Professional Documents

Culture Documents

Process Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 Supercedes

Uploaded by

phuongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 Supercedes

Uploaded by

phuongCopyright:

Available Formats

ISSUE: 04/15-1 SUPERCEDES:

Process Suitability.

Plasma Thermal HVOF

Yes Yes Yes

No Bond Coat Required

Used mainly as a bond coat for Plasma and Thermal processes. Produces a ‘Self Bonding’

dense coating which is resistant to oxidation.

Bond Coat.

Heat Treatment Fixtures.

Machine Slideways.

Abrasive Grains - Low Temperature Fretting - Intended Motion

Abrasive Grains - High Temperature Fretting - No Intended Motion

Oxidation up to 650C (1200F) Cavitation

Particle Erosion - High Temperature

Auminium 4.5 -325 mesh + 15 micron

Nickel Bal -45 + 15 microns

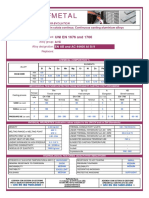

1. Machining:

Tool Carbide K 11 ‘D’ Shape

Work Speed Traverse In Feed Roughing In Feed Finishing

SFPM 10 in/rev 0.0025 inches 0.010 inches 0.005

m/sec 0.05 mm/rev 0.064 mm 0.25 mm 0.13

2. Wet Grinding:

Surface Cylindrical Centreless

Wheel GC46 - H11 - VR GC60 - J11 - VR GC60 - J11 - VR

Speeds

Wheel SFPM 5500 - 6500 5500 - 6500 5500 - 6500

Wheel m/min 1650 - 1950 1650 - 1950 1650 - 1950

Work SFPM N/A 70 - 100 70 - 100

Work m/min N/A 21 - 30 21 - 30

Table Inches/Min 400 - 600 12 N/A

Table mm/sec 170 - 254 5 N/A

Cross Feed inches 0.010 - 0.030 N/A N/A

Cross feed mm 0.25 - 0.76 N/A N/A

Regulating Wheel:

Angle N/A N/A 2

RPM N/A N/A 29

Notes:

01. The above is issued as a guide.

02. You may need to substitute alternative wheels, feeds and speeds to suit local conditions

or requirements.

03. To obtain finer finishes use finer grit wheels.

04. Do not glaze a coarse grit wheel to obtain a finer finish

Guide to Wheel Selection.

Softer Wheel Harder Wheel

Faster Stock Removal Finer Finish

Large Area of Contact Small Area of Contact

Light Pressure Heavy Pressure

Wide Wheels Narrow Wheels

Surface Preparation:

Pressure Suction

Blast Media psi bar psi bar Thermal Plasma HVOF

Aluminium Oxide Coarse 30 2.04 90 6.1 Yes Yes N/A

Aluminium Oxide Medium 30 2.04 90 6.1 Yes Yes N/A

Aluminium Oxide Fine 30 2.04 90 6.1 Yes Yes N/A

Angular Chilled Iron Grit

90 6.1 N/A N/A Yes Yes N/A

G24/G34

Aluminium Oxide is generally used to prepare:

01. Hardened surfaces.

02. Soft substrates, such as Aluminium.

03. Titanium and Titanium Alloys.

04. Surfaces which require thin coatings up to 0.020

Angular Chilled Iron Grit is generally used to prepare:

01. Unhardened surfaces.

02. Preparation for ‘Self Fluxing Alloys’ i.e. Fused coatings.

03. Surfaces which require thick coatings in excess of 0.020

Notes:

01. Aluminium Oxide breaks down readily; ensure that new grit is continually added to

maintain good quality.

02. Ensure that blasting media is free from contamination.

03. Components should be ‘air washed’ after blasting to remove dust and debris.

Sealing:

Not required.

Sprayseal M:

Not required

To comply with Health and Safety Legislation you are recommended to consult the COSHH

Data Sheet referring to this material.

You might also like

- SACS TrainingDocument105 pagesSACS TrainingAli Zaidi75% (8)

- Sandvik Pricelist 2019 - IN PDFDocument261 pagesSandvik Pricelist 2019 - IN PDFsteam steam50% (2)

- AlumexDocument153 pagesAlumexLakmal Galagoda50% (2)

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Document5 pagesDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- FGT30, Rev. 12-07 (English Version)Document15 pagesFGT30, Rev. 12-07 (English Version)phuongNo ratings yet

- Baffle Thickness CalculationDocument22 pagesBaffle Thickness CalculationAdrian Stoicescu100% (1)

- Rectangular Cooling Water Tank Design CalculationsDocument43 pagesRectangular Cooling Water Tank Design CalculationsNguyễn Quốc PhượngNo ratings yet

- Mini-Lathe: Mini Machine Tools SeriesDocument2 pagesMini-Lathe: Mini Machine Tools SeriesOho BohoNo ratings yet

- Metal Casting Process OverviewDocument125 pagesMetal Casting Process OverviewSabir AliNo ratings yet

- UR 65 310S y Su Comportamiento PDFDocument4 pagesUR 65 310S y Su Comportamiento PDFhugo diazNo ratings yet

- WWW - Toptech.tw: Metallographic Sample Preparation Equipment Cutting/ Mounting/ Grinding & PolishingDocument44 pagesWWW - Toptech.tw: Metallographic Sample Preparation Equipment Cutting/ Mounting/ Grinding & Polishingtien thanh doNo ratings yet

- High Speed Steel Round BarDocument4 pagesHigh Speed Steel Round BarMANJEET KUMARNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- Global Leader in Hydraulic BreakersDocument8 pagesGlobal Leader in Hydraulic BreakersHidayatNo ratings yet

- New Technology Mechanical Face Seal ManufacturingDocument21 pagesNew Technology Mechanical Face Seal ManufacturingRavi MirzaNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- m705 grn360 Kv20series20flyDocument2 pagesm705 grn360 Kv20series20flyKek Siang MingNo ratings yet

- Catalog PCBN enDocument2 pagesCatalog PCBN enXavierNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Nir 9 GB LevelDocument5 pagesNir 9 GB LevelYuri OrellanoNo ratings yet

- HSS CatalogueDocument56 pagesHSS CataloguenenmilNo ratings yet

- Piston Seals: Technical DetailsDocument4 pagesPiston Seals: Technical DetailsTeddy NsNo ratings yet

- Piston seal dimensions and specificationsDocument4 pagesPiston seal dimensions and specificationsQC RegianNo ratings yet

- Powders: Technical, Application & Safety DataDocument8 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- 14 Spline NutDocument24 pages14 Spline NutCAT MINING SHOVELNo ratings yet

- SHEET METALWORK DATA: ALUMINIUM 1050A (S1B) SHEETDocument2 pagesSHEET METALWORK DATA: ALUMINIUM 1050A (S1B) SHEETDectyo 'Fafa' FandryasNo ratings yet

- EagleBurgmann HJ92N enDocument4 pagesEagleBurgmann HJ92N enJohnNo ratings yet

- EN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Document1 pageEN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Raja Sekaran SajjaNo ratings yet

- Worm Gear Sets CatalogueDocument30 pagesWorm Gear Sets Cataloguefog900No ratings yet

- Worm Gear Sets CatalogueDocument29 pagesWorm Gear Sets Cataloguemohammad khoraminiaNo ratings yet

- Hardfacing by Flame Spraying - GBDocument16 pagesHardfacing by Flame Spraying - GBAzizNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- Material PropertiesDocument16 pagesMaterial PropertiesMadan Kulkarni100% (1)

- Basics of Grinding 1Document21 pagesBasics of Grinding 1maulikgadara100% (1)

- CDA 84400 phosphor bronze alloy propertiesDocument4 pagesCDA 84400 phosphor bronze alloy propertiesShariq KhanNo ratings yet

- AMIR TANKS REACTOR SPECIFICATIONDocument5 pagesAMIR TANKS REACTOR SPECIFICATIONNaam Ka KyaNo ratings yet

- Anti-Seize Stainless GBDocument3 pagesAnti-Seize Stainless GBKarinaNo ratings yet

- Grinding Inconel 718using A Galvanic Grinding WheelDocument6 pagesGrinding Inconel 718using A Galvanic Grinding WheelI Gede Nengah Wika GunawanNo ratings yet

- KASTAS k14_۲۰۲۴۰۴۱۳۱۰۴۵۳۶Document5 pagesKASTAS k14_۲۰۲۴۰۴۱۳۱۰۴۵۳۶mohammaddr1983No ratings yet

- Lobe Pump SLR.4 - enDocument6 pagesLobe Pump SLR.4 - enkhang.duong225No ratings yet

- Abbressive WheelDocument38 pagesAbbressive WheelFarrukh AhmadNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- Tungsten Carbide Mill Rolls and Guide RollersDocument2 pagesTungsten Carbide Mill Rolls and Guide RollersQuy SopNo ratings yet

- Technical Guide: 230M07Pb/EN1A Leaded FreecuttingDocument1 pageTechnical Guide: 230M07Pb/EN1A Leaded Freecuttingstart201169201169No ratings yet

- Free Cutting Mild Steel: Chemical Composition in Volume PercentageDocument1 pageFree Cutting Mild Steel: Chemical Composition in Volume PercentageGANESH KUMARNo ratings yet

- Sandvik 12R11 Strip Steel DatasheetDocument5 pagesSandvik 12R11 Strip Steel DatasheetKashish0% (1)

- SMB Radial Ball Bearing SpecificationsDocument1 pageSMB Radial Ball Bearing SpecificationsHector Alejandro Melin ContrerasNo ratings yet

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKNo ratings yet

- Eutalloy 11496Document2 pagesEutalloy 11496jorge_20120% (1)

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- Cold Rolled Products 1 0Document9 pagesCold Rolled Products 1 0Ruchi SahuNo ratings yet

- AA 3105-F Tread/Chequered Plates: Aluminium AlloyDocument1 pageAA 3105-F Tread/Chequered Plates: Aluminium AlloyAbolfazl HabibiNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Part Number: 688-2RS: SMB Bearings Radial Ball BearingDocument1 pagePart Number: 688-2RS: SMB Bearings Radial Ball BearingCecilio Díaz GijónNo ratings yet

- The Aluminium Evolution: Continuous Casting Aluminium AlloysDocument2 pagesThe Aluminium Evolution: Continuous Casting Aluminium AlloysHareth MRAIDINo ratings yet

- Dry Moly Spray - GBDocument3 pagesDry Moly Spray - GBwalidfawzNo ratings yet

- ANTI-SEIZE Stainless - GBDocument3 pagesANTI-SEIZE Stainless - GBHasan RazaNo ratings yet

- Ampco Vs SteelDocument9 pagesAmpco Vs SteelCopper AmpcometalNo ratings yet

- Rule No. 1Document64 pagesRule No. 1Albert AliminNo ratings yet

- Schedule of Technical Data For Belt Conveyors: Description Unit BC-001 BC-002Document3 pagesSchedule of Technical Data For Belt Conveyors: Description Unit BC-001 BC-002anon_440745729No ratings yet

- Eutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderDocument2 pagesEutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderYeison Piedrahita PérezNo ratings yet

- 1022 Carbon Steel Bar PDFDocument3 pages1022 Carbon Steel Bar PDFjeyakumarNo ratings yet

- CWC-BookletF1 24Document1 pageCWC-BookletF1 24Jagannath SahuNo ratings yet

- EBARA Horizontal Split Case Pump ManualDocument6 pagesEBARA Horizontal Split Case Pump ManualRido MardanNo ratings yet

- Uns S41500Document1 pageUns S41500phuongNo ratings yet

- ISP SUPPLEMENT - July 2020Document2 pagesISP SUPPLEMENT - July 2020phuongNo ratings yet

- JIS G3101 SS 400 Steel Plate Specification and PropertiesDocument1 pageJIS G3101 SS 400 Steel Plate Specification and PropertiesTerry Gunawan100% (2)

- Outokumpu Steel Grades Properties Global StandardsDocument20 pagesOutokumpu Steel Grades Properties Global StandardsLance BlackstarNo ratings yet

- PASSDocument1 pagePASSphuongNo ratings yet

- AWS D1.6 Structural Welding Code for Stainless SteelDocument2 pagesAWS D1.6 Structural Welding Code for Stainless SteelNguyễn Quốc PhượngNo ratings yet

- Ansys Structural Analysis PDFDocument157 pagesAnsys Structural Analysis PDFphuongNo ratings yet

- Max UC - BottomDocument1 pageMax UC - BottomphuongNo ratings yet

- QQ N 281D - 2Document38 pagesQQ N 281D - 2phuongNo ratings yet

- SACS TutorialDocument7 pagesSACS TutorialTempest_L0% (1)

- Powders: Technical, Application & Safety DataDocument8 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Result 3 DDocument1 pageResult 3 DphuongNo ratings yet

- Powders: Technical, Application & Safety DataDocument8 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Process Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 SupercedesDocument3 pagesProcess Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 SupercedesphuongNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Sacs Sacs: User Training Course Notes User Training Course Notes SEPT 2011 SEPT 2011 Ho Chi Minh City Ho Chi Minh CityDocument68 pagesSacs Sacs: User Training Course Notes User Training Course Notes SEPT 2011 SEPT 2011 Ho Chi Minh City Ho Chi Minh CityphuongNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- 05 - SACS2012ALL Software User GuideDocument327 pages05 - SACS2012ALL Software User GuidephuongNo ratings yet

- Ex-Post Project Evaluation 2010: Package II - 6 (Vietnam) : Japan International Cooperation AgencyDocument93 pagesEx-Post Project Evaluation 2010: Package II - 6 (Vietnam) : Japan International Cooperation AgencyphuongNo ratings yet

- Call/Wa 0811-30-8797 Harga Mesin CNC Router Mini YogyakartaDocument9 pagesCall/Wa 0811-30-8797 Harga Mesin CNC Router Mini Yogyakartaharga mesin cnc terbaru malangNo ratings yet

- MT-Series Joker Parts Catalog 2013Document100 pagesMT-Series Joker Parts Catalog 2013a04205No ratings yet

- Blanking DiesDocument24 pagesBlanking DiesPardeep KumarNo ratings yet

- 2005 Threading Full CatalogDocument427 pages2005 Threading Full CatalogMiranda RoodNo ratings yet

- Micro MachiningDocument25 pagesMicro MachiningVishalNaranjeNo ratings yet

- Of Kent USA Not ReproduceDocument53 pagesOf Kent USA Not Reproducetapas ranjan jenaNo ratings yet

- AS 1252-83-For DimensionsDocument36 pagesAS 1252-83-For DimensionsBharatNo ratings yet

- Flange Summary Data Sheet: Chemical RequirementsDocument1 pageFlange Summary Data Sheet: Chemical RequirementsarietilangNo ratings yet

- Alloy IndexDocument105 pagesAlloy IndexPeñaloz GustavoNo ratings yet

- (Elearnica) - Hardfacing Technologies For Improvement of Wear Characteristics of Hot WorkDocument13 pages(Elearnica) - Hardfacing Technologies For Improvement of Wear Characteristics of Hot WorkelmiraNo ratings yet

- Welding DefectsDocument5 pagesWelding DefectsDEEPAKNo ratings yet

- CNC Proğramlamada G Ve M KodlariDocument2 pagesCNC Proğramlamada G Ve M KodlariYUNUSNo ratings yet

- Anchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForDocument9 pagesAnchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForAdán Cogley CantoNo ratings yet

- Quorn: Tool and Cutter GrinderDocument4 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- CNC Milling Lab ReportDocument5 pagesCNC Milling Lab ReportMuhammad Iqmel33% (3)

- Metal Cutting and Machine Tools: 1 Lecture: IntroductionDocument43 pagesMetal Cutting and Machine Tools: 1 Lecture: IntroductionSrimanthula SrikanthNo ratings yet

- PDF Q0 Module 1 Carpentry 7 8Document19 pagesPDF Q0 Module 1 Carpentry 7 8Richard Sandoval Taganahan100% (1)

- 2020 Metal Cutting, Metrology, Metal FormingDocument213 pages2020 Metal Cutting, Metrology, Metal FormingAkshay100% (4)

- Miscellaneous PDFDocument18 pagesMiscellaneous PDFFederico GuillenNo ratings yet

- Machining Operations and Machine Tools: J.Ramkumar Dept of Mechanical EngineeringDocument36 pagesMachining Operations and Machine Tools: J.Ramkumar Dept of Mechanical EngineeringOm PrakashNo ratings yet

- Metal WorksDocument16 pagesMetal WorksMAXINE DELA ROSANo ratings yet

- Carpentry FINALDocument8 pagesCarpentry FINALSJ BatallerNo ratings yet

- Ab at InventoryDocument32 pagesAb at InventoryecirecirNo ratings yet

- CAPD & CAM Lab Manual PDFDocument14 pagesCAPD & CAM Lab Manual PDFSrikanth RangdalNo ratings yet

- Knives Saws For The Tissue Towel INdustriesDocument2 pagesKnives Saws For The Tissue Towel INdustriesJuan Pablo LopezNo ratings yet

- Mould TechnologyDocument71 pagesMould TechnologyS Karthick KeyanNo ratings yet

- Astm A 194 - A 194ma - 2012 PDFDocument11 pagesAstm A 194 - A 194ma - 2012 PDFRami ELLOUMINo ratings yet