Professional Documents

Culture Documents

PLC Inspection Check List

PLC Inspection Check List

Uploaded by

Navneet SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PLC Inspection Check List

PLC Inspection Check List

Uploaded by

Navneet SinghCopyright:

Available Formats

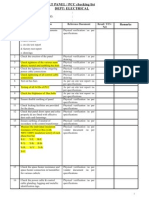

PLCPanelCheckList

Overallsystemcofigurationchecks

Pass

Fail

Comments

SystemName:

CheckModel,QuanityofthesystemmodulesagainsttherecordinBOM:

VisualInspectionChecks

Checkthesuitabilityofthetestingarea(stagingarea)

DegreeofMechanicalProtection

Cabinettype

Checkterminalstripsfunctionalseparation

checkfusingandfuserating

checkcheckofthewiringseparationofvariousvoltages

checkthefillingducts

checkofthespaceoffutureexpansion

Verifythecontrolandsignalcables

Paintworkfreefromscratches,blemishes,deformities

Eyeboltsfitted

Allmechanicalconnectionsaresecureandfitproperly

DoorsandLock/Keysarefittedsecurely

Nuts/bolts/screws/fastenersaretight

Allhazardouslabelsarefitted(voltage>50V)

Alldevicelabelsarefitted

ThetypetestCertificate(asperIDS)includingtheelectromagnetic

Compatibility,tropicalisationetc.

Checkofinstrumentcalibration(certificatefortheinstrumentsthatwillbe

usedforthetest)

safetygroundingcircuitcheckasperEN610101checkofthesafetyground

insulationtest

AllExteriorcabinetnamepltesarecorrectlylocatedandsquaredtofrontand

rearofcabinetforeasyviewing

PLCPanelCheckList

AllMCBlabelsarefitted

Allterminalblocklablesarefitted

Allearthbarlabelsarefitted

AllrackinterconnectI/Obuscablesarelabled

Randomlycheckcrimpedendsandscrewconnections

AllIOmodulesareincorrectRack/Slot

CheckLocationofeachcomponentagainstGeneralArrangementdrawing

ElectricalChecks

Allcabinetwiringshallbeinspectedpriortopowerup

ControlCabinets:

RandomCabinetpowerwiringvisualorcontinuitycheckedagainstdrawing

Randomferruletaggingvisualcheck,shouldbeclearandreadable

RandomPointtoPoint(resistancetest)

RandomPointtoGround(resistancetest)

Earthbondingtestshallnotexceed0.1ohmsbetweenbondeditemand

appropriateeathbusbar,usemeggertocheckearthing

PowerConnectionChecks

Thefollowingtestistoensureproperpowerfeedisconnectedtothesystem

priortopoweron.Notethatmainprocessorbatteriesshouldberemoved

priortopoweringup.Thismeansthesystemhaspowerbutithasno

appicationcode.

Verifythecorrectnessoftheconnectionwiththesupplysystem,correctpower

connectiontoterminalstrip,neutralandphase

CheckcabinetsareconnectedtoasuitableearthingpointintheFATpremise

Checka230VAC(+5%),50Hz(+1%)supplytoincomingUPSACsupply

terminals

Checka230VAC(+5%),50Hz(+1%)supplytoincomingUtilityACsupply

terminals

PLCPanelCheckList

CheckallMCB'sforthecorrectratingprotection(refertoElectricalPower

SystemPower(230VAC)Up

Check230VACavailableatterminal1&2

Switch'ON'Circuitbreaker'MCB',checkvoltageonitsoutputterminals.

FieldOutputPower(24VDC)Up

Checkthe230VACpowerontheinputterminalsof24VDCpowersupplyunit.

EnsureSystemHealthinessasbelow:

Ensurethemainrackpowersupplydoesnotshowanyalarm

230VACInputfeedVoltage:Current:

24VDCPowersupplyVoltage:Current:

SignalWiringChecks

Distribution&GroundingDrawing)

CheckVoltageonitsoutputterminals;ensuretherespectiveoutputdevices

are'ON'suchasFanunit,PanelLampandFieldPSunits.Ensureallcontrol

systemmodulesarein'ACTIVE'.

Switch'ON'powersupplyandcheckvoltageontheiroutputterminals

respectively.Alsocheckvoltageontheinputsideofthepowerdistribution

terminals(keepingthefusedterminals'OPEN').

Note:Usingatestmetermeasurethepowersupplymodule(offload)and

ensurethatthemeasuredoutputvoltageis24VDC+5%.IftheDCvoltageis

outsideofthespecifiedlimit,adjustpowersupplyoutputinaccordancewith

themanufacturer'sguide.

EnsurenoalarmontheIOmodulesafterpowerupofthe24VDCfieldpower

supply.

PowerConsumption

Foreachtypeofpowerfeeds,measurevoltageandtotalsystemcurrentwith

withsystem"NoLoad"conditionandrecordtheresults

Randomlythesignalwiringshallbeinspectedpriortoloopchecksand

applicationprogram(LogicSimulation)

PLCPanelCheckList

Cabinetwiringvisualorcontinuitycheckedagainstdrawing

Ferruletaggingvisualcheck,shouldbeclearandreadable

PointtoPoint(resistancetest)

PointtoGround(resistancetest)

Randomlycheckthewiringforpropercrimpingandtermination(TugTest)

SystemConfigurationChecks

Verifyexistenceofcontrolprogram

Checkthemoduleconfigurationasper'RackAssignment&I/ODetails'

ChecktheI/Oaddressingforthehardwarepoints100%

ChecktheI/Oaddressingforthesoftwarepoints100%

LoopChecks

Thischeckwillbedoneasperpretestbeforecheckingtheapplicationlogic.

AnalogInputs

Checkconfiguredanalogscalingandanalogalarm/triplevelsarecorrect

CheckconfiguredAlarmsforHMI

Recordresults

DigitalInputs

Note:Earthbondingtestshallnotexceed0.1ohmsbetweenbondeditemand

appropriateearthbusbar

Activateeachoftheanaloginputsbyvaryingthepotentiometeronthe

simulationpanel.

Checkthecurrentatthefieldterminalsusingamultimeter.

Checkthecorrectsystemreferenceaddressisactivatedandthevalueinthe

registervariescorrectly.

Activateeachofthedigitalinputsbytogglingtheswitchesonthesimulation

panel

CheckthecurrentRack/Slot/ChannelLEDilluminatesoninputmoduleand

correspondingHMIdisplayischangingtherespectivedevicecolorasspecified

PLCPanelCheckList

intheFDS

CheckconfiguredHMIalarmiscorrect

Recordresults

DigitalOutputs

UsingEngineeringstationforceON(energize)eachoutput

ConfirmthatcorrectRack/Slot/ChannelLEDilluminatesonoutputmodule

ConfirmthatcorrectlamponthesimulationpanelturnsON.

recordresults

Allthechangesinthelogicshallbevisualizedbysimulatorpanel

FieldI/ONormal

Note:AnydiscrepancywillbeinthepunchListandwillbeclearedbefore

startingtheApplicationLogicTest

ApplicationProgramChecks

ThepurposeofthistestistoverifytheLCPApplicationCodesagainstthe

sequenceofoperationasspecifiedintheControlLogicdiagram/FDS.The

simulationcabinetshavebeenwiredtoallowallI/Ogroupstobeoperated

withoutdelay.

Allthedigitalinputsintoitsnormalposition'Open'or'Close'aspernormal

processoperatingconditions

Allanaloginputsintoitsnormalposition'lessthanHighsetpoint'or'more

thanLowsetpoint'aspernormalprocessoperatingconditions

LogicTest

Thelogicsequencewillbetestedexactlyasperthecontrollogicdiagramand

normalplantoperatingconditions,witheachstepsperformedinsequence.

Anycorrectionsrequiredwillbedonethenorattheendofthetestbasedon

thecorrectionrequired.

RedundancyChecks

PLCPanelCheckList

CPURedundancyCheck

CheckchangeoverbetweenCPUA&CPUBandviceversa

PowersupplyRedundancyCheck

CheckchangeoverbetweenPSA&PSBandviceversa

EthernetSwitchRedundancyCheck

RIOBusRedundancyCheck

SpareCapacityChecks

Checkdigitalinputsquarequantityin%

Checkdigitaloutputsquarequantityin%

Checkanaloginputsquarequantityin%

Checkanalogoutputsquarequantityin%

SystemShutdown/RebootFunctionalityChecks

Endtheruntimeprogram,Turnoffpower,forallenclosuresObserveStatus

Switchonpower,forallenclosuresObserveStatus

CheckTestCertificates

Checkthetestcertificateasperdocument

CalibrationTestCertificates

Internaltestreportifany

MaterialTestCertificate

ConformityCertificate

You might also like

- Preventive Maintenance Electrical FormDocument7 pagesPreventive Maintenance Electrical FormMohammed Jahir Husain77% (39)

- Inspection Checklist For SMDBs & MDBsDocument5 pagesInspection Checklist For SMDBs & MDBsShirish67% (3)

- Switchboard Inspection ChecklistDocument2 pagesSwitchboard Inspection Checklistraza23960% (5)

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- Operations and Maintenance Preventive Maintenance ChecklistsDocument35 pagesOperations and Maintenance Preventive Maintenance Checklistssooriya_82100% (14)

- Panel Inspection Report FormatDocument5 pagesPanel Inspection Report Formatp mahesh goud100% (2)

- Electrical Control Panel Testing and Inspection ChecklisttDocument2 pagesElectrical Control Panel Testing and Inspection ChecklisttRanjit Singh100% (7)

- LT PANEL Testing ProcedureDocument5 pagesLT PANEL Testing Procedureaslam shaikh60% (5)

- FAT Procedure of PLC PanelDocument25 pagesFAT Procedure of PLC PanelDipti Bhanja83% (6)

- VFD Commissioning FormatDocument2 pagesVFD Commissioning FormatJun Lumayno100% (3)

- Pre-Commissioning Tests ChecklistDocument9 pagesPre-Commissioning Tests ChecklistIYAD100% (4)

- Checklist Control PanelDocument2 pagesChecklist Control PanelSaravana Kumar82% (22)

- Pre Commissioning ChecklistDocument5 pagesPre Commissioning ChecklistReymart Manablug100% (3)

- Maintenance ChecklistDocument2 pagesMaintenance ChecklistShreyasi Singh92% (13)

- Preventive Maintenance Electrical FormDocument7 pagesPreventive Maintenance Electrical FormAdriawan Annes100% (2)

- Attachment 12.7 - QA - QC Checklist - MCC & CBDocument6 pagesAttachment 12.7 - QA - QC Checklist - MCC & CBehteshamNo ratings yet

- Electrical CheckListDocument33 pagesElectrical CheckListYudo Heru PribadiNo ratings yet

- Generator Inspection ChecklistDocument2 pagesGenerator Inspection Checklistramakrishna6650% (4)

- 03 SOP Preventive Maintenance of TransformerDocument5 pages03 SOP Preventive Maintenance of TransformerPandu Birumakovela100% (2)

- SOP - 06 LT - PanelDocument9 pagesSOP - 06 LT - PanelPandu Birumakovela100% (2)

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth SolaNo ratings yet

- Checklist For Cable Try Fabrication and EractionDocument2 pagesChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Instrumentation ITPDocument2 pagesInstrumentation ITPprasanta2011100% (4)

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick Natrajan100% (1)

- E&I Quality PlanDocument9 pagesE&I Quality PlanJithuRajNo ratings yet

- Fabtech Export Industries, IncDocument2 pagesFabtech Export Industries, IncRaz LucciNo ratings yet

- Checklist For LT PanelDocument13 pagesChecklist For LT PanelSanket Jain80% (5)

- Panel Board ChecklistDocument2 pagesPanel Board Checklistanon_67491042No ratings yet

- Pre-Commissioning Check List of GeneratorDocument26 pagesPre-Commissioning Check List of Generatorvikivarma14780% (15)

- PLC Panel Check ListDocument6 pagesPLC Panel Check ListPATEL AKASHNo ratings yet

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureÁlvaro Manterola Lazcano100% (19)

- Check List LT PanelDocument1 pageCheck List LT PanelAnil Patel100% (1)

- Inspection Report For Installation of JB, Juncation BoxDocument1 pageInspection Report For Installation of JB, Juncation BoxnayumNo ratings yet

- Inspection Checklist For LV Electrical WorksDocument40 pagesInspection Checklist For LV Electrical WorksMOHAMMED EJAS83% (6)

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Electrical Preventive Maintenance and ChecklistDocument8 pagesElectrical Preventive Maintenance and ChecklistEdmund Yoong100% (4)

- Electrical ChecklistDocument2 pagesElectrical ChecklistAjay Oraon100% (2)

- Monthly Preventive Maintenance ChecklistDocument2 pagesMonthly Preventive Maintenance ChecklistAlia Marouf90% (10)

- Ups Installations ChecklistDocument2 pagesUps Installations Checklistusman amir67% (3)

- Electrical Safety Auditing Checkpoints: Compliance To Statutory RulesDocument8 pagesElectrical Safety Auditing Checkpoints: Compliance To Statutory RulesSoumya Mukherjee100% (3)

- Precommissioning Procedures of Testing Commissioning PDFDocument96 pagesPrecommissioning Procedures of Testing Commissioning PDFRatheesh Kumar100% (1)

- QAP - LT Panel PDFDocument8 pagesQAP - LT Panel PDFAkshay Ajay100% (2)

- HT Panel ChecklistDocument1 pageHT Panel Checklisttango member0% (1)

- Electrical Panel - Equipment Installation Method StatementDocument8 pagesElectrical Panel - Equipment Installation Method Statementadnanakhtarhrp60% (5)

- 1 AcdbDocument9 pages1 AcdbmaheshknmNo ratings yet

- Electrical MaintenanceDocument7 pagesElectrical MaintenanceKHUSHBOO198450% (2)

- Switchgear ChecklistDocument2 pagesSwitchgear ChecklistAnonymous IeFbdsfCo100% (1)

- Electrical Panels Installation ChecklistDocument2 pagesElectrical Panels Installation ChecklistAlvin Badz100% (3)

- SOP-04 Preventive Maintenance of DG SetsDocument11 pagesSOP-04 Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- Project: Expansion of Royal Hospital Testing and Commissioning ReportDocument2 pagesProject: Expansion of Royal Hospital Testing and Commissioning ReportBabuNo ratings yet

- Panel Check List 191206092316 PDFDocument6 pagesPanel Check List 191206092316 PDFmadantiwari200No ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- 700 Series AC Dielectric Test SetsDocument7 pages700 Series AC Dielectric Test SetsKhoilnNo ratings yet

- Radspeed Preventive MaintenanceDocument4 pagesRadspeed Preventive MaintenanceBashir MtwaklNo ratings yet

- GCS-VSD Course HSEDocument20 pagesGCS-VSD Course HSEMohamed MostafaNo ratings yet

- Electificador Con PicDocument9 pagesElectificador Con Picgeraldino2509208No ratings yet

- Monthly Check List For Electrical PanelDocument1 pageMonthly Check List For Electrical Panelqamar sayed100% (1)

- PV Array Check ListDocument2 pagesPV Array Check Listmohsin abbas Abba'sNo ratings yet

- Profitest100s IIDocument8 pagesProfitest100s IIKirilNo ratings yet

- Vol 12 PDFDocument19 pagesVol 12 PDFLeizer LipaNo ratings yet

- Education, Training and Learning in Geo-Sciences For Civil EngineeringDocument4 pagesEducation, Training and Learning in Geo-Sciences For Civil EngineeringAnonymous GnfGTwNo ratings yet

- GostDocument4 pagesGostPinkuNo ratings yet

- Mapping Agile Software Development Onto Iso12207Document12 pagesMapping Agile Software Development Onto Iso12207bejunoNo ratings yet

- MST For IPS Panels OriDocument3 pagesMST For IPS Panels OriBabuNo ratings yet

- STS-1st ActivityDocument5 pagesSTS-1st ActivityMateo, Elijah Jonathan C.No ratings yet

- Revised Minimum Performance Standards/ Specifications (By Technical Committee) I. Governing Codes and SpecificationsDocument6 pagesRevised Minimum Performance Standards/ Specifications (By Technical Committee) I. Governing Codes and SpecificationsBendaña KHayeNo ratings yet

- Technical Drawing: PROD 110, Semester One, 2019 Week One: IntroductionDocument21 pagesTechnical Drawing: PROD 110, Semester One, 2019 Week One: IntroductionHossein Najafzadeh100% (1)

- Asme B16.26 PDFDocument13 pagesAsme B16.26 PDFRuben Dario Mamani Arellano100% (1)

- Load Calculation For Air Compressor BuildingDocument27 pagesLoad Calculation For Air Compressor BuildingLandon Mitchell100% (1)

- Examples of Applications Sepam 80Document10 pagesExamples of Applications Sepam 80catalinccNo ratings yet

- Beam - To-Column Connection PDFDocument5 pagesBeam - To-Column Connection PDFValentinoNo ratings yet

- SNU Newsletter Edition 3Document28 pagesSNU Newsletter Edition 3Gopi CufuNo ratings yet

- Electrical Engineering Computer & Systems Engineering Electric Power Engineering Curricular & Career InformationDocument71 pagesElectrical Engineering Computer & Systems Engineering Electric Power Engineering Curricular & Career Informationdeskaug1No ratings yet

- Corbel DesignDocument12 pagesCorbel DesignprsscribdNo ratings yet

- Garun 4 XXX Qu XXX PR 004 00 Design Works Procedure As 20.11.2010Document23 pagesGarun 4 XXX Qu XXX PR 004 00 Design Works Procedure As 20.11.2010Mehmet Alper SahinNo ratings yet

- Pipeline Vs Piping - All About PipelinesDocument6 pagesPipeline Vs Piping - All About Pipelinesjulian2282254No ratings yet

- En 19Document1 pageEn 19Parvee K Nakwal100% (1)

- Mnit Newsletter June 2017Document16 pagesMnit Newsletter June 2017ChiefNo ratings yet

- Unit 1 PDFDocument30 pagesUnit 1 PDFpankajNo ratings yet

- ABET ENVE Program ReviewDocument252 pagesABET ENVE Program ReviewDien NoelNo ratings yet

- Client CV - Mechanical Engineer (MY)Document3 pagesClient CV - Mechanical Engineer (MY)SAIHA AZIZNo ratings yet

- Joints in ConstructionDocument25 pagesJoints in ConstructionWaqarSaleemChNo ratings yet

- myengg/wbjee/AIEEE Closing Rank 2010Document15 pagesmyengg/wbjee/AIEEE Closing Rank 2010Lokesh Kumar100% (1)

- Basis of Design 25000 ReservoirDocument3 pagesBasis of Design 25000 ReservoirAnonymous D1h2pKNo ratings yet

- Jogging Control CircuitsDocument2 pagesJogging Control CircuitskarthikNo ratings yet

- ChaudhriDocument10 pagesChaudhriسحر سلامتیانNo ratings yet

- H4 301e Saf 2009Document32 pagesH4 301e Saf 2009Taeu YuNo ratings yet

- Introduction of CADDocument6 pagesIntroduction of CADKhengling Lim100% (1)

- 2015 015 B.tech (It) Declare Result Dec2018Document53 pages2015 015 B.tech (It) Declare Result Dec2018ShubhamNo ratings yet