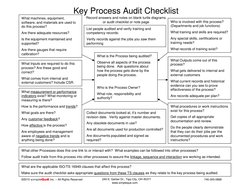

Key Process Audit Checklist

What machines, equipment, Record answers and notes on blank turtle diagrams

software, and materials are used to or audit checklist or note page Who is involved with this process?

do this process? (Departments and job functions)

List people audited and verify training and

Are there adequate resources? competency records: What training and skills are required?

Is the equipment maintained and Verify records against the jobs you saw them Any special skills, certifications or

supported? performing training needs?

Are there gauges that require What records of training exist?

calibration?

What is the Process being audited?

What Outputs come out of this

What Inputs are required to do this Observe all aspects of the process

process?

process? Are these good and being done. Ask questions about

correct? how the process gets done by the What gets delivered to internal and

people doing the process. external customers

What comes from internal and

external customers? Include CSR. What current records and historical

evidence can you see to prove

Who is the Process Owner?

effectiveness of the process?

What measurement or performance

What role, responsibility and

indicators exist? What monitoring or Are records adequate per plan?

authority?

measuring is there?

How is the performance and trends? What procedures or work instructions

exist for this process?

What goals are there? Collect documents looked at, it’s number and

revision date. Verify against master documents. Get copies of all appropriate

Any customer feedback?

documentation and review.

Any obsolete documents in use?

How effective is the process?

Do the people clearly demonstrate

Are all documents used for production controlled?

Are employees and management that they can do their jobs per the

aware of negative trends and is Are documents populated and signed as documented procedures and work

anything being done? required? instructions?

What other Processes does this one link to or interact with? What examples can be followed into other processes?

Follow audit trails from this process into other processes to assure the linkage, sequence and interaction are working as intended.

What are the applicable ISO/TS 16949 clauses that affect this process?

Make sure the audit checklist asks appropriate questions from these TS clauses as they relate to the key process being audited.

©2010 simpleQuE Inc. – All Rights Reserved 249 S. Garber Dr., Tipp City, OH 45371 740-305-0868

www.simpleque.com

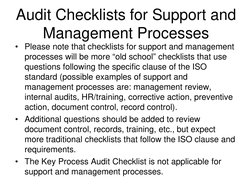

�Audit Checklists for Support and

Management Processes

• Please note that checklists for support and management

processes will be more “old school” checklists that use

questions following the specific clause of the ISO

standard (possible examples of support and

management processes are: management review,

internal audits, HR/training, corrective action, preventive

action, document control, record control).

• Additional questions should be added to review

document control, records, training, etc., but expect

more traditional checklists that follow the ISO clause and

requirements.

• The Key Process Audit Checklist is not applicable for

support and management processes.

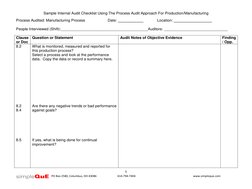

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):_________________________________________Auditors: ______________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

8.2 What is monitored, measured and reported for

this production process?

Select a process and look at the performance

data. Copy the data or record a summary here.

8.2 Are there any negative trends or bad performance

8.4 against goals?

8.5 If yes, what is being done for continual

improvement?

1

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

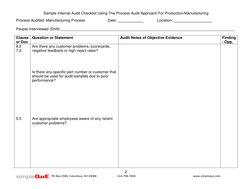

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

8.2 Are there any customer problems, scorecards,

7.2 negative feedback or high reject rates?

Is there any specific part number or customer that

should be used for audit samples due to poor

performance?

5.5 Are appropriate employees aware of any recent

customer problems?

2

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

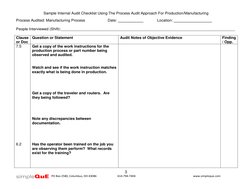

7.5 Get a copy of the work instructions for the

production process or part number being

observed and audited.

Watch and see if the work instruction matches

exactly what is being done in production.

Get a copy of the traveler and routers. Are

they being followed?

Note any discrepancies between

documentation.

6.2 Has the operator been trained on the job you

are observing them perform? What records

exist for the training?

3

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

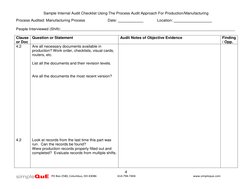

4.2 Are all necessary documents available in

production? Work order, checklists, visual cards,

routers, etc.

List all the documents and their revision levels.

Are all the documents the most recent version?

4.2 Look at records from the last time this part was

run. Can the records be found?

Were production records properly filled out and

completed? Evaluate records from multiple shifts.

4

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

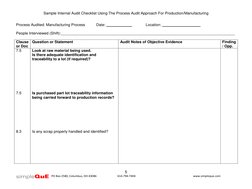

7.5 Look at raw material being used.

Is there adequate identification and

traceability to a lot (if required)?

7.5 Is purchased part lot traceability information

being carried forward to production records?

8.3 Is any scrap properly handled and identified?

5

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

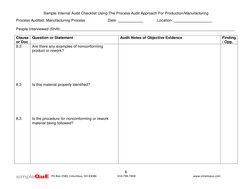

8.3 Are there any examples of nonconforming

product or rework?

8.3 Is this material properly identified?

8.3 Is the procedure for nonconforming or rework

material being followed?

6

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

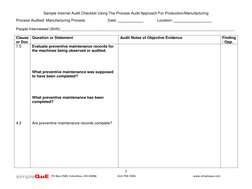

7.5 Evaluate preventive maintenance records for

the machines being observed or audited.

What preventive maintenance was supposed

to have been completed?

What preventive maintenance has been

completed?

4.2 Are preventive maintenance records complete?

7

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

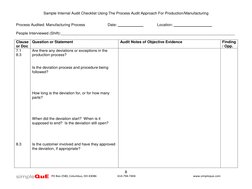

7.1 Are there any deviations or exceptions in the

8.3 production process?

Is the deviation process and procedure being

followed?

How long is the deviation for, or for how many

parts?

When did the deviation start? When is it

supposed to end? Is the deviation still open?

8.3 Is the customer involved and have they approved

the deviation, if appropriate?

8

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

7.6 Record information from any measurement

gauges or test equipment.

7.6 Check to see that gauge calibrations are up to

date and that calibration records are

maintained.

8.2 Are measurement records complete for any

inspections that are supposed to be recorded?

8.2 Are any measurements out of spec? If yes, what

was done? Is this per procedure?

9

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

8.1 Were there any targets for productivity and

8.2 effectiveness?

8.4

What is OEE versus the goal?

What is scrap versus the goal?

What is PPM versus the goal?

What is process capability versus the goal?

What is the standard time or rates versus the

goal?

6.2 Are operators aware of bad performance or

5.5 negative trends?

8.5 Is anything being done to make improvements in

areas that aren’t performing as planned?

10

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

6.1 Observe the work environment and

equipment.

Are there adequate resources (space,

equipment, and people) to do the job as

planned?

6.3 Is the work environment appropriate, clean

6.4 and safe?

11

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com

� Sample Internal Audit Checklist Using The Process Audit Approach For Production/Manufacturing

Process Audited: Manufacturing Process Date: ____________ Location: __________________

People Interviewed (Shift):__________________________________________________________________________________

Clause Question or Statement Audit Notes of Objective Evidence Finding

or Doc / Opp.

Add your own supplemental questions:

12

PO Box 2580, Columbus, OH 43086 614-794-7404 www.simpleque.com