Professional Documents

Culture Documents

PROFIL - SRG Measurement - Rev 1

Uploaded by

EduardOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PROFIL - SRG Measurement - Rev 1

Uploaded by

EduardCopyright:

Available Formats

T H Hill Associates, Inc.

Drilling Problem Solvers & Enforcers

Field Technicians • Engineering • Training • Software • Books

7676 Hillmont, Suite 360 • Houston, TX 77040 • (713) 934-9215 • (713) 934-9236 Fax

Date of Issue: THHA-TN-09-001 Rev 1

Technical Note Submitted: Pat Harrah

04FEB2009 Reviewed: Jack Cranfill

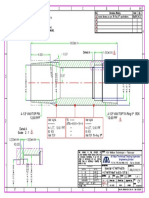

Pin Stress Relief Groove Measurement Approved: Keith Branch

Background

In the past there has been some confusion on how to measure Stress Relief Groove (SRG) width IAW DS-1, Vol 3,

paragraph 3.14.4.e. DS-1, Vol 3, Figure 3.14.2 shows that dimension “F” is the SRG width. API Specification 7, Section 8, Fig 16 and

API RP 7G, Section 13, Fig. 90 imply the measurement should be taken from the crest of the first thread to the Pin Shoulder.

However, due to the SRG machining process and API thread profiles, the “First Full Thread” grows to full height prior to developing

its full thread form and crest width, leading to a subjective determination of how to measure SRG width and meet the intent of the

illustrations in DS-1, API Specification 7 and API RP 7G.

Procedure

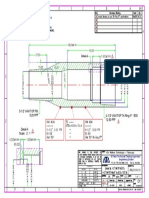

The “First Full Thread” is defined when the thread closest to the pin shoulder reaches the same height and thread profile

as the second thread. The measurement is taken by first laying a thread profile gauge on the thread taper. If light can be seen

between the thread form and profile gauge then the thread is not fully formed (Fig 1). Rotate the profile gauge until the absolute

minimum amount of light is visible between it and the first thread (Fig 2). This point is considered the “First Full Thread” and is the

point at which the SRG is measured. A machinist’s scale is then placed on the thread taper at this point, squared against the

connection shoulder and the measurement taken from the shoulder to the point directly above the First Full Thread (Fig 3).

(Fig 1) Thread not fully formed as seen (Fig 2) Lay thread profile gauge along (Fig 3) Square scale at the point of the

with light showing between profile gauge thread taper and rotate around the “First Full Thread” and take the

and thread. thread form until absolute minimum light measurement from shoulder side of

is visible between the profile gauge and thread profile to pin shoulder.

the first thread. Thread is fully formed

(First Full Thread).

7676 Hillmont, Suite 360 • Houston, Texas 77040 • Tel (713) 934-9215 • Fax (713) 934-9236

www.thhill.com

You might also like

- The Story GridDocument346 pagesThe Story Gridjoel3edwards97% (36)

- Hack and SlashDocument38 pagesHack and Slashyo100% (1)

- Science of Being - 27 Lessons (1-9) - Eugene FersenDocument202 pagesScience of Being - 27 Lessons (1-9) - Eugene FersenOnenessNo ratings yet

- Design of Hoisting Mechanism For Crane R1Document45 pagesDesign of Hoisting Mechanism For Crane R1Bhalchandra Desai100% (2)

- 66 Surveying BesavillaDocument586 pages66 Surveying BesavillaJeanelyn Tom100% (1)

- Sheave Manual SMDocument8 pagesSheave Manual SMLutfi IsmailNo ratings yet

- Summary of Bolt TensioningDocument16 pagesSummary of Bolt Tensioningpedro ylarretaNo ratings yet

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- SERMON - "Prayer Is Our Most Powerful Weapon" 11.12.2017Document9 pagesSERMON - "Prayer Is Our Most Powerful Weapon" 11.12.2017Jojo Mercolita EstolaNo ratings yet

- Parameters Mahr Roughness PDFDocument19 pagesParameters Mahr Roughness PDFCarlos RamirezNo ratings yet

- Analytic Geometry, Sixth Edition, (PDFDrive)Document480 pagesAnalytic Geometry, Sixth Edition, (PDFDrive)Alaine Paul Geronimo100% (1)

- REBARS (318-05) (Engineersdaily - Com)Document8 pagesREBARS (318-05) (Engineersdaily - Com)sawahNo ratings yet

- Science Culminating Task RubricDocument2 pagesScience Culminating Task Rubricapi-311644452No ratings yet

- Hydro Culv 21Document10 pagesHydro Culv 21Víctor García García ErasoNo ratings yet

- Marketing Mix ModelingDocument14 pagesMarketing Mix ModelingRajesh KurupNo ratings yet

- Job Hazard Analysis Site InspectionDocument12 pagesJob Hazard Analysis Site InspectionNonsoufo eze100% (1)

- Asme Sec. Viii Div-1) : Shell Plate (Disk) ConversionDocument33 pagesAsme Sec. Viii Div-1) : Shell Plate (Disk) ConversionuzairmetallurgistNo ratings yet

- Minimum Pulley Diameters - Fenner DunlopDocument6 pagesMinimum Pulley Diameters - Fenner Dunlopluis martinezNo ratings yet

- Grid FloorsDocument14 pagesGrid FloorsShashi Prakash100% (3)

- Sheet Metal Bending-3Document15 pagesSheet Metal Bending-3Sai Sujan100% (1)

- Steam Nozzle 1Document47 pagesSteam Nozzle 1Balaji Kalai100% (5)

- TLE-ICT-Technical Drafting Grade 10 LMDocument175 pagesTLE-ICT-Technical Drafting Grade 10 LMHari Ng Sablay87% (113)

- Turnout Calc PDFDocument47 pagesTurnout Calc PDFksvinyk7193100% (1)

- Cast Iron: Physical and Engineering PropertiesFrom EverandCast Iron: Physical and Engineering PropertiesRating: 5 out of 5 stars5/5 (1)

- 2.0-2.5R Series Parts ListDocument350 pages2.0-2.5R Series Parts ListRomanNo ratings yet

- Introduction To Belt Drive: SelectionDocument40 pagesIntroduction To Belt Drive: Selectionsohkimfai6340100% (2)

- 37 Rotational InertiaDocument4 pages37 Rotational InertiaMateo NegroNo ratings yet

- Lab 11 Rotational Inertia of Disk and Ring PDFDocument5 pagesLab 11 Rotational Inertia of Disk and Ring PDFJEPHTAH LosNo ratings yet

- Pipe PDFDocument6 pagesPipe PDFnguyendan81985No ratings yet

- Rmax Rz1Max RZDocument4 pagesRmax Rz1Max RZNEELNo ratings yet

- Tensioner Nuts & Bolts We Make Thread Gauges Cold Forgings From ChinaDocument4 pagesTensioner Nuts & Bolts We Make Thread Gauges Cold Forgings From ChinamohanjatinderNo ratings yet

- Compression 1 1 PDFDocument57 pagesCompression 1 1 PDFrahimi mohamadNo ratings yet

- Designing A Miniature Belt DriveDocument1 pageDesigning A Miniature Belt DriveKumar KumarNo ratings yet

- Is 7906 1 1997Document37 pagesIs 7906 1 1997paragbholeNo ratings yet

- Frame Analysis: by Abdullah Lajam, Adam Joshua & Mohammed AlazzaniDocument14 pagesFrame Analysis: by Abdullah Lajam, Adam Joshua & Mohammed AlazzaniAdam JoshuaNo ratings yet

- HW1 WellLog Bexultan PDFDocument4 pagesHW1 WellLog Bexultan PDFJustin ButlerNo ratings yet

- 8B - Yang Light Rail Aerial GuidewayDocument57 pages8B - Yang Light Rail Aerial GuidewayMohamedNo ratings yet

- Bridge DesignDocument29 pagesBridge DesignLeny Agrabio AlaroNo ratings yet

- Advanced Prestressed - Module 1 HandoutDocument69 pagesAdvanced Prestressed - Module 1 HandoutfranciscochittyNo ratings yet

- Spirit Aero Systems Final Presentation WebDocument36 pagesSpirit Aero Systems Final Presentation WebJacob Jack YoshaNo ratings yet

- Diseño de Gradas PDFDocument12 pagesDiseño de Gradas PDFAdrian Guerra EspinosaNo ratings yet

- Torsional - PendulumDocument5 pagesTorsional - Pendulumxogus6216No ratings yet

- Study On Groove Shape in Park Lock SystemDocument7 pagesStudy On Groove Shape in Park Lock SystemIJRASETPublicationsNo ratings yet

- Chapter 04 - Power Transmission DriveDocument60 pagesChapter 04 - Power Transmission DriveJoebert SabidoNo ratings yet

- 3.DME - ME3RD - UNIT-3.2 - Design of JointsDocument70 pages3.DME - ME3RD - UNIT-3.2 - Design of JointsCHITYALA YASHWANTH KRISHNA ,ECE18 Vel Tech, ChennaiNo ratings yet

- Section 41 Th&VerDocument131 pagesSection 41 Th&VerDiego AthaydeNo ratings yet

- Parts & Service NewsDocument10 pagesParts & Service NewsJose A. Basanta H.No ratings yet

- Elements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasDocument13 pagesElements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasRakeshvb10No ratings yet

- Belts, Ropes and Chain: Flexible ConnectorsDocument3 pagesBelts, Ropes and Chain: Flexible ConnectorsAdriel JohnNo ratings yet

- TR GSM 0301Document37 pagesTR GSM 0301Dhayou GraphyNo ratings yet

- Spring Manufacturing ProcessDocument4 pagesSpring Manufacturing ProcessUzma sijratNo ratings yet

- Design, Analysis and Development of Hydraulic Scissor LiftDocument8 pagesDesign, Analysis and Development of Hydraulic Scissor Liftmohit talrejaNo ratings yet

- Pipe Alignment & Grade, Control Syst - Ed01docxDocument4 pagesPipe Alignment & Grade, Control Syst - Ed01docxMesfin DerbewNo ratings yet

- Paper Helicopter - Experimental Optimum Engineering Design Classroom Prob-LEMDocument8 pagesPaper Helicopter - Experimental Optimum Engineering Design Classroom Prob-LEMEven OngNo ratings yet

- Fastener and Screw Torque DesignDocument6 pagesFastener and Screw Torque DesignjigneshNo ratings yet

- Torsion LabDocument22 pagesTorsion LabNeoXana01No ratings yet

- Design Report Cover Sheet: Bear River TrussDocument29 pagesDesign Report Cover Sheet: Bear River TrussMaitrabarun KarjeeNo ratings yet

- Application 1Document15 pagesApplication 1Jonh RiberosNo ratings yet

- Screw GaugeDocument2 pagesScrew GaugeABHISEK SAHUNo ratings yet

- Thomas Murray Andres Sanchez Floor VibrationsDocument62 pagesThomas Murray Andres Sanchez Floor Vibrationsdavidguillermo83No ratings yet

- David Tarboton, Dan Watson, Rob Wallace: Dtarb@usu - EduDocument49 pagesDavid Tarboton, Dan Watson, Rob Wallace: Dtarb@usu - EdurovallecNo ratings yet

- Circular ColumnDocument59 pagesCircular ColumnsanjayNo ratings yet

- Rebars (318-05)Document8 pagesRebars (318-05)Sana UllahNo ratings yet

- Reference Manual AND Spreadsheet Users Guide: Joist Girder Moment Connections To Wide Flange Columns - Knife PlatesDocument28 pagesReference Manual AND Spreadsheet Users Guide: Joist Girder Moment Connections To Wide Flange Columns - Knife PlatesRal GLNo ratings yet

- Guidebook to R Graphics Using Microsoft WindowsFrom EverandGuidebook to R Graphics Using Microsoft WindowsRating: 3 out of 5 stars3/5 (1)

- The Art of Timing Closure: Advanced ASIC Design ImplementationFrom EverandThe Art of Timing Closure: Advanced ASIC Design ImplementationNo ratings yet

- Acy 428Document1 pageAcy 428EduardNo ratings yet

- SCANDocument5 pagesSCANEduardNo ratings yet

- Inspection Report: Wesco LLCDocument8 pagesInspection Report: Wesco LLCEduardNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- Emdqp Ins 211Document10 pagesEmdqp Ins 211EduardNo ratings yet

- EMDC DQT Well Asset Daily Reporting SpreadsheetDocument42 pagesEMDC DQT Well Asset Daily Reporting SpreadsheetEduardNo ratings yet

- TSH-AR-00.0005 Rev.5Document10 pagesTSH-AR-00.0005 Rev.5EduardNo ratings yet

- MTC 4140 5.25-2.75 HT 986366-5Document9 pagesMTC 4140 5.25-2.75 HT 986366-5EduardNo ratings yet

- DR 039 00184Document2 pagesDR 039 00184EduardNo ratings yet

- Emtsli 01Document3 pagesEmtsli 01EduardNo ratings yet

- Emdqp Ins 212Document20 pagesEmdqp Ins 212EduardNo ratings yet

- ATTA.D.0193.18 Rev 01 - Crossover Sub, 3.50 VAM TOP PIn #9.20 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALDocument1 pageATTA.D.0193.18 Rev 01 - Crossover Sub, 3.50 VAM TOP PIn #9.20 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALEduardNo ratings yet

- EMAR 01 Rev01 FINALDocument12 pagesEMAR 01 Rev01 FINALEduardNo ratings yet

- Emdqp Ins 215Document16 pagesEmdqp Ins 215EduardNo ratings yet

- IOA 21073 Rev 1Document2 pagesIOA 21073 Rev 1EduardNo ratings yet

- UnpricedDocument4 pagesUnpricedEduardNo ratings yet

- ATTA-Quality Plan-19-001Rev.01-signedDocument5 pagesATTA-Quality Plan-19-001Rev.01-signedEduardNo ratings yet

- ATTA.D.0192.18 Rev 01 - Crossover Sub, 4.50 VAM TOP PIn #12.60 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALDocument1 pageATTA.D.0192.18 Rev 01 - Crossover Sub, 4.50 VAM TOP PIn #12.60 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALEduardNo ratings yet

- Al Nasr Metal Industries Location MapDocument1 pageAl Nasr Metal Industries Location MapEduardNo ratings yet

- EMDC DQT Well Asset Daily Reporting Spreadsheet - IOA21073Document42 pagesEMDC DQT Well Asset Daily Reporting Spreadsheet - IOA21073EduardNo ratings yet

- Serial Number Thread Depth Before CW Thread Depth After CW W18AFM0115 0.01 0.04 W18AFM0141 0.015 0.05 W18AFM0151 0.01 0.045Document1 pageSerial Number Thread Depth Before CW Thread Depth After CW W18AFM0115 0.01 0.04 W18AFM0141 0.015 0.05 W18AFM0151 0.01 0.045EduardNo ratings yet

- Emtmp Pur 204Document2 pagesEmtmp Pur 204EduardNo ratings yet

- String 3Document1 pageString 3EduardNo ratings yet

- Emtmp Pur 205Document3 pagesEmtmp Pur 205EduardNo ratings yet

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Document29 pagesMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardNo ratings yet

- X-Overs PQPDocument6 pagesX-Overs PQPEduardNo ratings yet

- Pups PQPDocument6 pagesPups PQPEduardNo ratings yet

- Pump in Sub PQPDocument2 pagesPump in Sub PQPEduardNo ratings yet

- 7.1.4 Environment For The Operation of ProcessesDocument2 pages7.1.4 Environment For The Operation of ProcessesGVS RaoNo ratings yet

- Quick Guide System 1200 - Monitoring Using Sets of AnglesDocument3 pagesQuick Guide System 1200 - Monitoring Using Sets of AnglesariyarathneNo ratings yet

- Measure and IntegralDocument5 pagesMeasure and Integralkbains7No ratings yet

- William Blomquist: Education SUNY Plattsburgh Work Experience Costco WholesaleDocument1 pageWilliam Blomquist: Education SUNY Plattsburgh Work Experience Costco WholesaleWilliam BlomquistNo ratings yet

- Descriptive Statistics I Theory Questions (1997-2016)Document9 pagesDescriptive Statistics I Theory Questions (1997-2016)Satyaki GhosalNo ratings yet

- Innovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemDocument8 pagesInnovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemRakesh BiswasNo ratings yet

- Introduction Manual: 30000mah Type-C Power BankDocument33 pagesIntroduction Manual: 30000mah Type-C Power BankIreneusz SzymanskiNo ratings yet

- "Universal Asynchronous Receiver and Transmitter" (UART) : A Project Report OnDocument24 pages"Universal Asynchronous Receiver and Transmitter" (UART) : A Project Report Ondasari himajaNo ratings yet

- Human Body: Digestion - Pathway and EnzymesDocument4 pagesHuman Body: Digestion - Pathway and EnzymesDiana VillanuevaNo ratings yet

- Ferrite Core Transformer Design Engineering and Technology 6Document10 pagesFerrite Core Transformer Design Engineering and Technology 6nedian_2006100% (1)

- Cementatious Waterproofing - KousterDocument3 pagesCementatious Waterproofing - KousterRaed HaloubNo ratings yet

- Data RepresentationDocument29 pagesData RepresentationAkshay MathurNo ratings yet

- CoveringlettersDocument45 pagesCoveringlettersbeautygirl3310No ratings yet

- Ed 352649Document269 pagesEd 352649Hồng HạnhNo ratings yet

- MTH 212 OdeDocument18 pagesMTH 212 OdeJames ojochegbNo ratings yet

- Relationship With Josephine BrackenDocument9 pagesRelationship With Josephine BrackenNothingNo ratings yet

- How To Represent Geospatial Data in SDMX 20181022Document47 pagesHow To Represent Geospatial Data in SDMX 20181022scorpio1878No ratings yet

- Ricardo Vargas Simplified Pmbok Flow 6ed PROCESSES EN-A4 PDFDocument1 pageRicardo Vargas Simplified Pmbok Flow 6ed PROCESSES EN-A4 PDFFrancisco Alfonso Durán MaldonadoNo ratings yet

- Sociologia Şi Ştiinţa Naţiunii În Doctrina Lui Dimitrie GustiDocument35 pagesSociologia Şi Ştiinţa Naţiunii În Doctrina Lui Dimitrie GustiSaveanu RazvanNo ratings yet

- English 9 Determiners PDF CbseDocument9 pagesEnglish 9 Determiners PDF CbseAarav SakpalNo ratings yet