Professional Documents

Culture Documents

Drilling & Related Operations

Uploaded by

Izi100%(1)100% found this document useful (1 vote)

3K views18 pagesDrilling & Related Operations

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDrilling & Related Operations

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

3K views18 pagesDrilling & Related Operations

Uploaded by

IziDrilling & Related Operations

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 18

LECTURE-03

DRILLING & RELATED OPERATIONS

NIKHIL R. DHAR, Ph. D.

DEPARTMENT OF INDUSTRIAL & PRODUCTION

ENGINEERING

BUET BANGLADESH

Introduction

Drilling is most common single

machining operation

Drilling makes up 25% of machining

Drilling occurs at the end of a tool

within the material, four actions take

place a the drill tip

A small hole is formed by the web—

chips are not cut here in the normal

sense.

Chips are formed by the rotating lips.

Chips are removed from the hole by the

screw action of the helical flutes.

The drill is guided by lands or margins

that rub against the walls of the hole

Department of Industrial & Production Engineering 18/2

Definition

Drill can be defined as a

rotary end cutting tool

having one or more

cutting lips, and having

one or more helical or

straight flutes for the

passage of chips and the

admission of a cutting

fluid.

Nomenclature and geometry of conventional twist drill

Department of Industrial & Production Engineering 18/3

Nomenclature and Geometry of a Twist Drill

Three main components are the:

Shank

Body

Point

Shank - This is the portion which is

“clamped” to provide the drive. Straight

shank for drill up to ½”. Shank is equal to

body diameter. Above ½”, shank can be

tapered or reduced.

Body

Flutes - Helical grooves cut around the

body which form the cutting edges

Allow coolant to flow to the cutting

edge

Allow chips to be withdrawn

Margin- Narrow raised section of the

body. Provides full body to hole support

to help keep it aligned as it drills.

Body clearance - Reduced section of the

drill between the flutes and margin.

Used to reduce friction between drill and

workpiece

Department of Industrial & Production Engineering 18/4

Web- Thin section in the center of

the drill which forms a “core” for

the drill. This feature increases as

it extends to the shank. Forms the

chisel edge of the drill.

Point - Chisel edge of the drill.

The spiral, or rate of twist in the

drill, controls the rate of chip

removal in a drill. A fast spiral drill

is used in high feed rate

applications under low spindle

speeds, where removal of a large

volume of swarf is required. Low

spiral drills are used in cutting

applications where high cutting

speeds are traditionally used, and

where the material has a tendency

to gall on the drill or otherwise clog

the hole, such as aluminum or

copper.

Department of Industrial & Production Engineering 18/5

The point angle is determined by

the material the drill will be operating

in. Harder materials require a larger

point angle, and softer materials

require a sharper angle. The correct

point angle for the hardness of the

material controls wandering, chatter,

hole shape, wear rate, and other

characteristics.

The lip angle determines the

amount of support provided to the

cutting edge. A greater lip angle will

cause the drill to cut more

aggressively under the same amount

of point pressure as a drill with a

smaller lip angle. Both conditions can

cause binding, wear, and eventual

catastrophic failure of the tool. The

proper amount of lip clearance is

determined by the point angle.

Department of Industrial & Production Engineering 18/6

Classifications

Classification Based on Construction

Solid Drills: Those made of one piece of material such as high speed steel

Tipped Solid Drills: Those having a body of one material with cutting lips made of

another material brazed or otherwise bonded in place

Composite Drills: Those having cutting portions mechanically held in place

Classification Based on Methods of Holding or Driving

Straight Shank Drills: Those having cylindrical shanks which may be the same or

different diameter than the body of the drill; the shanks may be made with or

without driving flats, tang, grooves or threads

Taper Shank Drills: Those having conical shanks suitable for direct fitting into

tapered holes in machine spindles, driving sleeves or sockets; tapered shanks

generally have a driving tang

Taper Shank Square Drills: Those having tapered shanks with four flat sides for

fitting a rachet or brace

Shell Core Drills: Core drills mountable on arbors specifically designed for the

purpose; commonly used with shell reamer arbors

Department of Industrial & Production Engineering 18/7

Threaded Shank Drills: Those made with threaded shanks generally used in close

center multiple spindle applications or portable angle drilling tools

Beaded Shank Bits: Drills with flat shanks having raised beads parallel to the axis

Classification Based on Number of Flutes

Two-Flute Drills: The conventional type of twist drill used for originating holes

Single-Flute Drills: Those having only one flute commonly used for originating

holes

Three-Flute Drills (Core Drills): Drills commonly used for enlarging and finishing,

drilled, cast, or punched holes; they will not produce original holes

Four-Flute Drills (Core Drills): Used interchangeably with three-flute drills; they

are of similar construction except for the number of flutes

Classification Based on Hand of Cut

Right-Hand Cut: When viewed from the cutting point the counterclockwise

rotation of a drill in order to cut; the great majority of drills are made right hand

Left-Hand Cut: When viewed from the cutting point the clockwise rotation of a

drill in order to cut

Department of Industrial & Production Engineering 18/8

Cutting Tools for Drilling Operations

Twist Drill: The twist drill is the most common type of drill. It has two

cutting edges and two helical flutes that continue over the length of the

drill body. The drill also consists of a neck and a shank that can be either

straight or tapered. A tapered shank id fitted by the wedge action into the

tapered socket of the spindle and has a tang that goes into a slot in the

spindle socket, thus acting as a solid means for transmitting rotation.

Straight shank drills are held in a drill chuck that is, in turn, fitted into the

spindle socket in the same way as tapered shank drills.

Twist drill

Core Drill: A core drill consists of the chamfer, body, neck and

shank. This type of drill may have three or four flutes and an

equal number of margins, which ensures superior guidance,

thus resulting in high machining accuracy.

Spade Drill: A spade drill is used for drilling

large holes of 90 mm or more. The design of

Core drilling: to

this type of drill results in a marked saving in increase diameter of

tool cost as well as in tangible reduction in tool existing holes

weight that facilitates its ease of handling.

Moreover, this drill is easy to grind.

Spade drill: for large,

deep holes

Department of Industrial & Production Engineering 18/9

Cutting Tools for Drilling Operations

Step Drill: A multiple diameter drill with one

set of drill lands which are ground to different

diameters

Step drill: for stepped holes

Gun Drill: A gun drill is used for drilling deep

hole. All gun drills are straight-fluted, and

each has a single cutting edge. A hole in the

body acts as a conduit to transmit coolant

under considerable pressure to the tip of the

Gun drill with holes for coolant

drill.

Center Drill: Center drill bits are used in metalworking to

provide a starting hole for a larger-sized drill bit or to make

a conical indentation in the end of a workpiece in which to

mount a lathe center. In either use, as the drill is either

establishing the center of a hole or making a conical hole

for a lathe center. However, the true purpose of a center

drill is the latter task, while the former task is best done

with a spotting drill.

Department of Industrial & Production Engineering 18/10

Operations Related to Drilling

Reaming: Reaming is used to slightly enlarge a hole, to

provide a better tolerance on its diameter and to improve its

surface finish. The tool is called a reamer and it usually has

straight flutes.

Tapping: This operation is performed

by an tap and is used to provide

internal screw threads on an existing

hole.

Counterboring: Counterboring provides a stepped hole, in

which a larger diameter follows a smaller diameter partially

into the hole. A counterboring hole is used to seat bolt heads

into a hole so the heads do not protrude above the surface.

Department of Industrial & Production Engineering 18/11

Operations Related to Drilling

Countersinking: This is similar to Counterboring, except

that the step in the hole is cone-shaped for flat head screws

and bolts.

Centering: Also called center drilling,

this operation drills a starting hole to

accurately establish its location for

subsequent drilling. This tool is called a

centerdrill.

Spotfacing: Spotfacing is similar to milling. It is used to

provide a flat machined surface on the workpart in a localized

area.

Department of Industrial & Production Engineering 18/12

Drills and Drilling Operations

Department of Industrial & Production Engineering 18/13

Drill Press

A drill press is preferable to a hand drill

when the location and orientation of the

hole must be controlled accurately. A

drill press is composed of a base that

supports a column, the column in turn

supports a table. Work can be supported

on the table with a vise or hold down

clamps, or the table can be swiveled out

of the way to allow tall work to be

supported directly on the base. Height of

the table can be adjusted with a table lift

crank than locked in place with a table

lock. The column also supports a head

containing a motor. The motor turns the

spindle at a speed controlled by a

variable speed control dial. The spindle

holds a drill chuck to hold the cutting

tools (drill bits, center drills, deburring

tools, etc.).

Department of Industrial & Production Engineering 18/14

Specialized Drill Presses

Gang-drilling machines: independent columns, each with different drilling

operation, work piece slid from one column to next

Turret-type, upright drilling machines: used when numerous drilling operation

are required in rapid succession, turret rotates needed tool into position for each

operation

Gang-drilling machines Turret-type, upright drilling machines

Department of Industrial & Production Engineering 18/15

Specialized Drill Presses

Radial drilling machines: used on large workpieces, spindle mounts on radial arm,

allowing drilling operations anywhere along the arm length

Multiple-spindle drilling machines: Single powerhead operates multiple spindles

enabling multiple holes at one time, each hole can be unique

Radial drilling machines Multiple-spindle drilling machines

Department of Industrial & Production Engineering 18/16

Summary

Drilling is the most common machining operation

Drilling can be performed on a number of machine tools,

drill presses are specialized machine tools for drilling

only

Drills come in a wide variety of types and tip geometries

depending upon production rate and accuracy needed

Hole geometries can be adjusted through the use of

counterboring, countersinking and reaming

Department of Industrial & Production Engineering 18/17

Questions

?

Department of Industrial & Production Engineering 18/18

You might also like

- Milling & Related OperationsDocument22 pagesMilling & Related OperationsIzi80% (5)

- Cutting Tool FundamentalsDocument25 pagesCutting Tool FundamentalssatenawuNo ratings yet

- Allen Precision Shooting Wildcat InformationDocument9 pagesAllen Precision Shooting Wildcat Informationshwn_petersNo ratings yet

- Machining Guide for Broaching ProcessesDocument35 pagesMachining Guide for Broaching ProcessesAbdulaziz FarhanNo ratings yet

- Sierra .300 Whisper Loading DataDocument8 pagesSierra .300 Whisper Loading Datarandomjunk999100% (2)

- Drills TheoryDocument56 pagesDrills TheoryrohanNo ratings yet

- Elements of Conventional Machine ToolsDocument77 pagesElements of Conventional Machine ToolsDeepan Raj100% (1)

- Drilling & Related OperationsDocument11 pagesDrilling & Related OperationsGonKilNo ratings yet

- JJ104 Workshop Technology Chapter6 Milling MachineDocument27 pagesJJ104 Workshop Technology Chapter6 Milling MachineAh Tiang100% (3)

- Lathe MachineDocument16 pagesLathe MachineVanamali Thirumalai100% (4)

- Chips Single PT Cutting ToolDocument4 pagesChips Single PT Cutting Toolbalamurugan_meNo ratings yet

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocument7 pagesLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNo ratings yet

- JJ104 Workshop Technology Chapter7 Grinding MachineDocument19 pagesJJ104 Workshop Technology Chapter7 Grinding MachineAh Tiang100% (1)

- LatheDocument14 pagesLatheHimanshu ModiNo ratings yet

- Introduction To Fitting Shop.Document11 pagesIntroduction To Fitting Shop.Mahmood AliNo ratings yet

- BOILERSDocument34 pagesBOILERSanuranjanshardaNo ratings yet

- LB3000 EX II MY Technical SheetDocument66 pagesLB3000 EX II MY Technical SheetFerenc Ungvári100% (1)

- Geometry of Plain Milling Cutter & Twist DrillDocument30 pagesGeometry of Plain Milling Cutter & Twist DrillTulsi ChouhanNo ratings yet

- Milling MachineDocument32 pagesMilling MachineIrfan Shaikh100% (2)

- CH-47 GAUI-Manual English 090307Document16 pagesCH-47 GAUI-Manual English 090307Pouilly Eric100% (1)

- Anadarko Marco Polo - Running ProcedureDocument91 pagesAnadarko Marco Polo - Running ProcedureBrunoPestana100% (1)

- DOP Test ProtocolDocument10 pagesDOP Test ProtocolIzi100% (2)

- MACHINING-lathe and Milling)Document29 pagesMACHINING-lathe and Milling)YosephNo ratings yet

- Fitting Shop Operations Nazeef'sDocument6 pagesFitting Shop Operations Nazeef'sFaheem Fiaz ChohanNo ratings yet

- Hybrid Electric VehicleDocument33 pagesHybrid Electric VehicleIzi75% (4)

- Production Technology Lab FileDocument45 pagesProduction Technology Lab FileSakshi RoyNo ratings yet

- IndexingDocument10 pagesIndexingsaddam hosenNo ratings yet

- Travel Motor DisasembleDocument8 pagesTravel Motor DisasembleMaimun maimunNo ratings yet

- Drilling MachineDocument9 pagesDrilling MachineAqib ZamanNo ratings yet

- F - BoringDocument44 pagesF - BoringedsaregNo ratings yet

- GEOMETRY OF SINGLE POINT TOOLSDocument13 pagesGEOMETRY OF SINGLE POINT TOOLSAkshay KakaniNo ratings yet

- Grinding MachineDocument9 pagesGrinding Machinejineesha p jNo ratings yet

- CG932H Part List (New) PDFDocument189 pagesCG932H Part List (New) PDFAbderrahim Boutabba100% (2)

- MillingDocument33 pagesMillingRavichandran G0% (1)

- Production Technology (IV Sem)Document24 pagesProduction Technology (IV Sem)Shubham AgrawalNo ratings yet

- Screw Thread MeasurementDocument55 pagesScrew Thread MeasurementMadhuNo ratings yet

- Metal FormingDocument49 pagesMetal FormingtejasNo ratings yet

- W8L20 - Special ToolsDocument2 pagesW8L20 - Special ToolsTuan Linh Vo100% (1)

- Shaping & Grinding and Realated OperationsDocument26 pagesShaping & Grinding and Realated OperationsIzi86% (7)

- Lecture-08-Theory of Metal Cutting-Theory of Chip FormationDocument22 pagesLecture-08-Theory of Metal Cutting-Theory of Chip FormationDipu SubranNo ratings yet

- Chip Formation: Manufacturing Technology-IiDocument20 pagesChip Formation: Manufacturing Technology-IiSachin BharadwajNo ratings yet

- Inding MachineDocument22 pagesInding MachineVikrant SharmaNo ratings yet

- CH 2 Metal Cutting ToolsDocument19 pagesCH 2 Metal Cutting ToolsAlex AdmasNo ratings yet

- Grinding Process OverviewDocument8 pagesGrinding Process OverviewhainerajaramanNo ratings yet

- Machine Elements, Power Transmission Devices-pages-BY MBOKEHDocument93 pagesMachine Elements, Power Transmission Devices-pages-BY MBOKEHAvopaul ZeNo ratings yet

- U-5 Boring and Jig Boring MachineDocument27 pagesU-5 Boring and Jig Boring Machineapi-271354682No ratings yet

- 5 Milling and Related OperationsDocument19 pages5 Milling and Related Operationsrabbi35_me10No ratings yet

- Machine Tools: Shaper Machine GuideDocument62 pagesMachine Tools: Shaper Machine GuideFaisal MaqsoodNo ratings yet

- Step and V-FittingDocument11 pagesStep and V-FittingME Rgukt100% (1)

- 7 - Cutting Forces & PowerDocument23 pages7 - Cutting Forces & Powerresza100% (1)

- Machining ProcessDocument51 pagesMachining ProcessSudeepNo ratings yet

- Module 1Document21 pagesModule 1AzizNo ratings yet

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 pagesManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNo ratings yet

- Principle Angle Single Point Cutting ToolsDocument16 pagesPrinciple Angle Single Point Cutting ToolsSoumik DasNo ratings yet

- CNC Milling Sample ProgramDocument16 pagesCNC Milling Sample ProgramjayyadavvpcNo ratings yet

- Broaching MachineDocument26 pagesBroaching Machinesanaashraf100% (1)

- CAD CAM Slot MachiningDocument5 pagesCAD CAM Slot MachiningMechanical FactsNo ratings yet

- Project Report on Rack and Pinion Gear DesignDocument15 pagesProject Report on Rack and Pinion Gear DesignWaqasNo ratings yet

- Marking OutDocument2 pagesMarking OutOladimeji TaiwoNo ratings yet

- 2016 Endmills and Drills Metric InchDocument396 pages2016 Endmills and Drills Metric InchyoungkyNo ratings yet

- Unit One Material and Geometry of Cutting Tools 2015Document46 pagesUnit One Material and Geometry of Cutting Tools 2015elnat feyisa100% (1)

- Milling: Prepared By: Dinbandhu Singh 1Document23 pagesMilling: Prepared By: Dinbandhu Singh 1Dino SinghNo ratings yet

- Workshop Practise: An IntroductionDocument21 pagesWorkshop Practise: An IntroductionjgkonnullyNo ratings yet

- Thread Cutting and Its MethodsDocument24 pagesThread Cutting and Its MethodsMr.N.S. NateshNo ratings yet

- Metal Joining PrcocessDocument42 pagesMetal Joining PrcocessDheerajSharmaNo ratings yet

- ShaperDocument20 pagesShaperMilan SainiNo ratings yet

- AMT-Forming (Compatibility Mode)Document15 pagesAMT-Forming (Compatibility Mode)Abdulhmeed MutalatNo ratings yet

- Tool Engineering and Design Design of SiDocument23 pagesTool Engineering and Design Design of Simulugeta assefaNo ratings yet

- Drilling - Production Process - Related OperationsDocument17 pagesDrilling - Production Process - Related OperationsMehmet Islam SaifulNo ratings yet

- Hand Drilling Lever FeedingDocument43 pagesHand Drilling Lever Feedingdevi saravananNo ratings yet

- Australian Wheat IndustryDocument1 pageAustralian Wheat IndustryIziNo ratings yet

- World Energy Scenarios - Composing Energy Futures To 2050 - Executive Summary PDFDocument44 pagesWorld Energy Scenarios - Composing Energy Futures To 2050 - Executive Summary PDFAmir HussainNo ratings yet

- openLCA 1.10.2 User-ManualDocument127 pagesopenLCA 1.10.2 User-ManualIziNo ratings yet

- Guide Driving TestDocument44 pagesGuide Driving TestDennis OngNo ratings yet

- 1442 IDocument6 pages1442 IIziNo ratings yet

- Australian Cotton Industry - CheckedDocument2 pagesAustralian Cotton Industry - CheckedIziNo ratings yet

- Australian Wheat Industry - CheckedDocument2 pagesAustralian Wheat Industry - CheckedIziNo ratings yet

- Form 1496i Family VisaDocument2 pagesForm 1496i Family VisaIziNo ratings yet

- Diesel Fuel InjectionDocument5 pagesDiesel Fuel InjectionIziNo ratings yet

- Usb 1616hs BNC SpecDocument8 pagesUsb 1616hs BNC SpecIziNo ratings yet

- Australian Cotton IndustryDocument1 pageAustralian Cotton IndustryIziNo ratings yet

- Alzheimer CheckedDocument2 pagesAlzheimer CheckedIziNo ratings yet

- Alzheimer's Disease: Memory Loss and Brain DegenerationDocument1 pageAlzheimer's Disease: Memory Loss and Brain DegenerationIziNo ratings yet

- Vortex 95 MsdsDocument13 pagesVortex 95 MsdsIziNo ratings yet

- Handout15 6333 PDFDocument17 pagesHandout15 6333 PDFIziNo ratings yet

- User ManualDocument18 pagesUser ManualIziNo ratings yet

- Calculating Standard Error Bars For A GraphDocument6 pagesCalculating Standard Error Bars For A GraphKona MenyongaNo ratings yet

- ASTM Biodiesel SpecDocument1 pageASTM Biodiesel SpecIziNo ratings yet

- Wang 2011 Bio Spary IgnitionDocument7 pagesWang 2011 Bio Spary IgnitionIziNo ratings yet

- Zakat GuideDocument15 pagesZakat GuideIziNo ratings yet

- Heat Flux Sensors Measure Fast Surface Temp ChangesDocument2 pagesHeat Flux Sensors Measure Fast Surface Temp ChangesIziNo ratings yet

- Usb 1616hs BNCDocument49 pagesUsb 1616hs BNCIziNo ratings yet

- GRE Words ListDocument2 pagesGRE Words ListIziNo ratings yet

- FtirDocument21 pagesFtirGaurav AcharyaNo ratings yet

- World Energy Assessment-2000Document506 pagesWorld Energy Assessment-2000IziNo ratings yet

- Sinus SamuraiDocument5 pagesSinus SamuraiIziNo ratings yet

- Unit 7Document39 pagesUnit 7vijay_oraerp1711No ratings yet

- Duct DesignDocument9 pagesDuct DesignjaswanthNo ratings yet

- Atlas Copco, Model ZH6 3 Stage Parts ListDocument63 pagesAtlas Copco, Model ZH6 3 Stage Parts ListStefan BesterNo ratings yet

- Design of Open Jet FacilityDocument8 pagesDesign of Open Jet FacilityJoe AjayNo ratings yet

- Brake Drum Micrometer: Operating Instructions and Parts IdentificationDocument4 pagesBrake Drum Micrometer: Operating Instructions and Parts IdentificationoldtrukluvrNo ratings yet

- Technical Drafting - G7 - 8 - Week 2 Compress LASDocument13 pagesTechnical Drafting - G7 - 8 - Week 2 Compress LASNorman PolilinNo ratings yet

- Actuated Ball Valve 357 A - BDKDocument3 pagesActuated Ball Valve 357 A - BDKfarhanakhtar ansariNo ratings yet

- CMECC-BEL JV Jet A-1 Pipeline Project Construction Equipment & Tools List & Mobilization PlanDocument17 pagesCMECC-BEL JV Jet A-1 Pipeline Project Construction Equipment & Tools List & Mobilization PlanHasan ShahriarNo ratings yet

- Basic Elements of Machine ToolsDocument9 pagesBasic Elements of Machine Tools4gen_70% (1)

- 02 - 06 June 2022 Hardware & Tool CatalogueDocument20 pages02 - 06 June 2022 Hardware & Tool CatalogueCape AccessNo ratings yet

- Ke Kelit Simplex Product Catalogue 2016Document283 pagesKe Kelit Simplex Product Catalogue 2016kdc termiceNo ratings yet

- Second Hand Catering EquipmentDocument64 pagesSecond Hand Catering EquipmentbuzzsuppliesNo ratings yet

- Chapter 17 Launching SystemsDocument14 pagesChapter 17 Launching SystemsMas OudNo ratings yet

- Sky Air Seasonal Classic Conductos Baja Silueta Serie DDocument1 pageSky Air Seasonal Classic Conductos Baja Silueta Serie DmiroNo ratings yet

- Khaire Sir Classes Advance Manufacturing IMP MCQ Unit: 02 Milling Machine & Milling ProcessDocument11 pagesKhaire Sir Classes Advance Manufacturing IMP MCQ Unit: 02 Milling Machine & Milling ProcessHarshraj WaniNo ratings yet

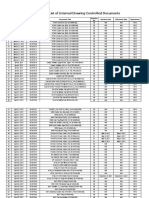

- Master List of Internal DrawingDocument26 pagesMaster List of Internal DrawingMaria Katherine Cruz PantojaNo ratings yet

- Light, Medium & Heavy Armor GuideDocument14 pagesLight, Medium & Heavy Armor GuideKeefeNo ratings yet

- Machine Tool Engineering SyllabusDocument2 pagesMachine Tool Engineering SyllabussahasanNo ratings yet

- Kitchen Equipment, Tools & SuppliesDocument11 pagesKitchen Equipment, Tools & SuppliesRonald BañaresNo ratings yet

- MOBILE CRANE Grove RT58D CLPDocument9 pagesMOBILE CRANE Grove RT58D CLPahmed sleemNo ratings yet

- Drilling MachineDocument30 pagesDrilling MachinePuneeth KumarNo ratings yet

- School Supplies Vocabulary Esl Matching Exercise Worksheets For KidsDocument4 pagesSchool Supplies Vocabulary Esl Matching Exercise Worksheets For KidsJorge BenítezNo ratings yet

- American Standard Pipe Thread Taper and DimensionsDocument6 pagesAmerican Standard Pipe Thread Taper and DimensionsleonardsiregarNo ratings yet

- VENOM 30mm 1Document4 pagesVENOM 30mm 1490 МедведьNo ratings yet