96% found this document useful (28 votes)

16K views114 pagesMarine Engineering System - Introduction

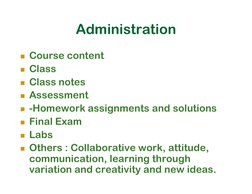

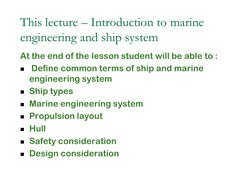

This document provides an overview of a marine engineering system course. It introduces common marine engineering terms and describes various ship and engine types, auxiliary systems, and safety considerations for ship operation. Key topics covered include evolution of marine engines, classification of ships by usage and support type, common shipboard systems like propulsion, sea water, and lubrication systems, and learning objectives for the course. The goal is to define fundamental terms and concepts in marine engineering and ship systems.

Uploaded by

Oladokun Sulaiman OlanrewajuCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

96% found this document useful (28 votes)

16K views114 pagesMarine Engineering System - Introduction

This document provides an overview of a marine engineering system course. It introduces common marine engineering terms and describes various ship and engine types, auxiliary systems, and safety considerations for ship operation. Key topics covered include evolution of marine engines, classification of ships by usage and support type, common shipboard systems like propulsion, sea water, and lubrication systems, and learning objectives for the course. The goal is to define fundamental terms and concepts in marine engineering and ship systems.

Uploaded by

Oladokun Sulaiman OlanrewajuCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd