Professional Documents

Culture Documents

SAIC-B-1002 Rev 8 (Final) Fireproofing Concrete Application Inspection Final

SAIC-B-1002 Rev 8 (Final) Fireproofing Concrete Application Inspection Final

Uploaded by

RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-B-1002 Rev 8 (Final) Fireproofing Concrete Application Inspection Final

SAIC-B-1002 Rev 8 (Final) Fireproofing Concrete Application Inspection Final

Uploaded by

RajCopyright:

Available Formats

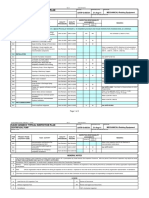

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Fireproofing Concrete Application Inspection SAIC-B-1002 31-Dec-14 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Concrete fireproofing shall be either cast-in-place, precast or gunite with SASD

A1

a minimum thickness of 50mm (2") from the reinforcing wire mesh AC-036711

The fireproofing concrete shall be a dense (structural) concrete with 28

day design compressive strength shall be 28 MPa (4000 psi) . SAES-Q-

001, Sec. 4.15.a.

Note: Ordinary dense concrete is the preferred fireproofing of structures SAES-B-006

A2

and supports because of its proven economy, durability, and Sec. 8.1

effectiveness in hydrocarbon fires. All reinforced concrete including

concrete with minimum reinforcement for temperature and shrinkage

control are defined as structural concrete.

All fireproofing concrete shall be chamfered as follows:

Pipe Supports: 50 mm

SASD

A3 Beams: 25 mm

AD-036711

Columns (except pipes): 25 mm

Angles: 25 mm

The minimum required number of concrete test cylinders shall be 1 for 3 SAES-Q-001 sec.

A4

days of age, 1 for 7 days of age and 2 for 28 days of age. 17.2

Vessels and heat exchangers, including stacked ones with a gross

volume of 2.5 m³ (15 barrels) or greater and that contain flammable

SAES-B-006

A5 liquid, or combustible liquid near or above its flashpoint, combustible

Sec. 5.3.1

gas, or potentially toxic material, shall have their supports and anchor

rings fireproofed from grade up to the level defined by A6 to A9 below.

A clearance of 30 mm shall be maintained between the vessel surface SAES-B-006

A6

and the fireproofing material on support legs, skirts, and saddles. Sec. 5.3.3.b

A clearance of 30 mm shall be provided between a sliding surface and SAES-B-006

A7

the fireproofing material on a sliding support. Sec. 5.3.3.c

An internally insulated vessel operating at a fluid temperature above SAES-B-006

A8

260°C shall not have the top 300 mm of the skirt fireproofed. Sec. 5.3.3.d

Vessel support legs shall be fireproofed from grade up to a level SAES-B-006

A9

30 mm below the contact line/surface between the legs and vessel. Sec. 5.3.3.e

The saddle supports for single horizontal vessels shall be fireproofed up

to the vessel midpoint; i.e., up to the 3 o'clock and 9 o'clock positions. If SAES-B-006

A10

the saddle supports do not extend to the vessel midpoint, fireproof the Sec. 5.3.3.f

entire saddle support.

Saudi Aramco: Company General Use

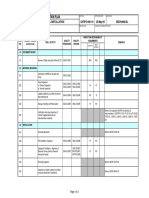

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Fireproofing Concrete Application Inspection SAIC-B-1002 31-Dec-14 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

The skirt supporting a tower or vertical vessel shall be fireproofed on the

inside and outside surfaces. Standard Drawing AC-036915.

Exception to: Fireproofing of the inside of a vessel skirt is not required if

the vessel skirt is provided with only one access opening and no more SAES-B-006

A11

than one pipe penetration. The access opening shall be no larger than Sec. 5.3.3.g

500 mm in dia. The clearance between the edge of the penetration

opening and the surface of the penetrating pipe shall not be larger than

13 mm.

The bolts for the support of shell-and-tube heat exchangers and the area SAES-B-006

A12

within 30mm of the bolts, shall not be fireproofed. Sec. 5.3.4

Wire mesh shall be provided in all fireproofing concrete. The wire mesh

A13 shall be either 4" x 4" - 10 GA. X 10 GA (SAMSS 12-743-625) or 2" x 2" - AD-036711

14GA x 14 GA (SAMSS 12-743-620).

20 mm diameter x 125 mm spacers (and connectors) tack welded at 600

A14 AD-036711

mm centers (SAMSS 12-720-570) shall be provided

For process heaters( in any service) or steam generator that are wholly

or partially located in fire hazardous zone, all vertical supports shall be SAES-B-006

A15

fireproofed from the foundation to the support point of the process heater Sec. 5.4.1

or steam generator

Horizontal beams in contact with a process heater floor or shell shall not

SAES-B-006

A16 be fireproofed. Any horizontal beams below the process heater and not

Sec. 5.4.2

in contact with it shall be fireproofed.

Vertical columns supporting a single level of piping shall be fireproofed

SAES-B-006

A17 up to of horizontal member(s) above the fire hazardous zone regardless

Sec. 5.5.1

of height, including any attached pipe supports other than spring or rods.

Vertical columns supporting multiple levels of piping shall be

SAES-B-006

A18 fireproofed up to the point of support of the lowest horizontal member

Sec. 5.5.2

located above the fire-hazardous zone, regardless of height.

Vertical columns which support both piping and air-cooled heat

SAES-B-006

A19 exchangers shall be fireproofed according to the requirements for air-

Sec. 5.5.3

cooled heat exchangers.

Horizontal cross members shall be fireproofed for their full length when

SAES-B-006

A20 one or more of the attached vertical columns are fireproofed up to or

Sec. 5.5.4

beyond the point of support of the horizontal member.

Cantilevers, bracing, and dummy supports shall be fireproofed when any SAES-B-006

A21

attached members are fireproofed. Sec. 5.5.5

In fire hazard zones, a fireproofed catch beam or pillar shall be provided

SAES-B-006

A22 for hydrocarbon or toxic material piping which is suspended from rods or

Sec. 5.5.6

supported by a spring.

Wood and other combustible materials shall not be used for temporary

SAES-B-006

A23 supports. Temporary piping supports in fire-hazardous areas shall be

Sec. 5.5.8

fireproofed.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Fireproofing Concrete Application Inspection SAIC-B-1002 31-Dec-14 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

For an air-cooled heat exchanger, the vertical supports located in a fire-

hazardous zone shall be fireproofed from grade up to the support point

SAES-B-006

A24 of the heat exchanger. Horizontal beams shall be fireproofed when one

Sec. 5.6

or more of the attached vertical columns are fireproofed up to or past the

point of support of the horizontal member.

Proprietary fireproofing material shall be applied in a manner approved SAES-B-006

A25

by the fireproofing manufacturer and Inspection Department. Sec. 8.2.1

Application shall be made in strict accordance with the approved method

SAES-B-006

A26 and manufacturer's guidelines regarding ambient temperature, storage

Sec. 8.2.3

temperature,materials, proportioning, and mixing.

Application of intumescent mastics or other approved proprietary

SAES-B-006

A27 fireproofing shall be performed only by personnel trained and certified by

Sec. 8.2.2

the material manufacturer.

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-B-006 -- Fireproofing for Plants, 20 November 2011

2- SAES-Q-001 -- Criteria for Design and Construction of Concrete Structures, 5 March 2008

3- SASD-AC-036404 Flame Impingement Shield for Flangeless Valves, 31 December 1994

4- SASD-AD-036711 -- Concrete Fireproofing for Structural Members, 1 September 2000

5- SASD-AC-036915 -- Details: Fireproofing Specifications for Columns and Vessel Skirts, 01 March 1999

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- The Official F-19 Stealth Fighter HandbookDocument194 pagesThe Official F-19 Stealth Fighter Handbookremow83% (6)

- Saudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechphilipyapNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Icao Doc 10000 - Flight Data Analysis Programme Manual - 1st Edition 2013 - Unedited 1Document24 pagesIcao Doc 10000 - Flight Data Analysis Programme Manual - 1st Edition 2013 - Unedited 1Bela Firmantoyo100% (1)

- SAIC-K-4039 Rev 7 Air-Cooled Condenser InstallationDocument2 pagesSAIC-K-4039 Rev 7 Air-Cooled Condenser InstallationshahzadaNo ratings yet

- Saudi Aramco Inspection Checklist: Air Filtration Devices Installation SAIC-K-4029 HvacDocument3 pagesSaudi Aramco Inspection Checklist: Air Filtration Devices Installation SAIC-K-4029 HvacshahzadaNo ratings yet

- SAIC-A-2013 Rev 0Document2 pagesSAIC-A-2013 Rev 0philipyapNo ratings yet

- Saic K 4001Document2 pagesSaic K 4001BilalNo ratings yet

- Saic N 2033Document5 pagesSaic N 2033aamirapiNo ratings yet

- Saudi Aramco Pre-Commissioning Form: LightingDocument2 pagesSaudi Aramco Pre-Commissioning Form: LightingHaleem Ur Rashid Bangash100% (1)

- Saudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacDocument1 pageSaudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacmohamadNo ratings yet

- Saudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacDocument1 pageSaudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacmohamadNo ratings yet

- Refinery ConfigurationDocument11 pagesRefinery ConfigurationIoana Popescu100% (2)

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- PMP-ResourcesDocument71 pagesPMP-ResourcesmohamadNo ratings yet

- SAIC-P-3003 Rev 7 FinalDocument7 pagesSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- SAIC-K-4001 Rev 7Document3 pagesSAIC-K-4001 Rev 7Rohit BassNo ratings yet

- FAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansFrom EverandFAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansRating: 5 out of 5 stars5/5 (2)

- SATR - J - 6702 Rev 0 PDFDocument8 pagesSATR - J - 6702 Rev 0 PDFAdel KlkNo ratings yet

- Satr K 4006Document2 pagesSatr K 4006Jerald SoteloNo ratings yet

- SAIC-K-4044 Rev 7 Pressurized Building HVAC RequirementsDocument6 pagesSAIC-K-4044 Rev 7 Pressurized Building HVAC RequirementsshahzadaNo ratings yet

- Saic A 2011Document5 pagesSaic A 2011Anonymous 4e7GNjzGWNo ratings yet

- Exercise Examples For Quality Control ChartsDocument4 pagesExercise Examples For Quality Control Chartsda_reaper_dasNo ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Document4 pages1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnNo ratings yet

- Saudi Diyar Consultants: Construction Supervision Department Procedures ManualDocument18 pagesSaudi Diyar Consultants: Construction Supervision Department Procedures ManualmohamadNo ratings yet

- Satip G 005 01Document2 pagesSatip G 005 01Anonymous 4e7GNjzGWNo ratings yet

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Document3 pages1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- Saic K 4002Document2 pagesSaic K 4002BilalNo ratings yet

- Building The Trident NetworkDocument243 pagesBuilding The Trident Networktlq1mpoNo ratings yet

- AMM 10-30-00-554-804-A - Return To Operation After A Parking PeriodDocument9 pagesAMM 10-30-00-554-804-A - Return To Operation After A Parking PeriodAndres MendezNo ratings yet

- Saudi Aramco Inspection Checklist: Passively Cooled Shelter Installation Inspection SAIC-K-4035 30-Apr-13 HvacDocument3 pagesSaudi Aramco Inspection Checklist: Passively Cooled Shelter Installation Inspection SAIC-K-4035 30-Apr-13 HvacshahzadaNo ratings yet

- Part - B: (Control and Instrumentation System)Document267 pagesPart - B: (Control and Instrumentation System)joydrathdey100% (1)

- SATR-J-6505-Rev 0 PDFDocument5 pagesSATR-J-6505-Rev 0 PDFAdel KlkNo ratings yet

- Peakvue Case History 2Document9 pagesPeakvue Case History 2ben_ramatlaNo ratings yet

- FMEA MaterialDocument18 pagesFMEA MaterialKarthi ThiyagarajanNo ratings yet

- 5 SDocument44 pages5 SFarhan Saleem67% (3)

- Seafaring As A CareerDocument15 pagesSeafaring As A Careerhutsonianp100% (2)

- Matching Dell Case SolutionDocument3 pagesMatching Dell Case SolutionAnuj Kumar HatoneyaNo ratings yet

- Saic - K-4006Document2 pagesSaic - K-4006Bander Al–kouhlaniNo ratings yet

- Saic K 4010Document3 pagesSaic K 4010mohamadNo ratings yet

- Saic S 4006Document2 pagesSaic S 4006mahdi_gNo ratings yet

- SAIC & SATR - InstrumentationDocument7 pagesSAIC & SATR - InstrumentationAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Satip-X-600-02 Rev 1 For CP SystemDocument4 pagesSatip-X-600-02 Rev 1 For CP SystemSaleem MohammedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- SATR-J-6406 Rev 0 PDFDocument10 pagesSATR-J-6406 Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistmohamadNo ratings yet

- Saic-P-3002 Rev 0Document4 pagesSaic-P-3002 Rev 0jwochNo ratings yet

- Saic - K-4027Document3 pagesSaic - K-4027Bander Al–kouhlaniNo ratings yet

- SAIC-N-2042 Rev 0Document2 pagesSAIC-N-2042 Rev 0philipyapNo ratings yet

- SAIC-S-4012 Rev 7Document5 pagesSAIC-S-4012 Rev 7Muhammad TariqNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingDocument9 pagesSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistMa.socorro SaballaNo ratings yet

- Saic - K-4017Document2 pagesSaic - K-4017Bander Al–kouhlaniNo ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistphilipyapNo ratings yet

- SAIC-A-2023 Rev 0Document2 pagesSAIC-A-2023 Rev 0philipyapNo ratings yet

- Saudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 ElectDocument3 pagesSaudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDocument17 pagesSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemNo ratings yet

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: D.C. Power System - Installation Inspection SAIC-T-5118 30-Apr-13 TelecomDocument6 pagesSaudi Aramco Inspection Checklist: D.C. Power System - Installation Inspection SAIC-T-5118 30-Apr-13 TelecomOmer aliNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument5 pagesAlert Operators Transmission - Aot: Customer Services DirectorateIbrahim KhalilNo ratings yet

- SATIP-K-001-06 - PACKAGED AIR CONDITIONING UNIT SystDocument3 pagesSATIP-K-001-06 - PACKAGED AIR CONDITIONING UNIT SystRAMAKRISHNA100% (1)

- SAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil SystemDocument3 pagesSAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil Systemবিপ্লব পালNo ratings yet

- PMP StakeholdersDocument62 pagesPMP StakeholdersmohamadNo ratings yet

- Project Management and Scheduling PDFDocument339 pagesProject Management and Scheduling PDFmohamadNo ratings yet

- Saudi Diyar Consultants: Construction Supervision Department Procedures ManualDocument52 pagesSaudi Diyar Consultants: Construction Supervision Department Procedures ManualmohamadNo ratings yet

- Saic K 4010Document3 pagesSaic K 4010mohamadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistmohamadNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001mohamadNo ratings yet

- Daily TaskDocument36 pagesDaily TaskmohamadNo ratings yet

- Port Aka Bin Case Study Lean ProductionDocument7 pagesPort Aka Bin Case Study Lean ProductionEmma JonesNo ratings yet

- ANSYS Solutions Winter02Document91 pagesANSYS Solutions Winter02SrashmiNo ratings yet

- Garments Dyeing For LearnerDocument5 pagesGarments Dyeing For LearnerMohammed Atiqul Hoque ChowdhuryNo ratings yet

- Certificado 5elem FM Actualizado 2016Document11 pagesCertificado 5elem FM Actualizado 2016dnup5No ratings yet

- Vishwakarma Institute of Technology, Pune: Seminar PresentationDocument26 pagesVishwakarma Institute of Technology, Pune: Seminar PresentationSHREYAS YADAVNo ratings yet

- Tarshier Customer - Brochure PDFDocument0 pagesTarshier Customer - Brochure PDFRajib DasNo ratings yet

- Visionsystemsdesign201604 DLDocument44 pagesVisionsystemsdesign201604 DLNehaoua FaresNo ratings yet

- Shortcuts and Hot KeysDocument1 pageShortcuts and Hot KeysMurali D MurthyNo ratings yet

- How Companies Become Platform LeaderDocument4 pagesHow Companies Become Platform Leaderbadal50% (2)

- Cogen 3 Technical Financial Analysis ModelDocument58 pagesCogen 3 Technical Financial Analysis ModelLai Mei EeNo ratings yet

- Rancang Bangun Mesin CNC Router Mini Untuk PembelaDocument7 pagesRancang Bangun Mesin CNC Router Mini Untuk PembelaAkhmad Khoirur RizalNo ratings yet

- Formula Blue 2 Prototype Book December 2020Document36 pagesFormula Blue 2 Prototype Book December 2020gauravconstructiondevelopersNo ratings yet

- 28th Revised Dolmen Harbour Front Executive Office Block Clifton - CircularDocument9 pages28th Revised Dolmen Harbour Front Executive Office Block Clifton - CircularMariyam Khan BalochNo ratings yet

- English CVDocument4 pagesEnglish CVFranky Tengo La Casa SolaNo ratings yet

- Advert For 50 Posts - Electrical Technicians DraftDocument7 pagesAdvert For 50 Posts - Electrical Technicians DraftEM NemiNo ratings yet

- A Seminar ReportDocument5 pagesA Seminar ReportRohit VishwakarmaNo ratings yet

- Energypac Presentatio N: Group Number: 3 Course Code: Marketing Management Course: MKT515 Section: 2 Session: Fall 2020Document8 pagesEnergypac Presentatio N: Group Number: 3 Course Code: Marketing Management Course: MKT515 Section: 2 Session: Fall 2020Redwan KhanNo ratings yet

- FPS 013 - Use of Boatswain chairREV1Document4 pagesFPS 013 - Use of Boatswain chairREV1grantNo ratings yet

- Market Survey Knitting OilDocument3 pagesMarket Survey Knitting OilSakthi Saravanan100% (1)

- 1 Yoga Fajar N - CV RevDocument1 page1 Yoga Fajar N - CV Revyoga fajarNo ratings yet