Professional Documents

Culture Documents

RTG 05 Hoist Wire Rope Damage

Uploaded by

Mohammed AtefOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RTG 05 Hoist Wire Rope Damage

Uploaded by

Mohammed AtefCopyright:

Available Formats

F-09-01

Incident Summary and corrective action recommendation

Type of incident: Near Miss Accident # Injury

Risk Value:

Probability (3) X Severity () = Time: 2:00 PM Shift Order: 08 A 42 RTG 05 1st

Date of Incident: 03-January-2014 Shift: Orange - Day Location of Incident: Equipment(s) involved: Details

While RTG 05 operator was trying to handle 40 container for loading in bay 08 A 42; the operator tried to catch a container from Raw Charlie (2nd tier) but the spreader wasnt well-landed on the container so he made a hoist up followed by hoist down on the same container resulting in an over slack on the hoist wire from the right/land-side that wasnt noticed by the operator so after repeating hoist ing up the operator noticed abnormal spreader pose from the land-side then stopped working at once and informed his direct S.V. If Injury Please state nature of injury: NA

If Asset Damage Please state nature of the asset damage: right/landside hoist wire rope damaged. If a permit to work was required, was it issued: Summary of statements Involved Person: Name: Hany Helaly Mostafa Department: Operations Experience: 2 years ID: Position: 1369 RTG Operator YES # NO

I got instructions to move gantry toward 08 A 42, and i was adjusting spreader position on the container needed to be loaded and made a hoist down twice on the container till the spreader position became correctly adjusted on the container but unfortunately the spreader wasnt well -landed so i tried to hoist down three times on the same container but in the 3rd time i noticed the spreader was listed toward seaside. Did you made hoist down in over speed in the 3rd time? I hoisted up for a slight height and adjusted my position by gantry to the right & left sides then made hoist down. Did you face any previous problems regarding spreader landing during your working hours? No, i was working for 1 hour on the RTG and it was the first time facing such problem, as I handled 5 containers before without any defects noticed. Issue #: 02 issue date: 01/07/2011 Revision: R002 Revision date: 29/04/2012

Are you sure the spreader was completely rested on the container you wanted to handle? I wasnt quite sure, as I feel that the spreader was landed on the container but I didnt check visually. Did you notice any wire slack after the last hoist down movement you made? Yes, the wire was slaked. Then, what you should do if you noticed any wire slack? If I noticed any wire slack i made hoist up normally and continue working. After slack happened, did the spreader stop working or not? No, hoist up and down functions worked normally after slack happened without any fault appeared. Did you receive a pre-shift safety talk: Did you receive training in how to do the task involved: Are you aware of the rules / procedures related to this work: If required, were you wearing the correct PPE: Did you receive supervision in the last 1hr of your work:

YES

NO NO NO NO NO

* YES * YES * YES * YES

How do you think this incident could be avoided in future? If i noticed any over slack in wires that looks more than normal; i have to stop working at once and inform engineering team. Direct Supervisor: Name: Ahmed Essam Department: Operation ID: 881 Position: Yard Supervisor

Did he/she give a pre-shift safety talk: Technical Advise/Report: Name: Mohamed Abd El-Aziz Department: Engineering

* YES

NO

ID: 1096 Position: First mechanical engineer

Comment: We made a simulation on the same RTG after hoist wire replacement in order to discover the real reason behind that incident and discover that: several conditions should be in place in order to let it happen: 1. RTG operator should made hoist down in over speed. 2. Spreader should be improperly landed on the container. 3. Wire slacking direction (uncontrolled/rarely happened) should be closed to protruded part of the head block. Immediate causes Hoist wire (right/land-side) on RTG 05 damaged after being strained around a protruded part on the spreader head block. Underline causes 1. RTG operator should made hoist down in over speed. Issue #: 02 issue date: 01/07/2011 Revision: R002 Revision date: 29/04/2012

2. Spreader was improperly landed on the container. 3. Wire slacking resulted in wire wrapping around protruded part of the head block. Root Cause People cause/Lack of attention: Although RTG operator noticed wire slacking, but he didnt observe that it became outside the pulley and wire wrapped around & strained on a protruded part of the head block. Corrective actions taken Live RTG 05 became out of order for hoist wire replacement. Comments and Recommendations by the Investigation committee on how this could be avoided in future # Corrective action Add this case in the daily TBT for all RTG operators, regarding: all RTG operators should keep an eye on the hoist wires upon handling containers for both loading/discharging and report immediately for any over slack observed to their direct S.V and didnt make any further movement till wires being checked by CHE. Engineering team. Deadline Ownership

26-01-2014

Operations

General Manager Comments:

To fill this part in case of high severity near misses & all LTIs and to be signed off by the GM

_______________________________________________________________________________________ _______________________________________________________________________________________ _______________________________________________________________________________________ GM signature: Date:

HOD Comments: To fill this part _______________________________________________________________________________________ _______________________________________________________________________________________ _______________________________________________________________________________________ HOD signature: Date:

Shift Manager: Salah Abd El-Aziz Investigation completed by: Operations: Mohamed Adel HSE: Mohamed Atef Issue #: 02 issue date: 01/07/2011 Engineering: Mohamed Abd El-Aziz

Revision: R002

Revision date: 29/04/2012

You might also like

- OSHA 3072 - Sling SafetyDocument28 pagesOSHA 3072 - Sling SafetyManoj Choyal100% (1)

- Learning French EbookDocument36 pagesLearning French EbookDonnette Davis100% (20)

- Common Mistakes in Dimensional Calibration MethodsDocument16 pagesCommon Mistakes in Dimensional Calibration MethodssujudNo ratings yet

- Mirdif Security & Safety Consultants Occupational Health and Safety ProgramDocument8 pagesMirdif Security & Safety Consultants Occupational Health and Safety ProgramMohammed AtefNo ratings yet

- Cargotec Lashing Systems Items FALDocument41 pagesCargotec Lashing Systems Items FALstopless_dalian685No ratings yet

- Bromma Spreader Ysx45e Actual DrawDocument28 pagesBromma Spreader Ysx45e Actual DrawLUIS FERNANDO DELGADILLO CORONANo ratings yet

- DRM450 InstallationDocument34 pagesDRM450 InstallationchanduNo ratings yet

- CSM Manual: Kalmar Industries Oy Ab P.O.Box 387 FIN-33101 Tampere FinlandDocument32 pagesCSM Manual: Kalmar Industries Oy Ab P.O.Box 387 FIN-33101 Tampere FinlandEdward Erney Salas ValenzuelaNo ratings yet

- Hydraulic valve block and solenoid functionsDocument8 pagesHydraulic valve block and solenoid functionsThanh CongNo ratings yet

- 07 Circuit Diagram Bromma DN4759070 A 1Document21 pages07 Circuit Diagram Bromma DN4759070 A 1phanhiep356No ratings yet

- Services Quick Reference Guide: QRG-2021-02-26-revision - Indd 1Document104 pagesServices Quick Reference Guide: QRG-2021-02-26-revision - Indd 1MahmoudNo ratings yet

- Operations Manual: Bromma Telescopic SpreaderDocument290 pagesOperations Manual: Bromma Telescopic Spreaderkron32No ratings yet

- 7 - Bus Bar & Ducts - YearlyDocument3 pages7 - Bus Bar & Ducts - Yearlyrishimaran100% (1)

- Flacs CFD ManualDocument658 pagesFlacs CFD ManualCyanNo ratings yet

- PSA Crane Spreader Cable Reel Data ProjeDocument72 pagesPSA Crane Spreader Cable Reel Data ProjeCristel Rodríguez BarríaNo ratings yet

- Service-Products TPS PDFDocument39 pagesService-Products TPS PDFJack CorreiaNo ratings yet

- SSX40 TrainingDocument20 pagesSSX40 TrainingDavid Adeola OgunyemiNo ratings yet

- RT378 379 Spreader Electrical Schematics BRMY ARF 1849-15-21268 70 - ADocument44 pagesRT378 379 Spreader Electrical Schematics BRMY ARF 1849-15-21268 70 - AMIGUEL PEÑANo ratings yet

- B-Repair Ad Maintenance Manual - Rev0Document82 pagesB-Repair Ad Maintenance Manual - Rev0Carlos Alberto Cortes OlivanNo ratings yet

- U2Asa: Double Angle Sensor Unit: Electrical CharacteristicsDocument2 pagesU2Asa: Double Angle Sensor Unit: Electrical CharacteristicsEngenharia03100% (1)

- SCU IntroductionDocument10 pagesSCU IntroductionMahen PereraNo ratings yet

- BGS ManualDocument144 pagesBGS ManualSubhaanNo ratings yet

- Rubber Tyre Gantry ReportDocument2 pagesRubber Tyre Gantry Reportdjrashid100% (1)

- Checklist For QCDocument12 pagesChecklist For QCvistalmarlonNo ratings yet

- Part of My Book of Preventive MaibtenanceDocument5 pagesPart of My Book of Preventive MaibtenanceMohamed Elnagdy0% (1)

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- 01 - General InformationDocument27 pages01 - General InformationFarah Omar Farah100% (1)

- C1574 (Q432118) User Manual Emerson IMHC1210 ItalGruuDocument39 pagesC1574 (Q432118) User Manual Emerson IMHC1210 ItalGruumliugongNo ratings yet

- 2632-1266-9900 StinisDocument302 pages2632-1266-9900 StinisJugaro OscarNo ratings yet

- KC SC Spreader en 01Document7 pagesKC SC Spreader en 01Mohammed Muzzammil100% (1)

- Expand Your Reach: Large Crane FamilyDocument5 pagesExpand Your Reach: Large Crane FamilyaltogarNo ratings yet

- Apm Terminals Hopper Manual: Port of CallaoDocument34 pagesApm Terminals Hopper Manual: Port of CallaoSaray Fernández SaavedraNo ratings yet

- B222 Drive Axle ModuleDocument36 pagesB222 Drive Axle ModuleMartin Vargas PedroNo ratings yet

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- "Big Red": Empty Container Handler Preliminary SpecificationsDocument4 pages"Big Red": Empty Container Handler Preliminary SpecificationsNeil DesaiNo ratings yet

- Load Moment Indicator: Maintenance and Operator's ManualDocument42 pagesLoad Moment Indicator: Maintenance and Operator's Manualилья100% (1)

- SMV Electric - DiagramsDocument7 pagesSMV Electric - Diagramshydro tec100% (1)

- Demag Crawler Cranes Spec CC1800 (300T)Document58 pagesDemag Crawler Cranes Spec CC1800 (300T)hariridkNo ratings yet

- RunnTech RT90 Series Multi-Axis Cobra Shaped Knob Joystick Controller - Password - RemovedDocument1 pageRunnTech RT90 Series Multi-Axis Cobra Shaped Knob Joystick Controller - Password - RemovedARTMehr Eng. GroupNo ratings yet

- الحسابات الهيدروليكية لأنظمة الإطفاءDocument7 pagesالحسابات الهيدروليكية لأنظمة الإطفاءhamadelsawi0% (1)

- Hyster j2 2 3 5xnDocument12 pagesHyster j2 2 3 5xnBraveBoy JalloNo ratings yet

- Transmision Meritor 9 Y10 Velocidades Mm99106Document3 pagesTransmision Meritor 9 Y10 Velocidades Mm99106leNo ratings yet

- Textiles and Clothing SustaninabilityDocument134 pagesTextiles and Clothing Sustaninabilitydike100% (1)

- Hydraulic Cleanliness Procedures: MaintenanceDocument24 pagesHydraulic Cleanliness Procedures: MaintenanceEsjoNo ratings yet

- SteelsDocument72 pagesSteelsLLNo ratings yet

- BD F118S en WW - LDocument12 pagesBD F118S en WW - LyusufNo ratings yet

- COOLING (Figure 2-45) : Unit Code B222 Europe 08/2007Document2 pagesCOOLING (Figure 2-45) : Unit Code B222 Europe 08/2007ncthanhckNo ratings yet

- Gantrex installs short rails on 5 quay cranesDocument12 pagesGantrex installs short rails on 5 quay cranesjhon jairo arangoNo ratings yet

- PSC Reachstackers & Heavy Lift TrucksDocument8 pagesPSC Reachstackers & Heavy Lift TrucksPinki SahayNo ratings yet

- 06 Drive AxleDocument25 pages06 Drive AxlegsrNo ratings yet

- Kalmar PDFDocument8 pagesKalmar PDFSimion PetruNo ratings yet

- hệ thống thủy lực DRF 450Document51 pageshệ thống thủy lực DRF 450Đại Anh HùngNo ratings yet

- Fantuzzi Reachstacker Cs 45 KM: Technical CharacteristicDocument9 pagesFantuzzi Reachstacker Cs 45 KM: Technical Characteristicwill wuNo ratings yet

- Hydraulic Plate: PART NO. 1638190 2000 SRM 1258Document30 pagesHydraulic Plate: PART NO. 1638190 2000 SRM 1258Juanjo Garcia JimenezNo ratings yet

- RAM Revolver for Fast, Flexible Containerized Bulk HandlingDocument4 pagesRAM Revolver for Fast, Flexible Containerized Bulk HandlingMarcos Rivera0% (1)

- 04.7A List of Faults NSC-E E V3.04 PDFDocument32 pages04.7A List of Faults NSC-E E V3.04 PDFAsfandyar KiyaniNo ratings yet

- 1t36Fw6 EeyXoKnOOj2WyxsHXiHvAZPKe PDFDocument150 pages1t36Fw6 EeyXoKnOOj2WyxsHXiHvAZPKe PDFANH LÊNo ratings yet

- BOOMDocument28 pagesBOOMDatNo ratings yet

- Adjust slewing gear valve block and motor speedsDocument3 pagesAdjust slewing gear valve block and motor speedsHERNANDO A BECERRANo ratings yet

- Cracks in STS SpreadersDocument3 pagesCracks in STS SpreadersMohamed Elnagdy100% (1)

- Weight Reduction of Reach Stacker (Konecrane)Document111 pagesWeight Reduction of Reach Stacker (Konecrane)Bruno SantosNo ratings yet

- D3549 2Document14 pagesD3549 2Minh Canh100% (1)

- Crane Operators Manual GuideDocument14 pagesCrane Operators Manual GuideDante WilliamsNo ratings yet

- Bromma Manual Electrical Circuit DiagramDocument45 pagesBromma Manual Electrical Circuit DiagramMalindaNo ratings yet

- Electric Reach Trucks Capacity 1400-2000 kg Technical SpecsDocument6 pagesElectric Reach Trucks Capacity 1400-2000 kg Technical Specsingenioso23No ratings yet

- Comp ElectricosDocument31 pagesComp ElectricosEdgardo Alfonso Ilabaca SaezNo ratings yet

- Crane Wheel Bearing Dimensions and SpecificationsDocument1 pageCrane Wheel Bearing Dimensions and SpecificationsayavuzbvsNo ratings yet

- Piston Pumps Series P2 / P3: Variable DisplacementDocument52 pagesPiston Pumps Series P2 / P3: Variable DisplacementHASSANI AdelNo ratings yet

- Kam Hybrid - ToC Europe - 090610v2Document31 pagesKam Hybrid - ToC Europe - 090610v2sajjad_naghdi241No ratings yet

- Letter of Handover10.07.2023Document1 pageLetter of Handover10.07.2023Oleksandr IvanovNo ratings yet

- Corrective-Prevention Actions Follow Up 2013Document2,651 pagesCorrective-Prevention Actions Follow Up 2013Mohammed AtefNo ratings yet

- Bm106 Container SecuringDocument6 pagesBm106 Container SecuringMohammed AtefNo ratings yet

- Fes TBT Mobile CraneDocument1 pageFes TBT Mobile CraneMohammed AtefNo ratings yet

- (From WWW - Metacafe.com) 1089734.6090630.1Document38 pages(From WWW - Metacafe.com) 1089734.6090630.1Mohammed AtefNo ratings yet

- (From WWW - Metacafe.com) 1089734.6090630.1Document38 pages(From WWW - Metacafe.com) 1089734.6090630.1Mohammed AtefNo ratings yet

- Stowage and Securing of Containers: BriefingDocument6 pagesStowage and Securing of Containers: BriefingMohammed AtefNo ratings yet

- DPTCurriculum GuideDocument8 pagesDPTCurriculum GuideMohammed AtefNo ratings yet

- Free SmsDocument6 pagesFree SmsArafat Al-eaziNo ratings yet

- Tutoring LogDocument1 pageTutoring LogMohammed AtefNo ratings yet

- Pickup 08 AccidentDocument14 pagesPickup 08 AccidentMohammed AtefNo ratings yet

- دورة الرفع والتصبين الآمن (Lifting & Rigging) 2Document4 pagesدورة الرفع والتصبين الآمن (Lifting & Rigging) 2Mohammed AtefNo ratings yet

- Safety Cages Under SpreaderDocument4 pagesSafety Cages Under SpreaderMohammed AtefNo ratings yet

- Fes TBT Lifing OperatsDocument1 pageFes TBT Lifing OperatsMohammed AtefNo ratings yet

- Fes TBT SlingsDocument1 pageFes TBT SlingsMohammed AtefNo ratings yet

- PMPDocument1 pagePMPMohammed AtefNo ratings yet

- السقالات نهائيDocument3 pagesالسقالات نهائيMohammed AtefNo ratings yet

- Pickup 08 AccidentDocument14 pagesPickup 08 AccidentMohammed AtefNo ratings yet

- Behavioral Based Safety (BBS) & Safety Leadership, 04 - 08 November 2012 DubaiDocument4 pagesBehavioral Based Safety (BBS) & Safety Leadership, 04 - 08 November 2012 Dubai360 BSINo ratings yet

- Truck 137 Hit Truck 48Document18 pagesTruck 137 Hit Truck 48Mohammed AtefNo ratings yet

- Army Individual Safety CardDocument10 pagesArmy Individual Safety CardDori BearNo ratings yet

- Fuel Safety Criteria - Tech Review (Csni-R99-25) (2000) WWDocument49 pagesFuel Safety Criteria - Tech Review (Csni-R99-25) (2000) WWMohammed AtefNo ratings yet

- Johan Bruekelaar - APM Terminals ICHCA PresentationDocument17 pagesJohan Bruekelaar - APM Terminals ICHCA PresentationMohammed AtefNo ratings yet

- Risk 2Document5 pagesRisk 2Mohammed AtefNo ratings yet

- Us Army Field Artillery School: Electrical/Electronic SafetyDocument10 pagesUs Army Field Artillery School: Electrical/Electronic SafetyMohammed AtefNo ratings yet

- Bulletin Officehazards Oct04Document2 pagesBulletin Officehazards Oct04Mohammed AtefNo ratings yet

- 01-44 Fall From Height, FatalityDocument2 pages01-44 Fall From Height, FatalityMohammed AtefNo ratings yet

- Deskripsi (Caffein)Document4 pagesDeskripsi (Caffein)jibefahlaNo ratings yet

- Foreign Body Airway ObstructionDocument6 pagesForeign Body Airway ObstructionReeja RajeshNo ratings yet

- Generador APD550PEDocument4 pagesGenerador APD550PEFTL1990No ratings yet

- Catalogus 2010 ENGELSDocument52 pagesCatalogus 2010 ENGELShacikadiNo ratings yet

- When Ceramic Sociology Meets Material SCDocument10 pagesWhen Ceramic Sociology Meets Material SCJosé Renato TeixeiraNo ratings yet

- Genética, Modificaciones y MutacionesDocument12 pagesGenética, Modificaciones y MutacionespokemaniacoplancheNo ratings yet

- yudaturana,+Manajer+Jurnal,+dr +nelson+rev+2+ (162-172)Document12 pagesyudaturana,+Manajer+Jurnal,+dr +nelson+rev+2+ (162-172)Fath TiaraNo ratings yet

- Cattlemans Steakhouse MenuDocument1 pageCattlemans Steakhouse Menuapi-300741654No ratings yet

- Design Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment ICDocument3 pagesDesign Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment IClagnajit dasNo ratings yet

- Comparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010Document6 pagesComparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010mtanaydinNo ratings yet

- VSD Power Supply Connections and EarthingDocument4 pagesVSD Power Supply Connections and EarthingHumaid ShaikhNo ratings yet

- Reles, Fuentes, Etc. Catalogo - ABBDocument452 pagesReles, Fuentes, Etc. Catalogo - ABBmpica100% (1)

- Sponge BobDocument4 pagesSponge BobchabriesNo ratings yet

- History of FlightDocument10 pagesHistory of FlightHanin AlanaziNo ratings yet

- Cs Project Book ManagementDocument22 pagesCs Project Book ManagementabNo ratings yet

- EniSpA - The Corporate Strategy of An International Energy Major PDFDocument24 pagesEniSpA - The Corporate Strategy of An International Energy Major PDFAnonymous 9ZMbuR75% (4)

- Validation of Correlations Between A NSPT PDFDocument12 pagesValidation of Correlations Between A NSPT PDFAgus WahyudiNo ratings yet

- Week 7: Nurses Role in Disaster: Home Mitigation and PreparednessDocument10 pagesWeek 7: Nurses Role in Disaster: Home Mitigation and PreparednessRose Ann LacuarinNo ratings yet

- Pneumatic Pruning Equipment American Arborist Supplies, Tree Care, Climbing EquipmentDocument1 pagePneumatic Pruning Equipment American Arborist Supplies, Tree Care, Climbing EquipmentSalman JoNo ratings yet

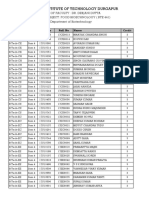

- List of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFDocument26 pagesList of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFArpan JaiswalNo ratings yet

- NTPC Training ReportDocument83 pagesNTPC Training ReportAbhishek Mittal100% (2)

- Explore the beaches and parks of Labuan IslandDocument2 pagesExplore the beaches and parks of Labuan IslandDudeNo ratings yet

- Erasmus Rotterdam University MCDocument24 pagesErasmus Rotterdam University MCAndreea CroitoruNo ratings yet

- Sliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallDocument4 pagesSliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallAbdul Aziz Julkarnain ZulkifliNo ratings yet