Professional Documents

Culture Documents

For Raw Mill Girth Gear Grease Spray System

Uploaded by

vinodsnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Raw Mill Girth Gear Grease Spray System

Uploaded by

vinodsnCopyright:

Available Formats

A

REVIEW REPORT

OVER

RE-SETTING OF PURGING INTERVAL

(FOR RAW MILL GIRTH GEAR GREASE SPRAY SYSTEM)

DATE: 31-03-2017

After the decision for revisal of new setting point for the raw mill girth gear grease spraying system and

necessary action taken by E&I Department; it has become very simple to understand the diversities in consumption of

grease ‘BECHEM BERULIT GA-400’. Here is a summary of review report over the re-setting of purging cycle for raw mill

girth gear grease spraying system along with exploration of increased service life of grease barrels.

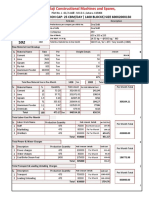

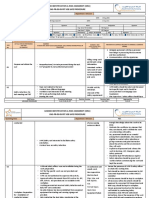

SR. PREVIOUS CURRENT

PARTICULARS UNIT REMARKS

NO. DATA DATA

1 Off-time interval Seconds 10:50 20:00

2 On-time interval Seconds 02:00 02:00

3 One purging interval Seconds 12:50 22:00

4 Grease quantity/interval mg/interval 2423.600 2423.600

5 Grease consumption quantity mg/minute 11633.280 6609.818

gm/minute 11.633 6.610

kg/hour 0.698 0.397

Expected running hours of raw

5 hrs./day 20 20

mill

Quantity of grease in each ‘BECHEM BERULIT

6 kg/barrel 190.000 190.000

barrel GA-400’

Service life of each grease

7 Hours 272.208 479.085

barrel

Days 13.610 23.954

Days 14 24 taking higher value

Consumption of grease barrel

8 barrel/month 2.20 1.25

per month

Effective saving of grease per

9 month with respect to barrel/month -- 0.95

previous consumptions

barrel/month -- 1 approx.

Increased service life of a with respect to previous

10 % -- 76.00

barrel one

11 Saving in terms of money NPR -- 1,14,950.00 1 Kg grease = NPR 605.00/-

1|Page

You might also like

- Sop - Belt ConveyorDocument2 pagesSop - Belt Conveyorvinodsn100% (2)

- Constellation Pharma (CNST) ThesisDocument17 pagesConstellation Pharma (CNST) Thesisjulia skripka-serry100% (2)

- Contract Management ChecklistDocument15 pagesContract Management ChecklistCreanga Georgian100% (1)

- Project On Curry PowderDocument8 pagesProject On Curry PowderSrj SoorajNo ratings yet

- RMC Production Cost and Batching Plant Charges-1Document4 pagesRMC Production Cost and Batching Plant Charges-1Mital Damani100% (1)

- DG SetDocument8 pagesDG Setanshul100% (1)

- Effective Crusher MaintenanceDocument8 pagesEffective Crusher MaintenanceMEHTAB HUSSAINNo ratings yet

- Cash Flow - Budget OperationDocument7 pagesCash Flow - Budget OperationhizkiaNo ratings yet

- Feasibility Study For Tank FarmDocument3 pagesFeasibility Study For Tank FarmFahmy ArdhiansyahNo ratings yet

- Batching PlantDocument2 pagesBatching PlantSarin100% (1)

- Eco Care Engineering PVT Limited: Alf Ro Plant # 2: Operation and Maintenance Report For The Month of Febuary-2018Document6 pagesEco Care Engineering PVT Limited: Alf Ro Plant # 2: Operation and Maintenance Report For The Month of Febuary-2018Rajesh MuthuNo ratings yet

- Test 896: Massey-Ferguson MF 165 (Diesel) (Also MF 165 8-Speed Diesel)Document2 pagesTest 896: Massey-Ferguson MF 165 (Diesel) (Also MF 165 8-Speed Diesel)Nour SkyperNo ratings yet

- Brief Regarding Purchase of Generator 100Kv For Water Supply Scheme, Disposal Works Flood EmergencyDocument2 pagesBrief Regarding Purchase of Generator 100Kv For Water Supply Scheme, Disposal Works Flood Emergencymuhammad iqbalNo ratings yet

- Perhitungan Kebutuhan Unit Dan EOCDocument21 pagesPerhitungan Kebutuhan Unit Dan EOCHanna Rizanti KartinaNo ratings yet

- Commissioning A New Machine For ReliabilityDocument6 pagesCommissioning A New Machine For ReliabilitySanjeevi Kumar SpNo ratings yet

- Machine Maintenance: From WM No. 5044 OnwardsDocument64 pagesMachine Maintenance: From WM No. 5044 OnwardsMohammedasifNo ratings yet

- RMC Proposal H1IV - JSR ConcretesDocument9 pagesRMC Proposal H1IV - JSR Concretesarunbalaji04100% (1)

- AdaaaaaaDocument6 pagesAdaaaaaaJaybert DumaranNo ratings yet

- Safe, Success To Deliver The Promise: Ruby Field Daily Production ReportDocument3 pagesSafe, Success To Deliver The Promise: Ruby Field Daily Production ReportMAMBO95TLNo ratings yet

- Lube Oil Cement Mill, Trunnion Bearings, Fixed & Floating: CJC™ Application StudyDocument1 pageLube Oil Cement Mill, Trunnion Bearings, Fixed & Floating: CJC™ Application StudyparidapapuNo ratings yet

- What Is A Performance CurveDocument8 pagesWhat Is A Performance CurveRanjit PaulNo ratings yet

- Value Summary Report DetailsDocument2 pagesValue Summary Report DetailsPeyush MehtoNo ratings yet

- III. Detailed Operations Tables: November 2000Document6 pagesIII. Detailed Operations Tables: November 2000keyur_197No ratings yet

- Bridge Chart & Bubble ChartDocument10 pagesBridge Chart & Bubble ChartNanda HendianaNo ratings yet

- LCC - BSD 75-8.5 BarDocument1 pageLCC - BSD 75-8.5 BarHardikNo ratings yet

- Two Week Maintenanace Activity ReportDocument2 pagesTwo Week Maintenanace Activity ReportHaftom TekluNo ratings yet

- COST of Concrete ProductionDocument14 pagesCOST of Concrete Productionebed_meleckNo ratings yet

- Calculation Sheet For ReferenceDocument10 pagesCalculation Sheet For ReferenceLL.B. ClassmateNo ratings yet

- M/s.Balaji Constructional Machines and Spares,: CLC Production Cap-25 Cbm/Day (1400 Blocks) Size 600X200X150Document2 pagesM/s.Balaji Constructional Machines and Spares,: CLC Production Cap-25 Cbm/Day (1400 Blocks) Size 600X200X150shakeebNo ratings yet

- Costing OverheadDocument5 pagesCosting OverheadbereketNo ratings yet

- Blueconnection Calculations RefurbishmentDocument16 pagesBlueconnection Calculations Refurbishment王俞文No ratings yet

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDocument6 pagesGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDurga PrasadNo ratings yet

- Integrated Cement Orient Cement ChittapurDocument38 pagesIntegrated Cement Orient Cement Chittapurdurgesh25No ratings yet

- Owning Operation Cost ALAT BERATDocument54 pagesOwning Operation Cost ALAT BERATsuraynioktaviaNo ratings yet

- Bamboo Chips Costing AnalysisDocument1 pageBamboo Chips Costing Analysisangdutta2No ratings yet

- Qubic BriketDocument13 pagesQubic BriketFebri Ardyanto putraNo ratings yet

- Conversion Factor-Qatar PetroleumDocument4 pagesConversion Factor-Qatar PetroleumrohanNo ratings yet

- Pre-Feasibility Report: Environmental ClearanceDocument78 pagesPre-Feasibility Report: Environmental ClearanceJigar100% (1)

- Engines 2G40 EngDocument6 pagesEngines 2G40 EngKenan TiroNo ratings yet

- 4 Project Description: 4.1 Baiji RefineryDocument123 pages4 Project Description: 4.1 Baiji Refineryduraid ahmadNo ratings yet

- Agro Service CentreDocument30 pagesAgro Service Centreyaduraj TambeNo ratings yet

- Monthly Report Kondli Oct-2021Document15 pagesMonthly Report Kondli Oct-2021Manish KaushikNo ratings yet

- Simulasi Fuel PurchaseDocument3 pagesSimulasi Fuel Purchasezulkarnain.epnNo ratings yet

- En-Biofuels From Coconuts-Krishna RaghavanDocument111 pagesEn-Biofuels From Coconuts-Krishna RaghavanSakoNo ratings yet

- 06 Daily Boiler Report Sep-22Document1 page06 Daily Boiler Report Sep-22sky textiles300No ratings yet

- RTA-63 Cylinder Oil Feed RatesDocument8 pagesRTA-63 Cylinder Oil Feed RatesCatalin CataNo ratings yet

- Hindustan Prefab Limited: (A Govt. of India Enterprises) Abstract of CostDocument4 pagesHindustan Prefab Limited: (A Govt. of India Enterprises) Abstract of CostSasi KumarNo ratings yet

- QUOTATIONDocument1 pageQUOTATIONPrathamesh NaikNo ratings yet

- Oil HSD Stock CalculationDocument14 pagesOil HSD Stock CalculationOunur RofiqNo ratings yet

- 79 Stai Annual Convention: Innovative and Sustainable Options For Improving Juice Extraction EfficiencyDocument38 pages79 Stai Annual Convention: Innovative and Sustainable Options For Improving Juice Extraction EfficiencyPrashantBudakeNo ratings yet

- (Approved) : Preparatory Tillage 1Document1 page(Approved) : Preparatory Tillage 1Clear MindNo ratings yet

- Equipment PankajDocument3 pagesEquipment Pankajpankaj topaleNo ratings yet

- Rashas OriginalsDocument7 pagesRashas OriginalsDhruv GandhiNo ratings yet

- Practica N - 7Document34 pagesPractica N - 7arely marinNo ratings yet

- SPH Chemical Consumable & MachineryDocument11 pagesSPH Chemical Consumable & Machinerykeyko.byasaNo ratings yet

- EE Benchmarking For Cement IndustrysDocument41 pagesEE Benchmarking For Cement Industrysshoaibhassan23100% (2)

- Autovillage Area Rate Analysis 21 SepDocument116 pagesAutovillage Area Rate Analysis 21 Seprashmi bhailaNo ratings yet

- Rashas Case Product Raw Material (In KG) Required Per Batch Material 1 Pain Relief Oil Hair Oil Tooth PowerDocument13 pagesRashas Case Product Raw Material (In KG) Required Per Batch Material 1 Pain Relief Oil Hair Oil Tooth PowerDhruv GandhiNo ratings yet

- DECEMBER 1-31, 2020: PM Group PM ActivitiesDocument8 pagesDECEMBER 1-31, 2020: PM Group PM ActivitiesBerp OnrubiaNo ratings yet

- Boiler Comparative 5.3.24Document13 pagesBoiler Comparative 5.3.24Rajendra GautamNo ratings yet

- Improve Phase: Implementation Reducing Fuel On HD785-5/7 by Dimention of ManDocument29 pagesImprove Phase: Implementation Reducing Fuel On HD785-5/7 by Dimention of ManDidik Sugiantoro100% (1)

- Lime Stone Cleaning Station - Project Proposal-03Document4 pagesLime Stone Cleaning Station - Project Proposal-03vinodsnNo ratings yet

- Organization Chart: (Mechanical Department)Document3 pagesOrganization Chart: (Mechanical Department)vinodsn100% (1)

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDocument2 pagesBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNo ratings yet

- Offer Letter-Manpower Supply & Project WorkDocument10 pagesOffer Letter-Manpower Supply & Project WorkvinodsnNo ratings yet

- 3.20 Removal of Conveyor Belt With New BeltDocument2 pages3.20 Removal of Conveyor Belt With New Beltvinodsn100% (1)

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDocument1 pageBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNo ratings yet

- Sop For Bag FilterDocument5 pagesSop For Bag FiltervinodsnNo ratings yet

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Document1 pageEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnNo ratings yet

- Sop For Cleaning & HousekeepingDocument4 pagesSop For Cleaning & HousekeepingvinodsnNo ratings yet

- Sop For Om For Ball MillDocument7 pagesSop For Om For Ball MillvinodsnNo ratings yet

- Sop Inert GasDocument5 pagesSop Inert GasvinodsnNo ratings yet

- Sop Welding & Gas CuttingDocument9 pagesSop Welding & Gas CuttingvinodsnNo ratings yet

- Costing Details E & I (2074-75)Document8 pagesCosting Details E & I (2074-75)vinodsnNo ratings yet

- Sop Ls CrusherDocument2 pagesSop Ls Crushervinodsn100% (1)

- 1-SOP For Raw Mill StartDocument2 pages1-SOP For Raw Mill Startvinodsn100% (2)

- Monthly Action Plan Process (March-2016)Document1 pageMonthly Action Plan Process (March-2016)vinodsnNo ratings yet

- Girth Gear RunoutDocument1 pageGirth Gear RunoutvinodsnNo ratings yet

- Sop ListDocument1 pageSop ListvinodsnNo ratings yet

- Gist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalDocument1 pageGist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalvinodsnNo ratings yet

- Girth Gear RunoutDocument1 pageGirth Gear RunoutvinodsnNo ratings yet

- Housekeeping Summary For Ucpl Plant: Raw Mill Section Area Date: 14/11/2017Document1 pageHousekeeping Summary For Ucpl Plant: Raw Mill Section Area Date: 14/11/2017vinodsnNo ratings yet

- Cover Letter: Curriculam VitaeDocument4 pagesCover Letter: Curriculam VitaevinodsnNo ratings yet

- Employee Salary Slip: Charkhal, Dillibazar, KathmanduDocument1 pageEmployee Salary Slip: Charkhal, Dillibazar, KathmanduvinodsnNo ratings yet

- Kiln Workshop Guide 4 - PPE PDFDocument3 pagesKiln Workshop Guide 4 - PPE PDFvinodsnNo ratings yet

- Presentation Sandeep Cool Hair OilDocument35 pagesPresentation Sandeep Cool Hair OilSandeep Sankar PaulNo ratings yet

- GSM Network SDCCH Congestion & Solutions-16Document15 pagesGSM Network SDCCH Congestion & Solutions-16abdullaaNo ratings yet

- Short Tricks To Remember GK EasilyDocument3 pagesShort Tricks To Remember GK EasilyManoj KiningeNo ratings yet

- Bonpak Catalogue 2011Document18 pagesBonpak Catalogue 2011George TowerNo ratings yet

- Method Used For The Prevention of RustingDocument9 pagesMethod Used For The Prevention of RustingSaadiah MohammadNo ratings yet

- Cargo Ventilation System On Liquefied Gas CarriersDocument19 pagesCargo Ventilation System On Liquefied Gas CarriersLukasz ZablockiNo ratings yet

- Water ProofingDocument5 pagesWater ProofingMalith De SilvaNo ratings yet

- OS Prosthetics Orthotics, L3, L4 & L5Document144 pagesOS Prosthetics Orthotics, L3, L4 & L5MaxNo ratings yet

- Biology Revision Notes Part3Document10 pagesBiology Revision Notes Part3volvanskyNo ratings yet

- Cake Makers GuidanceDocument16 pagesCake Makers GuidancegenebabaNo ratings yet

- History of Co-Operative Credit Society in IndiaDocument14 pagesHistory of Co-Operative Credit Society in IndiaTerry YanamNo ratings yet

- Material Considerations Irradiation Processing - SOTERADocument8 pagesMaterial Considerations Irradiation Processing - SOTERAeyalzuckermanNo ratings yet

- SK KK-Survey and DatabaseDocument8 pagesSK KK-Survey and DatabaseMaria ImmaNo ratings yet

- Architecture: Passive Design With ClimateDocument39 pagesArchitecture: Passive Design With ClimateamenrareptNo ratings yet

- Notes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsDocument1 pageNotes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsMohd KhaidirNo ratings yet

- Identify The Letter of The Choice That Best Completes The Statement or Answers The QuestionDocument18 pagesIdentify The Letter of The Choice That Best Completes The Statement or Answers The QuestionCeline YoonNo ratings yet

- Body Systems TestDocument6 pagesBody Systems TestIRENE DÁVALOS SMILGNo ratings yet

- Prasad 2017Document9 pagesPrasad 2017Dhruv MahajanNo ratings yet

- The Current Status of The "Food Security Doctrine" Implementation in The Russian Federation and Tasks For 2013-2020Document5 pagesThe Current Status of The "Food Security Doctrine" Implementation in The Russian Federation and Tasks For 2013-2020gautham28No ratings yet

- Water PotentialDocument2 pagesWater PotentialsmellybottomNo ratings yet

- DPPH (1,1-Diphenyl-2-Picrylhydrazyl) Radical Scavenging Activity of Flavonoids Obtained From Some Medicinal PlantsDocument4 pagesDPPH (1,1-Diphenyl-2-Picrylhydrazyl) Radical Scavenging Activity of Flavonoids Obtained From Some Medicinal PlantsEtika Ayu LestariNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor JumperDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor Jumpermohammed tofiqNo ratings yet

- Success Strategies Fro Grad SchoolDocument18 pagesSuccess Strategies Fro Grad SchoolbiplabdekaNo ratings yet

- Introduction To Chemical BondingDocument5 pagesIntroduction To Chemical BondingMini PGNo ratings yet

- Searchable SOR E&M 2022-23Document191 pagesSearchable SOR E&M 2022-23Jigar LadhavaNo ratings yet

- 1) Gobar Danga Model: Purpose of Visit: To IntroduceDocument6 pages1) Gobar Danga Model: Purpose of Visit: To IntroduceArun BiswasNo ratings yet

- Golf Pei Course Comparison ChartDocument1 pageGolf Pei Course Comparison ChartSteve DimondNo ratings yet

- Ruego Vs People - Physical InjuriesDocument10 pagesRuego Vs People - Physical Injuriesmldmolina75No ratings yet