Professional Documents

Culture Documents

Mix Design For Grade: M-40: A Data

Uploaded by

Swapnil KamerkarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mix Design For Grade: M-40: A Data

Uploaded by

Swapnil KamerkarCopyright:

Available Formats

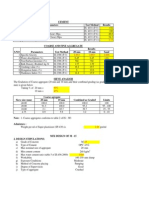

MIX DESIGN FOR GRADE: M-40

Design Mix. As Per I.S Codes: 10262 and 456

A DATA

Characterstic Compressive Strength required @ 28 Days

Standard deviation considered as per I.S.456

Target strength char. Strength + 1.64 X STDV

Maximum Size of Aggregate mm.

Degree of Workability

Cementitious Content (Min)

Flyash replacement

Cement

Flyash

Water Cement Ratio (Max)

Water content

Admixture (1.% of Cem. Material)

40

5

48

20

180

520

15%

444

76

0.3

156

5.20

0

B TEST DATA FOR MATERIALS

i) Specific Gravity of Cement

3.15

(ACC OPC 53 Grade Cement)

ii) Specific Gravity of Fly Ash

2.26

(Source: Ashtek)

iii) Specific Gravity of Coarse Aggregate

iv) Specific Gravity of Fine Aggregate

v) Water Absorption of Coarse Aggregate

vi) Water Absorption of Fine Aggregate

% age

% age

20 mm

10 mm

N/ Sand

C/ Sand

20 mm

10 mm

N/ Sand

C/ Sand

2.86

2.83

2.8

2.75

1.63

1.73

3.5

5.65

Aggregate Proportioning

Coarse Aggregate

Fine Aggregates

20 mm

10 mm

N/ Sand

C/ Sand

60%

40%

58

42

0

100

34.80%

25.20%

0.00%

40.00%

Amount of Air entrained in wet concrete in %

Hence effective volume shall be

2

980

Determination of Aggregates

water

Cement

Flyash

Aggreg.

1

980 =

+ Sp. Gravity + Sp. Gravity + Sp. Gravity x % age pr.

Mpa

Mpa

mm

mm

Kgs

Kgs

Kgs

Kgs

Concrete Mix Design Grade M-40

40

Cement

Flyash

444

76

Free W/C ratio

Water

A20

A10

N / Sand

C / Sand

MIX PROPORTION ON SSD

CONDITIONS

Grade of Concrete

W/a

%

0.3

156

646

463

0

714

1.63

1.73

3.5

5.65

2499

Effective Water

M/c

%

635

455

0

674

11

8

0

40

0

0

0

0

635

455

0

674

0

0

0

0

59

215

Cement

Flyash

Eff. W/C Ratio

Water

A20

A10

N / Sand

C / Sand

Admixture

Density

MIX PROPORTION AFTER

CORRECTION

Final Mix

444

76

0.41

215

635

455

0

674

5.20

Kgs.

Kgs.

2505

Kg / M3

Kgs.

Kgs.

Kgs.

Kgs.

Kgs.

Kgs.

REMARK / APPROVAL STATUS : The above parameters are based on Surface Saturated Dry ( S.S.D )

Due correction regarding water absortion and moisture correction are taken care while batching on the

RMC plant .Hence some of the aggregates weight may vary accordingly.Also with respect to sieve

analysis the proportioning may be decided at the time of batching.

08/29/2015

You might also like

- Is Concrete Mix DesignDocument21 pagesIs Concrete Mix DesignahmedanyNo ratings yet

- Material Test Data and Concrete Mix DesignDocument3 pagesMaterial Test Data and Concrete Mix DesignlombangrurusNo ratings yet

- M60 Grade Concrete Mix Design Using OPC 53 Grade CementDocument2 pagesM60 Grade Concrete Mix Design Using OPC 53 Grade CementgreatpicNo ratings yet

- Aramco Que - Civil InspectorDocument23 pagesAramco Que - Civil InspectorBasker Balu86% (7)

- Concrete Mix Design M60 Grade of Concrete OPC 53 GradeDocument3 pagesConcrete Mix Design M60 Grade of Concrete OPC 53 GradeAjinkya MahajanNo ratings yet

- Sec 610Document45 pagesSec 610Brad GotchNo ratings yet

- Group 1Document67 pagesGroup 1santoshNo ratings yet

- Syce Sem - Iv Mini ProjectDocument37 pagesSyce Sem - Iv Mini ProjectAmey KadulkarNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignGlyn A. Brinquez100% (1)

- Concrete (PCC) Mixture Designs For O'Hare Modernization ProgramDocument46 pagesConcrete (PCC) Mixture Designs For O'Hare Modernization ProgramAnandkumar PokalaNo ratings yet

- Aparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Document5 pagesAparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Kumar gsNo ratings yet

- CONCRETE MIX DESIGN DETAILSDocument24 pagesCONCRETE MIX DESIGN DETAILSaayushagarwal123100% (1)

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- Trail Mix M37-AccropodeDocument36 pagesTrail Mix M37-AccropodeKeerti Bongu50% (2)

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyNo ratings yet

- CEMENT CONCRETE MIX DESIGNDocument37 pagesCEMENT CONCRETE MIX DESIGNManoj Kumar SinghNo ratings yet

- CT E BookDocument107 pagesCT E BookKshitiz RawatNo ratings yet

- M30 Design CalculationDocument6 pagesM30 Design Calculationjeffkarthick1No ratings yet

- Mix Design M40 Grade Per IS 10262 & IS 456Document6 pagesMix Design M40 Grade Per IS 10262 & IS 456Sanjoy RoyNo ratings yet

- Concrete Mix Design M-40 (RCC) Grade: Name of Work Client Authority Engineer ContractorDocument34 pagesConcrete Mix Design M-40 (RCC) Grade: Name of Work Client Authority Engineer ContractorAshok amlapureNo ratings yet

- M30 Concrete Mix DesignDocument23 pagesM30 Concrete Mix DesignAjith RamuNo ratings yet

- M35 Bhole ConstructionDocument6 pagesM35 Bhole ConstructionBIPL REPORT100% (1)

- Concrete Mix DesignDocument14 pagesConcrete Mix Designchaos_atulNo ratings yet

- Quality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteDocument9 pagesQuality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteRadhakrishna KPNo ratings yet

- MCQ TestDocument4 pagesMCQ TestPrabhakar Kumar Barnwal0% (1)

- Concrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorDocument23 pagesConcrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorAshok amlapure75% (4)

- Concrete Making MaterialsDocument55 pagesConcrete Making Materialsjaffna100% (1)

- ACT SEMINAR PHD VENKATESHDocument26 pagesACT SEMINAR PHD VENKATESHGyanesh PatnaikNo ratings yet

- Test Procedure-25-08-06Document49 pagesTest Procedure-25-08-06Hariom GuptaNo ratings yet

- Department of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurDocument10 pagesDepartment of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurAjayvidyanand SharmaNo ratings yet

- Design Mix M 30Document4 pagesDesign Mix M 30SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Concrete Mix Design M20 GradeDocument4 pagesConcrete Mix Design M20 GradeSyerifaizal Hj. MustaphaNo ratings yet

- Experimental Study On Concrete Mix Design by Replacing Fine Aggregate by Crushed Tiles & Cement With Marble PowderDocument8 pagesExperimental Study On Concrete Mix Design by Replacing Fine Aggregate by Crushed Tiles & Cement With Marble PowderIJRASETPublicationsNo ratings yet

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- A) Design Stipulation For ProportioningDocument5 pagesA) Design Stipulation For ProportioningSandip RoyNo ratings yet

- M35 Revised Mix Design SheetDocument2 pagesM35 Revised Mix Design Sheetamol awateNo ratings yet

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocument9 pagesDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedNo ratings yet

- Mix Design M-25 GradeDocument9 pagesMix Design M-25 Gradeenjoy begening lifeNo ratings yet

- Mix Design FormatDocument18 pagesMix Design FormatChandan MondalNo ratings yet

- Contract Section (KM 1+564 To 10+000)Document2 pagesContract Section (KM 1+564 To 10+000)Nisar AhmadNo ratings yet

- Sec610 - Structural ConcreteDocument52 pagesSec610 - Structural ConcreteAmr Adel HameedNo ratings yet

- Concrete Mix Design M-40 (RCC) GradeDocument6 pagesConcrete Mix Design M-40 (RCC) GradeAshok amlapureNo ratings yet

- Concrete Mix Design M-40 (RCC) GradeDocument6 pagesConcrete Mix Design M-40 (RCC) GradeAshok amlapureNo ratings yet

- Specific Gravity & Water Absorption Test (I S 2386 Iii/63)Document11 pagesSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)End EndNo ratings yet

- Mix Design ProgramDocument32 pagesMix Design ProgramBilal Ahmed Barbhuiya67% (3)

- Concrete Mix Design, Is StandardDocument12 pagesConcrete Mix Design, Is StandardKumaresvaranNo ratings yet

- BITUMEN LAB TEST CHARGESDocument7 pagesBITUMEN LAB TEST CHARGESRenga PandiNo ratings yet

- Me 2 ReviewerDocument53 pagesMe 2 ReviewerShan AdriasNo ratings yet

- M25 DesignDocument4 pagesM25 DesignAmit KumarNo ratings yet

- Structural Engineering PG Lab ManualDocument47 pagesStructural Engineering PG Lab ManualKannan PNo ratings yet

- MEDocument2 pagesMEliezl binNo ratings yet

- Study On Behaviour of Concrete Partially Replacing Quartz Sand As Fine AggregateDocument6 pagesStudy On Behaviour of Concrete Partially Replacing Quartz Sand As Fine Aggregateshivanand hippargaNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Sardar Patel Bridge at Surat Load CalculationDocument1 pageSardar Patel Bridge at Surat Load CalculationSwapnil KamerkarNo ratings yet

- Shree Cement Stability CertificateDocument1 pageShree Cement Stability CertificateSwapnil KamerkarNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentSwapnil KamerkarNo ratings yet

- Our Project in Bahrain: Client: M/S. Awal Readymix Concrete Co.W.L.LDocument3 pagesOur Project in Bahrain: Client: M/S. Awal Readymix Concrete Co.W.L.LSwapnil KamerkarNo ratings yet

- Typ PTB 45X90Document20 pagesTyp PTB 45X90Swapnil KamerkarNo ratings yet

- Boq Summary: No. Material Unit Quantity Rate र Cost रDocument1 pageBoq Summary: No. Material Unit Quantity Rate र Cost रSwapnil KamerkarNo ratings yet

- HDPE Sheathing For Post-Tensioned Prestressed Concrete StructuresDocument11 pagesHDPE Sheathing For Post-Tensioned Prestressed Concrete StructuresSwapnil KamerkarNo ratings yet

- PTB 1Document53 pagesPTB 1Swapnil KamerkarNo ratings yet

- Wall CoordinateDocument2 pagesWall CoordinateSwapnil KamerkarNo ratings yet

- Terms and conditions for post-tensioning workDocument8 pagesTerms and conditions for post-tensioning workSwapnil KamerkarNo ratings yet

- Godown Stock StatementDocument2 pagesGodown Stock StatementSwapnil KamerkarNo ratings yet

- Post Tensioning Works Project Orovia Phase IDocument2 pagesPost Tensioning Works Project Orovia Phase ISwapnil Kamerkar100% (1)

- RCC Beam Option Boq PDFDocument1 pageRCC Beam Option Boq PDFSwapnil KamerkarNo ratings yet

- Boq Summary: No. Material Unit Quantity Rate र Cost रDocument1 pageBoq Summary: No. Material Unit Quantity Rate र Cost रSwapnil KamerkarNo ratings yet

- Form U Change of NameDocument5 pagesForm U Change of NamesunilgvoraNo ratings yet

- FORMAT (OTS-F-12) RTGS/ Neft - Mandate Authorisation FormDocument1 pageFORMAT (OTS-F-12) RTGS/ Neft - Mandate Authorisation FormSwapnil KamerkarNo ratings yet

- QhlogsDocument1 pageQhlogsMohit KoladiaNo ratings yet

- BrochureDocument25 pagesBrochureSwapnil KamerkarNo ratings yet

- 631 1841 1 PB PDFDocument8 pages631 1841 1 PB PDFGORTHI ANURAMNo ratings yet

- Expansion Joint ReportDocument1 pageExpansion Joint ReportSwapnil KamerkarNo ratings yet

- Column SizesDocument1 pageColumn SizesSwapnil KamerkarNo ratings yet

- Alfida 1Document3 pagesAlfida 1Swapnil KamerkarNo ratings yet

- Offer For Future Group R1Document2 pagesOffer For Future Group R1Swapnil KamerkarNo ratings yet

- Mid Span Stress Check Is1343Document6 pagesMid Span Stress Check Is1343Swapnil KamerkarNo ratings yet

- Stud Shear Connectors Paper PDFDocument8 pagesStud Shear Connectors Paper PDFSwapnil KamerkarNo ratings yet

- Manas-R2 Punching TributaryLoadsCheckDocument5 pagesManas-R2 Punching TributaryLoadsCheckSwapnil KamerkarNo ratings yet

- Alfida 1Document3 pagesAlfida 1Swapnil KamerkarNo ratings yet

- PT Flat Slab & PT Slab With PTB Option Cost DetailsDocument1 pagePT Flat Slab & PT Slab With PTB Option Cost DetailsSwapnil KamerkarNo ratings yet

- Scon Infrastructure PTB - 3: Thursday, June 16, 2016Document54 pagesScon Infrastructure PTB - 3: Thursday, June 16, 2016Swapnil KamerkarNo ratings yet

- Vibration Analysis CalculationDocument2 pagesVibration Analysis CalculationSwapnil KamerkarNo ratings yet