Professional Documents

Culture Documents

L&T Construction: Water & Effluent Treatment IC

Uploaded by

vinodmolkereOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L&T Construction: Water & Effluent Treatment IC

Uploaded by

vinodmolkereCopyright:

Available Formats

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. DATE

PROJECT:

DESIGNED CHECKED APPROVED

TITLE:

VCM

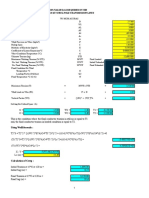

LONGITUDINAL LOADS (SAG TENSION)

Analysis Data:

Design wind speed & pressure (V d & Pd)

(As per Cl. 8.0, Pg: 03 of IS 802:2006 (reaffirmed))

Normal Span of the Conductor, ' L ' = 27 m (Refer Fig 1, Basic Wind Speed

Wind zone = 2 data)

Basic wind speed, ' V b ' = 39 m/s (As per Cl. 8.1, pg 3)

Reliability level of structure = 1 (As per Table 1, Cl. 7.1, pg 3)

Reduction Factor, ' K o ' = 1.375 (As per Cl. 8.2, pg 3)

Risk coefficient, ' k 1 ' = 1.0 (As per Cl. 8.3.1, pg 3)

Terrain roughness co efficient, ' k 2 ' = 1.080 (As per Table 3, Cl. 8.3.2, pg 4)

Temperature Details:

(As per Cl. 10.2, Pg: 09 of IS 802:2006 (reaffirmed))

(Refer Fig 4, Lowest min. Temp

Minimum = 0 °C Isopleths)

Every Day Temperature = 32 °C (As per Cl. 10.2, pg 9)

(Refer Fig 4, Highest Max.

Ambient Temperature = 47.5 °C Temp Isopleths)

Maximum conductor temperature (t max ) = 75 °C (As per Cl. 10.2.4, pg 10)

Meteorological reference wind speed, V R = Vb / Ko (As per Cl. 8.2, pg 3)

= 39/1.375

= 28.36 m/s

Design wind speed, V d = VR x k1 x k2 (As per Cl. 8.3, pg 3)

= 28.36 x 1 x 1.08

= 30.63 m/s

wind pressure, P = 0.6 x V d 2

= 0.6 x 30.63^ 2 / 1000

= 0.563 kN/m2

Conductor Properties:

(As per CBIP Manual, Annexure I, Pg 140)

Conductor Code = ACSR (Zebra)

Ulimate Tensile Strength (UTS) = 13289.00 kg

Area of Conductor, ' A ' = 4.85E-04 m2

Weight of Conductor, ' w ' = 1.621 kg/m

(As per, Annexure I, Pg 140)

Dia. of Conductor, ' d ' = 0.029 m

Modulus of Elasticity of Conductor, ' E ' = 7.04E+09 kg/m2

Coefficient of linear expansion, ' a ' = 0.0000193 /°C

Initial Condition (before Charging): (As per IS 802:2006 (reaffirmed))

Conductor Temperature = 24 °C

Initial unloaded Tension,' T 1 '

(Based on min. sag)

Max. Phase to Phase Clearance adopted = 2.500 m

(as per Switchyard Layout)

Max. Height of the bus str. Conductor point = 8.400 m

Max. ground Clearance as per CBIP Manual = 4.600 m

Max sag. Based on electrical clearance = 1.300 m

(as per Switchyard Layout)

# Sensitivity: LNT Construction Internal Use

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. DATE

PROJECT:

DESIGNED CHECKED APPROVED

TITLE:

VCM

Max. Sag Assumed in initial Stringing = 0.350 m

Sag, ' S ' = 𝑊𝐿2 "Considering Parabolic Catenary of Curve"

8𝑇

Initial unloaded Tension,' T 1 '

(Based on min. of following Cl.)

Therefor from above eqn., Tension ' T 1 ' = 422.04 kg ' or '

Total weight of the conductor over the length = 43.77 kg ' or '

= 35.00 % of UTS (As per Cl. 15, pg 14)

Sag, ' S ' = 3.38 m

(Corresponding to Weight of the conductor alone) > Provided electrical Clearance. Hence, Value Shall be

considered based on max. sag assumed

Initial stringing Tension Considered = 422.04 kg

Design wind load, w 1 =

(As per Cl. 7.3.1.1, Pg: 16 of IS 5613 Part 1/ Sec 1)

= 1.095 kg/m

Case I: 36% design wind pressure + Min. temp (i.e., d t = ( Min. Temperature - Initial Temp )):

Equivalent Wt.of Conductor, ' W 1 ' = 𝑤1 2 + 𝑤 2 @ Still wind Condition, w 1

(initial Condtion) = 1.620 kg/m =0

Equivalent Wt.of Conductor, ' W 2 ' = 𝑤1 2 + 𝑤 2 @ wind Condition, w 1 =

(due to 36% design Wind pressure) = 1.750 kg/m 36% of Wind Load

From CBIP Manual (Refer Pg: 103, Computation of Sag Tension)

2 2 2 2

24 𝐿 𝑊1 𝑊 2 2 3

𝑊2 𝑊

𝑓 23 + 𝐿3 /𝑓1 + 24𝐿α 𝑡2 − 𝑡1 − 24𝑓1 𝐿/𝐸 𝑓2 − 𝐿 =0

𝐸 𝑤 𝐴 𝑊 𝐴

of the form, ax 3 + bx 2 + cx + d = 0

Where, f 1 = T1/A = 871083.6 kg/m 2

Coefficients of Cubic eqn. a = 9.200E-08

b = -0.1

c = 0

d = -2.5679E+11

Solving The above Eqn. ' f 2 ' = 1878198.2 kg/m 2 Real Solution

Therefore, final Tension, ' T 2 ' = 910.00 kgs

Factor of Safety against UTS of Cable = 15 Safe

Case II: Still wind + Min. temp (i.e., d t = ( Min. Temperature - Initial Temp )):

Equivalent Wt.of Conductor, ' W 1 ' = 𝑤1 2 + 𝑤 2 @ Still wind Condition, w 1

(initial Condtion) = 1.620 kg/m =0

Equivalent Wt.of Conductor, ' W 2 ' = 𝑤1 2 + 𝑤 2 @ Still wind Condition, w1

(@ Still Wind) = 1.620 kg/m =0

# Sensitivity: LNT Construction Internal Use

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. DATE

PROJECT:

DESIGNED CHECKED APPROVED

TITLE:

VCM

From CBIP Manual (Refer Pg: 103, Computation of Sag Tension)

2 2 2 2

24 𝐿 𝑊1 𝑊 𝑊2 𝑊

𝑓 23 + 𝐿3 /𝑓12 + 24𝐿α 𝑡2 − 𝑡1 − 24𝑓1 𝐿/𝐸 𝑓2 2 − 𝐿3 =0

𝐸 𝑤 𝐴 𝑊 𝐴

of the form, ax 3 + bx 2 + cx + d = 0

Where, f 1 = T1/A = 871083.6 kg/m 2

Coefficients of Cubic eqn. a = 9.200E-08

b = -0.1

c = 0

d = -2.2006E+11

Solving The above Eqn. ' f 2 ' = 1813917.29 kg/m 2 Real Solution

Therefore, final Tension, ' T 2 ' = 879.00 kgs

Factor of Safety against UTS of Cable = 16 Safe

Case III: 100 % design wind + every day temp (i.e., d t = ( Every day Temperature - Initial Temp )):

Equivalent Wt.of Conductor, ' W 1 ' = 𝑤1 2 + 𝑤 2 @ Still wind Condition, w 1

(initial Condtion) = 1.620 kg/m =0

Equivalent Wt.of Conductor, ' W 2 ' = 𝑤1 2 + 𝑤 2 @ wind Condition, w 1 =

(due to 100 % design Wind pressure) = 1.960 kg/m 100% of Wind Load

From CBIP Manual (Refer Pg: 103, Computation of Sag Tension)

2 2 2 2

24 𝐿 𝑊1 𝑊 2 2 3

𝑊2 𝑊

𝑓 23 + 𝐿3 /𝑓1 + 24𝐿α 𝑡2 − 𝑡1 − 24𝑓1 𝐿/𝐸 𝑓2 − 𝐿 =0

𝐸 𝑤 𝐴 𝑊 𝐴

of the form, ax 3 + bx 2 + cx + d = 0

Where, f 1 = T1/A = 871083.6 kg/m 2

Coefficients of Cubic eqn. a = 9.200E-08

b = 0.31

c = 0

d = -3.2212E+11

Solving The above Eqn. ' f 2 ' = 905036.688 kg/m 2 Real Solution

Therefore, final Tension, ' T 2 ' = 439.00 kgs

Factor of Safety against UTS of Cable = 31 Safe

Case IV: 75 % design wind + every day temp (i.e., d t = ( Every day Temperature - Initial Temp )):

Equivalent Wt.of Conductor, ' W 1 ' = 𝑤1 2 + 𝑤 2 @ Still wind Condition, w 1

(initial Condtion) = 1.620 kg/m =0

Equivalent Wt.of Conductor, ' W 2 ' = 𝑤1 2 + 𝑤 2 @ wind Condition, w 1 =

(due to 75 % design Wind pressure) = 1.880 kg/m 75% of Wind Load

# Sensitivity: LNT Construction Internal Use

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. DATE

PROJECT:

DESIGNED CHECKED APPROVED

TITLE:

VCM

From CBIP Manual (Refer Pg: 103, Computation of Sag Tension)

2 2 2 2

24 𝐿 𝑊1 𝑊 𝑊2 𝑊

𝑓 23 + 𝐿3 /𝑓12 + 24𝐿α 𝑡2 − 𝑡1 − 24𝑓1 𝐿/𝐸 𝑓2 2 − 𝐿3 =0

𝐸 𝑤 𝐴 𝑊 𝐴

of the form, ax 3 + bx 2 + cx + d = 0

Where, f 1 = T1/A = 871083.6 kg/m 2

Coefficients of Cubic eqn. a = 9.200E-08

b = 0.31

c = 0

d = -2.9636E+11

Solving The above Eqn. ' f 2 ' = 871519.896 kg/m 2 Real Solution

Therefore, final Tension, ' T 2 ' = 423.00 kgs

Factor of Safety against UTS of Cable = 32 Safe

Case IV: 100 % design wind + Max. Cond. temp (i.e., d t = ( Max. Cond. temp - Initial Temp )):

Equivalent Wt.of Conductor, ' W 1 ' = 𝑤1 2 + 𝑤 2 @ Still wind Condition, w 1

(initial Condtion) = 1.620 kg/m =0

Equivalent Wt.of Conductor, ' W 2 ' = 𝑤1 2 + 𝑤 2 @ wind Condition, w 1 =

(due to 100 % design Wind pressure) = 1.960 kg/m 100% of Wind Load

From CBIP Manual (Refer Pg: 103, Computation of Sag Tension)

2 2 2 2

24 𝐿 𝑊1 𝑊 𝑊2 𝑊

𝑓 23 + 𝐿3 /𝑓12 + 24𝐿α 𝑡2 − 𝑡1 − 24𝑓1 𝐿/𝐸 𝑓2 2 − 𝐿3 =0

𝐸 𝑤 𝐴 𝑊 𝐴

of the form, ax 3 + bx 2 + cx + d = 0

Where, f 1 = T1/A = 871083.6 kg/m 2

Coefficients of Cubic eqn. a = 9.200E-08

b = 0.85

c = 0

d = -3.2212E+11

Solving The above Eqn. ' f 2 ' = 596636.619 kg/m 2 Real Solution

Therefore, final Tension, ' T 2 ' = 290.00 kgs

Factor of Safety against UTS of Cable = 46 Safe

Wind

Resultant Resultant Provided

Temperature Pressure Resultant Sag

Sl.No Case No. o Tension Tension Electrical Check

( C) (% of Full 'mm'

' Kgs ' ' kN ' Clearance

Wind)

1.0 Initial Condition 24.0 Nil 422.04 4.15 350 1300 Safe

min. temp & 36 % design

2.0

wind

0.0 36% 910.00 8.93 162.4 1300 Safe

3.0 min. temp & Still wind 0.0 Nil 879.00 8.63 168.1 1300 Safe

every day temp. & 100

4.0

% design wind

32.0 100% 439.00 4.31 336.5 1300 Safe

every day temp. & 75

5.0

% design wind

32.0 75% 423.00 4.15 349.3 1300 Safe

Max. conductor temp. &

6.0

100 % design wind

75.0 100% 290.00 2.85 509.4 1300 Safe

# Sensitivity: LNT Construction Internal Use

You might also like

- CATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 DrakeDocument12 pagesCATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 Drakedursun_yerlikaya100% (2)

- Sag Calculation ZebraDocument11 pagesSag Calculation ZebratanujaayerNo ratings yet

- Conductors sag calculation between unequal supportsDocument15 pagesConductors sag calculation between unequal supportsRatana Kem0% (1)

- Sag-Tension Calculations PresentDocument33 pagesSag-Tension Calculations PresentMilomir GavrilovicNo ratings yet

- Conductor Sag and Tension CalculatorDocument11 pagesConductor Sag and Tension CalculatorSanjeev KumarNo ratings yet

- Transmission Line Sag & TensionDocument37 pagesTransmission Line Sag & TensionCatrina Federico100% (2)

- Catenary Sag-Tension Calculator (Even and Uneven)Document2 pagesCatenary Sag-Tension Calculator (Even and Uneven)mohsin160No ratings yet

- Sag Tension 765kVDocument11 pagesSag Tension 765kVvikasrajput1989100% (1)

- Sag-Tension For EarthwireDocument1 pageSag-Tension For Earthwirelalit123indiaNo ratings yet

- Forces On Gantry-34Document5 pagesForces On Gantry-34vkjainabc100% (1)

- Inclined Span Module Estimates Sag and ClearanceDocument5 pagesInclined Span Module Estimates Sag and ClearanceAjay JayabalanNo ratings yet

- Sag Tension CalculationDocument3 pagesSag Tension Calculationajith143420No ratings yet

- Sagging CalculationDocument3 pagesSagging Calculationwiizt100% (5)

- Power Grid Corporation of India LTDDocument13 pagesPower Grid Corporation of India LTD1382aceNo ratings yet

- Sag CalculationDocument20 pagesSag Calculationrahu111112000No ratings yet

- Sag 340Document37 pagesSag 340ahmadove1No ratings yet

- Wind Calculation ManDocument12 pagesWind Calculation ManannuvyasNo ratings yet

- ACSR Conductor SelectionDocument12 pagesACSR Conductor SelectionSushant ChauguleNo ratings yet

- SAG Tension For TWIN-QUAD Conductor Considering Wind Effect - InputsDocument2 pagesSAG Tension For TWIN-QUAD Conductor Considering Wind Effect - InputsCassie Harvey100% (2)

- Engineering Method For Calculation of Short-CircuitDocument8 pagesEngineering Method For Calculation of Short-CircuitHakkim Sheik Thauth J100% (1)

- 400KV 34.5MTRS Sag Tension CalculationDocument7 pages400KV 34.5MTRS Sag Tension CalculationRaisinghani BhushanNo ratings yet

- Sag 340Document15 pagesSag 340tanujaayerNo ratings yet

- SAG Tension For TWIN-QUAD Conductor Considering No Wind - InputsDocument2 pagesSAG Tension For TWIN-QUAD Conductor Considering No Wind - InputsAnupam0103No ratings yet

- Sag Tension Calculation-765 KVDocument13 pagesSag Tension Calculation-765 KVHugh cabNo ratings yet

- Pathlaiya SS 132kV Busbar DesignDocument9 pagesPathlaiya SS 132kV Busbar DesignSantosh GairheNo ratings yet

- CATENARY SAG-TENSION CALCULATORDocument12 pagesCATENARY SAG-TENSION CALCULATORJetn SrisuthumNo ratings yet

- DSLP 11 3mDocument7 pagesDSLP 11 3msureshn829No ratings yet

- Earthing CalculationDocument6 pagesEarthing CalculationMKNo ratings yet

- Aluminium Conductor Sag & Tension Calculation Inclined SpanDocument5 pagesAluminium Conductor Sag & Tension Calculation Inclined Spansitifarhani100% (1)

- Load Calculation OptimizationDocument21 pagesLoad Calculation OptimizationghansaNo ratings yet

- Stub Cleat Design DD-DDEDocument1 pageStub Cleat Design DD-DDEHikmat AyerNo ratings yet

- Calculation Sheet Gantry Tower Gi 150kv Ambalut Extension - Rev1.0Document191 pagesCalculation Sheet Gantry Tower Gi 150kv Ambalut Extension - Rev1.0Iman RahmatullahNo ratings yet

- Sag Tension ChartDocument64 pagesSag Tension ChartSubhadeep Das100% (1)

- 132 KV LaDocument169 pages132 KV LaGuru MishraNo ratings yet

- Short Circuit Force For EquipmentDocument17 pagesShort Circuit Force For EquipmentHassen100% (1)

- Design Calculation: Larsen & Toubro LimitedDocument72 pagesDesign Calculation: Larsen & Toubro Limitedjm.mankavil6230No ratings yet

- Cantilever Strength CalculationsDocument2 pagesCantilever Strength Calculationsakash_ing7683100% (4)

- Conductor Sag & Tension CalculatorDocument6 pagesConductor Sag & Tension Calculatorsitifarhani100% (1)

- 33 SCF Tower Span 18mDocument25 pages33 SCF Tower Span 18mamrit90320No ratings yet

- Layout of Sub StationDocument31 pagesLayout of Sub StationVenugopal Patnaik100% (2)

- Project111 smcc144Document10 pagesProject111 smcc144burvanovNo ratings yet

- 132kV SAG CalculationDocument14 pages132kV SAG CalculationPramod B.Wankhade100% (4)

- Sag Tension Calculation 230mDocument1 pageSag Tension Calculation 230mArgaw Tadi100% (1)

- Sag-Tension Spreadsheet Free Calculator (Even and Uneven Supports Elevation) - Electrical Engineer ResourcesDocument2 pagesSag-Tension Spreadsheet Free Calculator (Even and Uneven Supports Elevation) - Electrical Engineer ResourcesSlobodan VajdicNo ratings yet

- 110KV SagTension Calculation 1Document13 pages110KV SagTension Calculation 1Atef Ben AmmarNo ratings yet

- 220kv Tower 44-41 Type E-A GGHPP Foundation Design CalculationsDocument28 pages220kv Tower 44-41 Type E-A GGHPP Foundation Design CalculationsMian M Khurram0% (1)

- Sag-Tension and Short Circuit Force CalculationDocument27 pagesSag-Tension and Short Circuit Force CalculationHugh cabNo ratings yet

- SAG-TENSION COMPUTATIONS FOR TRANSMISSION LINESDocument37 pagesSAG-TENSION COMPUTATIONS FOR TRANSMISSION LINESSmtakalkar TakalkarNo ratings yet

- Short Circuit Force For Equipment InterconnectionDocument17 pagesShort Circuit Force For Equipment Interconnectionudayakumart100% (4)

- Tower Foundation - Chapter 5Document45 pagesTower Foundation - Chapter 5kayshephNo ratings yet

- Formal record signatures and discipline QC proceduresDocument6 pagesFormal record signatures and discipline QC proceduresBenedict OgbaghaNo ratings yet

- Dokumen - Tips - 132kv Sag CalculationDocument14 pagesDokumen - Tips - 132kv Sag CalculationKunal AwaghadeNo ratings yet

- 9) Stability of Tank Against Wind Load (Ref: ASCE - 7)Document4 pages9) Stability of Tank Against Wind Load (Ref: ASCE - 7)SachinNo ratings yet

- 1 Peak DB - Single Acsr Bear - Wz4Document64 pages1 Peak DB - Single Acsr Bear - Wz4Newton AdhikariNo ratings yet

- Culvert Design Using Staad As Per IrsDocument171 pagesCulvert Design Using Staad As Per IrsTanvir Shahrier MahmudNo ratings yet

- Checking stability of steel building under EOT crane loadsDocument96 pagesChecking stability of steel building under EOT crane loadsSovan PramanickNo ratings yet

- Final 61 PicDocument6 pagesFinal 61 PicHaryy PrabowoNo ratings yet

- Design CalculationDocument11 pagesDesign CalculationShaikh Muhammad AteeqNo ratings yet

- Daøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudDocument21 pagesDaøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudMahendraSinghNo ratings yet

- Oaqøhv Fej Vuqikru Ekxzn'Khz FL Kar: HKKJRH EkudDocument44 pagesOaqøhv Fej Vuqikru Ekxzn'Khz FL Kar: HKKJRH EkudvinodmolkereNo ratings yet

- 2386 1 1963 Reff2021Document23 pages2386 1 1963 Reff2021Raghav TiwaryNo ratings yet

- NCMST 2014 ProceedingsDocument162 pagesNCMST 2014 ProceedingsvinodmolkereNo ratings yet

- Is 1893 Latest UpdatesDocument82 pagesIs 1893 Latest UpdatesvinodmolkereNo ratings yet

- Classical Laminate TheoryDocument1 pageClassical Laminate Theoryvinodmolkere100% (1)

- Standard Specifications AND Code of Practice FOR Road BridgesDocument89 pagesStandard Specifications AND Code of Practice FOR Road BridgesSagar Saadolalu R100% (1)

- Business Finance Week 2 2Document14 pagesBusiness Finance Week 2 2Phoebe Rafunsel Sumbongan Juyad100% (1)

- Performance Evaluation of Object Tracking AlgorithDocument9 pagesPerformance Evaluation of Object Tracking AlgorithEren Cem GöksülükNo ratings yet

- Ian Thompson - A Critique of Valuation Methods For Exploration PropertiesDocument12 pagesIan Thompson - A Critique of Valuation Methods For Exploration PropertiesZhuu Ming AngNo ratings yet

- Sumo Safari SpicerDocument3 pagesSumo Safari SpicerAbishek MongaNo ratings yet

- Tugas Kelompok Pend.b.asing 3Document5 pagesTugas Kelompok Pend.b.asing 3Akun YoutubeNo ratings yet

- SAPI S7dotNet InstructionsDocument9 pagesSAPI S7dotNet InstructionsEnrico Chicco PaluzzanoNo ratings yet

- Yard FacilitiesDocument30 pagesYard FacilitiesYgandranNo ratings yet

- Standard Resume SeafarersDocument1 pageStandard Resume Seafarersdurango8977% (107)

- Motion For New TrialDocument3 pagesMotion For New TrialKM MacNo ratings yet

- Ad Notam Manual DSTB-T S2Document28 pagesAd Notam Manual DSTB-T S2okejekNo ratings yet

- W.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueDocument2 pagesW.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueParth PatelNo ratings yet

- RESA 1st PBDocument9 pagesRESA 1st PBRay Mond0% (1)

- HI White Paper - Understanding The Effects of Selecting A Pump Performance Test Acceptance GradeDocument17 pagesHI White Paper - Understanding The Effects of Selecting A Pump Performance Test Acceptance Gradeashumishra007No ratings yet

- MEC-004 TMA: Harrod-Domar Model and Golden Age EquilibriumDocument11 pagesMEC-004 TMA: Harrod-Domar Model and Golden Age EquilibriumnitikanehiNo ratings yet

- In 002756Document1 pageIn 002756aljanaNo ratings yet

- Practical Research 2: Quarter 1 Module 1: Nature of Inquiry and ResearchDocument406 pagesPractical Research 2: Quarter 1 Module 1: Nature of Inquiry and ResearchJohn Michael Reyes RamosNo ratings yet

- Navigator Cisco Product Rental StockDocument6 pagesNavigator Cisco Product Rental StockSatish KumarNo ratings yet

- Final Project at NucsoftDocument97 pagesFinal Project at NucsoftmainasshettyNo ratings yet

- 1920s Irish Crochet Lace Edging OriginalDocument8 pages1920s Irish Crochet Lace Edging OriginalLaura HortopanuNo ratings yet

- White Paper On Cyberwar and Web Based Attacks by IM v8Document8 pagesWhite Paper On Cyberwar and Web Based Attacks by IM v8IM222No ratings yet

- Tooling Standard (Die Casting)Document39 pagesTooling Standard (Die Casting)Kmilo GiraldoNo ratings yet

- Vari-Green Motor: Start Saving NowDocument4 pagesVari-Green Motor: Start Saving NowRandy HawkinsNo ratings yet

- RollingDocument54 pagesRollingavutu_kunduru100% (1)

- Harty Vs Municipality of VictoriaDocument1 pageHarty Vs Municipality of VictoriaArah Mae BonillaNo ratings yet

- Onu - Escwa (Escwa) Report Workshop On International Migration and Development in The Arab Region: Integrating International Migration Into Development Strategies Beirut, 19-22 July 2010Document21 pagesOnu - Escwa (Escwa) Report Workshop On International Migration and Development in The Arab Region: Integrating International Migration Into Development Strategies Beirut, 19-22 July 2010ddufourtNo ratings yet

- The Weird Trading Trick That Wins Big and Wipes Out Losses: Hughes Optioneering Team RevealsDocument27 pagesThe Weird Trading Trick That Wins Big and Wipes Out Losses: Hughes Optioneering Team RevealsE TrialNo ratings yet

- Correlated Report and Action Plan - FinalDocument30 pagesCorrelated Report and Action Plan - FinalOpenFileCGYNo ratings yet

- Letter From Empower Oversight and Nixon Peabody To CongressDocument3 pagesLetter From Empower Oversight and Nixon Peabody To CongressThe FederalistNo ratings yet

- Product Specifications Product Specifications: SBNHH SBNHH - 1D45C 1D45C - SR SRDocument6 pagesProduct Specifications Product Specifications: SBNHH SBNHH - 1D45C 1D45C - SR SRjorgeerestrepoNo ratings yet

- Case Study:: Barangay HallDocument13 pagesCase Study:: Barangay HallReiner Gatdula50% (2)