

- PCS General Knowledge Paper 2021 PDFDocument4 pagesPCS General Knowledge Paper 2021 PDFfakhar mahtabNo ratings yet

- Business Plan FOR Expansion of Beruang Building Materials StoreDocument121 pagesBusiness Plan FOR Expansion of Beruang Building Materials StoreKoleyNo ratings yet

- Powepoint Presentation On Opportunity CostDocument10 pagesPowepoint Presentation On Opportunity CostRaghav GuptaNo ratings yet

- SAP PP-FI IntegrationDocument12 pagesSAP PP-FI Integrationrushikeshdeokar155No ratings yet

- Make Versus Buy: Facts of The CaseDocument2 pagesMake Versus Buy: Facts of The CaseJAYA KIRTANA.SNo ratings yet

- Chapter 2-Structural Design For Organizations: Multiple ChoiceDocument20 pagesChapter 2-Structural Design For Organizations: Multiple ChoiceRajat ShrinetNo ratings yet

- Store Keeping: Dr. Mridula SahayDocument14 pagesStore Keeping: Dr. Mridula SahayMohd Shadaab100% (1)

- Chapter 2 Part 1Document8 pagesChapter 2 Part 1Aya MasoudNo ratings yet

- Public Register - Tax Practitioners BoardDocument1 pagePublic Register - Tax Practitioners BoardLuke CasleyNo ratings yet

- Auditing PractiseDocument37 pagesAuditing PractiseJamsari SulaimanNo ratings yet

- UntitledDocument6 pagesUntitledomdeviNo ratings yet

- At.3211 - Further Audit ProceduresDocument5 pagesAt.3211 - Further Audit ProceduresDenny June CraususNo ratings yet

- NMD Delivery OperationDocument61 pagesNMD Delivery Operationjohnlester delacruz0% (1)

- Nama Nama AkunDocument26 pagesNama Nama AkunTia YuliandiniNo ratings yet

- Teacher's Satisfaction Survey 2023Document2 pagesTeacher's Satisfaction Survey 2023Arnel AmbrocioNo ratings yet

- Case Study in EthicsDocument4 pagesCase Study in EthicsJarvis DacanayNo ratings yet

- Little Green BookDocument73 pagesLittle Green BookghedjioskNo ratings yet

- MacroC10 The Swan-Solow ModelDocument66 pagesMacroC10 The Swan-Solow ModelNgọc Minh Đỗ NguyễnNo ratings yet

- Sono Koya Training FilelDocument56 pagesSono Koya Training FilelVegeta12527100% (4)

- Cost Management A Strategic Emphasis 6th Edition Blocher Solutions ManualDocument25 pagesCost Management A Strategic Emphasis 6th Edition Blocher Solutions ManualLisaWyattxgkf100% (53)

- Gartner It Score For Infrastructure and Operations Sample ExcerptDocument8 pagesGartner It Score For Infrastructure and Operations Sample ExcerptmwhaliNo ratings yet

- Contoh Kasus Job Order CostingDocument14 pagesContoh Kasus Job Order CostingMuhammadIrfanNo ratings yet

- Key To Reading - Hp1 Unit 1: Economic Activity Oral QuestionsDocument30 pagesKey To Reading - Hp1 Unit 1: Economic Activity Oral QuestionsKIỆT NGUYỄN QUỐCNo ratings yet

- ZABI RESUME - Planing EngineerDocument3 pagesZABI RESUME - Planing EngineerMohammed Saifuddin MudassirNo ratings yet