Professional Documents

Culture Documents

Lifting Lug Calculation

Lifting Lug Calculation

Uploaded by

Marco ViniciusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Lug Calculation

Lifting Lug Calculation

Uploaded by

Marco ViniciusCopyright:

Available Formats

RIVELIN CONSULTANTS LIMITED

CLIENT UNITED ENGINEERING SERVICES LTD. Date 9-May-11

PROJECT PETROTRIN Precast concrete foundation pads By M Rampersad

Location Lifting lug design checks Job Ref 241-002

Sub-Location Pipe Supports Page

REF OUTPUT

References

1. Client Drawing DET-1

2. AISC 360-05 Specification for structural steel buildings

3. AISC LRFD Manual 1999

4. DNV 2.7-1 Std. for Certification, Offshore containers

5. Load analysis from Client

6. W-shapes dimensions to ASTM A6M

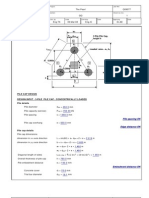

Padeye dimensions:

Min distance from pinhole to edge, y-direction, a = 76.2 mm

Min distance from pinhole to edge, x-direction, b = 56.1 mm

Pinhole diameter, d

h

= 50.8 mm

Pin diameter, d

pin

= 48.3 mm

Padeye plate thickness, t = 20.0 mm

Padeye width, w = 165.0 mm

Padeye effective outer distance, r

o

= 101.6 mm

Cheek plate diameter, d

c

= 50.8 mm

Cheek plate thickness, t

c

= mm

Distance from fixed edge to pinhole centre, h

1

= 152.4 mm

Loading:

DESCRIPTION

Loading:

Ref 5 Angle = 90.0 deg

Angle = 1.571 rad

Sling force R

S

= 45.0 kN

Horizontal component (x-direction) R

Sx

= 0.1 kN

Vertical component (y-direction) R

Sy

= 45.0 kN

h1=153

w=165

dc=51

dpin=49

dh=51

a=77

r0=102

b=57

t=20

tc=0

Rs=45kN

Rsx=0.1kN

Rsy=45kN

6mmE60xx

dc=51

dpin=49

RIVELIN CONSULTANTS LIMITED

CLIENT UNITED ENGINEERING SERVICES LTD. Date 9-May-11

PROJECT PETROTRIN Precast concrete foundation pads By M Rampersad

Location Lifting lug design checks Job Ref 241-002

Sub-Location Pipe Supports Page

REF OUTPUT DESCRIPTION

Padeye material

Select grade of padeye steel A36

Yield strength, F

y

245.0

N/mm

2

Ultimate tensile strength, F

u

400.0

N/mm

2

GEOMETRIC CHECKS

b

eff

= 2t+16mm b

2t+16= 56.0 mm

Check for b

eff

< b OK

w 2b

eff

+ d

2b

eff

+ d = 162.8 mm

Check forw 2b

eff

+ d OK

a 1.33b

eff

1.33b

eff

= 74.5 mm

Check for a 1.33b

eff

OK

CODE CHECKS

Tension on Net effective area

General formula

Eqn D3-1

P = 2tb F

Ref 3 Clause

D3-1b

Ref 2, Clause

C-D5

Ref 3 Clause

D3-1b

Ref 3 Clause

D3-1a (a)

Eqn D3-1

P

n

= 2tb

eff

F

u

2tb

eff

F

u

= 896.0 kN

Design strength in tension = P

n

= 0.75 [unitless]

Design strength in tension, P

n

= 672.0 kN

Check against R

s

45.0 kN OK with Rs in tension

Check against R

sx

0.1 kN OK with Rsx in tension

Check against R

sy

45.0 kN OK with Rsy in tension

Shear on the effective area

General formula

Eqn D3-2

P

n

= 0.6A

sf

F

u

Design strength in shear = P

n

= 0.75 [unitless]

y-axis x-axis

Ref 3 Clause

D3-1a (b)

y

a+dh/2 b+dh/2

x

RIVELIN CONSULTANTS LIMITED

CLIENT UNITED ENGINEERING SERVICES LTD. Date 9-May-11

PROJECT PETROTRIN Precast concrete foundation pads By M Rampersad

Location Lifting lug design checks Job Ref 241-002

Sub-Location Pipe Supports Page

REF OUTPUT DESCRIPTION

Check shear due to R

sy

For the R

sy

component, A

sf

= 2 [t(a+d

h

/2) + 2yt

c

] = 4064.0

mm

2

where y = [(d

c

2

-d

h

2)

/4] = mm

P

ny

= 0.6A

sf

F

u

= 975.4 kN

P

ny

= 731.5 kN

Check against actual R

sy

45.0 kN OK with Rsy in shear

Check shear due to R

sx

For the R

sx

component, A

sf

= 2 [t(b+d

h

/2) + 2xt

c

] = 3260.0

mm

2

where x = [(d

c

2

-(d

h

2

/2)] = 44.0 mm

P

nx

= 0.6A

sf

F

u

= 782.4 kN

P

nx

= 586.8 kN

Check against actual R

sx

45.0 kN OK with Rsx in shear

Bearing on projected pin area

General formula (assuming milled, drilled, reamed or bored holes)

Eqn J8-1

R

n

= 1.8F

y

A

pb

Design strength in bearing = R

n

= 0.75 [unitless]

Ref 3 Clause

J8 (a)

Check bearing (both axes are the same)

Projected bearing area (same either axis), A

pb

= d

pin

(t+2t

c

) = 965.2

mm

2

1.8F

y

A

pb

= 425.7 kN

Design strength in bearing, R

n

= 319.2 kN

Check against R

sx

0.1 kN OK with Rsx in bearing

Check against R

sy

45.0 kN OK with Rsy in bearing

Yield in gross section

General formula

Eqn D1-1

P

n

= F

y

A

g

Where A

g

= Gross cross-sectional area through padeye in the direction of the force

Design strength in yield =

t

P

n

t

= 0.90 [unitless]

y-axis x-axis

Ref 3 Clause

D1 (a)

RIVELIN CONSULTANTS LIMITED

CLIENT UNITED ENGINEERING SERVICES LTD. Date 9-May-11

PROJECT PETROTRIN Precast concrete foundation pads By M Rampersad

Location Lifting lug design checks Job Ref 241-002

Sub-Location Pipe Supports Page

REF OUTPUT DESCRIPTION

Check gross tension due to R

sy

A

gy

= 2(tb+2t

c

[(d

c

-d

h

)/2]) 1122.0

mm

2

P

ny

= F

y

A

gy

= 274.9 kN

Design strength in yield,

t

P

ny

= 247.4 kN

Check against R 45 0 kN OK ith R i i ld

y-axis x-axis

Check against R

sy

45.0 kN OK with Rsy in yield

Check gross tension due to R

sx

A

gx

= at+(h

1

t-d

h

/2)+2t

c

[(d

c

-d

h

)/2]) 4546.6

mm

2

P

nx

= F

y

A

gx

= 1113.9 kN

Design strength in yield,

t

P

nx

= 1002.5 kN

Check against R

sx

45.0 kN OK with Rsx in bearing

BENDING CHECKS

Bending due to R

sx

(about Z-Z axis)

Lever arm to R

sx

component, h

1

= 152.4 mm

Moment M

x

= 15,240 Nmm

Moment of inertia for padeye (bd

3

/12), I

zz

= 7,486,875

mm

4

Bending stress, = 0.2 N/mm

2

OK in bending about zz axis

WELDING CHECKS

Select welding electrode strength 60,000 ksi

design strength of fillet weld, p

w

= 414

N/mm

2

Select nominal fillet weld size, a = 6 mm

Use the directional method as per BS5950 Cl 6.8.7.3

Check longitudinal weld shear capacity P

L

(in direction of x-axis)

P

L

= p

w

a

Longitudinal weld capacity per unit length, P

L

= 2484.0 N/mm

Total length of weld, 2w = 330.0 mm

Total longitudinal weld shear capacity, P

L

= 819.7 kN

Check against R

sx

= 0.1 kN Weld OK in longitudinal shear

RIVELIN CONSULTANTS LIMITED

CLIENT UNITED ENGINEERING SERVICES LTD. Date 9-May-11

PROJECT PETROTRIN Precast concrete foundation pads By M Rampersad

Location Lifting lug design checks Job Ref 241-002

Sub-Location Pipe Supports Page

REF OUTPUT DESCRIPTION

Check transverse weld shear capacity P

T

(in direction of y-axis)

P

T

= KP

L

K = 1.25 [1.5/(1+cos

2

)]

= angle between vertical and throat of weld = 45 deg

= 0.785 rad

K = 1.25 [unitless]

Transverse weld capacity per unit length, P

T

= 3105.0 N/mm

Total length of weld, 2w = 330.0 mm

Total transverse weld shear capacity, P

T

= 1024.7 kN

Check against R

sy

= 45.0 kN Weld OK in transverse capacity

Unity check on transverse and longitudinal capacity

(R

SX

/P

L

)

2

+(R

SY

/P

T

)

2

1

(R

SX

/P

L

)

2

= 0.000 [unitless]

(R

SY

/P

T

)

2

= 0.002 [unitless]

(R

SX

/P

L

)

2

+(R

SY

/P

T

) = 0.002 [unitless] Unity check on weld OK

ADDITIONAL CODE CHECKS TO DNV 2.7-1 (if required)

Tear-out stress

General formula from DNV

R

e

3R

SL

/(2Ht-d

h

t)

*

U i thi l l ti t i l

Ref 4 Appx D3

Using this calculation terminology

DNV Code [R

e

] = min. yield stress of padeye material = [F

y

] this calculation

DNV code [RSL] = sling load (factored) = [Rs] this calculation

DNV code [H] = centre of hole to min. outer edge = [r

0

] this calculation

F

y

3R

S

/(2r

0

t-d

h

t)

3R

S

/(2r

0

t-d

h

t) = 44.3

N/mm

2

F

y

= 245.0

N/mm

2

OK in DNV tear-out stress

* Note: cheek thickness not allowed by DNV 2.7-1 as part of this calculation

Contact stress

General formula from DNV

R

e

23.7 (R

SL

/d

h

t)

Using this calculation terminology as above

F

y

23.7(R

S

/d

h

[t+2t

c

])

23.7(R

S

/d

h

[t+t

c

]) = 157.7

N/mm

2

F

y

= 245.0

N/mm

2

OK in DNV contact stress

Shackle pin diameter

General formula from DNV

d

pin

94% d

h

d

pin

= 48.3 mm

0.94d

h

= 47.8 mm OK in DNV pin diameter

Total thickness at contact area is (padeye thickness + 2

X

cheek thickness)

Ref 4 Clause

4.4.1

Ref 4 Appx D3

You might also like

- Spreader Beam BLOCK EDocument23 pagesSpreader Beam BLOCK Evaminos85% (13)

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- Padeye Design CheekDocument3 pagesPadeye Design CheekBolarinwa89% (9)

- Lifting Lug CalculationDocument3 pagesLifting Lug Calculationdhirendarji83% (6)

- Sample Scoping ReportDocument92 pagesSample Scoping ReportEm Mar0% (1)

- 2016-Harley-Davidson-Street-Bob Owners ManualDocument193 pages2016-Harley-Davidson-Street-Bob Owners ManualCristiano TavaresNo ratings yet

- Internal Combustion Engine Parts: 1.crankshaft-Is 8.wrist Pin - 15.exhaustDocument3 pagesInternal Combustion Engine Parts: 1.crankshaft-Is 8.wrist Pin - 15.exhaustAngelika Pangilinan100% (1)

- Guideline Lifting Lug DesignDocument10 pagesGuideline Lifting Lug Designye-kyaw-aung80% (10)

- Lifting Lug CalculationDocument7 pagesLifting Lug CalculationErin JohnsonNo ratings yet

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocument48 pagesVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalNo ratings yet

- Lifting Beam Deign Staad 82187560 Design Calc 10t Spreader Beam PDFDocument20 pagesLifting Beam Deign Staad 82187560 Design Calc 10t Spreader Beam PDFDhanraj VasanthNo ratings yet

- Lifting LugsDocument2 pagesLifting LugsAdi Cahyoko82% (11)

- Lifting Sets Calculation - API RP 2ADocument11 pagesLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Design of Lifting LugDocument7 pagesDesign of Lifting Luga_toups100% (1)

- Padeye Calculation For Lifting AnalysisDocument3 pagesPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- FIN PLATE - Beam To BeamDocument71 pagesFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Pile Cap Design 1Document6 pagesPile Cap Design 1kjpatel2100% (2)

- Composite Beam Simply Supported DesignDocument21 pagesComposite Beam Simply Supported DesignTharanga Pradeep100% (1)

- Brigde Loading 07-08Document72 pagesBrigde Loading 07-08Em Mar100% (1)

- Standard Lighting Column FoundationsDocument2 pagesStandard Lighting Column FoundationsEm MarNo ratings yet

- Handfield-Supply Chain RedesignDocument398 pagesHandfield-Supply Chain RedesignEm Mar75% (4)

- CKLaw Problems Chap 6Document4 pagesCKLaw Problems Chap 6f0% (1)

- Pad Eye New ReleaseDocument10 pagesPad Eye New ReleaseRaza AidanNo ratings yet

- Lifting Lug DesignDocument6 pagesLifting Lug DesignmaniaxpdfNo ratings yet

- Design Calculation LiftingDocument19 pagesDesign Calculation LiftingAbu Al Sayyid100% (1)

- Padeye CalculationDocument11 pagesPadeye CalculationMarvan100% (2)

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Lifting Lug Design (3064)Document37 pagesLifting Lug Design (3064)Ganesh Bhardwaj50% (2)

- Calculation Sheet: Padeye Calculations LoadsDocument28 pagesCalculation Sheet: Padeye Calculations Loadsghoshamit4100% (5)

- Spreader Beam DesignDocument3 pagesSpreader Beam DesignCHENo ratings yet

- Pad-Eye MainDocument8 pagesPad-Eye MainPradeep ChitluriNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationAndy Chan100% (1)

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- (B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationDocument7 pages(B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationArt G. Enzi100% (1)

- ACI Pad Foundation ExampleDocument7 pagesACI Pad Foundation ExampleEm MarNo ratings yet

- 3-Pile Cap DesignDocument9 pages3-Pile Cap DesignMitra RampersadNo ratings yet

- EC2 Continuous Beam DesignDocument14 pagesEC2 Continuous Beam Designikanyu79No ratings yet

- Anchor Bolt Design (ACI318)Document5 pagesAnchor Bolt Design (ACI318)Ashraful AlamNo ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Link Look UpDocument7 pagesLink Look UpValerioZucchelliNo ratings yet

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- Bolted Cover Plate Splice Connection B1Document4 pagesBolted Cover Plate Splice Connection B1ikanyu79No ratings yet

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- CorbelDocument2 pagesCorbelaahtagoNo ratings yet

- Cold Formed BendingDocument8 pagesCold Formed BendinggeorgeispasoiuNo ratings yet

- Round HSS Design LRFDDocument4 pagesRound HSS Design LRFDklynchelleNo ratings yet

- F - Deludge SystemDocument11 pagesF - Deludge Systemkelvin_totNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Lug 0-5 Ton DesignDocument6 pagesLug 0-5 Ton DesignkalpanaadhiNo ratings yet

- Design of Headed Concrete AnchorDocument121 pagesDesign of Headed Concrete AnchorkalpanaadhiNo ratings yet

- Beam SpliceDocument7 pagesBeam SpliceJuan BradleyNo ratings yet

- CorbelDocument5 pagesCorbelBharathi ThadigotlaNo ratings yet

- Cant SlabDocument4 pagesCant Slabinsane88No ratings yet

- RC Corbel Design (ACI318)Document2 pagesRC Corbel Design (ACI318)Emad KhanNo ratings yet

- Timber Examples - TeddsDocument19 pagesTimber Examples - TeddsTom KwoNo ratings yet

- Ysd P02 0208 Ar SJF CD F0005 BDocument47 pagesYsd P02 0208 Ar SJF CD F0005 BChandra MohanNo ratings yet

- Cobble Design - Sample NewDocument2 pagesCobble Design - Sample NewBekele AmanNo ratings yet

- Steel Column BeamDocument6 pagesSteel Column Beamdharul khairNo ratings yet

- Embed Design - Core WallDocument39 pagesEmbed Design - Core Wallkalpanaadhi100% (1)

- Embedpl v1-4 Demo PDFDocument5 pagesEmbedpl v1-4 Demo PDFMWKELIOLANo ratings yet

- 2 Way Slab Design - 31 Jul 13Document111 pages2 Way Slab Design - 31 Jul 13Vance Kang100% (1)

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- RC Corbel Design (ACI318-05)Document2 pagesRC Corbel Design (ACI318-05)Mohammed Z. AlSaqqa100% (1)

- Connection No.: 66: Load Ver. Brace L120X120X10 AxialDocument5 pagesConnection No.: 66: Load Ver. Brace L120X120X10 Axialrts123No ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Broad: The Idiots' Guide To Highways MaintenanceDocument5 pagesBroad: The Idiots' Guide To Highways MaintenanceEm MarNo ratings yet

- Olympic Proportions Cost and Cost Overrun at The Olympics 1960 To 2012Document24 pagesOlympic Proportions Cost and Cost Overrun at The Olympics 1960 To 2012Em MarNo ratings yet

- Daikin UK Product CatalogueDocument240 pagesDaikin UK Product CatalogueEm MarNo ratings yet

- This Is A To Available Bitumen Coated Macadams, As Specified in B.S. 4987Document9 pagesThis Is A To Available Bitumen Coated Macadams, As Specified in B.S. 4987Em MarNo ratings yet

- NY DOT Geotech ManualDocument97 pagesNY DOT Geotech ManualEm MarNo ratings yet

- The Idiots' Guide To Highways Maintenance: Bituminous Mixture / Process DiagramsDocument7 pagesThe Idiots' Guide To Highways Maintenance: Bituminous Mixture / Process DiagramsEm MarNo ratings yet

- Wind Design To ASCE7-10Document4 pagesWind Design To ASCE7-10Em MarNo ratings yet

- AASHTO Steel Bridge Bearing Design & GuidelinesDocument50 pagesAASHTO Steel Bridge Bearing Design & GuidelinesNils Antoine FreundNo ratings yet

- Student Guide To Steel Bridge DesignDocument32 pagesStudent Guide To Steel Bridge Designkhayagski100% (1)

- ACI Pad Foundation ExampleDocument7 pagesACI Pad Foundation ExampleEm MarNo ratings yet

- PCI Bridge ManualDocument34 pagesPCI Bridge ManualEm MarNo ratings yet

- CFD Design TemplateDocument5 pagesCFD Design TemplateEm MarNo ratings yet

- Mooring Fender DesignDocument8 pagesMooring Fender DesignEm Mar100% (1)

- AASHTO Steel Bridge Bearing Design & GuidelinesDocument50 pagesAASHTO Steel Bridge Bearing Design & GuidelinesNils Antoine FreundNo ratings yet

- Coade Pipe Stress AnalysisDocument477 pagesCoade Pipe Stress AnalysisEm MarNo ratings yet

- River Protection Design GuideDocument13 pagesRiver Protection Design GuideEm MarNo ratings yet

- Anchor Bolt Design GuideDocument82 pagesAnchor Bolt Design GuideEm Mar100% (4)

- Daikin Pocket Guide To Air ConditioningDocument84 pagesDaikin Pocket Guide To Air ConditioningEm Mar100% (3)

- Is Iec 41 1991Document214 pagesIs Iec 41 1991Tonny SuakNo ratings yet

- Application of PFD and PFMEA in Manufacturing of Clutch Release Fork of Heavy Motor VehiclesDocument12 pagesApplication of PFD and PFMEA in Manufacturing of Clutch Release Fork of Heavy Motor VehiclesAnand PathakNo ratings yet

- Yale Eletrica MS16 (A959 2015) PDFDocument94 pagesYale Eletrica MS16 (A959 2015) PDFTiago NondilloNo ratings yet

- Training Schedule 2019 PT - Fiqry Jaya Manunggal WebDocument11 pagesTraining Schedule 2019 PT - Fiqry Jaya Manunggal WebandiNo ratings yet

- ContractorsAbovegroundPiping PDFDocument2 pagesContractorsAbovegroundPiping PDFIvan SFNo ratings yet

- ICS 5000 Flue System: High Positive PressureDocument28 pagesICS 5000 Flue System: High Positive PressureSebastian StefanescuNo ratings yet

- Cop 1132 8311 1280 00-EDocument51 pagesCop 1132 8311 1280 00-EOrhanNo ratings yet

- General Engineering Knowledge For Marine EngineersDocument31 pagesGeneral Engineering Knowledge For Marine EngineersSrini VasanNo ratings yet

- Mechanical Engineering Collection List 2017 1Document33 pagesMechanical Engineering Collection List 2017 1Hanita SlaterNo ratings yet

- 1997 Ubc Wind / Snow Design Calculations: File NameDocument2 pages1997 Ubc Wind / Snow Design Calculations: File NameAli Al-BashaNo ratings yet

- Course Format: Sean Dalton WWW - Itsligo.ie/staff/sdaltonDocument33 pagesCourse Format: Sean Dalton WWW - Itsligo.ie/staff/sdaltonUC ProductionNo ratings yet

- Yanmar Test ListeDocument595 pagesYanmar Test ListeMilanNo ratings yet

- B.tech Brochure RegisterDocument28 pagesB.tech Brochure RegisterP Mohan ReddyNo ratings yet

- Hyunsangparts-Company Products Introduction PDFDocument140 pagesHyunsangparts-Company Products Introduction PDFHenrique Moto PeçasNo ratings yet

- Pekos - Ansi NuevoDocument12 pagesPekos - Ansi Nuevocristianovalverde76No ratings yet

- Owner's Manual: Water Pump WH15X/WH20XDocument64 pagesOwner's Manual: Water Pump WH15X/WH20XSeanpilibNo ratings yet

- Bijur DelimonDocument24 pagesBijur DelimonAyanaNo ratings yet

- BMM1523 Engineering Materials Teaching PlanDocument7 pagesBMM1523 Engineering Materials Teaching PlannabilqayyumNo ratings yet

- Material Data Sheet Stainless Steel Sheet Aisi 301Document2 pagesMaterial Data Sheet Stainless Steel Sheet Aisi 301Andrea MartinezNo ratings yet

- Plane Strain Mechanical Characteristics of Liquefied Cement-Treated Soil - Y. HayashiDocument6 pagesPlane Strain Mechanical Characteristics of Liquefied Cement-Treated Soil - Y. HayashiNguyen Quoc KhanhNo ratings yet

- Wankle Exhausts and The Relevance of Two-Stroke Design: An Engine's Exhaust Port Can Be Thought of As A Sound GeneratorDocument11 pagesWankle Exhausts and The Relevance of Two-Stroke Design: An Engine's Exhaust Port Can Be Thought of As A Sound GeneratorAndré Matsumoto100% (2)

- Gnosis 2.0 DesignSynopsisDocument17 pagesGnosis 2.0 DesignSynopsisHimanshu vishwakarmaNo ratings yet

- 05 Q400 LandingDocument2 pages05 Q400 LandingMalikAlrahabiNo ratings yet

- 40 Ton Crane Tender DocumentDocument12 pages40 Ton Crane Tender DocumentJaay VelNo ratings yet

- Analysis of Rock/Soil Strength Using Rocdata Hoek-Brown ClassificationDocument1 pageAnalysis of Rock/Soil Strength Using Rocdata Hoek-Brown ClassificationAlfredo Gaspar ApazaNo ratings yet