Professional Documents

Culture Documents

Sheet Metal Working

Uploaded by

Bhupendhar HarshawardanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet Metal Working

Uploaded by

Bhupendhar HarshawardanCopyright:

Available Formats

SHEET METAL WORKING

1. Introduction Sheet metal is simply metal formed into thin and flat pieces. It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. Countless everyday objects are constructed of the material. Thicknesses can vary significantly, although extremely thin thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate. 2. Sheet metal processing The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the sheets are thin and very long, they may be in the form of rolls. Therefore the first step in any sheet metal process is to cut the correct shape and sized blank from larger sheet. 3. Sheet metal forming processes Sheet metal processes can be broken down into two major classifications and one minor classification 1. 2. 3. 4. 5. Shearing processes -- processes which apply shearing forces to cut, fracture, or separate the Forming processes -- processes which cause the metal to undergo desired shape changes Finishing processes -- processes which are used to improve the final surface characteristics. Punching: shearing process using a die and punch where the interior portion of the sheared Blanking: shearing process using a die and punch where the exterior portion of the material. without failure, excessive thinning, or cracking. This includes bending and stretching. 3.1 Shearing Process sheet is to be discarded. shearing operation is to be discarded. Perforating: punching a number of holes in a sheet Parting: shearing the sheet into two or more pieces Notching: removing pieces from the edges

6.

Lancing: leaving a tab without removing any material

Fig.1Shearing Operations: Punching, Blanking and Perforating 3.2 Forming Processes Bending: forming process causes the sheet metal to undergo the desired shape change by Stretching: forming process causes the sheet metal to undergo the desired shape change by Drawing: forming process causes the sheet metal to undergo the desired shape change by Roll forming: Roll forming is a process by which a metal strip is progressively bent as it bending without failure. Ref fig.2 & 2a stretching without failure. Ref fig.3 drawing without failure. Ref fig.4 passes through a series of forming rolls. Ref fig.5

Fig.2 Common Die-Bending Operations

Fig.2a

Various Bending Operations

Fig.3 Schematic illustration of a stretch-forming process.

Fig.4 Schematic of the Drawing process.

Fig.5 Eight-roll sequence for the roll forming of a box channel 3.3 Finishing processes Material properties, geometry of the starting material, and the geometry of the desired final product play important roles in determining the best process 4. Equipments Basic sheet forming operations involve a press, punch, or ram and a set of dies

4.1 Presses Mechanical Press - The ram is actuated using a flywheel. Stroke motion is not uniform. Ref fig.6 Hydraulic Press - Longer strokes than mechanical presses, and develop full force throughout the stroke. Stroke motion is of uniform speed, especially adapted to deep drawing operations. Ref fig.7

Fig.6 Mechanical Press

Fig.7 Hydraulic Press 4.2 Dies and Punches Simple- single operation with a single stroke Compound- two operations with a single stroke Combination- two operations at two stations Progressive- two or more operations at two or more stations with each press stroke, creates what is called a strip development

Fig 8 Progressive dies Punches 5. Tools and Accessories The various operations such as cutting, shearing, bending, folding etc. are performed by these tools. 5.1 Marking and measuring tools Steel Rule - It is used to set out dimensions. Try Square - Try square is used for making and testing angles of 90degree Scriber It used to scribe or mark lines on metal work pieces. Divider - This is used for marking circles, arcs, laying out perpendicular lines, bisecting lines, etc

Fig.9 Marking and measuring tools 5.2 Cutting Tools Straight snip - They have straight jaws and used for straight line cutting. Ref fig.10 Curved snip - They have curved blades for making circular cuts. Ref fig.10a

Ref fig.10 Straight snip

Ref Fig.10a Curved Snip 6. Striking Tools Mallet - It is wooden-headed hammer of round or rectangular cross section. The striking face is made flat to the work. A mallet is used to give light blows to the Sheet metal in bending and finishing. Ref fig.11

Fig.11 Types of Mallets 6. Merits 7. Demerits Wrinkling and tearing are typical limits to drawing operations Different techniques can be used to overcome these limitations o Draw beads o Vertical projections and matching grooves in the die and blank holder Trimming may be used to reach final dimensions Roofings Ductings High strength Good dimensional accuracy and surface finish Relatively low cost

8. Applications

9. Part A

Vehicles body buildings like 3 wheelers, 4 wheelers, ships, aircrafts etc. Furnitures, House hold articles and Railway equipment

Questions: 1. What is sheet metal work? 2. Write down any four sheet metal characteristics 3. What is meant by clearance? 4. What is stretching? 5. Define the term spring back 6. How force exerted on the form block is calculated 7. What are the formability test methods? 8. What is super plasticity of metals? 9. What is metal spinning process? 10. What is sheet metal?

Part B 11. What are Punching, Nibbling, Blanking, Piercing, tools/machines are needed for these processes? 12. What is deep drawing? Provide a few examples of products/parts made using deep drawing operations. 13. What is progressive die stamping? 14. Describe shearing operations in a sheet metal work with a neat sketch 15. Describe various types of bending operations with its neat sketches 16. Explain any one method of stretch forming operation with a neat sketch 17. Explain hydro forming process with its neat sketches. State their advantage and applications 18. Explain the power spinning process with a neat sketch .give their applications 19. How magnetic pulse forming process is carried out on sheet metal?Explain peen forming process with a neat sketch 20. What is super plastic of metal? How this process is carried out on sheet metals? END

11. References Book Manufacturing Technology by Hajra choudry Sheet metal working by Robert cook www.efunda.com www.esnips.com

Website

You might also like

- Gear BoxDocument36 pagesGear BoxNimoNo ratings yet

- Sheet Metal WorkingDocument26 pagesSheet Metal Workingvelavansu0% (1)

- CuñaDocument20 pagesCuñaJulian Granados RicoNo ratings yet

- Jig and Fixture Design GuideDocument53 pagesJig and Fixture Design Guidettetslm100% (2)

- Increase Productivity with Jigs and FixturesDocument4 pagesIncrease Productivity with Jigs and FixturesjoshivishwanathNo ratings yet

- TB Grinding EnglishDocument20 pagesTB Grinding EnglishVk PrabakranNo ratings yet

- Metric StandardDocument42 pagesMetric StandarddamzoNo ratings yet

- Ch21 Fundamentals of Cutting2Document70 pagesCh21 Fundamentals of Cutting2manojc68No ratings yet

- Progressive Tool Design StudyDocument34 pagesProgressive Tool Design Studysudheer9289% (9)

- Forging: Shaping Metal Through CompressionDocument81 pagesForging: Shaping Metal Through CompressionsuneethaNo ratings yet

- Milling CutterDocument11 pagesMilling CutterRing MasterNo ratings yet

- Manufacturing Technology (MEC - 205) : Unit - 1 Introduction To Manufacturing and Metal CastingDocument74 pagesManufacturing Technology (MEC - 205) : Unit - 1 Introduction To Manufacturing and Metal CastingShridhar SavatNo ratings yet

- 2 Unit 2 - Brazing, Soldering and Adhesive BondingDocument13 pages2 Unit 2 - Brazing, Soldering and Adhesive BondingAditya KumarNo ratings yet

- Bench Working and Fitting Shop: (1) Holding DeviceDocument10 pagesBench Working and Fitting Shop: (1) Holding DeviceAashish KushwahaNo ratings yet

- Sudipta Nath: Materials EngineeringDocument19 pagesSudipta Nath: Materials EngineeringSudipta NathNo ratings yet

- Types of JigDocument27 pagesTypes of JigRushabh SapariaNo ratings yet

- Learn Jigs & Fixtures Design in SolidWorksDocument1 pageLearn Jigs & Fixtures Design in SolidWorksAnup TripathiNo ratings yet

- JigDocument6 pagesJigArun ManoNo ratings yet

- Sheet Metal Forming Processes ExplainedDocument38 pagesSheet Metal Forming Processes ExplainedPriya ChilukuriNo ratings yet

- Drill Press Text BookDocument138 pagesDrill Press Text BookKartik Sheth100% (1)

- Sheet Metal WorkingDocument23 pagesSheet Metal WorkingSujit MishraNo ratings yet

- Unit 4 Sheet Metal ProcessDocument65 pagesUnit 4 Sheet Metal ProcessMANOJ MNo ratings yet

- Primary Functions of A ThreadDocument10 pagesPrimary Functions of A ThreadEng-Mohammed Abu NuktaNo ratings yet

- Fine Blanking TechnologyDocument30 pagesFine Blanking TechnologyEngineer100% (2)

- Tungsten Carbide Tools Training ManualDocument209 pagesTungsten Carbide Tools Training ManualMarin Ionut-EduardNo ratings yet

- Production Engineering Lab VIII SemDocument24 pagesProduction Engineering Lab VIII Semsunil kumawatNo ratings yet

- Joining Processes: Permanent JointsDocument31 pagesJoining Processes: Permanent JointsgemnikkicNo ratings yet

- ME2309 CAD CAM Lab Manual PDFDocument39 pagesME2309 CAD CAM Lab Manual PDFAnonymous bj8F8c100% (1)

- Force Power in Metal CuttingDocument7 pagesForce Power in Metal CuttingRavinder AntilNo ratings yet

- Tools, Jigs and Die Design GuideDocument2 pagesTools, Jigs and Die Design GuideTamirat Nemomsa100% (1)

- 31 Screw Threads and Gear Manufacturing MethodsDocument17 pages31 Screw Threads and Gear Manufacturing MethodsPRASAD326100% (8)

- Design of Jigs Fixtures and Press Tools PDFDocument4 pagesDesign of Jigs Fixtures and Press Tools PDFniharika kadiriNo ratings yet

- RivetsDocument28 pagesRivetsMS JAMWALNo ratings yet

- Tabletop CNC Wire Bender Machine Using DXF by Generating CNC CodesDocument4 pagesTabletop CNC Wire Bender Machine Using DXF by Generating CNC CodesPrasanna RahmaniacNo ratings yet

- Production Process.II (CBCGS) Module.1 Metal CuttingDocument24 pagesProduction Process.II (CBCGS) Module.1 Metal CuttingOmkar BedadeNo ratings yet

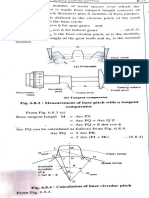

- Base Tangent LengthDocument1 pageBase Tangent LengthKalpesh BawankarNo ratings yet

- Production Drawings & Process ModelsDocument15 pagesProduction Drawings & Process ModelsnotonectalNo ratings yet

- Screw Thread MeasurementsDocument77 pagesScrew Thread MeasurementsSridhar SreeNo ratings yet

- Micro MillingDocument38 pagesMicro MillingBhushan ChhatreNo ratings yet

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 pagesManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNo ratings yet

- An Innovative Shearing Process For AHSS Edge Stretchability ImprovementsDocument28 pagesAn Innovative Shearing Process For AHSS Edge Stretchability ImprovementsYogesh PatelNo ratings yet

- Reverse Engineering ExplainedDocument47 pagesReverse Engineering ExplainedMohannadNo ratings yet

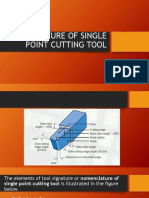

- Tool Signature ElementsDocument11 pagesTool Signature ElementsMaljon Daren DalanginNo ratings yet

- MP II - Lecture 3 - Thread and Gear ManufacturingDocument57 pagesMP II - Lecture 3 - Thread and Gear ManufacturingArif Hossain100% (1)

- Colour Coding of Patterns: Patterns Are Imparted Certain Colours and Shades in Order ToDocument1 pageColour Coding of Patterns: Patterns Are Imparted Certain Colours and Shades in Order ToAppu MukundanNo ratings yet

- PT (Types of Jigs) - 9570Document22 pagesPT (Types of Jigs) - 9570Sanjay NayeeNo ratings yet

- Mitsu 14 TECHNICAL DATA PDFDocument52 pagesMitsu 14 TECHNICAL DATA PDFMohan PreethNo ratings yet

- Sheet Metalworking Processes ExplainedDocument26 pagesSheet Metalworking Processes ExplainedRama SatriotamaNo ratings yet

- Ch31 Solid-State WeldingDocument28 pagesCh31 Solid-State WeldingNaveen KumarNo ratings yet

- Chapter 5-Sheet MetalworkingDocument82 pagesChapter 5-Sheet MetalworkingSeab PisethNo ratings yet

- Resistance WeldingDocument13 pagesResistance Weldingpavithra222No ratings yet

- Surface EngineeringDocument43 pagesSurface Engineering10rajNo ratings yet

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDocument16 pagesLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarNo ratings yet

- Work HoldingDocument5 pagesWork HoldingKANDALA RAJASHEKAR REDDYNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Sheet MATALDocument9 pagesSheet MATALSunil KumarNo ratings yet

- SBP Sheet Metal Working 1Document39 pagesSBP Sheet Metal Working 1Preet DamaniNo ratings yet

- Sheet Metal WorkingDocument23 pagesSheet Metal WorkingAlrino Dwi PrasetyoNo ratings yet

- Covering LetterDocument1 pageCovering LetterBhupendhar HarshawardanNo ratings yet

- Introductory Concepts of MachiningDocument2 pagesIntroductory Concepts of MachiningBhupendhar HarshawardanNo ratings yet

- The Big Bang Theory: An Overview of the Popular Theory of the Universe's OriginDocument1 pageThe Big Bang Theory: An Overview of the Popular Theory of the Universe's OriginBhupendhar HarshawardanNo ratings yet

- Nuclear EnergyDocument30 pagesNuclear EnergyBhupendhar HarshawardanNo ratings yet

- Im Such A Stupid With GirlsDocument1 pageIm Such A Stupid With GirlsBhupendhar HarshawardanNo ratings yet