Professional Documents

Culture Documents

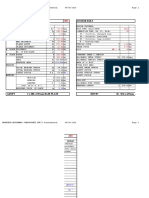

N, TO) +@,'T) : Worked Example

Uploaded by

lyhalim0 ratings0% found this document useful (0 votes)

3 views1 pageThis document provides an example calculation for determining the buckling resistance of a steel I-beam. It lists the geometric properties of the beam and determines it is made of steel grade S275. It then calculates the lateral-torsional buckling slenderness ratio and selects buckling curve 'c' for the calculation. Finally, it determines the buckling reduction factor is 0.70 based on the selected buckling curve and properties of the rolled steel beam.

Original Description:

Original Title

24

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an example calculation for determining the buckling resistance of a steel I-beam. It lists the geometric properties of the beam and determines it is made of steel grade S275. It then calculates the lateral-torsional buckling slenderness ratio and selects buckling curve 'c' for the calculation. Finally, it determines the buckling reduction factor is 0.70 based on the selected buckling curve and properties of the rolled steel beam.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageN, TO) +@,'T) : Worked Example

Uploaded by

lyhalimThis document provides an example calculation for determining the buckling resistance of a steel I-beam. It lists the geometric properties of the beam and determines it is made of steel grade S275. It then calculates the lateral-torsional buckling slenderness ratio and selects buckling curve 'c' for the calculation. Finally, it determines the buckling reduction factor is 0.70 based on the selected buckling curve and properties of the rolled steel beam.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

530

Worked example

Beam example 4

Sheet2of4

Rev

Try 457 x 152 x 74 U K B

Geometric properties:

h = 462.0mm; h = 154.4mm; t , = 9.6mm; ti = 17.0mm;

cl /ti = 3.66; c, / t , = 42.5; iz = 3.33 cm = 33.3 mm;

Wz,,,,,= 16.70 cm' = 16.70 x IO'mm-'

Steel

Building

Design:

Design Data

Maximum component thickness is,flange thickness tt = 19.6mm > 16.0mm

:. f , =265 N/mmz

BS EN

10025-2

Using NCCI SN002 (Method 3 of Reference 7),lateral torsional buckling

slenderness is defined as:

For class I or 2 sections, = 1.0. Conservatively ,for I-sections, take UV = 0.9. For

the ratio of end moments ty =377/406 = 0.93, 1I& = 0.98 (by interpolation)

from Table 16.7 (Table 6.4 of Reference 7).

Table 17.7

A L,, tiz - 3000133.3

A,=>== 1.02

~

:.

Ll

A1

88.4

%IT

= 0.98 ~

= -UVnz&

&

0 . x9 1 . 0 2 ~ 1 . 0

= 0.90

Buckling curve selection:

h / h = 462.0/154.4 = 2.99

For the case of rolled and equivalent welded sections, for I-sections with

2 < h / h 53.1, use buckling curve 'c' ( a = 0.49).

For rolled sections, p = 0.75 and

U K N A to

BS EN

1993-1-1

1,T O = 0.4.

Buckling reduction factor xLI:

=0

= 0.5[I

XLI

-n,TO)+@,'T]

BS EN

1993-1-1

C1 6.3.2.3

4 1+ a r T ( z r

+ 0.49(0.90- 0.4) + (0.75x 0.90')] = 0.92

I

=

QL1

+,/a=

+

0.92 40.92'

- 0.75 x

0.90'

= 0.70

You might also like

- Structural Design For Low Rise BuildingDocument42 pagesStructural Design For Low Rise BuildingMohammed SumerNo ratings yet

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Base PlateDocument45 pagesBase PlateMuhammed Ali60% (5)

- Column Reinforcement Design: Uex UeyDocument15 pagesColumn Reinforcement Design: Uex Ueyswargadwari consultancyNo ratings yet

- Design of Rectangular Water TankDocument280 pagesDesign of Rectangular Water TankNoppolNorasri95% (42)

- Weld Design CalculationsDocument7 pagesWeld Design CalculationsanwarNo ratings yet

- Shutter DesignDocument28 pagesShutter Designsubhananya50% (4)

- 2 Way Slab Design-Roof SlabDocument120 pages2 Way Slab Design-Roof SlabSambhav PoddarNo ratings yet

- Testbeams For Ver Pile CapacityDocument13 pagesTestbeams For Ver Pile CapacitytmssorinNo ratings yet

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Section Size: W200X36: Refer Appendix D For Support ReactionsDocument10 pagesSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04No ratings yet

- Compound Die Design: A Case Study: Sneha S. Pawar, R. S. DaluDocument4 pagesCompound Die Design: A Case Study: Sneha S. Pawar, R. S. DaluchupchapNo ratings yet

- Top Circular Slab DesignDocument3 pagesTop Circular Slab Designanshutomar791580% (5)

- 32 Meter Chimney CalculationsDocument9 pages32 Meter Chimney Calculationsmazumdar_satyajitNo ratings yet

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- Design of Machine Elements ParDocument197 pagesDesign of Machine Elements Parboyo999100% (7)

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- 3) Initial Sizing of MembersDocument5 pages3) Initial Sizing of MembersKenNo ratings yet

- Steel Column BeamDocument6 pagesSteel Column Beamdharul khairNo ratings yet

- Design of Base PlateDocument14 pagesDesign of Base Plateruel galutanNo ratings yet

- SCBD Lot 10 BMU Calculation RevisionDocument18 pagesSCBD Lot 10 BMU Calculation RevisionRifki WaliardiNo ratings yet

- Design of Rectangular Water TankDocument308 pagesDesign of Rectangular Water Tankලහිරු විතානාච්චි100% (1)

- 77-9 Design of CranesDocument10 pages77-9 Design of Cranesrip111176No ratings yet

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsFrom EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsRating: 3 out of 5 stars3/5 (1)

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- (XLL XLL: Beam Example 4 Sheet3Of4 RevDocument1 page(XLL XLL: Beam Example 4 Sheet3Of4 RevlyhalimNo ratings yet

- Https:/bpmis - Gov.rw/asset Data/form 201251/files/element 77 3d9990a970Document22 pagesHttps:/bpmis - Gov.rw/asset Data/form 201251/files/element 77 3d9990a970emuan vanessaNo ratings yet

- Hoist Design Procedure For EOT CraneDocument14 pagesHoist Design Procedure For EOT CraneKeerthi KumarNo ratings yet

- Unit 3 32,33,34,35Document3 pagesUnit 3 32,33,34,35Deepanshu VermaNo ratings yet

- 76 9 Design of CranesDocument11 pages76 9 Design of Cranesrip111176No ratings yet

- Shear Wall DesignDocument6 pagesShear Wall DesignAayush AdhikariNo ratings yet

- 5L DesignDocument23 pages5L Designsam 08No ratings yet

- Strap FootingDocument6 pagesStrap Footingrukesh104No ratings yet

- RCD Chapter 6Document14 pagesRCD Chapter 6jereck loquisoNo ratings yet

- SlabDocument4 pagesSlabAbdo SalahNo ratings yet

- 78 - 9 - HookDocument14 pages78 - 9 - Hookrip111176No ratings yet

- Manyam Dr.s House 2.5Document33 pagesManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNo ratings yet

- Manyam Dr.s HouseDocument33 pagesManyam Dr.s HouseDurga Rama Swamy KalvakolanuNo ratings yet

- Design of Beams 1design of Beams A1-A2 and A2-A3Document4 pagesDesign of Beams 1design of Beams A1-A2 and A2-A3Sreenathareddy GajjalaNo ratings yet

- Vibration Serviceability of Composite SlabsDocument8 pagesVibration Serviceability of Composite SlabsDelahan AbatyoughNo ratings yet

- Eyab AssignmentDocument8 pagesEyab AssignmentAbnet BeleteNo ratings yet

- Designing of Ground Level Water Tank 2003 FormatDocument4 pagesDesigning of Ground Level Water Tank 2003 Formatajith chandranNo ratings yet

- Structural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesDocument122 pagesStructural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesPascasio PascasioNo ratings yet

- PILE FOUNDATION DESIGN Manual Cal - CommentsDocument6 pagesPILE FOUNDATION DESIGN Manual Cal - CommentsDilip PatelNo ratings yet

- UK Afternoon WorkshopDocument50 pagesUK Afternoon WorkshopanhkhoacgNo ratings yet

- Perhitungan Baja II CremonaDocument27 pagesPerhitungan Baja II CremonaAdi Indra BrugmanNo ratings yet

- 4.5 - Design of DRS - Simply SupportedDocument18 pages4.5 - Design of DRS - Simply Supportedron thombareNo ratings yet

- Design Example - Composite BeamDocument7 pagesDesign Example - Composite Beamzaroon_mNo ratings yet

- Column (1) SRCDocument17 pagesColumn (1) SRCpratik ranaNo ratings yet

- Assignment of SteelDocument25 pagesAssignment of SteelSamih S. BarzaniNo ratings yet

- Nptel CombinedDocument76 pagesNptel CombinedRADHE GRAPHICSNo ratings yet

- At Very Low Cutting SpeedsDocument40 pagesAt Very Low Cutting SpeedsThulasi Ram100% (1)

- Week 11 Lecture Material - WatermarkDocument57 pagesWeek 11 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- CE 71 DRB Internal-2-Answer Key (Student Copy)Document22 pagesCE 71 DRB Internal-2-Answer Key (Student Copy)PaulNo ratings yet

- Check For Punching Shear:: Pile Cap Design (PC3a)Document6 pagesCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanNo ratings yet

- Prestressed Beam Girder Floor Made of High Strength ConcreteDocument18 pagesPrestressed Beam Girder Floor Made of High Strength ConcreteSebastian GusetuNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet