Professional Documents

Culture Documents

STEP 1: Define The System Specifications: P P E K P P ×100 80 P P × 100 20

Uploaded by

Argel Linard Francisco MabagaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STEP 1: Define The System Specifications: P P E K P P ×100 80 P P × 100 20

Uploaded by

Argel Linard Francisco MabagaCopyright:

Available Formats

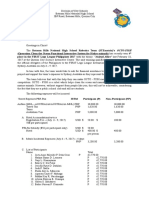

STEP 1: Define the system specifications

Vlinemin = 100 V

Vlinemax = 240 V

fL = 60 Hz

Po = 7 W

Eff = 75%

P =

Po

7

=

=9.33 W

E ff 0.75

K L(5) =

Po (5) 5.6

=

100=80

Po

7

K L(12)=

Po (12)

Po

1.4

100=20

7

STEP 2: Determine DC link capacitor and DC link voltage range

Dch = 0.2

C DC =( 3 106 ) (7 W )=21 F

V DC min = 2 ( V linemin )

P ( 1Dch )

( 9.33 ) (10.2 )

2

= 2 ( 100 )

C DC f L

( 21 106 ) ( 60 )

V DC min =118.643 V

V DC max = 2 V linemax =( 2 ) ( 240 )

V DC max =339.411 V

STEP 3: Determine maximum duty ratio (Dmax)

V DS nom =( 600 )( 0.7 )=420V

V RO =V DS

V RO =

nom

V dc

max

=420339.411=80.859 V

Dmax

V min

1Dmax DC

80.859=

D max

( 118.643 )

1D max

D max =0.4045

STEP 4: Determine transformer primary inductance (Lm)

KRF = 0.5

fS = 67 KHz

Lm=

(V dc min Dmax )

2 P f S K RF

I EDC =

P

min

(V DC ) ( D max )

[ ( 118.643 ) ( 0.4045 ) ]

3

( 2 ) ( 9.33 ) ( 67 10 ) ( 0.5 )

=

( 118.643 )(0.4045)

( 3.684 103 ) (67 103 )

I =0.1944313136

I dc peak =I EDC + ( I /2 )2

0.1944313136

2

Dmax

3

I dc peak =194.411 103 +

I dc

I

peak

rms

ds

=0.2916267327

I

= 3(I EDC ) +

2

2

( )

I dsrms =0.1296459243

V

CCM

dc

I

1

=

2lmfsPin V RC

=3.684 103 H

9.33

=194.411 103 A

( 118.543 ) ( 0.4045 )

V DC

l

( m)( f s )

( min) ( Dmax )

I =

I=

CCM

V dc

=424.8762256 V

STEP 5: Choose the proper FPS considering the input power and current limit

I =I dspeak +I dspeak (0.12)

I >326.621 mA

STEP 6: Determine the proper core and the minimum primary turnsk

Lm I

N min

106

p =

B sa + A e

N

min

p

( 3.684 103 ) (326.621 103 )

( 0.35 ) (20.1)

10

N min

p =171turns

STEP 7: Determine the number of turns for each output

STEP 8: Determine the wire diameter for each winding

K

STEP 9: Choose the rectifier diode in the secondary side

K

STEP 10: Determine the output capacitor

K

STEP 11: Design RCD snubber

K

STEP 12: Design feedback control loop

K

You might also like

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- EE 310 Problem Set No. 1 Solutions: (A) Ma (I) VDocument5 pagesEE 310 Problem Set No. 1 Solutions: (A) Ma (I) Vssb5107No ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- SPR 2002 EE567 Design of 2-Stage Op Amp: Layout & Simulation FilesDocument20 pagesSPR 2002 EE567 Design of 2-Stage Op Amp: Layout & Simulation Files9448877344No ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Insta Laci Ones Electrostatic As I IDocument12 pagesInsta Laci Ones Electrostatic As I IEnrique ArturoNo ratings yet

- Problem Solutions: R R R R V I R R IDocument69 pagesProblem Solutions: R R R R V I R R IAkhila RajagopalNo ratings yet

- Timber DesignDocument62 pagesTimber DesignLovely Brecio CalixtroNo ratings yet

- Concrete Cracking Based On AciDocument3 pagesConcrete Cracking Based On AciFajar Fikriyansyah Sidik100% (1)

- Flowcharts and Design Equations - Eurocode 2Document7 pagesFlowcharts and Design Equations - Eurocode 2ChineseAssassinNo ratings yet

- NDECKDocument12 pagesNDECKNhân Lê TrọngNo ratings yet

- Crack Check: Ec N Es / Ec FR 4700 FC'Document3 pagesCrack Check: Ec N Es / Ec FR 4700 FC'kamakshi100% (2)

- USD FootingDocument3 pagesUSD Footingdash1991No ratings yet

- Basic Design EquationsDocument2 pagesBasic Design EquationsChineseAssassinNo ratings yet

- Unit 3 Limit State of ServiceabilityDocument55 pagesUnit 3 Limit State of ServiceabilityManoj SharmaNo ratings yet

- Desain Forward ConverterDocument5 pagesDesain Forward ConverterBramasto Adi NugrohoNo ratings yet

- RCD LAB and Load TransferDocument11 pagesRCD LAB and Load TransferRaymond Lee CurazaNo ratings yet

- Amplifier StagesDocument5 pagesAmplifier StagesNelsonLucioRodriguezPenagosNo ratings yet

- Design of Concrete SlabDocument20 pagesDesign of Concrete SlabDavis Chad MagalongNo ratings yet

- Mosfet Power Dissipation CalculationDocument8 pagesMosfet Power Dissipation CalculationDinesh DangiNo ratings yet

- EC2 Flowcharts - DimensionamentoDocument5 pagesEC2 Flowcharts - DimensionamentoTiago Valente100% (1)

- Trabajo Final Carretera 1Document18 pagesTrabajo Final Carretera 1Marianyi AyalaNo ratings yet

- Calculation of Column Reinforcement Area According To en 1992Document6 pagesCalculation of Column Reinforcement Area According To en 1992Florian EsnaultNo ratings yet

- Farm STR ProjectDocument17 pagesFarm STR ProjectShinyi GanNo ratings yet

- Prestressed Example LossesDocument14 pagesPrestressed Example LossesmagdyamdbNo ratings yet

- PRPC Assignment2Document13 pagesPRPC Assignment2fathima camangianNo ratings yet

- Chapter 9 SolutionDocument15 pagesChapter 9 Solutionjayeshbankoti100% (1)

- Technical Calculation of Segmental PC I Beam For Bridge SPAN (CTC) L I. DataDocument30 pagesTechnical Calculation of Segmental PC I Beam For Bridge SPAN (CTC) L I. DataAnisha MayaNo ratings yet

- Engineering Measurements ch2 SolutionDocument30 pagesEngineering Measurements ch2 SolutionGanesh ShankarNo ratings yet

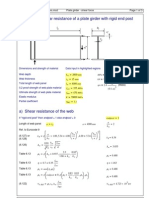

- Plate Girder DesignDocument8 pagesPlate Girder Designkalpanaadhi100% (1)

- 2 Storey Event CenterDocument5 pages2 Storey Event CenterjohnNo ratings yet

- Problem Solutions: V S SC Ts Vs SC R Ts SRCDocument37 pagesProblem Solutions: V S SC Ts Vs SC R Ts SRCLuis AntonioNo ratings yet

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- Solutions Exam 2001Document17 pagesSolutions Exam 2001bmmostefaNo ratings yet

- 2N3903, 2N3904 General Purpose Transistors: NPN SiliconDocument7 pages2N3903, 2N3904 General Purpose Transistors: NPN SiliconGabrielRuedaDiazNo ratings yet

- Calculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Document18 pagesCalculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Liviu Ion100% (1)

- Assignment ZZZZZZZZZZZDocument45 pagesAssignment ZZZZZZZZZZZSophanPhannakolNo ratings yet

- Lasac. Assignment 3. Ce43s4Document9 pagesLasac. Assignment 3. Ce43s4Karyme MendezNo ratings yet

- Tuto2 (S) 2016 30102016204804033Document5 pagesTuto2 (S) 2016 30102016204804033Chandini ManoharanNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Annex 4 - Delivery Format - Task 3Document14 pagesAnnex 4 - Delivery Format - Task 3carlosNo ratings yet

- Power System Nagrath Kothari SolutionsDocument88 pagesPower System Nagrath Kothari SolutionsAjeetKumar100% (1)

- Chapter 9 Homework SolutionDocument27 pagesChapter 9 Homework Solutionjoe100% (3)

- Exercise Solutions EX11.1: I I V V V V V V V V VDocument12 pagesExercise Solutions EX11.1: I I V V V V V V V V VLuis AntonioNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- RC Beam DesignDocument23 pagesRC Beam DesignBhemalee Tono DimalaluanNo ratings yet

- Pre Stressed Concrete Solving ExampleDocument25 pagesPre Stressed Concrete Solving Examplemohamed19751st100% (1)

- Bab III Gording FixDocument11 pagesBab III Gording FixSatria IstanaNo ratings yet

- Problem Solutions: Chapter 10Document10 pagesProblem Solutions: Chapter 10arcg89No ratings yet

- Structural Computation RevisedDocument5 pagesStructural Computation RevisedJay HernandezNo ratings yet

- Chapter 10Document24 pagesChapter 10kamal__singhNo ratings yet

- Solucion Engranaje MathcadDocument3 pagesSolucion Engranaje MathcadcristobalmonopeluoNo ratings yet

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Ref. Calculations Output Specification: 25 N/MM 500 N/MMDocument4 pagesRef. Calculations Output Specification: 25 N/MM 500 N/MMadib jamilNo ratings yet

- Mt21mvd013 Lab Assignment 04 Kola SrikanthDocument9 pagesMt21mvd013 Lab Assignment 04 Kola SrikanthSrikanth KolaNo ratings yet

- Machine Design 1: College of EngineeringDocument10 pagesMachine Design 1: College of EngineeringThink EngineeringNo ratings yet

- Final Exam SEE3433 Mei (Solution)Document9 pagesFinal Exam SEE3433 Mei (Solution)Fizah Abdul RahmanNo ratings yet

- Column 8Document3 pagesColumn 8Smile CollectivesNo ratings yet

- Design of Dog Legged StaircaseDocument2 pagesDesign of Dog Legged Staircasekhalidq_1850% (2)

- MomentumDocument1 pageMomentumArgel Linard Francisco MabagaNo ratings yet

- A Night of Broadway at St. Peter Parish ShrineDocument1 pageA Night of Broadway at St. Peter Parish ShrineArgel Linard Francisco MabagaNo ratings yet

- Vici Line Card 2015Document14 pagesVici Line Card 2015Argel Linard Francisco MabagaNo ratings yet

- Now ShowingDocument5 pagesNow ShowingArgel Linard Francisco MabagaNo ratings yet

- Second Condition of EquilibriumDocument2 pagesSecond Condition of EquilibriumArgel Linard Francisco MabagaNo ratings yet

- Quotes For Centau RoomDocument11 pagesQuotes For Centau RoomArgel Linard Francisco MabagaNo ratings yet

- Now ShowingDocument5 pagesNow ShowingArgel Linard Francisco MabagaNo ratings yet

- QM Data300 PDFDocument22 pagesQM Data300 PDFArgel Linard Francisco MabagaNo ratings yet

- Second Condition of EquilibriumDocument2 pagesSecond Condition of EquilibriumArgel Linard Francisco MabagaNo ratings yet

- Advantages of ContraceptivesDocument4 pagesAdvantages of ContraceptivesArgel Linard Francisco MabagaNo ratings yet

- Now ShowingDocument5 pagesNow ShowingArgel Linard Francisco MabagaNo ratings yet

- Nasc 9 Microbial CultureDocument5 pagesNasc 9 Microbial CultureArgel Linard Francisco MabagaNo ratings yet

- My Life in You PDFDocument9 pagesMy Life in You PDFBougart SigaNo ratings yet

- The Kinematic EquationsDocument2 pagesThe Kinematic EquationsArgel Linard Francisco MabagaNo ratings yet

- Eng RecitDocument5 pagesEng RecitArgel Linard Francisco MabagaNo ratings yet

- PerfectDocument2 pagesPerfectArgel Linard Francisco MabagaNo ratings yet

- Navigational AidsDocument14 pagesNavigational AidsArgel Linard Francisco MabagaNo ratings yet

- MomentumDocument1 pageMomentumArgel Linard Francisco MabagaNo ratings yet

- The Kinematic EquationsDocument2 pagesThe Kinematic EquationsArgel Linard Francisco MabagaNo ratings yet

- Disorders and TreatmentDocument5 pagesDisorders and TreatmentArgel Linard Francisco MabagaNo ratings yet

- PerfectDocument2 pagesPerfectArgel Linard Francisco MabagaNo ratings yet

- AmplifiersDocument16 pagesAmplifiersAlpynNo ratings yet

- Robotics Consent LetterDocument1 pageRobotics Consent LetterArgel Linard Francisco MabagaNo ratings yet

- Second Condition of EquilibriumDocument2 pagesSecond Condition of EquilibriumArgel Linard Francisco MabagaNo ratings yet

- Percdc Multiple Choice Questions in Est by Melvin C. ArceoDocument453 pagesPercdc Multiple Choice Questions in Est by Melvin C. ArceocathyNo ratings yet

- GEAS Practice SolvingDocument15 pagesGEAS Practice SolvingRennel MallariNo ratings yet

- Electronics Engineer PassersDocument48 pagesElectronics Engineer PassersArgel Linard Francisco MabagaNo ratings yet

- The Kinematic EquationsDocument2 pagesThe Kinematic EquationsArgel Linard Francisco MabagaNo ratings yet

- (Certii) Multiple Choice Questions in CommunicationsDocument36 pages(Certii) Multiple Choice Questions in CommunicationsJunel GenorgaNo ratings yet

- MayorDocument30 pagesMayorArgel Linard Francisco MabagaNo ratings yet