Professional Documents

Culture Documents

Structural Glass

Uploaded by

hamiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Glass

Uploaded by

hamiCopyright:

Available Formats

PROJECT :

CLIENT :

JOB NO. :

DATE :

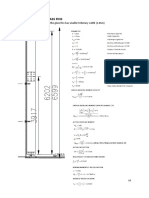

Structural Glass Design, Based on ASTM E1300 & CAN/CGSB-12.20, using Finite Element Method

INPUT DATA & DESIGN SUMMARY

GLASS PANEL SIZE

GLASS PANEL THICKNESS

Weight =

77

W=

L=

1.5

5

PAGE :

DESIGN BY :

REVIEW BY :

ft, (457 mm)

ft, (1524 mm)

t = 0.787402 in, (20 mm)

lbs, (35 kg)

CONNECTION TYPE ( 0 or 1)

, only corner pinned.

allow =

ALLOWABLE GLASS STRENGTH

3.5

ksi,

(24 N / mm2)

(Annealed: 3.5 ksi, Heat-strengthened: 6.5 ksi, Tempered: 14.5 ksi - verify reqd.)

ALLOWABLE DEFLECTION

L / 240

( The max value suggested: L / 60 for window or curtain wall, L / 180 for stair.)

UNIFORM AREA LOAD (Perpendicular to Plane)

POINT LOAD (Including Impact Factor)

D=

P=

10

0.3

psf, ASD level

kips, ASD level

THE DESIGN IS ADEQUATE.

ANALYSIS

GLASS PROPERTIES

=

E=

=

156

10150

0.22

lbs / ft3 (2500 kg / m3)

ksi (70 kN / mm2)

, Poisson's ratio

JOINT DEFLECTIONS, REACTIONS, & PLATE SECTION FORCES

P=

0.3

kips,( Point load at Joint 9.)

Joint

Number

1

2

3

4

5

6

7

8

9

in

0

0.14

0.21

0.00

0.14

0.21

0.00

0.14

0.21

R

kips

-0.09

CHECK BENDING CAPACITY

Mn / b = allow d t2/ 6 =

Where

CHECK DEFLECTION

max =

Where

4.34

d=

12

M = (M6-92 + M8-92 )0.5 =

0.21

Bending

Section

7-8

8-9

3-6

6-9

in

L = Max (L , W) =

M

ft-k/ft

0.03

0.04

0.42

0.42

ft-k/ft

>

M=

[Satisfactory]

0.42

ft-k/ft

0.42

ft-k/ft

in, (1 ft)

<

[Satisfactory]

60.0

in

L / 240

0.25

in

You might also like

- Design Calculation-Glass BalustradeDocument8 pagesDesign Calculation-Glass Balustrademsiddiq1100% (2)

- DESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m HeightDocument15 pagesDESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m Heightmsiddiq1100% (2)

- Glass PanelDocument2 pagesGlass PanelEIWAA50% (2)

- Glass Fin Calculation in LTBDocument7 pagesGlass Fin Calculation in LTBAmro Ahmad Ali100% (2)

- Curtain Wall CalculationDocument8 pagesCurtain Wall CalculationKenneth OkoyeNo ratings yet

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Document29 pages10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- Astm E1300Document8 pagesAstm E1300ARYA100% (1)

- Bolted Connection in Glass StructureDocument52 pagesBolted Connection in Glass StructureCristiana Gruia-Paun100% (2)

- Fin Glass 6Document6 pagesFin Glass 6EIWAA100% (1)

- Project Name: Glass BalustradeDocument11 pagesProject Name: Glass BalustradeNp Pw100% (1)

- LGS Facade Wall Design Calculation SampleDocument62 pagesLGS Facade Wall Design Calculation SampleWaqas HaiderNo ratings yet

- Structural Glass DesignDocument84 pagesStructural Glass Designgks6043100% (4)

- Design Calculations For Aluminium Profile-13795Document8 pagesDesign Calculations For Aluminium Profile-13795msiddiq1100% (1)

- Aluminium Mullion AnalysissDocument24 pagesAluminium Mullion Analysissvtalex100% (4)

- Sg12 Frameless Balustrades Structural CalculationsDocument12 pagesSg12 Frameless Balustrades Structural CalculationsAhmed Mohamed LabibNo ratings yet

- Balustrade GlassDocument13 pagesBalustrade GlassARYANo ratings yet

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- Glass DeflectionDocument1 pageGlass Deflectionwaweng22No ratings yet

- CalculationDocument1 pageCalculationLaurence Sarmiento100% (1)

- Structural Glass Design-BS6399Document6 pagesStructural Glass Design-BS6399msiddiq1100% (2)

- Structural Glass Design-UBCDocument6 pagesStructural Glass Design-UBCmsiddiq1100% (1)

- Glass Laminate Thicness - No Reduc For Cantilever GlassDocument1 pageGlass Laminate Thicness - No Reduc For Cantilever GlassLaurence Sarmiento100% (1)

- Glass CheckDocument7 pagesGlass CheckMuraleedharanNo ratings yet

- Excel For Glass FinDocument4 pagesExcel For Glass FinZaido Al HalabiNo ratings yet

- Deflection ASTM E1300-02Document1 pageDeflection ASTM E1300-02Albert de GuzmanNo ratings yet

- SKYLIGHT REPORT - Rev 01Document16 pagesSKYLIGHT REPORT - Rev 01Muraleedharan100% (1)

- Design of Mullion-BS enDocument16 pagesDesign of Mullion-BS enPrasad kapure100% (1)

- Curtain Wall-Report REv 1-10-21Document11 pagesCurtain Wall-Report REv 1-10-21MuraleedharanNo ratings yet

- 1analysis For Curtain Wall GlassDocument2 pages1analysis For Curtain Wall GlassEIWAANo ratings yet

- Glass BalustradeDocument7 pagesGlass BalustradeARYANo ratings yet

- Structural Glass Design-CP3Document5 pagesStructural Glass Design-CP3msiddiq1No ratings yet

- Alum SampleDocument2 pagesAlum Samplewaweng22No ratings yet

- Bolted Glass AssembliesDocument4 pagesBolted Glass AssembliesTomás Aires PereiraNo ratings yet

- Standard Practice For Determining Load Resistance of Glass in BuildingsDocument62 pagesStandard Practice For Determining Load Resistance of Glass in BuildingsBegging CoinsNo ratings yet

- Fin Glass 6Document4 pagesFin Glass 6EIWAANo ratings yet

- The Dubai Chamber of Commerce and Industry Building ExtensionDocument22 pagesThe Dubai Chamber of Commerce and Industry Building ExtensionAhammad KabeerNo ratings yet

- Calculation Sheet 0Document10 pagesCalculation Sheet 0Bahiya Al-rifaiiNo ratings yet

- Glass Design CalculationDocument15 pagesGlass Design CalculationAnand100% (1)

- Design Calculations For Aluminium Profile 13794Document14 pagesDesign Calculations For Aluminium Profile 13794Wilson PesantezNo ratings yet

- 1-1) Typical Glass Balustrade PanelDocument7 pages1-1) Typical Glass Balustrade PaneldanieldumapitNo ratings yet

- As1288 Glass Deflection CriteriaDocument1 pageAs1288 Glass Deflection Criteriaahsan khanNo ratings yet

- ConnectionDocument2 pagesConnectionEIWAANo ratings yet

- Curtain Wall Glazing Stick System CALCUL PDFDocument11 pagesCurtain Wall Glazing Stick System CALCUL PDFAli SaifNo ratings yet

- Advanced Design of Glass Structures - Lecture 8 - General Design GuidelinesDocument34 pagesAdvanced Design of Glass Structures - Lecture 8 - General Design GuidelinesMauricio Riquelme100% (1)

- SJ Mepla Handbuch Programm EngDocument53 pagesSJ Mepla Handbuch Programm Engromanbulugin100% (1)

- Check For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Document5 pagesCheck For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Laurence SarmientoNo ratings yet

- SSG Manual: Dow Performance SiliconesDocument59 pagesSSG Manual: Dow Performance SiliconesAditya KNo ratings yet

- 200205-MYH-MYS-000-021 Structural Analysis of Aluminum Cladding Under Co...Document74 pages200205-MYH-MYS-000-021 Structural Analysis of Aluminum Cladding Under Co...Dana KadriNo ratings yet

- Design of Glass ColumnDocument8 pagesDesign of Glass ColumnCristiana Gruia-PaunNo ratings yet

- Structural Calculation Curtain WallDocument93 pagesStructural Calculation Curtain Wallashaswamy100% (1)

- Structural Calculation of Link Bridge Curtain Wall 20160930Document94 pagesStructural Calculation of Link Bridge Curtain Wall 20160930Ronald RoblesNo ratings yet

- 10th Aug. 2011 Structural Calculation (For Sub.) - 05Document26 pages10th Aug. 2011 Structural Calculation (For Sub.) - 05Nguyễn Tiến ViệtNo ratings yet

- Structural GlassDocument1 pageStructural GlassEr Chandra BoseNo ratings yet

- The Design Is Inadequate, See AnalysisDocument1 pageThe Design Is Inadequate, See AnalysisZiyad MonierNo ratings yet

- Structural GlassDocument1 pageStructural GlassBoy BangusNo ratings yet

- Structural GlassDocument1 pageStructural GlassErick Santiago CubillosNo ratings yet

- Basement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryDocument46 pagesBasement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryHizbar ArsjadNo ratings yet

- WarehouseDocument51 pagesWarehouseAnonymous q0irDXlWAm100% (2)

- Structural GlassDocument1 pageStructural GlassFred SalgadoNo ratings yet

- Concrete DesignDocument169 pagesConcrete DesignabuzahrauNo ratings yet

- Rc:Prngnpiy Unit Bis. NRW Drlhi. IndiaDocument1 pageRc:Prngnpiy Unit Bis. NRW Drlhi. Indiasamgivp2869No ratings yet

- Dolby 3D For DevicesDocument0 pagesDolby 3D For Devicessamgivp2869No ratings yet

- GRACO King 45-1 PartsDocument10 pagesGRACO King 45-1 Partssamgivp2869No ratings yet

- Zurich Vista Switch FormDocument1 pageZurich Vista Switch Formsamgivp2869100% (1)

- Obaid Hareb Building Contracting LLC: "Turnkey Structural Solutions"Document6 pagesObaid Hareb Building Contracting LLC: "Turnkey Structural Solutions"samgivp2869No ratings yet

- Beam - Column Connection - Ver W2.5.04 - 20 Jul 2010 Title: Code of Practice: Created: Notes and AssumptionsDocument14 pagesBeam - Column Connection - Ver W2.5.04 - 20 Jul 2010 Title: Code of Practice: Created: Notes and Assumptionssamgivp2869No ratings yet

- Honeywell Eng. ProfileDocument6 pagesHoneywell Eng. Profilesamgivp2869No ratings yet