Professional Documents

Culture Documents

FCH Mse604a Jan 2018 PDF

Uploaded by

Adarsh Barnwal0 ratings0% found this document useful (0 votes)

79 views2 pagesOriginal Title

FCH_MSE604A_JAN_2018.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

79 views2 pagesFCH Mse604a Jan 2018 PDF

Uploaded by

Adarsh BarnwalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

First Circular Handout_MSE604A_JAN_2018

Course number: MSE604

Course name: Science and Technology of Thin Films and Device Fabrication

Prerequisite: None

Credits: [3-0-0-9]

Instructor: Prof. Monica Katiyar

Course Objective: To provide the essential basic knowledge related to thin films and device fabrication.

Emphasis will be placed on various thin film technologies based on vacuum processes and chemical

process followed by detailed discussion on device fabrication including aspects of photolithography,

patterning, etching, heat treatment(s), and metallization by considering certain device cases.

Contents:

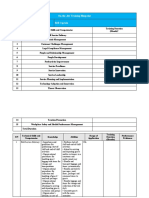

Sl. No. TOPICS # Lectures

1. Introduction • Introduction to device processing steps 4

• Examples of various devices (with emphasis on solar cells

and MOSFETs)

• Need for miniaturization

Thin Film Deposition

2. Basics of thin film • Brief review of kinetic theory

growth • Adsorption and desorption

• Film growth: nucleation and growth kinetics 3

• Epitaxy

• Thin film growth control

3. PVD Processes • Evaporation (Thermal and e-beam)

• Principles of glow discharge and various sputtering 5

processes

4. Chemical Growth • Fundamentals of CVD growth

Processes • Modern variants: MOCVD, PECVD and ALD 4

• Spin Coating

5. Basic Thin Film • Thickness measurement

Characterization • Phase analysis

1

• Optical analysis

• Morphology analysis

Device Fabrication

6. Substrate selection • Selection of substrates

and preparation • Single crystal growth (Silicon)

• Role of substrate surface and contaminants 3

• Physical and chemical methods of substrate surface

preparation

7. Pattern fabrication • Concepts of lithography

• Photoresists (Negative, Positive etc)

• Exposure 5

• Development

• Masking

• Variants of lithography with emphasis on Photo and e-

beam

• Precautionary steps

8. Material Removal • Wet (Chemical) and dry (Plasma, RIE etc.) etching 5

9. Ion implantation, • Doping and Ion Implantation

Doping, oxidation • Diffusion control of composition in devices 6

and heat treatment • Oxidation and heat treatment

10. Metallization and • Adhesion and morphology issues

Interconnects • Introduction to electromigration vis-à-vis metallization:

2

Impact on device performance and methods of prevention

•

11. Process Integration • Example of process integration for a particular kind of

for a particular device e.g. Si Solar Cell, MOSFET, III-V solar cell devices 4

case (take the case

of a device)

Total 42

Lecture: 5:00-6:30 pm (MW)

Venue: WL226

Office Hours: Drop-in or take appointment– 7941 (Off. Phone)

Evaluation Components & Policies:

End Sem 30%

Mid Sem 20%

Quiz (2) 30%

Assignments (6-8) 20%

Books & References: (Additional references will be provided for specific topics)

• VLSI Fabrication: S.K. Gandhi

• Si Processing (Volume I and II)

• Lou and Mayer

• Introduction to Microfabrication by Sami Fransilla (Wiley)

• Fundamentals of Microfabrication: The Science of Miniaturization by Marc Madou (CRC Press)

• Thin film deposition by Donald Smith (Mc Graw Hill)

• Materials science of thin films by Milton Ohring (Academic Press)

• Pulsed Laser deposition of thin films by Chrisey and Hubler (Wiley Interscience)

You might also like

- Lab Report Introduction To Sample Preparation and Optical Microscope For Metallographic ObservationDocument20 pagesLab Report Introduction To Sample Preparation and Optical Microscope For Metallographic Observationshuhada sulaiman86% (7)

- L01 Introduction To Particle TechnologyDocument35 pagesL01 Introduction To Particle TechnologyPhan NeeNo ratings yet

- Al Perk Oak Thin Film Lab Reports OnDocument31 pagesAl Perk Oak Thin Film Lab Reports OnSara AwniNo ratings yet

- 961 Beer Literatur 1Document49 pages961 Beer Literatur 1Budy s RaharjaNo ratings yet

- NSDC PPT For Ges 2018Document20 pagesNSDC PPT For Ges 2018Pooja Malhotra Kwatra100% (2)

- Course Title Course No(s) DE ZC415/MEL ZC415 Credit UnitsDocument15 pagesCourse Title Course No(s) DE ZC415/MEL ZC415 Credit UnitsUmesh BhadaleNo ratings yet

- De ZC415 Course HandoutDocument14 pagesDe ZC415 Course Handoutgofem10387No ratings yet

- Fabrication Course OutlineDocument4 pagesFabrication Course OutlineOmarNo ratings yet

- 38 Materials Fabrication and Characterization TechniquesDocument1 page38 Materials Fabrication and Characterization TechniquesMPD19I001 VITHISHA MNo ratings yet

- MVLD507L - Ic-Technology - TH - 1.0 - 73 - MVLD507L - 67 AcpDocument2 pagesMVLD507L - Ic-Technology - TH - 1.0 - 73 - MVLD507L - 67 AcpMahesh N 22MVD0090No ratings yet

- IC FabricationDocument78 pagesIC FabricationSayandip KarNo ratings yet

- Chap 1Document28 pagesChap 1ALIYAN ALINo ratings yet

- 01 Histology and Its MethodsDocument49 pages01 Histology and Its MethodsZylene RoldaNo ratings yet

- PP Syllabus (R2019)Document3 pagesPP Syllabus (R2019)shaikh javedNo ratings yet

- BMM 453 - Micro/Nano Fabrication Lecture - 1: Dr. Öğr. Üyesi Yavuz Nuri ERTAŞDocument20 pagesBMM 453 - Micro/Nano Fabrication Lecture - 1: Dr. Öğr. Üyesi Yavuz Nuri ERTAŞAli KeserciNo ratings yet

- 05 NanomaterialsDocument28 pages05 NanomaterialsVacker GuzelNo ratings yet

- Nanotech SyllabusDocument2 pagesNanotech Syllabusserf007No ratings yet

- 18 STFPtocDocument3 pages18 STFPtocevilplueNo ratings yet

- Module-1 AM PDFDocument46 pagesModule-1 AM PDFbilal hasanNo ratings yet

- Icft Mel ZG611 Course HandoutDocument4 pagesIcft Mel ZG611 Course Handoutsaireddykakumanu97No ratings yet

- Total - MT COURSE Module 1 65pgsDocument65 pagesTotal - MT COURSE Module 1 65pgshuynhvuduyNo ratings yet

- ME 503-N Manufacturing TechnologyDocument4 pagesME 503-N Manufacturing Technologyhrana287No ratings yet

- Comphrensive PPT - 071959Document14 pagesComphrensive PPT - 071959zahoorNo ratings yet

- Indian Univ Sensor Slybuss-5Document1 pageIndian Univ Sensor Slybuss-5ADI SINGHNo ratings yet

- Birla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Digital Learning Part A: Content DesignDocument5 pagesBirla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Digital Learning Part A: Content Designkansal611No ratings yet

- Course Outline - Fall 2022 Advanced Manufacturing ProcessesDocument5 pagesCourse Outline - Fall 2022 Advanced Manufacturing ProcessesAbuzar AliNo ratings yet

- Mn7203 Material Testing and Characterization L T P CDocument5 pagesMn7203 Material Testing and Characterization L T P CAnonymous p8bHAAxNo ratings yet

- Mel ZG611Document5 pagesMel ZG611jitendraNo ratings yet

- L2A PhotolithographyDocument18 pagesL2A PhotolithographydeevesshaNo ratings yet

- Partie 2 Film Deposition EtchingDocument89 pagesPartie 2 Film Deposition EtchingyasmineNo ratings yet

- Coating & Painting Inspections Fundamentals: Pdhonline Course M478 (5 PDH)Document78 pagesCoating & Painting Inspections Fundamentals: Pdhonline Course M478 (5 PDH)Corrosion Factory100% (1)

- Silicon Photonics Design: From Devices To Systems: March 2015Document3 pagesSilicon Photonics Design: From Devices To Systems: March 2015Cristian VargasNo ratings yet

- Silicon Photonics Design: From Devices To Systems: March 2015Document3 pagesSilicon Photonics Design: From Devices To Systems: March 2015Fawaz LabeebNo ratings yet

- Micro Course FileDocument47 pagesMicro Course FileRatish DhimanNo ratings yet

- IC Fabrication TechnologyDocument5 pagesIC Fabrication TechnologyEldo N BabyNo ratings yet

- IC FabricationDocument40 pagesIC FabricationRajkumari MishraNo ratings yet

- Ece3038 Mems-And-nano-sensors TH 1.1 47 Ece3038Document2 pagesEce3038 Mems-And-nano-sensors TH 1.1 47 Ece3038Sai ViswanathNo ratings yet

- Section 1 Intro Winter 2011Document9 pagesSection 1 Intro Winter 2011Matthew MouNo ratings yet

- Faculty of Engineering, UNIMASDocument4 pagesFaculty of Engineering, UNIMASjohnNo ratings yet

- Optical Projection LithographyDocument40 pagesOptical Projection LithographyApoorv GargNo ratings yet

- Mec424 Material ScienceDocument17 pagesMec424 Material ScienceNur Atiqah Nabila100% (2)

- MM Week1-Introduction PDFDocument26 pagesMM Week1-Introduction PDFMuhammad AzeemNo ratings yet

- Mce 653 Advanced Manufacturing TechnologyDocument1 pageMce 653 Advanced Manufacturing TechnologypathakatulNo ratings yet

- 1 THDocument2 pages1 THAditya TNo ratings yet

- MA505-N-C Modern Manufacturing ProcessesDocument3 pagesMA505-N-C Modern Manufacturing Processeshrana287No ratings yet

- Gujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807Document2 pagesGujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807ganeshNo ratings yet

- PT Lec 1Document91 pagesPT Lec 1Irtiza RasulNo ratings yet

- PDFDocument2 pagesPDFAndhdNo ratings yet

- Nptel: Science and Technology of Polymers - Web CourseDocument2 pagesNptel: Science and Technology of Polymers - Web CoursedvphaneeswarNo ratings yet

- Nanoimprint Lithography: Presented by Group 7Document27 pagesNanoimprint Lithography: Presented by Group 7Samia SafaNo ratings yet

- 08 - Chapter 2Document37 pages08 - Chapter 2Patar PoshakNo ratings yet

- IntroductionDocument38 pagesIntroductionMohamedNo ratings yet

- Emg 4102 CN 1Document3 pagesEmg 4102 CN 1MaxwellNo ratings yet

- METS Mineral Processing Course PresentationDocument17 pagesMETS Mineral Processing Course PresentationAdham ElbrawyNo ratings yet

- PSSG - SPWLA Petrophysics Skill Set Guidelines - Jan - 2021Document7 pagesPSSG - SPWLA Petrophysics Skill Set Guidelines - Jan - 2021krackku kNo ratings yet

- Applied Sciences: Inspection and Classification of Semiconductor Wafer Surface Defects Using CNN Deep Learning NetworksDocument13 pagesApplied Sciences: Inspection and Classification of Semiconductor Wafer Surface Defects Using CNN Deep Learning NetworksJake CloneyNo ratings yet

- Unit-Ii: Micromachining Technologies (Microfabrications)Document15 pagesUnit-Ii: Micromachining Technologies (Microfabrications)Rayees AhmedNo ratings yet

- Universiti Teknologi Mara Lab 1Document11 pagesUniversiti Teknologi Mara Lab 1Ilman Faiq67% (9)

- Non Destructive Testing (NDT L-2) Course ContentsDocument2 pagesNon Destructive Testing (NDT L-2) Course ContentsHarminder KumarNo ratings yet

- A ThesisDocument101 pagesA ThesisMurtaza SieamNo ratings yet

- Engineering Materials 1: An Introduction to Properties, Applications and DesignFrom EverandEngineering Materials 1: An Introduction to Properties, Applications and DesignRating: 5 out of 5 stars5/5 (1)

- Fabrication of Microelectronic Devices Final - 2 PDFDocument30 pagesFabrication of Microelectronic Devices Final - 2 PDFAdarsh BarnwalNo ratings yet

- ME 301 Lec 24 PDFDocument55 pagesME 301 Lec 24 PDFAdarsh BarnwalNo ratings yet

- ME301 Lec 17 PDFDocument12 pagesME301 Lec 17 PDFAdarsh BarnwalNo ratings yet

- ME301 Lec 21 PDFDocument10 pagesME301 Lec 21 PDFAdarsh BarnwalNo ratings yet

- 3M Touch Solutions - Marketing PlanDocument23 pages3M Touch Solutions - Marketing PlanManzil MadhwaniNo ratings yet

- Q1.a) Discuss The Nature and Process of Corporate Planning. AnsDocument19 pagesQ1.a) Discuss The Nature and Process of Corporate Planning. AnsRajni KumariNo ratings yet

- BIM Technology Implementation in Vietnam - An Institutional Perspective On A Bridge ProjectDocument14 pagesBIM Technology Implementation in Vietnam - An Institutional Perspective On A Bridge ProjectMinh Truyền ĐỗNo ratings yet

- About Us Sustainability Report and Policy Annual Report 2007 en PDFDocument140 pagesAbout Us Sustainability Report and Policy Annual Report 2007 en PDFwindaNo ratings yet

- InsurTech Conference 2020Document3 pagesInsurTech Conference 2020Jere ChikambureNo ratings yet

- Case SummDocument13 pagesCase SummTamene AmareNo ratings yet

- Chen Neo 2019 Texting The Waters An Assessment of Focus Groups Conducted Via The Whatsapp Smartphone MessagingDocument10 pagesChen Neo 2019 Texting The Waters An Assessment of Focus Groups Conducted Via The Whatsapp Smartphone MessagingOlivia MNo ratings yet

- Entrepreneurship Lesson 4-7Document9 pagesEntrepreneurship Lesson 4-7Kelvin Jay Sebastian SaplaNo ratings yet

- EMF Towards A Circular EconomyDocument99 pagesEMF Towards A Circular EconomyRashmi BahadurNo ratings yet

- Critical Success Factors For Six Sigma Projects: SciencedirectDocument14 pagesCritical Success Factors For Six Sigma Projects: SciencedirectNatali Beltran TenorioNo ratings yet

- For Social Innovation: Author Kyriaki PapageorgiouDocument72 pagesFor Social Innovation: Author Kyriaki PapageorgiouMonica Grau SarabiaNo ratings yet

- Dela Torre - Critique Paper 2Document2 pagesDela Torre - Critique Paper 2Wynona Mae Dela TorreNo ratings yet

- Break-The-Pattern - Final - Print-Ready 2017 12 11Document93 pagesBreak-The-Pattern - Final - Print-Ready 2017 12 11Aaron Alibi100% (1)

- Unit III: Dr. Shipra Agrawal Assistant Professor Aryabhatta CollegeDocument91 pagesUnit III: Dr. Shipra Agrawal Assistant Professor Aryabhatta CollegeShipra agrawalNo ratings yet

- On-the-Job Training Blueprint - Bell CaptainDocument17 pagesOn-the-Job Training Blueprint - Bell CaptainRHTi BDNo ratings yet

- Ambition For Children - Save The ChildrenDocument11 pagesAmbition For Children - Save The ChildrenSomao JoeNo ratings yet

- Cover Letter For Entry Level Procurement SpecialistDocument8 pagesCover Letter For Entry Level Procurement Specialisthkodlxegf100% (1)

- Understanding The Right Ecosystem For StartupsDocument5 pagesUnderstanding The Right Ecosystem For StartupsRaza AliNo ratings yet

- Developing An Effective Business ModelDocument24 pagesDeveloping An Effective Business Modeldedila nachar100% (1)

- Techno ExamDocument7 pagesTechno ExamReign NeyraNo ratings yet

- Intellectual Property RightsDocument196 pagesIntellectual Property Rightslin linNo ratings yet

- Ze Gcp01a15 EngDocument300 pagesZe Gcp01a15 EnggeorgeNo ratings yet

- KLIJN KOPPENJAN - Governance Network Theory - Past, Present and FutureDocument19 pagesKLIJN KOPPENJAN - Governance Network Theory - Past, Present and FutureBusri BusriNo ratings yet

- Pastilyema 1Document38 pagesPastilyema 1Marck John Pagurayan100% (1)

- NASSCOM Strategic Review 2015 Executive SummaryDocument14 pagesNASSCOM Strategic Review 2015 Executive SummaryRatnadeep JoshiNo ratings yet

- AF Revista Salao Design CASA BRASIL 2013 CD inDocument86 pagesAF Revista Salao Design CASA BRASIL 2013 CD inJanine MouraNo ratings yet

- AI and PR PDFDocument18 pagesAI and PR PDFMwintoNo ratings yet