Professional Documents

Culture Documents

Quality Control Procedure Sample 1

Quality Control Procedure Sample 1

Uploaded by

MIbrAHimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Control Procedure Sample 1

Quality Control Procedure Sample 1

Uploaded by

MIbrAHimCopyright:

Available Formats

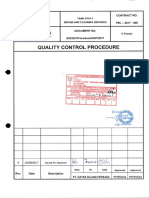

Document No.

:

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

TABLE OF CONTENTS

PAGE

1. SCOPE 2

2. DI FI NATI ON 2

3. REFERENCE 2

4. RAW MATERI AL PROCUREMENT 2

5. MATERI AL RECEI VI NG I NSPECTI ON 3

6. MATERI AL CONTROL 3

7. QUALI TY CONTROL I NSPECTI ON PROGRAMS FOR

FABRI CATI ON 4

8. ACCEPTANCE CRI TERI A FOR DI MENSI ON CHECK 5

9. QUALI TY CONTROL I NSPECTI ON PROGRAMS FOR

PAI NTI NG 5

10. QUALI TY CONTROL I NSPECTI ON PROGRAMS FOR

PAI NTI NG 6

11. DOCUMENTATI ON 7

APPENDI XES 8

APPENDI X 1 DI MENSI ON TOLERANCE 8

APPENDI X 2 WELDI NG DI MENSI ON TOLERANCE. 9

12. ATTACHENT 11

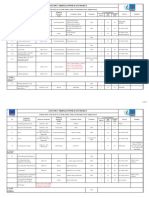

ATTACHMENT 1 I nspection Record For I ncoming Material. 12

ATTACHMENT 2 Dimension I nspection Report. 13

ATTACHMENT 3 Welding I nspection Report. 14

ATTACHMENT 4 Coating I nspection Report. 15

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

1. SCOPE

a) I nspection and test of equipment shall be based on approved drawing and

approved applicable procedures.

b) The quality Control Department shall responsible for the following but not be

limited:

Continuous check for all production process during the whole fabrication

periods.

Conduct all required tests, checks, and inspection.

Maintain the record for all the quality control document for

review/ reference at all times and final MDR.

2. DEFI NI TI ONS

The following definitions shall apply throughout the specification:

a) The Contractor shall mean. .PT. .

b) The Subcontractor shall mean PT

3. REFERENCE

Material : ASTM: A36, ASME: SA 240, J I S: E3101: 2004, SNI ,

SI I .

Welding : AWS D1.1

Client Specification : PT. . . Drawing Approval.

4. RAW MATERI AL PROCUREMENT

a) All raw material will be supplied by Subcontractor shall be Backed up by and

conform to their relevant mill/ tests certificates.

b) when material received from the mill does not satisfy the standards

tolerance for camber, profile, flatness or sweep corrective work by the use of

controlled heating, chemical and mechanical straightening, subj ect to the

limitation of the standards, may be perform. I t could be done or shall be

replace with a new one and precise one.

c) Steel material for fabrication shall not be heavily pitted or rusted.

d) Subcontractor shall provide the following documents for record and control

of material.

Material List & Cutting Plan.

Material Test Report/ Mill Certificate(from the supplier)

Delivery List

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

5. MATERI AL RECEI VI NG I NSPECTI ON

a) Upon arrival of the material at fabrication yards, Warehouse Section will

inform QA-QC Department and Proj ect Control to recheck the raw material.

Scope of the inspection shall include visual dimension, sharpness, thickness,

heat no. or manufacturer no. , etc.

b) I dentification marks of material grade shall be clearly marked on all pieces

of material including those cut from stock or from the whole material itself.

This identification marks shall remain clearly visible at all times.

Recommended type of medium for identification marking shall be stamp,

paint or crayons. Subcontractor shall propose to Contractor the method

inspection.

c) Any non- conformance between Client document and material received by PT.

, QA/ QC Department will inform with Quality Assurance

Confirmation (QAC).

d) When some material are unacceptable, QA/ QC Department marked the

material as REJ ECTED

e) Repair material shall client specification and repair procedure approved by

client.

f) I nspection result shall be reported in Material Receiving Report .

6. MATERI AL CONTROL

a) After material received inspection has been conducted and material been

accepted, the Warehouse Section shall store the material and issue to the

fabrication section upon instruction.

b) The material received by Warehouse Section and material issue for

fabrication shall be continuously reported to Proj ect Control of status the

Proj ects materials.

c) The excess raw material from the fabrication section shall clearly be

identified and returned to the Warehouse Section for restore.

d) Stock material on warehouse shall be checked for visual and Dimension by

quality control. Material should be store in secure place to preserve the

accuracy and quality before process fabrication.

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

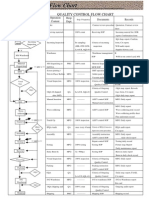

7. QUALI TY CONTROL I NSPECTI ON PROGRAMS FOR FABRI CATI ON

All fabricated part shall be inspected to the following items:

7.1. I DENTI FI CATI ON MARKS

a) Transfer of identification marks (include heat no.) shall be

check prior to cutting.

b) Material traceability report shall be made.

7.2. MARKI NG

a) Giving the mark OK, if result of mark is correct.

b) After giving mark OK, we can do the next process.

7.3. DI MENSI ON

a) Checking the MAL according on the place.

b) MAL made the duplicated equipment as same as one from

paper/ plywood.

c) I dentity that the MAL has been made and checked in accordance

to drawing approval.

d) Only approved MAL will be used for fabrication process (marking,

cutting, bending, rolling, beveling)

e) Progressive dimensional check shall be conducted at stages

before, during and after the manufacturing process.

f) Dimensional marking shall be checked prior to cutting, beveling,

bending, and rolling. After part or final assembling, all dimensional

marks are to be reconfirmed for accuracy prior to further works such as

reforming, etc. in which the dimensional inspection shall be conducted.

g) All measuring Tools to be used for Measuring and I nspections shall be

calibrated by an Authorized Agency. The Calibration records shall be

kept as a QA records.

h) Check with measuring tools all dimensional of individual members/ shop

assemblies, within the specified tolerance.

i) I nspection result shall be reported in the from of Dimension

I nspection Report (Attachment 2)

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

8. ACCEPTANCE CRI TERI A FOR DI MENSI ONAL CHECK

a) Steel Structures :

Dimension tolerance for steel structure fabrication shall be accordance with

Appendix 1

9. QUALI TY CONTROL I NSPECTI ON PROGRAMS FOR WELDI NG

a) Prior to welding activity, welding procedure qualification test, welding

procedure specification, welding map, welder performance test and welder

list shall be reviewed and approved by Contractor and Company.

b) All fabricated parts shall be inspected as to the following :

Visual I nspection.

- Welding inspection shall ensure all parameter and condition

- As per WPS/ PQR and welder has been full filled before welding, during

welding and after welding.

- All welding will be visually inspected to check if that there are defects

such as undercut, crack, blow hole, slag inclusion, and fused spatter.

- All parts shall be thoroughly cleaned.All dirt, welding electrode stubs

and foreign matter shall be removed.

- The leg size of fillet should be in accordance with the design

stipulation.

- Formed corner of bracket shall be visually checked, and shall be no

crack or harmful defects is produced.

- Welding tolerance shall be accordance with Appendix 2

NDE

- Non destructive examination (NDE) of pressure boundary Weld and

attachment welds to pressure boundary shall be done in accordance

with the approved NDE Procedure.

c) When PWHT and hardness test is required, therefore Subcontractor shall

maintain these activities to comply with the approved procedures.

d) I nspection result shall be reported in the from Welding I nspection Report.

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

10. QUALI TY CONTROL I NSPECTI ON PROGRAMS FOR PAI NTI NG

e) All surfaces prepared for painting are to be inspected and the surface

preparation standard and paint used shall be reviewed and approved by

Contractor prior to the start of the work.

f) Contractor shall be notified of any defects, improper material or

workmanship or any conditions which affect the satisfactory performance

and permanency of work.

g) No work shall proceed at any stage of the j ob until the following stage

inspections have been carried out and approved :

Before blasting :

- The surface shall cleaned from dirt, dust, and other foreign matter.

- The surface have cleaned shall be dried.

After blasting :

- Grades surface preparation.

- Surface profile.

h) I mproper procedures during application, even though the specified total dry

film thickness has been achieved, shall be sufficient cause for complete

removal of the applied material and re- application using the specified

procedure.

i) I nspection result shall be reported in the form Coating I nspection Report

(Attachment 3).

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

11. DOCUMENTATI ON

I nspection report shall be maintained by Subcontractor and approved by the

involved parties.

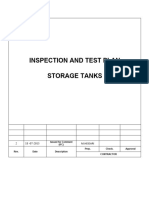

Table Content of MDR :

- I nspection Release Certificate (I RC)

- Certificate Of Compliance for fabricated for item

- I nspection Test and Plan

- Non Conformance Report (NCR)

- Welding Procedure I ncluding Production Test Result WPS/ PQR.

- Welder List Qualification Records

- Material Mill Certificate.

- Fabrication Procedure

- Painting Procedure

- Packing Procedure

- I nspection Report for I ncoming Material

- Material Certificate

- I nspection Report

- Dimension Report and Welding Report

- Painting Report

- Environment Condition

- Surface Preparation

- Coating Application

- Film Thickness (DFT)

- Shop I nspection Test

- NDE report

- NDE Personal Qualifications

- Deviation Control

- Leak Test Procedure

- Maj or Welds Repair

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

No

Description

Figure

Tolerance

6

Excess Weld

Metal

(e2)

7

Under Cut

(e3)

e3 1 mm

8

Over Lap

(e4)

e4 = Unacceptable

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

No

Description Figure Tolerance

9

Porosity

( )

1. 1.5 mm

2. 1.5 mm

3. Cl ust er i s

unaccept abl e

Crack

Unacceptable

Sparter

Unacceptable

Excess

Cupping

B b 5 per 150 mm

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

b) Attachment 2 : Dimension I nspection Report

c) Attachment 3 : Welding I nspection Report

Document No. :

Revision/Edition :

Date :

Company

TECHNICAL IMPLEMENTATION MANUAL

Page :

QUALITY CONTROL PROCEDURE

You might also like

- Material Inspection Report (Steel) FormDocument1 pageMaterial Inspection Report (Steel) Formfoxeylady80% (15)

- Material Receiving Inspection ReportDocument1 pageMaterial Receiving Inspection ReportNugrawan Satria0% (1)

- Material Inspection ChecklistDocument1 pageMaterial Inspection Checklistrahulsiva100% (6)

- Material Control Procedure SAMPLEDocument24 pagesMaterial Control Procedure SAMPLEJanardhan Surya82% (17)

- Inspection Test PlanDocument2 pagesInspection Test PlanBalaji Guru90% (10)

- Fabrication ProcedureDocument17 pagesFabrication ProcedureThi Pham100% (9)

- Itp For Steel Structure Erection (Content) Rev.1Document3 pagesItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (6)

- Quality Control ProcedureDocument12 pagesQuality Control ProcedureZiya Ahmed100% (6)

- Welding Quality Manual SampleDocument18 pagesWelding Quality Manual SampleDanem Halas100% (1)

- 03 Welding Control Procedure - Asf QC WCP 001Document7 pages03 Welding Control Procedure - Asf QC WCP 001el_sharkawy2011100% (1)

- Procedure For Material Identification & Traceability (Rev.0)Document27 pagesProcedure For Material Identification & Traceability (Rev.0)jishnunelliparambil100% (3)

- Traceability ProcedureDocument9 pagesTraceability Procedurekingofpenetration100% (3)

- Quality Control ManualDocument78 pagesQuality Control ManualRajeshSekar100% (3)

- Procedure For Installation of Steel Stair StructureDocument6 pagesProcedure For Installation of Steel Stair StructureImamah AliNo ratings yet

- QAQC Procedure For FabricationDocument7 pagesQAQC Procedure For FabricationRajesh K Pillai100% (6)

- Traceability ProcedureDocument9 pagesTraceability ProcedureRoshan Aravinth100% (2)

- Inspection Test PlanDocument7 pagesInspection Test PlanWalha Wassim100% (1)

- QMS Inspection ProcedureDocument5 pagesQMS Inspection ProcedureSang Hà100% (1)

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Inspection Test Plan - SampleDocument12 pagesInspection Test Plan - SampleZaheedManooNo ratings yet

- Quality Control ManualDocument84 pagesQuality Control ManualMario100% (1)

- SOP For Fixed Assets MainagementDocument12 pagesSOP For Fixed Assets MainagementJAK Group100% (1)

- Control of Calibrated Equipment ProcedureDocument8 pagesControl of Calibrated Equipment ProcedureFaisalNo ratings yet

- Quality ManualDocument34 pagesQuality Manualchao gao100% (9)

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- Inspection and Test PlanDocument28 pagesInspection and Test Planmfvallega88% (17)

- QAP-07 Material Control Procedure PDFDocument22 pagesQAP-07 Material Control Procedure PDFnaseema1100% (9)

- QIR-001-Material Receiving Inspection ReportDocument1 pageQIR-001-Material Receiving Inspection ReportSamer Bayati100% (1)

- Inspection and Test PlantDocument121 pagesInspection and Test PlantMajid Dixon89% (9)

- Incoming Material ProcedureDocument2 pagesIncoming Material ProcedureTridib Dey100% (6)

- QMS Audit Checklist On FFS Rev2 1Document8 pagesQMS Audit Checklist On FFS Rev2 1henry faigaoNo ratings yet

- Ipc 4101C TocDocument5 pagesIpc 4101C TocSubrahmanyam Singaraju VenkataNo ratings yet

- Bitner-Dop NHXH Fe180 Ph90 E90Document2 pagesBitner-Dop NHXH Fe180 Ph90 E90Alexandru CraiovanNo ratings yet

- Egatra: Quality ControlDocument6 pagesEgatra: Quality ControlAndreas Schlager100% (3)

- SOP Material InspectionDocument2 pagesSOP Material InspectionConsar natrayan50% (2)

- Receiving InspectionDocument5 pagesReceiving InspectionUmair AwanNo ratings yet

- Quality Control Flow ChartDocument1 pageQuality Control Flow Chart同道文档中心100% (17)

- Quality PlanDocument32 pagesQuality PlannayumNo ratings yet

- Fabrication Inspection ProcedureDocument11 pagesFabrication Inspection Procedurewill_herry100% (6)

- QIR-105-Material Receiving Inspection ReportDocument2 pagesQIR-105-Material Receiving Inspection ReportSamer Bayati50% (2)

- Structural Steel Procedure.Document9 pagesStructural Steel Procedure.Janardhan Surya100% (1)

- Quality Control ProcedureDocument29 pagesQuality Control Procedurekj_mekanikal33% (3)

- Welding Consumable Control Procedure 1Document9 pagesWelding Consumable Control Procedure 1eklavyak076757100% (4)

- ISO - Control of Non-Conforming ProductsDocument5 pagesISO - Control of Non-Conforming ProductsAlmario SagunNo ratings yet

- Fulima Steel Structure General Quality Control Program/Executive ManualDocument51 pagesFulima Steel Structure General Quality Control Program/Executive ManualFULIMA Steel StructureNo ratings yet

- Sample - Project Quality PlanDocument12 pagesSample - Project Quality PlanSuraj Mani100% (1)

- Quality PlanDocument37 pagesQuality PlanEastWinds0% (1)

- Quality Assurance ProceduresDocument75 pagesQuality Assurance Proceduresviorelu99100% (5)

- QC Sample Manual GenericDocument34 pagesQC Sample Manual GenericIan Stewart PorterNo ratings yet

- Inspection and Test Plan (Itp)Document20 pagesInspection and Test Plan (Itp)المهندس محمد الزواهرة Eng Mohummed Al-zawhreh100% (2)

- Inspection Quality AssuranceDocument16 pagesInspection Quality AssuranceMihajloDjurdjevic100% (2)

- Inspection Test Plan For FabricationDocument4 pagesInspection Test Plan For FabricationAshwani Dogra100% (10)

- Appendix C Scope of Work of TpiDocument1 pageAppendix C Scope of Work of Tpienuvos engineeringNo ratings yet

- Quality Control 2013: Skycoat, LLCDocument27 pagesQuality Control 2013: Skycoat, LLCDharma Tej ReddyNo ratings yet

- Quality Control ManualDocument50 pagesQuality Control ManualKhairul Azri100% (1)

- Boxt Field Quality PlanDocument86 pagesBoxt Field Quality PlanHariom GuptaNo ratings yet

- QMS Audit Checklist On FFS Rev2 1Document8 pagesQMS Audit Checklist On FFS Rev2 1Xion100% (1)

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Inspection and Test Plan For Surface Preparation and PaintingDocument2 pagesInspection and Test Plan For Surface Preparation and PaintingNoor Rose Eka RoseNo ratings yet

- QA QC Civil Site Engineer Interview NotesDocument10 pagesQA QC Civil Site Engineer Interview Notesengineersalam786No ratings yet

- Quality Execution Plan CREH ApprovedDocument19 pagesQuality Execution Plan CREH Approvedkarthikeyan.dNo ratings yet

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- Exhibit F Chapt F5 PDFDocument91 pagesExhibit F Chapt F5 PDFfaisal jasimNo ratings yet

- Buildings Bulletin 2016-005: NYC Buildings Department 280 Broadway, New York, NY 10007 Rick D. Chandler, PE, CommissionerDocument3 pagesBuildings Bulletin 2016-005: NYC Buildings Department 280 Broadway, New York, NY 10007 Rick D. Chandler, PE, CommissionerbclarkeoobNo ratings yet

- Answers To QC QuestionDocument37 pagesAnswers To QC QuestionDot PidotNo ratings yet

- RR2009 - Generale-RrDocument39 pagesRR2009 - Generale-Rrhemant9315No ratings yet

- UOP Inspection Training Manual Volume 1Document571 pagesUOP Inspection Training Manual Volume 1phuongnhsfcNo ratings yet

- ASTM D-5161 Inspección de Pintura RequerimientoDocument3 pagesASTM D-5161 Inspección de Pintura RequerimientoJulio F. Ruiz AuxNo ratings yet

- Paes 207 Rice Mill Methods of Test PDFDocument22 pagesPaes 207 Rice Mill Methods of Test PDFEdsel Jay RaperNo ratings yet

- Local Regulatory Governance in The Philippines: FOCUS ON Quezon CityDocument38 pagesLocal Regulatory Governance in The Philippines: FOCUS ON Quezon Cityjack leybagNo ratings yet

- Sample: Retail Food Establishment Inspection ReportDocument2 pagesSample: Retail Food Establishment Inspection Reportnarasimma8313No ratings yet

- Saep 365 PDFDocument32 pagesSaep 365 PDFRami ElloumiNo ratings yet

- NEOM-NEN-GGD-002 - 02.00 - Guideline - Third Party Testing LaboratoryDocument20 pagesNEOM-NEN-GGD-002 - 02.00 - Guideline - Third Party Testing LaboratoryAymanEssamNo ratings yet

- Fitness-for-Service Engineering Assessment Procedure: Quest Integrity October 2015Document7 pagesFitness-for-Service Engineering Assessment Procedure: Quest Integrity October 2015امينNo ratings yet

- Method Statement For Chlorination & Disinfection of Water Supply SystemDocument9 pagesMethod Statement For Chlorination & Disinfection of Water Supply SystemAhmad OmarNo ratings yet

- Inspection & Test Plan TemplateDocument11 pagesInspection & Test Plan Templatefanghao5345No ratings yet

- ITP - CCTV System InstallationDocument6 pagesITP - CCTV System InstallationGultom Juliana LiliesNo ratings yet

- Cold Drawn Seamless Steel Tubes For Mechanical ApplicationsDocument8 pagesCold Drawn Seamless Steel Tubes For Mechanical ApplicationsAndres FlorezNo ratings yet

- Tender058 190318Document79 pagesTender058 190318jayasiinputNo ratings yet

- Satip A 004 04Document3 pagesSatip A 004 04Ahmed GamalNo ratings yet

- CV - Kushal B CDocument3 pagesCV - Kushal B Ckushal B CNo ratings yet

- ANPQP - 3.0 - Category 9Document10 pagesANPQP - 3.0 - Category 9jefry sitorusNo ratings yet

- Commissioning Methodologies (CM) - MUBS-12 Modulating Valve + Actuator Testing Method StatementDocument3 pagesCommissioning Methodologies (CM) - MUBS-12 Modulating Valve + Actuator Testing Method StatementNikhil AggarwalNo ratings yet

- TB - T 2843-2007Document21 pagesTB - T 2843-2007erdemNo ratings yet

- Checklist For Heavy Equipment - 1Document15 pagesChecklist For Heavy Equipment - 1Katita ChascaNo ratings yet

- Compendium Food Import Regulations 05 06 2022Document45 pagesCompendium Food Import Regulations 05 06 2022SumanswapnilNo ratings yet

- Lrut Job Preparation Questionnaire Long Range Guided Wave InspectionDocument4 pagesLrut Job Preparation Questionnaire Long Range Guided Wave Inspectionkucing_batamNo ratings yet

- SANS 3000-2!2!2008 - Railway Safety RegulatorDocument30 pagesSANS 3000-2!2!2008 - Railway Safety RegulatorBertus ChristiaanNo ratings yet

- PD Enec 308 - May 2012Document2 pagesPD Enec 308 - May 2012Abraham Seco ArmestoNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet