Professional Documents

Culture Documents

Biogàs PDF

Uploaded by

Demian VeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biogàs PDF

Uploaded by

Demian VeCopyright:

Available Formats

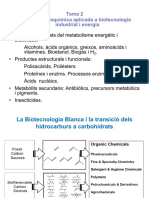

Biomassa, Biocombustibles i

Biogs

Biomassa, Biocombustibles i Biogs

Biogs

Biomasa:

Fuente renovable de carbn a partir de materia virgen o

residuos orgnicos.

Combustible con un almacenamiento de energa solar reciente:

no fsil.

Fuente: Energas Renovables. J. Gonzlez. Ed. Revert. 2009

Biomassa, Biocombustibles i Biogs

Biogs

6 CO2 ( g ) 6H 2O(l )

chlorophyll

sunlight

C6 H12O6 ( s ) 6 O2 ( g )

H o 2,8103 kJ

For each mole of carbon fixed (MC=12 gmol-1) is required 470 kJ (112 kcal)

Biomassa, Biocombustibles i Biogs

Biogs

Fuente: ainia

Biomassa, Biocombustibles i Biogs

Biogs

Biomassa, Biocombustibles i Biogs

How can we recover the energy contained in the biomass?

Thermal conversion

Combustion

Pyrolysis

Gasification (Syngas)

Biogs

Biological conversion

Anaerobic digestion (biogas)

Fermentation

Biomassa, Biocombustibles i Biogs

Biogs

Biomassa, Biocombustibles i Biogs

Biogs

Biomassa, Biocombustibles i Biogs

Biogs

HHV (Higher Heating Value). USA

LHV (Lower Heating Value). Europa

Biomassa, Biocombustibles i Biogs

Biogs

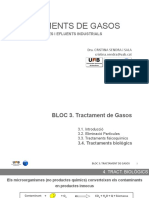

Biogas typically refers to a (biofuel) gas produced by the

anaerobic digestion or fermentation of organic matter including

manure, sewage sludge, municipal solid waste, biodegradable

waste or any other biodegradable feedstock, under anaerobic

conditions. Biogas is comprised primarily of methane and carbon

dioxide.

The natural generation of biogas is an important part of the

biogeochemical carbon cycle. Methanogens (methane producing

bacteria) are the last link in a chain of micro-organisms which

degrade organic material and return the decomposition products

to the environment. In this process biogas is generated, a source

of renewable energy.

Biomassa, Biocombustibles i Biogs

Biogs

Fuente: ainia

Biomassa, Biocombustibles i Biogs

Biogs

Fuente: Biogas from waste and renewable resources. D. Deublin & A. Steinhauser. Wiley-VCH. 2008

Biomassa, Biocombustibles i Biogs

Biogs

Biomassa, Biocombustibles i Biogs

Biogs

EurObservER 2008

Landfill gas

Urban sewage and industrial

effluents

Agricultural waste, MSW,

OFMSW, co-digestion plants

Biomassa, Biocombustibles i Biogs

Biogs

Anaerobic digestion advantages

The main advantages of the AD technology are:

- Stabilize organic matter

- Feasible for a wide variety of waste and flow rates

- Reduce greenhouse gases emission global warming

- Low sludge production

- Positive energy balance

Energy from biogas

Low operational cost

- No or very little use of chemicals

Biomassa, Biocombustibles i Biogs

Biogs

Which wastes can be anaerobically digested?

AD has long been used to stabilize organic wastes before its final

disposal.

Today, AD is a consolidated technology used to stabilize:

- Sewage sludge from wastewater treatment plants

- Municipal solid wastes (MSW)

- Industrial wastewaters

- Agricultural wastes

- animal manure

- crops waste

16

Biomassa, Biocombustibles i Biogs

Biogs

Biogas energy value

Biogas can be used in a combustion heat and power unit (CHP) to

produce electricity and another form of energy (steam or hot water).

> Methane lower heating value is 35,800 KJ/m 3

> Natural gas* heating value is 37,300 KJ/m 3

Biogas lower heating value range from 21,300 to

23,400 KJ/m3 as function of the % CH4

An estimation of the lower heating value of

biogas can be done by:

Biogas heating value (kJ/m3 )

35,800

% CH 4

100

* Natural gas is a mixture of methane, propane and butane.

Biomassa, Biocombustibles i Biogs

Biogs

6 CO2 ( g ) 6H 2O(l )

sunlight chlorophyll

C6 H12O6 ( s ) 6 O2 ( g )

Mean components of plants without N and S:

Carbohydrates: Starch, inulin, cellulose, sugar, pectin

Fat: Fat, fatty acids, oil, phophatides, waxes, carotene

Protein: Protein, nucleoproteid, phosphoproteid

Other: Vitamins, enzymes, resins, toxins, etc..

Average elementary composition of plants dry matter:

C38H60O26

Cc H hOo N n S s + yH 2O xCH 4 + (c - x)CO2 + nNH 3 + sH2 S

Where:

X = 0.125(4c+h-2o-3n+2s)

y = 0.250(4c-h-2o+3n+2s)

or, simplified

Cc H hOo (

c h o

- )CH 4

2 8 4

Biomassa, Biocombustibles i Biogs

Biogs

Biomassa, Biocombustibles i Biogs

Biogas C. Biolgica

Biogs

10

Biomassa, Biocombustibles i Biogs

AD scheme*

Biogs

* Gujer and Zehnder, 1983

Biomassa, Biocombustibles i Biogs

Biogs

11

Biomassa, Biocombustibles i Biogs

Biogs

Biomassa, Biocombustibles i Biogs

ADM1 scheme

Biogs

12

Biomassa, Biocombustibles i Biogs

Biogs

ADM1 scheme

A.

Desintegration

B. Hydrolysis

Sugar fermentation

Amino acids fermentation

LCFA degradation

Propionate degradation

Valeric/butiric degradation

Acetate Methanogesis

H2 Methanogesis

25

Biomassa, Biocombustibles i Biogs

Total and volatile solids

Biogs

Total solids (TS)

The material left in a crucible after drying a sample, overnight, in an oven at

103 105 C.

Fixed solid (FS)

The remaining solids after igniting a previously dried sample during 2 hours

at 550 C.

Volatile solid (VS or TVS)

The weight loss when the dried sample was ignited

13

Biomassa, Biocombustibles i Biogs

Biogs

Substrate

Also known as feedstock, waste, influent, input, food supply,

Substrate characterization:

ORGANIC MATTER:

ORGANIC COMPOUNDS:

- Solids (TS, FS, VS)

- Proteins

- Suspended solids (TSS, VSS)

- Lipids

- COD (total and soluble)

- Carbohydrates

- BOD

- Fibrers (cellulose, hemicellulose, lignin)

- TOC and DOC

NUTRIENTS:

- TKN

- TAN

- Total Phosphorous

Acid-base properties:

- pH

- VFA

- Alkalinity

ELEMENTAL COMPOSITION:

- C, H, N, O, P and S

HEAVY METALS:

- Cr, Co, Cu, Fe, Hg, Mn, Mo,

Ni, Zn,

Biomassa, Biocombustibles i Biogs

Biogs

Total and volatile solids

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

% H20

gr

ai

n

e

ce

r in

Ba

rle

y

G

ly

sil

ag

e

ai

ze

Ba

rle

y

be

et

SW

% FS

Su

ga

r

O

FM

m

an

ur

e

Ra

pe

Ca

ttl

e

O

ra

ng

e

Pe

ar

Ap

pl

e

an

ur

e

Su

nf

lo

we

r

m

g

Pi

W

W

TP

slu

dg

e

0%

% VS

14

Biomassa, Biocombustibles i Biogs

Biogs

Hydraulic Retention Time

It is defined as the ratio of the reactor volume to the influent substrate

flow rate. Thus, it is a measure of the average time that the substrate

spends inside the digester:

HRT (days)

V

Q

Solid Retention Time

It is the average retention time which the sludge has remained in the

system:

SRT days

V X reactor

X

HRT reactor

Q X effluent

X effluent

Organic Loading Rate

Is the amount of substrate introduced into the digester volume in a given time:

kg SV Q S

S

OLR 3

HRT

m digesterday V

Biomassa, Biocombustibles i Biogs

Biogs

Biogas yield

Specific Gas Production (SGP)

It is the biogas produced per unit of substrate fed.

m3 biogas

SGP

kg SV

Q biogas

Q S

Gas Production Rate (GPR)

It is the biogas production per m3 of digester and day.

m3 biogas Q biogas

GPR 3

V

m digesterday

30

15

Biomassa, Biocombustibles i Biogs

Biogs

Chemical Oxygen Demand

The Chemical Oxygen Demand (COD) is an indirect measure of the

organic matter.

It is defined as the amount of oxygen required to oxidize the matter

present in the sample, using a strong oxidizing agent under acid

conditions.

COD is expressed in terms of mg O2 L-1.

Biomassa, Biocombustibles i Biogs

Biogs

Biodegradability

Substrate removal yield

SMP (L methane / kg SV)

150

125

100

VS removal

75

B0 = 140 L / kg VS

50

VS 0 VS f

100

VS 0

25

0

0

10

12

14

16

18

20

22

24

26

28

30

days

CODremoval

COD0 CODf

100

COD0

Bo

VSo

Initial SV

Anaerobic

VSf

Digester

Final VS

Non biodegradable organic matter

16

Biomassa, Biocombustibles i Biogs

Biogs

Kinetic information from biodegradability test

SMP (L methane / kg SV)

150

Bo

125

100

75

50

Anaerobic

VSo

VSf

Digester

25

0

0

10

12

14

16

18

20

22

24

26

28

30

days

Considering first order kinetics:

The evolution of the VS concentration is obtained from:

S

kS

t

St Si e kt

However, the evolution of these parameters is difficult.

Biomassa, Biocombustibles i Biogs

Biogs

En el proceso de digestin anaerobia, el valor energtico de la biomasa se

mide con unidades de demanda qumica de oxigeno DQO (chemical oxygen

demand COD)

Cada unidad de COD digestado da como resultado 5.6 m3 de metano

Una digestin anaerobia efectiva generalmente convierte el 90% del COD

disponible en metano

Cada m3 de metano produce aproximadamente 1,000 BTU (British Thermal

Unit; 1 BTU 252,2 cal 1055 J) de energa.

17

Biomassa, Biocombustibles i Biogs

Biogs

Nutrientes

COD/N/P 600/7/1

C/N 25/1

Otros micronutrientes: Fe, Ni, Mg, Ca, Na, Ba, Mo, Se, Co,

vitaminas.

Substancias txicas

En baja concentracin: efectos beneficiosos

Alta concentracin: efectos inhibidores o txicos

VAF (cidos grasos voltiles) producidos en la primera fase

NH3/NH4+, H2S, SO42-, O2, metales pesados.

Biomassa, Biocombustibles i Biogs

Biogs

Factores que intervienen en el proceso

de digestin anaerobia

Nutrientes

Substancias txicas

Temperatura

pH

Potencial redox

18

Biomassa, Biocombustibles i Biogs

Biogs

Temperature range

for anaerobic

digestion. Optima are

for mesophilic

around 30-35C and

for thermophilic

around 55-60C.

Installed capacity

on both industrial

ranges of

temperature

(mesophilic and

thermophilic) for

anaerobic

digestion of

OFMSW.

Biomassa, Biocombustibles i Biogs

Residuos

Biogs

Residuos Slidos Urbanos

4a b 2c 3d

4a b 2c 3d

4a b 2c 3d

Ca H bOc N d

H 2O

CH 4

CO2 d NH 3

4

8

8

19

Biomassa, Biocombustibles i Biogs

Biogs

TRANSPORT

URBAN

COLLECTION

Bag of

organics

Heat

BIOGAS

CONDITIONING

Electricity

BIOMETHANIZATION

REACTOR

WASTEWATER

(Nutrient flow)

LIQUIDS

Filtration

SOLIDS

COMPOST

Biomassa, Biocombustibles i Biogs

Biogs

REACTOR CONFIGURATION

There are five basic reactors configurations:

- Expanded / Fluidized bed

- Anaerobic filter

Higher-rate AD

- UASB (Upflow Anaerobic Sludge Blanket)

- Anaerobic contact

- Two-stage digester

- CSTR (Continious Stirred Tank Reactor)

40

20

Biomassa, Biocombustibles i Biogs

Expanded / Fluidized bed

- The microorg. are attached to mobile carrier particles (sand,) to

Biogs

form

granular sludge which have good settling characteristics.

Expanded bed are more easily operated

Bed expansion, which generates good contact

between biomass and waste is due to:

High liquid velocities

Lifting action of the biogas

Biomassa, Biocombustibles i Biogs

Anaerobic filter

Biogs

- The microorg. are attached to the packing material

- Used for liquid wastes

- HRT << SRT

Problems:

Clogging of the bed

Overcome with a primary settler

21

Biomassa, Biocombustibles i Biogs

Biogs

UASB Upflow Anaerobic Sludge Blanket

In one of the most popular systems

- High SRT since biomass is aggregated (flocs or granules)

- Internal gas-liquid-solid separation system

- No mechanical mixing is needed

Treating agro-industrial wastewaters

Biomassa, Biocombustibles i Biogs

Biogs

UASB Upflow Anaerobic Sludge Blanket

The UASB is based in:

- Good contact between the biomass and the waste

- The gas collection device acts as a three

phase separator.

Problems:

Good inlet distribution necessary

Overcome with uniformly feeding

22

Biomassa, Biocombustibles i Biogs

Biogs

Anaerobic contact

- The recycle of the clarified increase the biomass conc. in the AD

- Used for pasty industrial waste

Problems:

Settleability of the sludge

Vacuum

Overcome with intermittent mixing,

degasifier

which give enhance sludge

sedimentation properties

Biomassa, Biocombustibles i Biogs

Biogs

Two-stage AD

Acidognic

Methanogenic

- To keep an equilibrium between acidogenic and methanogenic phases

- Each phase has its own HRT and operating Temperature

23

Biomassa, Biocombustibles i Biogs

Continuous stirred tank reactor (CSTR)

Biogs

- Cheap and very extended

- Void volume equipped with heating and stirring systems

- SRT = HRT; HRT is between 10 30 dyas

Biomassa, Biocombustibles i Biogs

Mixes digesters

Biogs

24

Biomassa, Biocombustibles i Biogs

Biogas C. Biolgica

Biogs

Biomassa, Biocombustibles i Biogs

Biogs

25

You might also like

- Ex Final 1a Conv.2014-15Document7 pagesEx Final 1a Conv.2014-15Gemma SánchezNo ratings yet

- Tema 1 Enginyeria Bioquímica I BiotecnologiaDocument40 pagesTema 1 Enginyeria Bioquímica I BiotecnologiaSara OzochiNo ratings yet

- Apuntes BioreactoresDocument103 pagesApuntes BioreactoresDarío Iruela OrtizNo ratings yet

- Memòria ExempleDocument77 pagesMemòria ExempleWallace A A GuedesNo ratings yet

- UF2 EDAR Teoria CompletaDocument302 pagesUF2 EDAR Teoria CompletaGiancarlo Vásquez BancesNo ratings yet

- Enginyeria de Processos Químics I BiotecnològicsDocument61 pagesEnginyeria de Processos Químics I BiotecnològicsrenatagdeoNo ratings yet

- Contaminacio Aigua - Sessió 6 I 7Document76 pagesContaminacio Aigua - Sessió 6 I 7Hanan AmarkiNo ratings yet

- Treball ReciclatgeDocument18 pagesTreball ReciclatgeCarla MurielNo ratings yet

- Problemes Tema 7Document2 pagesProblemes Tema 7FranlyLuhanNo ratings yet

- 01 BUA PresGeneral24Document90 pages01 BUA PresGeneral24rNo ratings yet

- Tercera Part TECE-T1-P3-2019-2020-Q1Document28 pagesTercera Part TECE-T1-P3-2019-2020-Q1Dani PerezNo ratings yet

- Unidad 2Document16 pagesUnidad 2Gerardo Feliú VarelaNo ratings yet

- U2 Catabolisme 2021 22Document27 pagesU2 Catabolisme 2021 22LAURA GIL FERNÁNDEZNo ratings yet

- Captura 2023-10-26 A Las 17.59.19Document1 pageCaptura 2023-10-26 A Las 17.59.19DavidNo ratings yet

- 01 Introducció MetabolismeDocument13 pages01 Introducció MetabolismeNatàlia Guerrero LópezNo ratings yet

- FE 2122 - Parcial 2Document3 pagesFE 2122 - Parcial 2Merce ArisaNo ratings yet

- 1 Pràctica BUNA 21-22Document3 pages1 Pràctica BUNA 21-22chaimae mokhtari khaledNo ratings yet

- Aeb Tema1 PDFDocument277 pagesAeb Tema1 PDFHasnae SalimNo ratings yet

- Alimentacio Baixa en Emissions D e CO2eq.Document26 pagesAlimentacio Baixa en Emissions D e CO2eq.Judit Cos BusquetsNo ratings yet

- Presentación Sostenibilidad y Ecología Scrapbook Ilustrado MarrónDocument9 pagesPresentación Sostenibilidad y Ecología Scrapbook Ilustrado Marrónariadna paytuviNo ratings yet

- TEMA 3 - Quimica - FinaDocument13 pagesTEMA 3 - Quimica - FinaMarta Gutierrez BarnetoNo ratings yet

- Central de BiomassaDocument15 pagesCentral de Biomassabmvives1No ratings yet

- TEMA 2.1 Marc Legal - ResidusDocument34 pagesTEMA 2.1 Marc Legal - Residusekisde zvoicerNo ratings yet

- EtudiReaccions Quimiques PDFDocument12 pagesEtudiReaccions Quimiques PDFJginer RiusNo ratings yet

- Aeb Tema2 22 23 PDFDocument184 pagesAeb Tema2 22 23 PDFHasnae SalimNo ratings yet

- Bloc 3 - 3.3 - Tractament de Gasos - Part 3Document36 pagesBloc 3 - 3.3 - Tractament de Gasos - Part 3Francesc Romero GómezNo ratings yet

- Termodinamica Dels Sistemes Biologics - Treball Practic - SolucionsDocument30 pagesTermodinamica Dels Sistemes Biologics - Treball Practic - SolucionsSurgaveryNo ratings yet

- Gsa Caso 1Document2 pagesGsa Caso 1gamerdrareg20No ratings yet

- Tema 3 - Combustió ATENEA 2019-20 Q2Document79 pagesTema 3 - Combustió ATENEA 2019-20 Q2Arnau ReyesNo ratings yet

- Infografía EscolarDocument1 pageInfografía EscolarMercedes Astals SunNo ratings yet

- Examen 26 - 2 - 19 M2 - UF2Document54 pagesExamen 26 - 2 - 19 M2 - UF2Dropu Nake100% (1)

- Parametres Dinamica EcosistemaDocument23 pagesParametres Dinamica EcosistemarannielbrynerNo ratings yet

- 3 El Metabolisme Dels Lípids I ProteïnesDocument45 pages3 El Metabolisme Dels Lípids I ProteïnesSergioNo ratings yet

- EXERCICIS2 Catabolisme PDFDocument12 pagesEXERCICIS2 Catabolisme PDFShota ImerNo ratings yet

- Practica 1 - Grup M.11 - Arnau, Pablo, JaumeDocument9 pagesPractica 1 - Grup M.11 - Arnau, Pablo, JaumearnauNo ratings yet

- A4. Exercicis U1Document3 pagesA4. Exercicis U1gamerdrareg20No ratings yet

- Teoria Biologia Semana 5Document13 pagesTeoria Biologia Semana 5Antonny Edson Aliaga TorresNo ratings yet

- Còpia de Problemes AiguaDocument1 pageCòpia de Problemes AiguasofianzeriouhibachaouiNo ratings yet

- Imprimir Resum TMADocument2 pagesImprimir Resum TMAmvraplicacionsNo ratings yet

- Tema 1 - F. Tecnologia - Done.Document16 pagesTema 1 - F. Tecnologia - Done.carla marchNo ratings yet

- 6.1 oPMDocument5 pages6.1 oPMAidaa CatalanNo ratings yet

- Practica 1Document6 pagesPractica 1ahmedahmed1991No ratings yet

- Cicle CarboniDocument66 pagesCicle CarboniManuNo ratings yet

- Pràctica Combustible 2Document3 pagesPràctica Combustible 2Paula Llidó FernándezNo ratings yet

- UNITAT 1. ELS RECURSOS ENERGÈTICS-Part 1eraDocument12 pagesUNITAT 1. ELS RECURSOS ENERGÈTICS-Part 1eraEric CasañéNo ratings yet

- EDAR Línia de FangsDocument36 pagesEDAR Línia de Fangstitielog13No ratings yet

- Equilibri Químic IIDocument17 pagesEquilibri Químic IImohamed bellaliNo ratings yet

- UD 3 Recursos EnergèticsDocument23 pagesUD 3 Recursos EnergèticsjoanromeobahamonruizNo ratings yet

- 22-23 Guio Cinètica MicrobianaDocument6 pages22-23 Guio Cinètica MicrobianaNina ChNo ratings yet

- Primer Examen An Âo PasadoDocument10 pagesPrimer Examen An Âo Pasadosaramartori.2002No ratings yet

- BioetanolDocument3 pagesBioetanolCristina LopezNo ratings yet

- Tema 4Document44 pagesTema 4Jennyfer PaizNo ratings yet

- Ejercicios TMA Final de 2023Document27 pagesEjercicios TMA Final de 2023FranlyLuhanNo ratings yet

- Guia Compostatge AGRICLOSEDocument108 pagesGuia Compostatge AGRICLOSEancanto71No ratings yet

- PresentacióDocument17 pagesPresentacióxcarlixNo ratings yet

- Problemes 1r PrincipiDocument2 pagesProblemes 1r PrincipielmejortaxistaweyNo ratings yet

- TEMA 8 - Química FinaDocument11 pagesTEMA 8 - Química FinaNina ChNo ratings yet

- T6 Problemes Processos Tèrmics 22 - 23Document5 pagesT6 Problemes Processos Tèrmics 22 - 23Jihan El Kichouhi SalhiNo ratings yet