Professional Documents

Culture Documents

32 Meter Chimney Calculations

Uploaded by

mazumdar_satyajitCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

32 Meter Chimney Calculations

Uploaded by

mazumdar_satyajitCopyright:

Available Formats

Bayer Crop science-Ankleshwar

Design Calculations

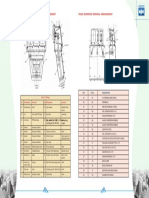

32 Meter, Self Supporting Chimney

The Chimney will be erected at Mysore

Design Data:

Total Height of Chimney

Location

Design Codes of Practice

32

Ankleshwar

IS 6533

IS 6533

IS 875

IS 800

IS 1893

meters

Type of Chimney

Material of Construction

Self Supporting

Mild Steel for Chimney Shell

Part 1

Part 2

Part 3

Inputs:

Description

From

32.00

21.00

11.00

16.00

5.00

11.00

5.00

5.50

5.50

0.00

5.50

Height of Chimney

Range of Zone 1

Length of Zone 1

Range of Zone 2

Length of Zone 2

Range of Zone 3

Length of Zone 3

Range of Zone 4

Length of Zone 4

Range of Zone 5

Length of Zone 5

To

32.00

21.00

16.00

11.00

5.50

Unit

meters

meters

meters

meters

meters

meters

meters

meters

meters

meters

meters

Size Requirements:

As per Clause 7.2.4 of I.S. 6533 Part 2

Minimum height of Flared Portion

=

=

The provided height of Flared Portion is

Hence, OK

Maximum Outside Diameter of Flared Portion at Botto

=

=

Whereas provided Inside Diameter of Flared Portion is

Hence, OK

1/3

0.33

10.667

11.000

Total Height of Chimney

32

meters

meters

meters

1.6

1.6

0.96

1.00

Outside Diameter at Top

0.6

meters

meters

meters

Wind Pressure Calculations:

Basic Wind Speed Vb

Risk Co efficient K1

Risk Co efficient K2

Topography Factor K3

44.00

1.07

1.13

1.00

m/sec

Category 1, Class B

Assumed Flat Ground

Calculations:

Vz (Design Wind Velocity) = Vb x K1 x K2 x K3

= 53.2004

m/sec

Design Wind Pressure = 0.6 x Vz x Vz

= 1698.16954

= 169.81695

Safety Factor for Circular Exposed Surface

KN/sq. m

Kg/sq. m

0.7

Calculations for Wind Moment and Checking for Stresses

As Per I.S 6533 (part-2 ) Cl 8.2.2 of I.S.6533-part2, to

determine the wind force acting at different heights of the

chimney, the chimney shall be divided in to five Zones.

Description

Zone

Zone

Zone

Zone

Zone

1

2

3

4

5

From

21.00

16.00

11.00

5.50

0.00

To

32.00

21.00

16.00

11.00

5.50

Unit

meters

meters

meters

meters

meters

Calculations for Zone 1:

Thickness of Shell

Outside Diameter of Shell (OD)

Inside Diameter of Shell (ID)

Pi

21.00

32.00

meters

0.6

cm.

72.0

cm.

60.0

cm.

3.142

Moment of Inertia I = (3.142/64) x (OD4 ID4)

= 0.0490875 13913856

= 682996.41

Cm4

Modulus of Section Z = I x (2/OD)

= 18972.1224

Cm3

Note: For wind force on Ladder etc. 20% of Ladder Dia is considered for calculation

Diameter of Ladder

0.7

meters

[OD x Design wind pr. x safe

factor x (sq of height of zone) /

Therefore, Wind Moment at 21 meters from Base, M = 2] + [dia. of ladder x Design

wind pr. x 20% dia. of ladder x

(sq of height of zone) / 2]

= 11880.7677

= 1188076.8

kg m

kg cm

Self Weight of Stack and Ladder P

1900

kg

Cross Sectional Area of Chimney A

(3.142/4) x OD2

= 4072.032

sq. cm.

Stress at 21 meters from Base,

Height to Diameter Ratio

(M/Z) + (P/A)

= 63.088836

Height/Mean Diameter

= 16.6666667

=

7.31

Diameter to Thickness Ratio

=

Refer to table -3 of I.S 6533 (part-2 ).

Maximum Permissible Stress for mild steel

Therefore Section is Safe

kg/sq. cm

Mean Diameter/Shell Thickness

251

1013

kg/sq. cm.

Calculations for Zone 2:

Thickness of Shell

Outside Diameter of Shell (OD)

Inside Diameter of Shell (ID)

Pi

16.00

21.00

meters

0.8

cm.

151.6

cm.

150.0

cm.

3.142

Moment of Inertia I = (3.142/64) x (OD4 ID4)

= 0.0490875 21948064

Cm4

= 1077375.6

Modulus of Section Z = I x (2/OD)

= 14213.398

Cm3

Note: For wind force on Ladder etc. 20% of Ladder Dia is considered for calculation

Diameter of Ladder

0.7

meters

[OD x Design wind pr. x safe

factor x (sq of height of zone) /

Therefore, Wind Moment at 16 meters from Base, M = 2] + [dia. of ladder x Design

wind pr. x 20% dia. of ladder x

(sq of height of zone) / 2]

= 25197.032

= 2519703.2

kg m

kg cm

Self Weight of Stack and Ladder P

3040

kg

Cross Sectional Area of Chimney A

(3.142/4) x OD2

= 18052.801

sq. cm.

Stress at 21 meters from Base,

Height to Diameter Ratio

(M/Z) + (P/A)

= 177.44501

Height/Mean Diameter

= 10.6100796

=

10.61

Diameter to Thickness Ratio

=

Refer to table -3 of I.S 6533 (part-2 ).

Maximum Permissible Stress for mild steel

Therefore Section is Safe

kg/sq. cm

Mean Diameter/Shell Thickness

188.5

1187

kg/sq. cm.

Calculations for Zone 3:

Thickness of Shell

Outside Diameter of Shell (OD)

Inside Diameter of Shell (ID)

Pi

11.00

16.00

meters

0.8

cm.

151.6

cm.

150.0

cm.

3.142

Moment of Inertia I = (3.142/64) x (OD4 ID4)

= 0.0490875 21948064

Cm4

= 1077375.6

Modulus of Section Z = I x (2/OD)

= 14213.398

Cm3

Note: For wind force on Ladder etc. 20% of Ladder Dia is considered for calculation

Diameter of Ladder

0.7

meters

[OD x Design wind pr. x safe

factor x (sq of height of zone) /

Therefore, Wind Moment at 11 meters from Base, M = 2] + [dia. of ladder x Design

wind pr. x 20% dia. of ladder x

(sq of height of zone) / 2]

= 43405.8247

= 4340582.5

kg m

kg cm

Self Weight of Stack and Ladder P

4000

kg

Cross Sectional Area of Chimney A

(3.142/4) x OD2

= 18052.801

sq. cm.

Stress at 21 meters from Base,

Height to Diameter Ratio

(M/Z) + (P/A)

= 305.60825

Height/Mean Diameter

= 13.9257294

=

13.92

Diameter to Thickness Ratio

=

Refer to table -3 of I.S 6533 (part-2 ).

Maximum Permissible Stress for mild steel

Therefore Section is Safe

kg/sq. cm

Mean Diameter/Shell Thickness

188.5

1187

kg/sq. cm.

Calculations for Zone 4:

Thickness of Shell

Outside Diameter of Shell (OD)

Inside Diameter of Shell (ID)

Pi

5.50

11.00

meters

1.0

cm.

197.0

cm.

195.0

cm.

3.142

Moment of Inertia I = (3.142/64) x (OD4 ID4)

= 0.0490875 60237856

Cm4

= 2956925.8

Modulus of Section Z = I x (2/OD)

= 30019.551

Cm3

Note: For wind force on Ladder etc. 20% of Ladder Dia is considered for calculation

Diameter of Ladder

0.7

meters

[OD x Design wind pr. x safe

factor x (sq of height of zone) /

Therefore, Wind Moment at 5.5 meters from Base, M = 2] + [dia. of ladder x Design

wind pr. x 20% dia. of ladder x

(sq of height of zone) / 2]

= 88069.0463

= 8806904.6

kg m

kg cm

Self Weight of Stack and Ladder P

6200

kg

Cross Sectional Area of Chimney A

(3.142/4) x OD2

= 30484.4695

sq. cm.

Stress at 21 meters from Base,

Height to Diameter Ratio

(M/Z) + (P/A)

= 293.57568

Height/Mean Diameter

= 13.5204082

=

13.52

Diameter to Thickness Ratio

=

Refer to table -3 of I.S 6533 (part-2 ).

Maximum Permissible Stress for mild steel

Therefore Section is Safe

kg/sq. cm

Mean Diameter/Shell Thickness

196

1187

kg/sq. cm.

Calculations for Zone 5:

Thickness of Shell

Outside Diameter of Shell (OD)

Inside Diameter of Shell (ID)

Pi

0.00

5.50

meters

1.0

cm.

242.0

cm.

240.0

cm.

3.142

Moment of Inertia I = (3.142/64) x (OD4 ID4)

= 0.0490875 111982096

Cm4

= 5496921.1

Modulus of Section Z = I x (2/OD)

= 45429.1

Cm3

Note: For wind force on Ladder etc. 20% of Ladder Dia is considered for calculation

Diameter of Ladder

0.7

meters

[OD x Design wind pr. x safe

factor x (sq of height of zone) /

Therefore, Wind Moment at 5.5 meters from Base, M = 2] + [dia. of ladder x Design

wind pr. x 20% dia. of ladder x

(sq of height of zone) / 2]

= 155807.734

= 15580773

kg m

kg cm

Self Weight of Stack and Ladder P

8400

kg

Cross Sectional Area of Chimney A

(3.142/4) x OD2

= 46002.022

sq. cm.

Stress at 21 meters from Base,

Height to Diameter Ratio

(M/Z) + (P/A)

= 343.15161

Height/Mean Diameter

= 13.2780083

=

13.52

Diameter to Thickness Ratio

=

Refer to table -3 of I.S 6533 (part-2 ).

Maximum Permissible Stress for mild steel

Therefore Section is Safe

kg/sq. cm

Mean Diameter/Shell Thickness

241

1147

kg/sq. cm.

[OD at Bottom+OD of Zone 4]/[2 x Designed

Wind Pressure x Factor of Safety x Ht. of

Zone 1]+[OD at Top x Designed Wind

Pressure x Factor of Safety x Ht. of Zone 2]+

[Factor of Safety x Designed Wind Pressure x

20 % of Total Height]

Total Horizontal Force at Base Plate Level

= 5131.4608

kg.

Check for Combined Stresses and Stability

As per I.S. 6533 - part-2 CL. 9.1.1, the chimney is 1.6(s + s ) 0.9s < 1.8 s

w

m

e

a

stable provided the following is satisfied.

Where,

sw = Stress produced by Wind load

M/Z

= 342.96901

sm = Stress produced by any other load which acts at all

times & will reduce the combined stress

se = Stress due to Dead load

Therefore, 1.8 sa

Final Calculations

kg/sq. cm.

0

P/A

= 0.1826007

kg/sq. cm.

617.67289

kg/sq. cm.

1.6(sw + sm) 0.9se < 1.8 sa

548.58607

<

1111.81

Therefore Structure is Safe.

Design of Foundation Bolts

Maximum Bending Moment M

Maximum Shear Q

Weight of Chimney

###

5131.46

13050.00

Maximum Force on one Anchor Bolt T = (4M / n D) W / n

Where, n = number of bolts used

24

D = PCD of Bolts

275

8899.14298

Tensile Capacity of each M36 Bolt

Maximum Shear Capacity

nos.

cm

kg.

10.178cm2 x 1300Kgs/cm213232.4

10.178 x 1100

11195.8

kgs.

kgs.

Check for Combined Stress for Shear and tension

(Max. Tensile

Force/Tensile Cap. Of

each Bolt)+(Total

Horizontal Force on

Base/Max. shear Cap.)

1.1308653

<

1.4

Hence Design is Safe

T / Pi x d x tbd

Bolt Embedment Length in concrete = l =

tbd = Permissible stress in bond

Diameter of the Bolt, d

8

Kgs/Cm2 (for M20 Concrete)

3.6

cms

81.581143

cms

Whereas Provided Length is more than

100

cms.

Hence OK

Design of Baseplate

Maximum Bending Moment M

###

Diameter of Chimney at Base d=

242.00

cms.

Weight of Chimney W =

13050.00 kgs.

Maximum compressive force / unit length of circumference = 4M/ Pi D2 + W / PiD

354.7

kg/cm

Provided Baseplate Thickness T

25

cms.

Fbe = Bearing Pressure

Fc/T

14.188

kg/sq. cm.

Which is less than 40 Kg/sq. cm. (For Concrete)

Thickness of Base plate T = Nb x (3 x Fbe / sb)0.5

Where Nb = Maximum projection =

15

cms.

Fbe =

14.188

kg/sq. cm.

sb =Permissible Bending Stress

1650

kg/sq. cm.

Therefore T=

Whereas provided thickness is 2.5 cms.

Hence, OK.

2.4

cms

You might also like

- CH Design-R1 PDFDocument12 pagesCH Design-R1 PDFmazumdar_satyajitNo ratings yet

- Chimney Calculations, Dia 400 MM, 30 M HeightDocument15 pagesChimney Calculations, Dia 400 MM, 30 M HeightMANOJNo ratings yet

- Analysis of RCC ChimneyDocument26 pagesAnalysis of RCC ChimneynaveenaeeNo ratings yet

- Chimney CalculationsDocument2 pagesChimney CalculationsRamesh Kuppili75% (4)

- Chimney/ring Fdn. DesignDocument3 pagesChimney/ring Fdn. Designmasum91032No ratings yet

- Chimney DesignDocument6 pagesChimney Designneel0% (1)

- Design of Circular ChimneyDocument15 pagesDesign of Circular ChimneyPatel TosifNo ratings yet

- Chimney Calculations 800 Dia 35 M Ht-1Document9 pagesChimney Calculations 800 Dia 35 M Ht-1nilesh100% (2)

- Design of Steel Chimney According to IS StandardsDocument24 pagesDesign of Steel Chimney According to IS StandardsG S Deshpande100% (1)

- Chimney Design Guide LinesDocument9 pagesChimney Design Guide LinesluckynaveenrajNo ratings yet

- Chimney FootingDocument3 pagesChimney FootingUttam Kumar GhoshNo ratings yet

- Design of Steel Chimney and RCC Foundation As Per Indian Code 22052014Document12 pagesDesign of Steel Chimney and RCC Foundation As Per Indian Code 22052014Ahmad Badsha Quadri58% (19)

- Chimney DesignDocument12 pagesChimney DesignVivek PremjiNo ratings yet

- Design of Circular ChimneyDocument15 pagesDesign of Circular ChimneyPatel TosifNo ratings yet

- Draft Code for Design of Reinforced Concrete ChimneysDocument54 pagesDraft Code for Design of Reinforced Concrete Chimneysakshay chauhan67% (3)

- Design of ChimneyDocument39 pagesDesign of ChimneyVenkatesha Hebbar100% (2)

- Chimney Calculation SheetDocument12 pagesChimney Calculation SheetVinoth Rajendra40% (5)

- Design Calculation Report-Steel ChimneyDocument15 pagesDesign Calculation Report-Steel ChimneyUJJWAL SUTHAR100% (2)

- Chimney Sizing Calculation-R1Document3 pagesChimney Sizing Calculation-R1Arun Kumar67% (3)

- ASME STS-1Document19 pagesASME STS-1sivaraju1100% (4)

- ChimneyDocument41 pagesChimneyhemantkle2u100% (2)

- Wind & Seismic CalculationsDocument3 pagesWind & Seismic CalculationsSajal Kulshrestha33% (3)

- NEO Steel Chimney DesignDocument8 pagesNEO Steel Chimney DesignAnil Pradeep100% (1)

- Anchor Bolt DesignDocument1 pageAnchor Bolt Designnishant131No ratings yet

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationNitesh SinghNo ratings yet

- ChimneyDocument42 pagesChimneyAnand SwamiNo ratings yet

- Stack Design CalculationDocument27 pagesStack Design Calculationrupam dey100% (6)

- KONARK CHIMNEY Chimney Calculation SheetDocument18 pagesKONARK CHIMNEY Chimney Calculation SheetBimal DeyNo ratings yet

- Isolated Footing Design: Forces DetailsDocument7 pagesIsolated Footing Design: Forces DetailsMukhlish AkhatarNo ratings yet

- Tank DesignDocument89 pagesTank Designpatrickandreas77No ratings yet

- Design of Wind Pressure of SiloDocument1 pageDesign of Wind Pressure of SilosrinivasNo ratings yet

- Chimney Calculation SheetDocument14 pagesChimney Calculation SheetSrinivasa Rao VenkumahanthiNo ratings yet

- HRSG stack design load calculation and analysisDocument35 pagesHRSG stack design load calculation and analysislightsons100% (1)

- Wind Load Is 875Document2 pagesWind Load Is 875Gaurav BhabadNo ratings yet

- Sizing Stack HeightDocument1 pageSizing Stack Heightashwini_kumar19840% (1)

- STEEL STACK Sample Report PDFDocument12 pagesSTEEL STACK Sample Report PDFRamesh Subramani RamachandranNo ratings yet

- Dynamic Analysis of Self Supported Steel Chimney As Per Indian StandardDocument81 pagesDynamic Analysis of Self Supported Steel Chimney As Per Indian Standardmoganna73No ratings yet

- Rectangular Ground Water TankDocument26 pagesRectangular Ground Water TankJhon DonNo ratings yet

- 6 Design of Constant Dia RCC Chimney and Foundation 23052014Document16 pages6 Design of Constant Dia RCC Chimney and Foundation 23052014Ahmad Badsha Quadri0% (1)

- Tank CalculationDocument3 pagesTank CalculationSudjono BroNo ratings yet

- Design of Overhead Water Tank 29Document28 pagesDesign of Overhead Water Tank 29rashmi bhailaNo ratings yet

- Dike Wall DesignDocument4 pagesDike Wall Designdantevarias100% (1)

- Calculations Tank S6Document19 pagesCalculations Tank S6Joshue Adele100% (1)

- Water Tank Design As Per Moody ChartDocument20 pagesWater Tank Design As Per Moody ChartMukhlish AkhatarNo ratings yet

- RCC Chimney DesignDocument13 pagesRCC Chimney DesignJaydip PatelNo ratings yet

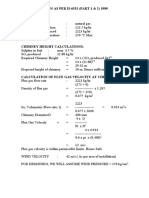

- Design of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992Document76 pagesDesign of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992bhargavramudu 2019No ratings yet

- Design of Rectangular Water Tank (L/B 2)Document14 pagesDesign of Rectangular Water Tank (L/B 2)Abhay ThakurNo ratings yet

- ManholeDocument2 pagesManholeTukuboya MTaufanNo ratings yet

- Design of Const Dia RCC ChimneyDocument16 pagesDesign of Const Dia RCC ChimneyVadirajNHalgeri100% (3)

- Strap Beam DesignDocument18 pagesStrap Beam DesignRabin BhattaraiNo ratings yet

- DmTank Ring Wall Foundation+&+Annular+RaftDocument29 pagesDmTank Ring Wall Foundation+&+Annular+RaftpcmaraujoNo ratings yet

- ART20161236 Design Chimney ThisesDocument5 pagesART20161236 Design Chimney ThisesAnand.5No ratings yet

- DESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m HeightDocument15 pagesDESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m Heightmsiddiq1100% (2)

- Ba Culvertf TestDocument16 pagesBa Culvertf TestsanjuktaacharyyaNo ratings yet

- Design Calculation RCC Sleeper Type 6Document9 pagesDesign Calculation RCC Sleeper Type 6DrAmit Dutta100% (4)

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Aci BeamDocument6 pagesAci BeamkumsbamaNo ratings yet

- Structural design and analysis of a low-rise buildingDocument42 pagesStructural design and analysis of a low-rise buildingMohammed SumerNo ratings yet

- 2-WAY SLAB OPTIMIZATIONDocument120 pages2-WAY SLAB OPTIMIZATIONSambhav PoddarNo ratings yet

- Design of Combined FootingDocument26 pagesDesign of Combined FootingSujan SinghNo ratings yet

- Calculation For The Fault CurrentDocument1 pageCalculation For The Fault Currentmazumdar_satyajitNo ratings yet

- Ventilation: Thumb Rule For Calculation of Air Flow From An Louvered OpeningDocument1 pageVentilation: Thumb Rule For Calculation of Air Flow From An Louvered Openingmazumdar_satyajitNo ratings yet

- 14 Q KG/HR) 0.3 GM/HR 14 0.01998 X (Fuel Rate in G/HR) X (%fuel Sulphur by WT.)Document2 pages14 Q KG/HR) 0.3 GM/HR 14 0.01998 X (Fuel Rate in G/HR) X (%fuel Sulphur by WT.)mazumdar_satyajitNo ratings yet

- Chimney Cost Breakup Details: Base Plate, Comp Ring, Gussets, Flanges Weights and CostsDocument1 pageChimney Cost Breakup Details: Base Plate, Comp Ring, Gussets, Flanges Weights and Costsmazumdar_satyajitNo ratings yet

- General Technical Versions: Motor Terminal BoxesDocument1 pageGeneral Technical Versions: Motor Terminal Boxesmazumdar_satyajitNo ratings yet

- PE SolarliteKanjanaburi eDocument1 pagePE SolarliteKanjanaburi emazumdar_satyajitNo ratings yet

- Phase Segregated Terminal Arrangement Phase Seperated Terminal ArrangementDocument1 pagePhase Segregated Terminal Arrangement Phase Seperated Terminal Arrangementmazumdar_satyajitNo ratings yet

- PPT6Document1 pagePPT6mazumdar_satyajitNo ratings yet

- Ventilation: Installation ConsiderationsDocument2 pagesVentilation: Installation Considerationsmazumdar_satyajitNo ratings yet

- Phase Segregated Terminal Box: Atex / Iecex Gas & Dust CertifiedDocument2 pagesPhase Segregated Terminal Box: Atex / Iecex Gas & Dust Certifiedmazumdar_satyajitNo ratings yet

- Chimney WT CalculationDocument3 pagesChimney WT Calculationmazumdar_satyajitNo ratings yet

- Genon 15 06 10Document6 pagesGenon 15 06 10mazumdar_satyajitNo ratings yet

- Engine Manufacturing COmpanyDocument2 pagesEngine Manufacturing COmpanymazumdar_satyajit0% (1)

- Cooling Tower Calculations-TR CapacityDocument10 pagesCooling Tower Calculations-TR Capacitymazumdar_satyajitNo ratings yet

- China Nonroad EmissionsDocument6 pagesChina Nonroad Emissionsmazumdar_satyajitNo ratings yet

- Fault Level CalculationDocument43 pagesFault Level Calculationmazumdar_satyajitNo ratings yet

- Section 6 Battery SizingDocument54 pagesSection 6 Battery SizingAca ChchNo ratings yet

- Exhaust System Back Pressure CalculationDocument1 pageExhaust System Back Pressure Calculationmazumdar_satyajitNo ratings yet

- Heat Balance CalculationDocument1 pageHeat Balance Calculationmazumdar_satyajitNo ratings yet

- VMA 1826 Approval Standards Rev 3Document54 pagesVMA 1826 Approval Standards Rev 3mazumdar_satyajitNo ratings yet

- Installation of acoustic panels and sound attenuatorsDocument11 pagesInstallation of acoustic panels and sound attenuatorsmazumdar_satyajitNo ratings yet

- Data SheetDocument1 pageData Sheetmazumdar_satyajitNo ratings yet

- Chimney Calculations 14-7-2003Document4 pagesChimney Calculations 14-7-2003surinder yadavNo ratings yet

- Room AcousticDocument19 pagesRoom AcousticMenandro AmbanlocNo ratings yet

- E 3Document1 pageE 3mazumdar_satyajitNo ratings yet

- Calculation of fault current for paralleled generatorsDocument1 pageCalculation of fault current for paralleled generatorsmazumdar_satyajitNo ratings yet

- KEI Cable Price List 2008Document7 pagesKEI Cable Price List 2008mazumdar_satyajitNo ratings yet

- Pid 2Document1 pagePid 2mazumdar_satyajitNo ratings yet

- HS CodeDocument2 pagesHS Codemazumdar_satyajitNo ratings yet

- Re-Bar Staggered Lap SplicesDocument4 pagesRe-Bar Staggered Lap Splicestyger089100% (2)

- FD StatisticsDocument5 pagesFD Statisticssalma salmaNo ratings yet

- Copper-Based Alloys For Structural High-Heat-Flux Applications: A Review of Development, Properties, and Performance of Cu-Rich Cu-Cr-Nb AlloysDocument33 pagesCopper-Based Alloys For Structural High-Heat-Flux Applications: A Review of Development, Properties, and Performance of Cu-Rich Cu-Cr-Nb Alloysgerardo saucedoNo ratings yet

- Guided Wave Radar in Steam Boiler Service: Measuring Water Level Accurately Despite ChallengesDocument14 pagesGuided Wave Radar in Steam Boiler Service: Measuring Water Level Accurately Despite ChallengesRoger SeaverNo ratings yet

- A Guide To Experimental Particle Physics Literature 1994-1998Document453 pagesA Guide To Experimental Particle Physics Literature 1994-1998Chris Ioannou GksNo ratings yet

- Aci Automation ComponentsDocument106 pagesAci Automation ComponentsEduardo Marcelo SilveiraNo ratings yet

- Determining Sediment Concentration in Water Samples: Standard Test Methods ForDocument6 pagesDetermining Sediment Concentration in Water Samples: Standard Test Methods ForFajar Adi NugrohoNo ratings yet

- Human Rights Lesson by SlidesgoDocument39 pagesHuman Rights Lesson by SlidesgoJaewonNo ratings yet

- 5 Measure of Central TendencyDocument54 pages5 Measure of Central Tendencyeshet chafNo ratings yet

- LITHOGRAPHY-Chapter 5: - Litography Limits The Minimum Feature Size That Can Be Printable On The WaferDocument22 pagesLITHOGRAPHY-Chapter 5: - Litography Limits The Minimum Feature Size That Can Be Printable On The WafereniNo ratings yet

- Scientificattitude 141215223938 Conversion Gate01 PDFDocument41 pagesScientificattitude 141215223938 Conversion Gate01 PDFfillereyesNo ratings yet

- Cal1 Midterm 2020-21 S1 QsDocument2 pagesCal1 Midterm 2020-21 S1 QsTrần Xuân QuỳnhNo ratings yet

- Essential exam review covering biology, chemistry, physics, history and moreDocument15 pagesEssential exam review covering biology, chemistry, physics, history and moreRoi Vincent MontenegroNo ratings yet

- A Simple Relationship Between Lu Ders Elongation andDocument4 pagesA Simple Relationship Between Lu Ders Elongation andle hoangNo ratings yet

- Stochastic Processes Notes on Markov Chains and Infinitesimal GeneratorsDocument3 pagesStochastic Processes Notes on Markov Chains and Infinitesimal Generatorsxi shengNo ratings yet

- Chapter 5 Vector CalculusDocument69 pagesChapter 5 Vector CalculusJosamy MartinezNo ratings yet

- Physical Science: 2 Sem Module 9 Chapter: Beyond Every Day ExperienceDocument7 pagesPhysical Science: 2 Sem Module 9 Chapter: Beyond Every Day ExperienceDan Kirk FormenteraNo ratings yet

- Lesson 4 - Measures of VariationDocument3 pagesLesson 4 - Measures of VariationMeleza Joy Satur100% (1)

- Turntable Rotary Actuator R2Document6 pagesTurntable Rotary Actuator R2Loc NguyenNo ratings yet

- DCM Jhs 8scienceDocument12 pagesDCM Jhs 8scienceJogil ParaguaNo ratings yet

- FORMAT UAS GANJIL 21-22 Bahasa Inggris (Dr. H. Masrupi, M.Pd.2021Document15 pagesFORMAT UAS GANJIL 21-22 Bahasa Inggris (Dr. H. Masrupi, M.Pd.2021IfdaNo ratings yet

- Solved Problems - Design of Cam Clutches and BrakesDocument9 pagesSolved Problems - Design of Cam Clutches and BrakesSashankNiroulaNo ratings yet

- The Complete Smith Chart: Black Magic DesignDocument1 pageThe Complete Smith Chart: Black Magic DesignHagoro kaguNo ratings yet

- Crypt AirthmeticDocument13 pagesCrypt Airthmetic20BCA011 Divyasri TNo ratings yet

- 4ph1 1p Que 20231117Document40 pages4ph1 1p Que 20231117wonbin.nriizeNo ratings yet

- BDU-BIT-Electromechanical Engineering Curriculum (Regular Program)Document187 pagesBDU-BIT-Electromechanical Engineering Curriculum (Regular Program)beselamu75% (4)

- Weekly Assessment for Math, Social Studies and EnglishDocument9 pagesWeekly Assessment for Math, Social Studies and EnglishKriztelle A. ReyesNo ratings yet

- Civil Engineering Hydraulics ProblemsDocument2 pagesCivil Engineering Hydraulics ProblemsLenielle AmatosaNo ratings yet

- Munson, Young and Okiishi's Fundamentals of Fluid Mechanics, 8th Edition (2016) - Book ReviewDocument7 pagesMunson, Young and Okiishi's Fundamentals of Fluid Mechanics, 8th Edition (2016) - Book ReviewCristian De Jesus Nuñez GarciaNo ratings yet

- Nanoscale Lithography, Techniques and TechnologyDocument29 pagesNanoscale Lithography, Techniques and TechnologysanthoshNo ratings yet