Professional Documents

Culture Documents

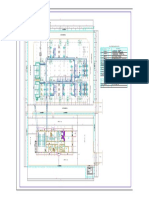

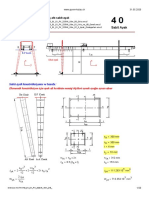

45 m3 LPG Tank Genel Görünüş - Bombe H 709-Model

Uploaded by

akın ersözOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

45 m3 LPG Tank Genel Görünüş - Bombe H 709-Model

Uploaded by

akın ersözCopyright:

Available Formats

500 60

10418

9000

1000 2000 2000 2000 2000

270

270

10

135

TYPE OF TANKS LPG TRANSPORT TANKS

SERIAL NUMBER

10

45

12 PRODUCTION DATE

118 DESIGN PRESSURE 16 BAR

5

WPS-2 WPS-2

R3 R3

60

R1

700

7 0 WPS-1 WPS-1 WPS-1 WPS-1 WPS-1 WPS-1

70 TEST PRESSURE

R19 N1 12

2 0 R19 DESIGN TEMPERATURE -20/+50 c

WPS-5 WPS-5 WPS-5 WPS-5

20

260 500 VOLUME 45000 lt.

WPS-5 WPS-5 WPS-5 WPS-5

MAIN MATERIAL P355GH ( 1.0473 )

Ø2420

270

16 SET PRESSURE

200 320 WPS-1 WPS-1

TEST DATE

R2

R2

100 N2

5

10 17 10 10 11 STORAGE PRODUCTS LPG

790 11

130°

70

WPS-1 DESIGN STANDART EN12493:2013+A1/AC : 2015

700

R3

120°

160° CONTROL

636

70

12 6 7 RADIOGRAPHIC TEST %100

°

62

45 45

1 2 3 4 5

18 709 709

DESING DATA

16

END DETAILS

DESING CODE : ADR 2017 EN 12493:2013 + A1/AC : 2015

200

30 120

TANK ADR COD : P16BN

max.3390 liters 2310 liters max.6800 liters max.6800 liters max.6800 liters max.6800 liters max.6800 liters max.4630 liters max.3390 liters GEOMETRICAL VOLUME : 45 CUBIC METER RANGE

UN CODE : UN 1965

CONTENT : Ligiud Petrolium Gas - UN1965 / class 2 MIXTURE A, A01, A02, A0,

12

1500

100

510 1500 1500 1500 1500 990

250

30

DESING PRESSURE : 16 BAR

8 9

SADDLE DETAIL TEST PRESSURE : 16 BAR

10

45 45

DESING TEMPERA TURE : -20 C / +50 C

MAX. ALLWABLE WORKING PRESSURE : 15 BAR

160 N8 N9

R3 SURGE PLATE WPS-5 WPS-5 WPS-5 WPS-5 WPS-5 800 3 WELDING FACTOR : 1

10 80 0 SURGE PLATE SURGE PLATE

58

70

7

Ø7 12 0 Ø 1

SCOBE OF NON - DESTRUCTIVE TEST

718

R19

20 22

WPS-5 N10 RADIOGRAPHIC OR ULTRASONIC TEST : ALL PRESSURIZED PARTS LONGITUDIAL AND CIRCUMFERENTIAL JOINTS %100

320 110

WPS-5 WPS-5 WPS-5 WPS-5 WPS-5

LIQUID PENETRANT OR MAGNETIC TEST : ALL PRESSURIZED PARTS NOZZLES AND REIN .

21

Ø2420

Ø2400

1335

320 VISUAL CONTROL TEST : ALL WELD JOINTS

390 1250 NOTES : Acceptance Criteria EN 12493 Annex I

N11 N12

SURGE PLATE SURGE PLATE WPS-5

LIFTING LUGS DETAIL N3 20

SURGE PLATE 130°

120°

WPS-5 WPS-5 WPS-5 19 22°

BILL OF METARIAL

860 600 COMPONENT NAME

ITEM NO QTY. METARIAL STANDARD TYP. OF CERT. DIMENTIONS

10

45 100

10

CYLINDRICAL BODY SHELL PLATES L:2000 D: 2420

1,2,3,4,5 5 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 10 mm

HEAD SHELL PLATES R:1920 r:370 D: 2420

6,7 2 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 12 mm

8,9 LIFTING LUG 4 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 10 mm

390x320 r:25

10,11 LIFTING LUG PAD 2

4

14 P355GH EN 10028-2 EN 10204 3.1 THK:10mm

13

12 SAFETY VALVE COVER 1 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 10 mm

13 SURGE PLATE PAD 24

430

8348 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 10 mm

14 SURGE PLATE LUG 24 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 10 mm

4750

15 SURGE PLATE 24 S355J2 EN 10025-2 EN 10204 3.1 THK.MIN. 4 mm

430

MENHOLE DETAIL

16 SADDLE PAD 4 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 10 mm

25 17 SADDLE LEG 4

30 S355J2 EN 10025-2 EN 10204 3.1 THK.MIN. 12 mm

15 59

40

7,5 BOLT M 33 - 20 PIECES

18 SADDLE BASE PLATE 8 S355J2 EN 10025-2 EN 10204 3.1 THK.MIN. 16 mm

N5 D O :180 D I :88.9

50

WPS-4

N1 SAFETY VALVE NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1 THK.: 50 mm

40 50 D O :180 D I :88.9

0 WPS-2 32 N2 SAFETY VALVE NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1 THK.: 50 mm

A D O :150 D I : 60

N3 MAGNETIC LEVEL INDICATOR NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1 THK.: 50 mm

KESIT A-A 50

107,5 107,5 N4 DRAIN NOZZLE 1 D O :81.5 D I : 38.5

Ø2420

P355GH EN 10028-2 EN 10204 3.1

1302

THK.: 50 mm

430

490

670

685

500

595

D O :185 D I : 92.5

215 215 215 489.5 N5 VAPOUR PHASE NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1 THK.: 50 mm

D O :185 D I : 92.5

N6 LIQUID FILL NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1

Ø62

THK.: 50 mm

0 N7

40 R3

70 N7 LIQUID PHASE DISCHARGE NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1

D O :220 D I : 110

N4 GASKET ( PTFE) THK.: 50 mm

D O :81.5 D I : 39.5

50 N8 EMERGENCY DISCHARGE NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1

7,5

THK.: 50 mm

N4 NOZZLE DETAIL

59 N9 EMERGENCY DISCHARGE NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1

D O :81.5 D I : 39.5

THK.: 50 mm

Ø81,5 N6 D O :62 D I : 31

N10 MECHANICAL LEVEL INDICATOR NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1

10

THK.: 50 mm

D O :62 D I : 24.7

N1-N2 NOZZLE DETAIL N11 MANOMETER NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1 THK.: 50 mm

50

D O :35 D I : 19

Ø180 N12 TERMOMETRE NOZZLE 1 P355GH EN 10028-2 EN 10204 3.1 THK.: 135 mm

Ø88,8 165 950 1300 1000 990 D O :114.3 D I : 400

19 PIPE 2

10

P235GH EN 10216-2 EN 10204 3.1 THK.: 5 mm

WPS-3 Ø38,3 5590

CHASIS DETAIL 20 PIPE REDUCTION 2 P235GH EN 10216-2 EN 10204 3.1 DN50 x DN100

50

D O :60.3 L:1700

21 PIPE 1 P235GH EN 10216-2 EN 10204 3.1 THK.: 5 mm

N5-N6 NOZZLE DETAIL

WPS-3

BOLT M 33 - 20 PIECES 22 ELBOW 1 P235GH EN 10216-2 EN 10204 3.1 D O :60.3 THK:2.9

Ø185 28 BOLT 32 8.8 CLASS EN 10269 EN 10204 2.2 M20x60

10

N8-N9 NOZZLE DETAIL N3 NOZZLE DETAIL N10 NOZZLE DETAIL N11 NOZZLE DETAIL N12 NOZZLE DETAIL 29 BOLT 20 8.8 CLASS EN 10269 EN 10204 2.2 M36x85

50

WPS-3

Ø3

30 MENHOLE FLANGE INNER 1 P355GH EN 10028-2 EN 10204 3.1 D O :670 D I : 430

9,5

Ø24,7

10 31 MENHOLE FLANGE OUTER 1 P355GH EN 10028-2 EN 10204 3.1 D O :670

135

Ø31

Ø62

Ø62

WPS-3 WPS-3 WPS-4

Ø92,5

81,

50 50 R:370 r:72 D: 430

32 MENHOLE DOMED COVER 1 P355GH EN 10028-2 EN 10204 3.1 THK.MIN. 8 mm

50

5

S-4

WP 33 GASKET 1 PTEF

N7 NOZZLE DETAIL

Ø150

Ø220 12 12 12

35

Ø110 12

WPS-4

10

19

Ø60

WPS-5

50

50

WPS-3

WPS-1 WPS-2 WPS-3 WPS-4 WPS-5

35° 28° 35 35 35 35

3 5° 35° WPS-5

<8

<7

.5

2 2

9)

MANUFACTURING SHELL THICKNESS

(>

12

12

12

10

10

10

10

10

3

>7

Welding process : 121 Welding process : 121 1 1 1 1

Weld Type : Grave

Joint Desing : Butt

Weld Type : Grave

Joint Desing : Butt

FOR CYLINDRICAL SHELL FOR HEADS

Grave Type : Single-vee Grave Type : Single-vee Welding process : 136 Welding process : 136 Welding process : 136

Weld Type : Grave Weld Type : Grave Weld Type : Fillet

Joint Desing : T Joint Joint Desing : T Joint Joint Desing : T Joint

Grave Type : Single-bevel Grave Type : Single-bevel

10 mm 12 mm 1/2 1/2.5 1/5

You might also like

- TSE EN - 10216 2 Boru StandartDocument35 pagesTSE EN - 10216 2 Boru StandartUğur Aydemir100% (1)

- İpragaz LNG Sistem ÖzellikleriDocument7 pagesİpragaz LNG Sistem ÖzellikleriAli ÖzgençNo ratings yet

- TS en 10028-2Document25 pagesTS en 10028-2Gökhan TEZCAN50% (2)

- 3 LPG Yerst Stoklama TankiDocument2 pages3 LPG Yerst Stoklama TankizallpallNo ratings yet

- TS en 13445-5 Ek A4Document2 pagesTS en 13445-5 Ek A4Gökhan ÇiçekNo ratings yet

- TS en 13445-1Document13 pagesTS en 13445-1Gökhan Çiçek100% (1)

- Mmo Basincli Kaplar TayiniDocument23 pagesMmo Basincli Kaplar TayiniKenan KiliçaslanNo ratings yet

- TS en 13480-5 - 2004Document25 pagesTS en 13480-5 - 2004Selami MandaciNo ratings yet

- AD 2000 ÖzellikleriDocument6 pagesAD 2000 ÖzellikleriOnur ÇiğdemNo ratings yet

- İgdaş Baca ŞartnamesiDocument8 pagesİgdaş Baca ŞartnamesiBaca TemizlemeNo ratings yet

- 4.klasor Risk DeğerlendirmeDocument274 pages4.klasor Risk Değerlendirmegelgelebilirsen007No ratings yet

- TS en 13445-4Document51 pagesTS en 13445-4Gökhan Çiçek100% (1)

- TS en 10298Document26 pagesTS en 10298kayadumutNo ratings yet

- TS en 10216-3 PDFDocument31 pagesTS en 10216-3 PDFGökhan TEZCANNo ratings yet

- Soyvalve Katalog 2019 PDFDocument136 pagesSoyvalve Katalog 2019 PDFAndrey100% (1)

- Gaz Türbini Çalışma Donanımlarının Incelenmesi Axstream Programıyla Eksenel Akışlı Kompresör Ve Türbin Dizaynı AnaliziDocument264 pagesGaz Türbini Çalışma Donanımlarının Incelenmesi Axstream Programıyla Eksenel Akışlı Kompresör Ve Türbin Dizaynı AnaliziNebahat PolatNo ratings yet

- TS en 10028-7Document44 pagesTS en 10028-7Gökhan TEZCAN100% (2)

- Basınçlı Kaplar El KitabıDocument72 pagesBasınçlı Kaplar El KitabısamettekNo ratings yet

- ISO4017Document15 pagesISO4017naimalimliNo ratings yet

- Endüstride Malzeme Seçimi PDFDocument75 pagesEndüstride Malzeme Seçimi PDFAhmet Malik AşgınNo ratings yet

- 05 Çekme Deneyi, TS 138 EN 10002-1, 2004 PDFDocument49 pages05 Çekme Deneyi, TS 138 EN 10002-1, 2004 PDFyigitefe_03100% (5)

- TS en 13445-2Document61 pagesTS en 13445-2Gökhan Çiçek50% (2)

- Baca HesabıDocument11 pagesBaca HesabıFettah KaraağaçNo ratings yet

- 15-Yağmur Suyu HesabiDocument1 page15-Yağmur Suyu HesabiKEMAL ÖZCANNo ratings yet

- DONE KOD 1-2 FixDocument81 pagesDONE KOD 1-2 FixRezaTrisnaWahyudiNo ratings yet

- Disli Cark Hesaplari Sikloid Egrili Kremayer Disli TablosuDocument1 pageDisli Cark Hesaplari Sikloid Egrili Kremayer Disli TablosuAhmet CoşkunNo ratings yet

- Floating Roof Calculations For Naphtha Storage TanksDocument6 pagesFloating Roof Calculations For Naphtha Storage TanksErol DAĞNo ratings yet

- TS en 13445 4 PDFDocument51 pagesTS en 13445 4 PDFMustafaSaylav100% (1)

- TS en 12952-6Document33 pagesTS en 12952-6Emrah Akcay100% (1)

- Kaynak BağlantılarıDocument72 pagesKaynak BağlantılarıAlpar DalgicNo ratings yet

- Knock Out Drum - 01: Tipe: Bahan: Jumlah: 1 (Satu)Document45 pagesKnock Out Drum - 01: Tipe: Bahan: Jumlah: 1 (Satu)AmaliaLocketsShawolR'alNo ratings yet

- Ts 377-2 en 12953-2 (Si̇li̇ndi̇ri̇k Kazanlar - Bölüm 2 KazanlariDocument9 pagesTs 377-2 en 12953-2 (Si̇li̇ndi̇ri̇k Kazanlar - Bölüm 2 KazanlariKhwanas LuqmanNo ratings yet

- TS en 12952-1Document16 pagesTS en 12952-1hakan gecer100% (1)

- Türk Standardi: TS EN 1856-1Document53 pagesTürk Standardi: TS EN 1856-1Uğur GörkemNo ratings yet

- Koruyucu GazlarDocument4 pagesKoruyucu GazlarmuratcanNo ratings yet

- Katodik Koruma Proje HesabiDocument2 pagesKatodik Koruma Proje Hesabikübra100% (1)

- DBFZ Turkiye Biyogaz Potansiyel RaporuDocument148 pagesDBFZ Turkiye Biyogaz Potansiyel Raporune gerek var anonimNo ratings yet

- TS en 10216-2 2014Document44 pagesTS en 10216-2 2014ariNo ratings yet

- Hidrostatik Test RaporuDocument134 pagesHidrostatik Test Raporudahzah100% (1)

- Kaynak prb2013Document25 pagesKaynak prb2013ozlem ozdemirNo ratings yet

- Menhole Flange CalculationDocument2 pagesMenhole Flange Calculationakın ersözNo ratings yet

- Paslanmaz ÇeliklerDocument83 pagesPaslanmaz Çeliklershaqtr81No ratings yet

- Kaynak Mukavemeti Hesabi-MMODocument43 pagesKaynak Mukavemeti Hesabi-MMOmagxstone100% (1)

- TS en 13445-5Document67 pagesTS en 13445-5Gökhan Çiçek100% (3)

- Kaynak Dikişlerinin Mukavemet Hesabı PDFDocument14 pagesKaynak Dikişlerinin Mukavemet Hesabı PDFosman osmanNo ratings yet

- Termo Vana Ve Armaturleri PDFDocument28 pagesTermo Vana Ve Armaturleri PDFHede Hödö100% (1)

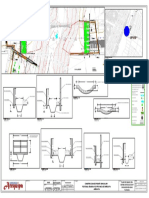

- Trafo Merkezi̇ Şalt Sahasi Temel Kanal PlaniDocument1 pageTrafo Merkezi̇ Şalt Sahasi Temel Kanal PlaniHülya Çelik BilginNo ratings yet

- Antikunas S.A.C: Quebrada N°10Document1 pageAntikunas S.A.C: Quebrada N°10jhon charlesNo ratings yet

- Plano de Canales Del Sistema de Recoleccion y EvacuacionDocument1 pagePlano de Canales Del Sistema de Recoleccion y EvacuaciongilberNo ratings yet

- Pablo de Rokha-Layout1Document1 pagePablo de Rokha-Layout1FranCeronNo ratings yet

- Plano Clave: N E W N E WDocument10 pagesPlano Clave: N E W N E WdrayazoniNo ratings yet

- 02 Planta y Perfil LongitudinalDocument1 page02 Planta y Perfil LongitudinalYorbi Eber GrupocivilercNo ratings yet

- PP PTDocument1 pagePP PTCristian Valencia SegundoNo ratings yet

- Örnek Hidrojeolojik Değerlendirme RaporuDocument63 pagesÖrnek Hidrojeolojik Değerlendirme RaporuYasin VuralNo ratings yet

- San Juan Solis SegundoDocument1 pageSan Juan Solis SegundoGUSTAVOQ DE LA CRUZNo ratings yet

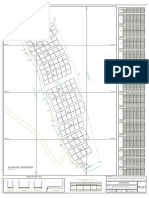

- Plano Ultimo-LotizacionDocument1 pagePlano Ultimo-LotizacionerickNo ratings yet

- Il Buono, Il Brutto e Il Cattivo - Ennio MorriconeDocument3 pagesIl Buono, Il Brutto e Il Cattivo - Ennio Morriconepietro.tonon09No ratings yet

- Plano 1Document1 pagePlano 1Darnell Aguilera PereiraNo ratings yet

- M T +burgos+2021Document1 pageM T +burgos+2021FranciscoNo ratings yet

- Kati Elektrika PDFDocument1 pageKati Elektrika PDFburimNo ratings yet

- Yatak Bi̇lgi̇ Seçi̇m FormuDocument2 pagesYatak Bi̇lgi̇ Seçi̇m Formuakın ersözNo ratings yet

- Dişli GeometrisiDocument31 pagesDişli Geometrisiakın ersözNo ratings yet

- Celik HalatDocument60 pagesCelik Halatakın ersözNo ratings yet

- 43 00 PortalVinc CK 2017Document84 pages43 00 PortalVinc CK 2017akın ersöz100% (1)

- Çağdaş Otomasyon KatalogDocument99 pagesÇağdaş Otomasyon Katalogakın ersözNo ratings yet

- Yücel BoruDocument1 pageYücel Boruakın ersözNo ratings yet

- Vinclerde Frekans TS - ISO - 22986 PDFDocument12 pagesVinclerde Frekans TS - ISO - 22986 PDFakın ersözNo ratings yet

- 43 00 PortalVinc CK 2017Document84 pages43 00 PortalVinc CK 2017akın ersöz100% (1)

- 05 1 GerilmelerDocument53 pages05 1 GerilmelerAli TaskentNo ratings yet

- Npi Yatay BukumDocument3 pagesNpi Yatay Bukumakın ersözNo ratings yet

- 40 4 Frenler GenelDocument7 pages40 4 Frenler Genelakın ersözNo ratings yet

- Tibet Makina 2015 PDFDocument52 pagesTibet Makina 2015 PDFakın ersözNo ratings yet

- Köprülü VinçDocument13 pagesKöprülü VinçAhmet IritasNo ratings yet

- F.E.M 1.001 TurkceDocument151 pagesF.E.M 1.001 Turkceakın ersöz100% (4)

- Xtek Teker ÖzellikleriDocument1 pageXtek Teker Özellikleriakın ersözNo ratings yet

- Mukavemet FORMÜLLERDocument18 pagesMukavemet FORMÜLLERalo72No ratings yet

- Mil GobekDocument100 pagesMil GobekFatih YıldızNo ratings yet

- En 9692 1 Kaynak Ağzı HazırlığıDocument19 pagesEn 9692 1 Kaynak Ağzı Hazırlığıosman osmanNo ratings yet

- Xtek Teker ÖzellikleriDocument1 pageXtek Teker Özellikleriakın ersözNo ratings yet

- Elk Motor Katalog-Nisan.2018Document48 pagesElk Motor Katalog-Nisan.2018Fani MadidaNo ratings yet

- ElkMotor Elektrik Motorları, Elektirik Motoru Elk MotorDocument2 pagesElkMotor Elektrik Motorları, Elektirik Motoru Elk Motorakın ersözNo ratings yet

- Mantar RaylarDocument5 pagesMantar Raylarakın ersözNo ratings yet

- Portal Vinç Sabit Ayak Hesabı - GüvenkutayDocument20 pagesPortal Vinç Sabit Ayak Hesabı - Güvenkutayakın ersözNo ratings yet

- 43 00 PortalVinc CK 2017Document84 pages43 00 PortalVinc CK 2017akın ersöz100% (1)

- 43 00 PortalVinc CK 2017Document84 pages43 00 PortalVinc CK 2017akın ersöz100% (1)

- Özel Ceraskal Tasarım Sonuçları (Ana Kaldırma)Document6 pagesÖzel Ceraskal Tasarım Sonuçları (Ana Kaldırma)akın ersözNo ratings yet

- İnşaat Hesaplar PDFDocument165 pagesİnşaat Hesaplar PDFakın ersözNo ratings yet

- Portal Rüzgarlı YürütmeDocument8 pagesPortal Rüzgarlı Yürütmeakın ersözNo ratings yet

- 75 Ton Portal Rüzgar HesabıDocument5 pages75 Ton Portal Rüzgar Hesabıakın ersözNo ratings yet

- Crane GearboxDocument382 pagesCrane GearboxEmre YamanNo ratings yet