Professional Documents

Culture Documents

Fits and Tolerances

Uploaded by

andrew27112002Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fits and Tolerances

Uploaded by

andrew27112002Copyright:

Available Formats

First-Year Engineering Program

Engineering H191 Engineering Fundamentals and Laboratory I

Week 07 Day 01 Tolerancing: Control of Variability

First-Year Engineering Program

Objectives

Understand description and control of variability through tolerancing Understand various classes of fits Introduce multiple part tolerancing

AU 2005

First-Year Engineering Program

Tolerance

Tolerance is the total amount a dimension may vary. It is the difference between the maximum and minimum limits. Ways to Express: 4. Direct limits or as tolerance limits applied to a dimension 5. Geometric tolerances 6. A general tolerance note in title block 7. Notes referring to specific conditions

AU 2005

First-Year Engineering Program

1. Direct Limits and Tolerance Values

AU 2005

First-Year Engineering Program

1. Direct Limits and Tolerance Values Plus and Minus Dimensions

AU 2005

First-Year Engineering Program

2. Geometric Tolerance System

Geometric Dimensioning and Tolerancing (GD&T) is a method of defining parts based on how they function, using standard ANSI symbols. Feature Control Frame Concentricity Symbol

AU 2005

First-Year Engineering Program

3. Tolerance Specifications in Title Block

General tolerance note specifies the tolerance for all unspecified toleranced dimensions.

AU 2005

First-Year Engineering Program

4. Notes Referring to Specific Conditions

General Tolerances could be in the form of a note similar to the one shown below: ALL DECIMAL DIMENSIONS TO BE HELD TO .002" Means that a dimension such as .500 would be assigned a tolerance of 0.002, resulting in a upper limit of .502 and a lower limit of .498

AU 2005 8

First-Year Engineering Program

Important Terms Single Part

Nominal Size general size, usually expressed in common fractions (1/2" for the slot) Basic Size theoretical size used as starting point (.500" for the slot) Actual Size measured size of the finished part (.501" for the slot)

AU 2005 9

First-Year Engineering Program

Important Terms Single Part

Limits maximum and minimum sizes shown by tolerances (.502 and .498 larger value is the upper limit and the smaller value is the lower limit, for the slot) Tolerance total allowable variance in dimensions (upper limit lower limit) object dimension could be as big as the upper limit or as small as the lower limit or anywhere in between

AU 2005 10

First-Year Engineering Program

Important Terms Multiple Parts

Allowance the minimum clearance or maximum interference between parts Fit degree of tightness between two parts Clearance Fit tolerance of mating parts always leave a space Interference Fit tolerance of mating parts always interfere Transition Fit sometimes interfere, sometimes clear

AU 2005 11

First-Year Engineering Program

Fitting Multiple Parts

Tolerance of B Part B

Fit Tolerance: Clearance or Interference Tolerance of A Part A

AU 2005

12

First-Year Engineering Program

Fitting Multiple Parts

AU 2005

13

First-Year Engineering Program

Shaft and Hole Fits

Clearance Interference

AU 2005

14

First-Year Engineering Program

Shaft and Hole Fits

Transition

CLEARANCE FIT + .003

AU 2005

15

First-Year Engineering Program

Standard Precision Fits: English Units

Running and sliding fits (RC) Clearance locational fits (LC) Transition locational fits (LT) Interference locational fits (LN) Force and shrink fits (FN)

See Table A.1 in the Appendix (pp. A-3 to A-9)

AU 2005

16

First-Year Engineering Program

Basic Hole System or Hole Basis

Definition of the "Basic Hole System": The "minimum size" of the hole is equal to the "basic size" of the fit Example: If the nominal size of a fit is 1/2", then the minimum size of the hole in the system will be 0.500"

AU 2005

17

First-Year Engineering Program

Basic Hole System

Clearance = Hole Shaft Cmax = H____ S____ Cmin = H____ S____ Fill in the subscripts (min, max) in the equations above.

SMAX SMIN HMAX HMIN

AU 2005

18

First-Year Engineering Program

Basic Hole System

Clearance = Hole Shaft Cmax = Hmax Smin Cmin = Hmin Smax

Both Cmax and Cmin <0 _________ fit Both Cmax and Cmin >0 _________ fit Cmax > 0; Cmin < 0 ___________ fit

SMAX SMIN HMAX HMIN

What types of fits are these?

AU 2005

19

First-Year Engineering Program

Basic Hole System

Clearance = Hole Shaft Cmax = Hmax Smin Cmin = Hmin Smax

Both Cmax and Cmin <0 Interference fit Both Cmax and Cmin >0 Clearance fit Cmax > 0; Cmin < 0 Transition fit

SMAX SMIN HMAX HMIN

System Tolerance = Cmax Cmin Allowance = Min. Clearance = Cmin

AU 2005

20

First-Year Engineering Program

Basic Hole System

Calculate Maximum and Minimum Clearance Clearance = Hole Shaft Cmax = Hmax Smin Cmax = .510 .485 = .025 Cmin = Hmin Smax Cmin = .505 .490 = .015 What type of fit is this? Cmax > Cmin > 0 Clearance

AU 2005 21

.490 .485 .510 .505

First-Year Engineering Program

Metric Limits and Fits

Based on Standard Basic Sizes ISO Standard, see the Appendix material (Table A.2 on pp. A10 to A-13 in text) Note that in the Metric system: Nominal Size = Basic Size Example: If the nominal size is 8, then the basic size is 8

AU 2005 22

First-Year Engineering Program

Metric Preferred Hole Basis System of Fits

AU 2005

23

First-Year Engineering Program

Metric Tolerance Homework TOL-1B

Free Running H9/d9 Basic Size: 8 (1) Nominal Size: 8 ? (2) Shaft Limits: (3) Shaft Tolerance: 0.036 ???? 7.960 ???? 7.924 ???? 8.036 ???? 8.000 ????

(7) Minimum Clearance: 0.040 ???? (8) Maximum Clearance: 0.112 ????

(4) Hole Limits: (5) Hole Tolerance: 0.036 ???? (6) Ts: 0.072 ????

AU 2005

CHECK: 0.072 Ts = Cmax = 0.112 Cmin? 0.040 = 0.072

24

First-Year Engineering Program

Good Review Material

TG Chapter 6 Dimensions and Tolerances Specifically pages 6-18 to 6-22 TG Chapter 7 Dimensions For Production

AU 2005

25

First-Year Engineering Program

Today's Assignment

Drawing 33 G27 Drawing 34 TOL-1A

AU 2005

26

You might also like

- Sheet Metal Design-Handbook-Rev3 PDFDocument12 pagesSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Plastic Properties HandbookDocument15 pagesPlastic Properties HandbookguilloteARGNo ratings yet

- SpringDocument30 pagesSpringlin_meckylogiNo ratings yet

- Module IV: Gears and Gear TrainsDocument38 pagesModule IV: Gears and Gear TrainsSuraj VinayNo ratings yet

- Limits and FitsDocument6 pagesLimits and Fitscamohunter71No ratings yet

- BearingsDocument52 pagesBearingsrahul singhNo ratings yet

- Design of Keys and CouplingsDocument20 pagesDesign of Keys and CouplingsAliya A KhanNo ratings yet

- Unit 2 MEASUREMENT (BME) Basic Mechanical ENGINEERINGDocument8 pagesUnit 2 MEASUREMENT (BME) Basic Mechanical ENGINEERINGAlok Patel100% (2)

- Tractive Effort PDFDocument8 pagesTractive Effort PDFPrithviraj DagaNo ratings yet

- Production Drawing & Pracctice Lab ManualDocument23 pagesProduction Drawing & Pracctice Lab ManualVenkateswar Reddy Mallepally88% (8)

- METROLOGY JNTUK Mech III - IIDocument103 pagesMETROLOGY JNTUK Mech III - IIRajesh Shah0% (3)

- Mecha World Compendium Playbooks BWDocument12 pagesMecha World Compendium Playbooks BWRobson Alves MacielNo ratings yet

- GD&T IntroductionDocument147 pagesGD&T IntroductionPrithviraj Daga100% (6)

- Module-II 2.gear DrivesDocument36 pagesModule-II 2.gear Drivesvanishree n100% (1)

- 3-Limits Fits and TolerancesDocument22 pages3-Limits Fits and TolerancesAbhay Sharma100% (1)

- Evidence Prove DiscriminationDocument5 pagesEvidence Prove DiscriminationRenzo JimenezNo ratings yet

- GearsDocument45 pagesGearsSomendra Brijesh Pandey100% (1)

- Gears FundamentalDocument25 pagesGears FundamentalMOHD ZULHELMIE ZAINAL ABIDINNo ratings yet

- Introduction To GearsDocument28 pagesIntroduction To Gearssandeep_gaikwad2100% (4)

- Application of Chain Drive and Its Selection Method in AutomobileDocument18 pagesApplication of Chain Drive and Its Selection Method in AutomobileSumedh sonawaneNo ratings yet

- Design of ShaftDocument32 pagesDesign of ShaftaliNo ratings yet

- Screw Threads and Assembly Drawing Class NotesNotesDocument17 pagesScrew Threads and Assembly Drawing Class NotesNotesRay NjorogeNo ratings yet

- Lubrication & Journal Bearings (Compatibility Mode)Document44 pagesLubrication & Journal Bearings (Compatibility Mode)Abhinav TiwariNo ratings yet

- Drilling MachineDocument9 pagesDrilling MachineAqib ZamanNo ratings yet

- Polyurethane (PU) : HistoryDocument28 pagesPolyurethane (PU) : HistoryPrithviraj Daga83% (12)

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocument7 pagesLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNo ratings yet

- Metrology Chapter 1Document45 pagesMetrology Chapter 1venkeekuNo ratings yet

- Limits, Fits and TolerancesDocument17 pagesLimits, Fits and TolerancesSarswati SuryawanshiNo ratings yet

- Limits Fits Engineering TolerancesDocument29 pagesLimits Fits Engineering TolerancesEmmanuel Nicholas100% (2)

- IrisDocument7 pagesIrisPrithviraj DagaNo ratings yet

- Metal Forming Machines: PressesDocument35 pagesMetal Forming Machines: PressesMohammed Alnashar0% (1)

- Design of BearingsDocument46 pagesDesign of BearingsSatyaprakash Dinesh Vispute100% (1)

- 1 Design of Machine Tool DrivesDocument23 pages1 Design of Machine Tool DrivesFurkan Ahmad100% (1)

- Limts Fit & TolerenceDocument60 pagesLimts Fit & TolerenceGummanur SreenathNo ratings yet

- Crypto Wall Crypto Snipershot OB Strategy - Day Trade SwingDocument29 pagesCrypto Wall Crypto Snipershot OB Strategy - Day Trade SwingArete JinseiNo ratings yet

- Bearing 2016Document98 pagesBearing 2016Nikesh MoreNo ratings yet

- GearboxesDocument24 pagesGearboxesPrithviraj Daga100% (2)

- Engineering MetrologyDocument84 pagesEngineering MetrologyLalit MohanNo ratings yet

- Tutorial Chapter 5 - Power System ControlDocument2 pagesTutorial Chapter 5 - Power System ControlsahibNo ratings yet

- Limits Fits TolerancesDocument15 pagesLimits Fits TolerancespankajdharmadhikariNo ratings yet

- Types of GearsDocument22 pagesTypes of GearsAnonymous 2RbW9dNo ratings yet

- Limits, Fits, ToleranceDocument51 pagesLimits, Fits, ToleranceAnthony Lopes0% (1)

- Limit GaugesDocument68 pagesLimit Gaugesaneesh19inNo ratings yet

- Gear TerminologyDocument21 pagesGear TerminologyAns ahmed100% (1)

- Module 1 - Fits, LimitsDocument18 pagesModule 1 - Fits, LimitsShanhoodNo ratings yet

- Measurement of Screw ThreadsDocument21 pagesMeasurement of Screw ThreadsAnthony LopesNo ratings yet

- UNIT-2 Design of Spur GearDocument56 pagesUNIT-2 Design of Spur GearMarthandeNo ratings yet

- Spur Gears - SlidesDocument45 pagesSpur Gears - SlidesKim Jeff BeringuelNo ratings yet

- Highlights ASME Guides Preheat PWHT IDocument4 pagesHighlights ASME Guides Preheat PWHT IArul Edwin Vijay VincentNo ratings yet

- Limit, Fit and ToleranceDocument14 pagesLimit, Fit and ToleranceKesava Prasad100% (1)

- PETAL Sentence StartersDocument1 pagePETAL Sentence StartersSnip x Hunt manNo ratings yet

- Railways Technical InformationDocument88 pagesRailways Technical InformationPrithviraj Daga100% (2)

- ComparatorsDocument54 pagesComparatorsbasanna_rvce60% (5)

- A.tcharkhtchi-Simulation of Roto Molding ProcessDocument28 pagesA.tcharkhtchi-Simulation of Roto Molding ProcessPrithviraj Daga100% (1)

- Limits Fits TolerancesDocument19 pagesLimits Fits TolerancesBrijesh VermaNo ratings yet

- Fits and Tolerance T11Document13 pagesFits and Tolerance T11ZaorabNo ratings yet

- Single Point Cutting ToolDocument16 pagesSingle Point Cutting ToolSoumik DasNo ratings yet

- Machine Elements, Power Transmission Devices-pages-BY MBOKEHDocument93 pagesMachine Elements, Power Transmission Devices-pages-BY MBOKEHAvopaul ZeNo ratings yet

- Lecture Slide Metrology and Inspection - PPT PDFDocument30 pagesLecture Slide Metrology and Inspection - PPT PDFEdo EdgarNo ratings yet

- 18-Limit, Fit, ToleranceDocument15 pages18-Limit, Fit, ToleranceMitul75% (4)

- Chapter 5, CH 6, Tolerances, FitsDocument55 pagesChapter 5, CH 6, Tolerances, Fitssamuel mekuriawNo ratings yet

- KEYSDocument21 pagesKEYSAndrea Douglas100% (1)

- Geometrical Tolerancing (GD&T)Document12 pagesGeometrical Tolerancing (GD&T)Kishor kumar BhatiaNo ratings yet

- Basics of Belt DrivesDocument12 pagesBasics of Belt DrivesSrinivasan Ravi100% (1)

- Mechanical Design Engineer Interview QuestionsDocument13 pagesMechanical Design Engineer Interview QuestionspravagaNo ratings yet

- ClutchesDocument17 pagesClutchesRanjit RajendranNo ratings yet

- Elementary Transmission For Transforming Rotary Into Translatory MotionDocument14 pagesElementary Transmission For Transforming Rotary Into Translatory Motionshreyas jadhavNo ratings yet

- Fits and TolerancesDocument26 pagesFits and TolerancesMaher ShehabNo ratings yet

- Lecture21 PDFDocument22 pagesLecture21 PDFVignesh WaranNo ratings yet

- Fits and Tolerances: Engineering H191 - Drafting / CADDocument22 pagesFits and Tolerances: Engineering H191 - Drafting / CADVignesh WaranNo ratings yet

- Mechanical Drawing Tolerances and FitsDocument26 pagesMechanical Drawing Tolerances and FitsVignesh WaranNo ratings yet

- Limit Dimensions: Permissible Variation in A Part Feature Size, Consisting of The Maximum and Minimum Dimensions AllowedDocument48 pagesLimit Dimensions: Permissible Variation in A Part Feature Size, Consisting of The Maximum and Minimum Dimensions Allowedajeng.saraswatiNo ratings yet

- MEM201 L6-Tolerance RCDocument31 pagesMEM201 L6-Tolerance RCKaliya PerumalNo ratings yet

- 04 GDTDocument54 pages04 GDTAfrina PutraNo ratings yet

- MaglevDocument21 pagesMaglevPrithviraj DagaNo ratings yet

- Bombardier TraxxDocument12 pagesBombardier TraxxPrithviraj DagaNo ratings yet

- Electrodynamic Suspension SystemDocument88 pagesElectrodynamic Suspension SystemPrithviraj Daga100% (1)

- Gear DesignDocument18 pagesGear DesignJitendra BagalNo ratings yet

- BT PresentationDocument34 pagesBT PresentationPrithviraj DagaNo ratings yet

- Transient Stress Analysis On Spur GearDocument8 pagesTransient Stress Analysis On Spur GearPrithviraj DagaNo ratings yet

- Contact Stress Analysis of Spur Gear Teeth PairDocument6 pagesContact Stress Analysis of Spur Gear Teeth PairPrithviraj DagaNo ratings yet

- MD Spur DesignDocument8 pagesMD Spur DesignPrithviraj DagaNo ratings yet

- Gear StressDocument12 pagesGear StressPrithviraj Daga100% (1)

- Consumer Product Design WP ENGDocument8 pagesConsumer Product Design WP ENGPrithviraj DagaNo ratings yet

- Sheet Metal Bend AllowanceDocument3 pagesSheet Metal Bend AllowancePrithviraj DagaNo ratings yet

- Shipping, Logistics Management - Container Dimensions, Container Capacity, Rating, Tare Mass and Payload of ContainersDocument4 pagesShipping, Logistics Management - Container Dimensions, Container Capacity, Rating, Tare Mass and Payload of ContainersPrithviraj Daga80% (5)

- Analysis Guide Machine Design WP ENGDocument10 pagesAnalysis Guide Machine Design WP ENGPrithviraj Daga100% (3)

- Tutorials For Pro Engineer Wildfire 2.0Document101 pagesTutorials For Pro Engineer Wildfire 2.0shuklahouseNo ratings yet

- Pro/E - Efficient Wall Thickness Analysis Methods For Optimal Design of Casting PartsDocument9 pagesPro/E - Efficient Wall Thickness Analysis Methods For Optimal Design of Casting PartsPrithviraj DagaNo ratings yet

- ProE Wildfire 4 Tutorial 4-3D AnnotationsDocument26 pagesProE Wildfire 4 Tutorial 4-3D AnnotationsPrithviraj Daga100% (3)

- ProCNC - Design Guide ForCost Effective Machined Parts - IVDocument4 pagesProCNC - Design Guide ForCost Effective Machined Parts - IVPrithviraj DagaNo ratings yet

- Research FinalDocument55 pagesResearch Finalkieferdem071908No ratings yet

- SP-Chapter 14 PresentationDocument83 pagesSP-Chapter 14 PresentationLoiDa FloresNo ratings yet

- SPC FD 00 G00 Part 03 of 12 Division 06 07Document236 pagesSPC FD 00 G00 Part 03 of 12 Division 06 07marco.w.orascomNo ratings yet

- SilmaDocument12 pagesSilmanobleconsultantsNo ratings yet

- Img 20201010 0005Document1 pageImg 20201010 0005Tarek SalehNo ratings yet

- VimDocument258 pagesVimMichael BarsonNo ratings yet

- CISF Manual Final OriginalDocument17 pagesCISF Manual Final OriginalVaishnavi JayakumarNo ratings yet

- A.meaning and Scope of Education FinalDocument22 pagesA.meaning and Scope of Education FinalMelody CamcamNo ratings yet

- 4th Sept - Marathon Series Lecture 8 - General AwarenessDocument208 pages4th Sept - Marathon Series Lecture 8 - General AwarenessManbir ArinNo ratings yet

- 220245-MSBTE-22412-Java (Unit 1)Document40 pages220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhNo ratings yet

- 2 Design of DOSAGE DESIGNDocument16 pages2 Design of DOSAGE DESIGNMarjo100% (1)

- Yale Revision WorksheetDocument3 pagesYale Revision WorksheetYASHI AGRAWALNo ratings yet

- Manuel SYL233 700 EDocument2 pagesManuel SYL233 700 ESiddiqui SarfarazNo ratings yet

- Geotechnical PaperDocument16 pagesGeotechnical PaperTxavo HesiarenNo ratings yet

- Smartfind E5 g5 User ManualDocument49 pagesSmartfind E5 g5 User ManualdrewlioNo ratings yet

- Jacob Stewart ResumeDocument2 pagesJacob Stewart Resumeapi-250063152No ratings yet

- I. Learning Objectives / Learning Outcomes: Esson LANDocument3 pagesI. Learning Objectives / Learning Outcomes: Esson LANWilliams M. Gamarra ArateaNo ratings yet

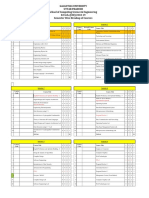

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDocument2 pagesGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiNo ratings yet

- AE Notification 2015 NPDCLDocument24 pagesAE Notification 2015 NPDCLSuresh DoosaNo ratings yet

- KDE11SSDocument2 pagesKDE11SSluisgomezpasion1No ratings yet

- Hockney-Falco Thesis: 1 Setup of The 2001 PublicationDocument6 pagesHockney-Falco Thesis: 1 Setup of The 2001 PublicationKurayami ReijiNo ratings yet

- Pathophysiology of Myocardial Infarction and Acute Management StrategiesDocument11 pagesPathophysiology of Myocardial Infarction and Acute Management StrategiesnwabukingzNo ratings yet

- XII CS Material Chap7 2012 13Document21 pagesXII CS Material Chap7 2012 13Ashis PradhanNo ratings yet