Professional Documents

Culture Documents

2019-10-01 - GMR Safran PEB Works - BOQ - Rev5

Uploaded by

Rakesh SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2019-10-01 - GMR Safran PEB Works - BOQ - Rev5

Uploaded by

Rakesh SharmaCopyright:

Available Formats

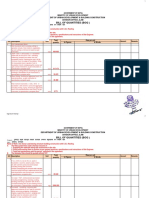

GMR Safran, Hyderabad PEB

SAFRAN - PHASE I AND PHASE II

PROPOSED CONSTRUCTION OF FACTORY BUILDINGS AND UTILITY BLOCKS AT GMR AEROSPACE INDUSTRIAL PARK AT

HYDERABAD

BILLS OF QUANTITIES FOR PEB WORKS

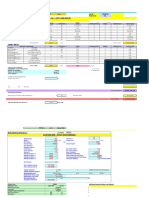

S.No Description Qty Unit Rate Amount (Rs.)

A Pre - Engineered Building

NOTE TO TENDERERS :

Description of items in Bills of Quantities (BOQ) is a shorted version and by

itself is not fully descriptive in all respects. For a full intent, BOQ description

shall be read along with latest architectural and Structural Tender Drawings,

Preamble and Technical Specifications. Rate quoted in the BOQ by tenderers is

deemed to have included all aspects covered in these documents unless stated

otherwise. All features and details shown in latest architectural and structural

Tender Drawings are deemed to have been included in the Rates quoted for

corresponding items in the BOQ. The PEB Contractor must strictly follow the

specification as per the Tender document. In case of any discrepancy /

variation in dimensions observed in the BOQ, Tender Drawings Same should be

highlighted immediately by the vendor for further clarification.

PEB Tenderers are to make sure that their PEB is designed as per and

conforms to FM Global standards. Roof & wall cladding Purlins, Roof sheeting,

wall cladding, clips & fasteners should be as per FM standards.

Design, engineering, drawing, fabrication, supply and erection of Pre-Engineered

steel building to be comply with Zurich/ FM Global Standards. Analysis and design

shall be based on

i) AISC 360-16 - American Institute of Steel Construction - Latest version

ii) ASTM - American Society for Testing and Materials - Latest version

iii) Dead load, Live load, Wind load and Seismic loads are to be followed as per latest

version of IS Codal provisions and submitting the same to CLIENT / PMC.

iv) Wind loading and other requirements are as per FM requirements.

The collateral load shall be 100kg/sqm. in roof purlins and rafters. Contractor shall be

required to suitably enforceable warranties such as building stability, water tightness,

weather tightness etc for the period as specified in technical specifications, from the

time of taking over the completed buildings and structures by the Client / PMC.

PEB scope is only supply and fixing of Rafters, purlins, roof /wall cladding sheets,

rain water gutter and fascia cladding sheet as shown in the latest architectural

drawing. Contractor shall be require to furnish suitably enforceable warranties such

as building stability, water tightness, weather tightness etc. Roof Live Load should be

0.75 KN/Sqm.

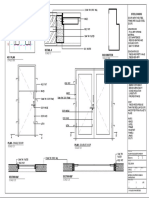

Reference Drawing numbers with latest revisions:

Roof plan : CRN - FAC -AR01-RF-51-251448

Sections: CRN - FAC -AR02-01-01-250504

Factory Ground Floor Plan : GMR-FAC1-AR01-GR-01-250489

Factory First Floor Plan : GMR-FAC1-AR01-01-01-250493

Canopy for all Rolling shutter, Windows and door openings shall be provided as

shown in the latest architectural Elevation / Section drawings.

Note: Glass Canopies - Two numbers on South side will be under the scope of

Façade Vendor.

Lump sum Price to include all the works mentioned above and for providing supply,

fabrication and erection the following :

1 PRIMARY MEMBERS.

All primary steel (refer to rigid frames, lean to rafters, column canopy rafter, interior

column members and end wall wind columns etc.,) shall be built up sections from

plates or bar stock shall have flanges and web joined on both sides of the web by

continuous welding process. The minimum plate thickness shall be 6 mm. The plate

or bar stock shall have a minimum yield strength of 345 Mpa, grade 50 plates to

ASTM A 572 Grade 50 equivalent to IS-2062. The built up sections shall be prepared

by continuous submerged arc welding to double side. Supply and Installation of the

Monorail Hoist Beam are in the scope of the PEB Contractor. PEB contractor to

provide complete supporting arrangements to accommodate Crane & Crane Rail.

2 SECONDARY MEMBERS.

All secondary structural framing shall refer to purlins, girts, eaves struts, wind

bracings, flange bracings, base angles, clips, and other miscellaneous structural

parts.

Purlins, girts and eaves struts shall be cold formed pregalvanised from steel coils

which has a minimum thickness of 2.5 mm thick in all areas and minimum yield

strength of 250 Mpa and will confirm to the physical specification of ASTM A-607

(Grade 50 or equivalent).

All other miscellaneous secondary members shall have a minimum yield strength of

250 Mpa and coating thickness shall be 275 gsm.

3 WELDING

All shop connections shall be welded with double side automatic submerged arc

welding and welding shall be in accordance with IS 814 / AWS E 6013 for thickness

upto 20 mm and AWS E 7018 for thickness above 20 mm and as approved.

Ultrasonic test to be done as per IS 3664-(latest version), for cranes, Dye

penetration test as per IS 3658- (latest version). Welding quality test done at factory it

self 10% of welding to be tested.

C.R. Narayana Rao

1 Bill Of Quantities- Rev4

(Consultants) Private Limited

GMR Safran, Hyderabad PEB

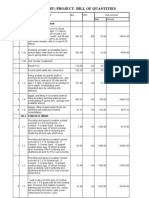

S.No Description Qty Unit Rate Amount (Rs.)

4 STANDING SEAM ROOFING SYSTEM WITH FM APPROVAL

DOUBLE SKIN WITH INSULATION - TOP SHEET WITH STANDING SEAM, ROCK

WOOL INSULATION WITH ONE SIDE ALUMINIUM FOIL & LINER PANEL WITH

TRAPEZOIDAL PROFILE : ( FM APPROVED )

Supplying and fixing Standing seam profiled Bare galvalume sheet with standing

seam and insulation as Roof sheeting, manufactured out of 0.55 mm TCT Cold Rolled

Steel coil of 345 Mpa yield strength with hot dip metallic coating of minimum 150

gm/sq.m. zinc-Aluminium alloy coating mass (55% Aluminium, 43% zinc and 1.5%

silicon) Sheets to be site roll formed so as to provide a single length panel from ridge

to eaves and the joints between the joints are seamed using seaming machine. The

liner panel shall be with Single skin Galvalume metal sheet 0.5 mm thick at all

heights using Regular modified polyester (RMP) paint with necessary self drilling

screws, EPDM bonded GI washer, sub girts etc. The liner panel for roof sheeting

shall be with colour at bottom and alkyd Paint on top ( inside ).

ROOF INSULATION

50 mm thick Rock wool insulation shall conform to I.S.8183 latest edition with

amendments. And the material density shall be of 48 kg per Cu.m, weight. The

Insulation shall be covered with Aluminium foil on one side in between outer sheet

and liner panel. Insulation shall be supported by using 10 G GI wires tied diagonally

with the purlin to avoid sag.

Liner panel to be considered above purlin. The colour should match with wall cladding

sheet. Trapezoidal profile sheets shall be fixed with ordinary pierce fixation. The steel

manufacturers test certificate for the chemical and mechanical properties of steel

shall be submitted for approval by the concerned authority prior to installation. The

sheet shall have brand marking of the manufacturer on the back of the sheet at every

1 m c/c for confirming genuinity of the material.

The sheet should satisfy the U value of around 0.62 W/m2K as per IGBC standards

and necessary test certificate to be submitted to meet the above mentioned U value

SINGLE SKIN WITHOUT INSULATION - TOP SHEET WITH STANDING SEAM:

FOR UTILTY BUILDING

Supplying and fixing Standing seam profiled Bare galvalume sheet with insulation as

Roofing sheet, manufactured out of 0.55 mm TCT Cold Rolled Steel coil of 345 Mpa

yield strength with hot dip metallic coating of minimum 150 gm/sq.m. zinc-Aluminium

alloy coating mass (55% Aluminium, 43% zinc and 1.5% silicon) and Top to be

finished with Solar Reflective paint. The test for Solar reflectance, solar absorbance

and Thermal emittance should be done and test certificate for the same should be

produced.. Sheets to be site roll formed so as to provide a single length panel from

ridge to eaves and the joints between the joints are seamed using seaming machine.

5 WALL CLADDING SYSTEM

DOUBLE SKIN WITH INSULATION - OUTER SHEET WITH TRAPEZOIDAL

PROFILE, ROCK WOOL INSULATION WITH BOTH SIDES ALUMINIUM FOIL &

LINER PANEL WITH TRAPEZOIDAL PROFILE : (FM APPROVED)

Outer skin shall be precoated Galvalume metal sheet wall cladding with insulation at

all heights using Regular modified polyester (RMP) paint colour coated 0.55 mm TCT

550 Mpa profiled Galvalume steel (Aluminium zinc alloy coating 150 gms / sqm total

of both sides) and with necessary self drilling screws, EPDM bonded GI washer etc

for wall cladding. Trapezoidal profile sheets shall be fixed with ordinary pierce

fixation. The colour of the sheet should be approved by the client / PMC / Architect.

Galvalume metal sheet 0.5 mm thick at all heights using Regular modified polyester

(RMP) paint with necessary self drilling screws, EPDM bonded GI washer, sub girts

etc. The liner panel shall be with colour coated Galvalume sheet outside and alkyd

paint inside. Liner panel to be considered below girt i.e., Girt will not be visible inside

the building. The colour should match with wall cladding sheet. Trapezoidal profile

sheets shall be fixed with ordinary pierce fixation. The steel manufacturers test

certificate for the chemical and mechanical properties of steel shall be submitted for

approval by the concerned authority prior to installation. The sheet shall have brand

marking of the manufacturer on the back of the sheet at every 1 m c/c for confirming

genuinity of the material.

The sheet should satisfy the U value of around 0.62 W/m2K as per IGBC standards

and necessary test certificate to be submitted to meet the above mentioned U value

WALL INSULATION

50 mm thick Rock wool insulation shall conform to I.S.8183 latest edition with

amendments. And the material density shall be of 48 kg per Cu.m, weight. The

Insulation shall be covered with Aluminium foil on one side in between outer sheet

and liner panel. Insulation shall be supported by using GI holding clips to avoid sag.

C.R. Narayana Rao

2 Bill Of Quantities- Rev4

(Consultants) Private Limited

GMR Safran, Hyderabad PEB

S.No Description Qty Unit Rate Amount (Rs.)

6 SINGLE SKIN SHEETING WITHOUT INSULATION - FOR UTILITY BUILDINGS

Supply of colour coated 0.45mm base metal thickness, profile sheeting of 1110 mm

effective cover width profile with nominal 3.5 mm deep ribs at pitch of nominal 50.5

mm center to center distance The steel sheet shall have minimum yield strength of

550MPa, metallic coated with Aluminium-zinc alloy (i.e. Zincalume), AZ150 (min 150

gsm/m2 total on both side), conforms to AS 1397 / ASTM A 792M / IS15961, pre-

painted with Super Durable Polyester Colorbond XRW with higher SRI value

(Thermatech technology) and uses only use inorganic pigments in paint system

conforms to AS/NZS 2728 type 4 / IS 15965 class 3 of Tata BlueScope Steel make or

approved equivalent. The profile sheet, fastener size etc. needs to be approved by

the concern authority. All the accessories like gutter/ flashing / capping shall be made

from the same material is used for main cladding. The measurement shall be based

on finished/covered surface area. The contractor shall prepare the shop drawings

based on the latest drawings supplied by the Engineer-in-charge or the concern

authority. These shall be submitted in five sets sufficiently in advance to the concern

authority for approval.

7 FASCIA OUTER SINGLE SKIN CLADDING SHEET.

Height and other details to be as shown in the latest Architectural drawings

8 STAINLESS STEEL GUTTER WITH G.I.SUPPORT.

Gutter shall be as shown in the latest Architectural drawings. Gutter shall be designed

based on the rain water and catchment area calculations and accordingly the size

shall be calculated. The outside face of the gutters shall be supported with galvanised

steel clamps support suitably designed for fixing to the eaves members. To avoid

bimetallic corrosion/ to avoid direct contact 1.5 mm texself tape to be applied between

gutter and galvanised steel clamp support. The vendor shall submit all design

calculations of gutter sizing & down takes based on the 100mm rain fall intensity

runoff and get the approval from Client / PMC. The sealant filling shall be considered

around the downspout cutouts. Roof rain water Down spouts shall be SWR B class

pipe with density 6 kg/ Sqcm and shall have a 45 degree elbow at the bottom and

shall be supported by clamp to the wall cladding sheet with color coated steel clamp

at a designed spacing. Gutter welding at gutter joints shall not be any surface level

difference. Gutter slope to be maintained for easy flow of rain water to downspout.

Both the end of gutter to be closed with end plate and Emergency over flow drain

pipe to be welded with end plate after make a suitable size hole which have to free

over flow. Accordingly suitable hole to make at fascia cladding sheet for emergency

over flow drain pipe.

Note: Drain spout , down take etc shall be placed as shown in the latest

9 GALVALUME SHEET CAPPING/FLASHING FOR ROOF/WALL.

Supply and Fixing of galvalume Capping / Flashing Colour to match roofing/wall

cladding sheet. Supply and Fixing with 0.5 mm thick Galvalume Capping / Flashing

maximum width 500 mm. Colour to match Wall Cladding material. Flashings and/or

trim shall be furnished at the rake, corners, and eaves, framed openings and

wherever necessary to provide weather tightness and finished appearance matching

with wall finish or as approved by Client / PMC. Color coated steel for flashing, metal

closure, trim and miscellaneous uses shall be of the same specification as the roof

and wall covering material. Foam closures shall be used additionally to match the

panel profile made up of polyurethane or similar material.

Note : Girts spacing should be as per Zurich/FM standard.

10 TATA BLUE SCOPE PRODUCT OR APPROVED EQUIVALENT- SMARTDEK 51,

1mm thick DECK SHEET WITH SHEAR STUD CONNECTOR FOR MEZZANINE

FLOOR.

Supply and fixing of SMARTDEK-51 or approved equivalent, 1 mm thick 125 gsm

Galvanized l Decking sheets of 960 mm effective width and 51 mm rib height with min

yield strength of 550 MPa with include shear Stud on Beam / joist. Shear stud to be

welded with shear stud welding machine at site. 150 mm x 2 mm thick equal angle

to be fixed all the edges properly. Rate shall include cost of materials, labour,

equipment and machinery, loading and unloading, transportation, lead, necessary

scaffolding works and all other incidental charges etc.., complete. Locations as

specified in the latest architectural drawing.

11 ROOF FALL PROTECTION SYSTEM (Roof Life Line System)

Supply & Installation of Madras tools and tackles /INNOTECH FALL PROTECTION

SYSTEM suitable to the Standing Seam roofing sheets using suitable clamps/post

etc .

The Fall Protection System shall be tested to EN795-2012 Class A2 & Class C and

be capable of supporting 2 users working simultaneously at any point along the 8 mm

7 x 7 stainless steel cable even in the same area between 2 posts and shall

demonstrate that an individual post is capable of absorbing a direct dynamic load of

300 kg dropped through 1.5m and limit the force to the roof to 10 kN in shear without

damage to the roofing substrate. Each individual post shall have a unique traceable

serial No. and be manufactured from 5083 Aluminium and 316 stainless steel.

Evidence of salt sprays testing to 1000 hrs. with no corrosion shall also be provided.

Detailed drawings to be submitted along with the Offer.

The fall protection cable system length comprising start, end and intermediate posts.

The above system shall include 2 sets of Personal Protective Equipment (PPE) with

one set consisting of 1 No. each of 1. Rotary travelling device (Trans fastener) 2.

Fixed lanyard - 1.75mtr 3. Full body harness,

The permanent fall protection system on the roof shall have a product life span of 20

years. System warranty of minimum 10 years to be provided.

12 ROOF ACCESS GI CAGE LADDER

C.R. Narayana Rao

3 Bill Of Quantities- Rev4

(Consultants) Private Limited

GMR Safran, Hyderabad PEB

S.No Description Qty Unit Rate Amount (Rs.)

Supplying, Fabricating and Erecting GI caged ladder at all levels to specified

alignment and level as per latest Architectural drawings. Rate includes providing

necessary insert plates/clamps, Bolts nuts, washers, other necessary operations

such as straightening, cutting, machine drilling holes, grinding, edge preparation,

welding , splices for making member length required, holding in position by guy ropes

during erection with suitable temporary guys, and removing the same after placing in

stable position Members will be fabricated as per structural drawing provided to us.

Rate to include Crane for material lifting & erection. The cage ladder should extent

1.5m below from FFL/NGL.

13 ROOF SERVICE WALKWAY PLATFORM. -

DELETED

B STRUCTURAL ANALYSIS AND DESIGN FOR FACTORY BUILDING.

1 PEB Structures

The structural analysis of PEB Structures is carried out by using STAAD Pro V8i

software package and Limit State design shall be performed based on analysis

results. Appropriate loads and its combinations, as per relevant clauses in IS codes

mentioned in section 11 are applied in STAAD model and design is performed for

most unfavorable effects of analysis results. All structural elements are checked for

deflection as per allowable limits specified in respective codes as mentioned in the

technical specification.

The limiting permissible vertical and horizontal deflection for structural Steel members

shall be as specified in IS: 800-2007, table-6.

The limiting horizontal deflection of entire structure shall be as specified in IS: 1893-

2002.

2 The proposed Structure should be strictly designed as per codes mentioned in the

Technical specifications. Dead load shall be as per IS 875 Part I and Live loads as per

IS 875 Part II,( latest version).

Analysis and Design of PEB should be carried out as specified in the technical

specification.

3 Collateral Loads:

All steel frames shall be designed for an additional collateral load of 100 kg/sqm.

Note: Collateral Load will be a part of Dead Load.

4 Live Load:

PEB Roof loading of factory : 100 kg/sqm.

5 Wind Load: ZURICH/FM std

As specified in Technical Specification

6 Seismic Loads:

As specified in Technical Specification

7 All PEB columns to be designed subject to the condition mentioned in the latest

Architectural drawing that the profile of the column should not interfere with the inner

and outer Masonry walls. The block will be provided by the civil contractor which is

not in the scope of PEB contractor. Height of block wall are as shown in the latest

Architectural section drawings.

8 PEB column base plate: All main and end wall column height has to be minimum

100mm to 200 mm below from the FFL, so that all the baseplates, anchor bolts &

stiffeners are below FFL and also to avoid protrusion of Anchor bolts & Nuts above

FFL

9 Preliminary column reactions along with supporting baseplate drawing to be

submitted along with the submission of Bid. Columns, rafters and purlins to be

designed and considering to taking load of utility pipings, cable trays, ducts, light

fittings etc and utility supports structures dead load and live load as shown in the

latest Architectural drawings.

C SUPPORTING STRUCUTURE FOR EOT CRANE (EOT CRANE NOT IN PEB

SCOPE)

1 CRANE BRACKET AND RUNWAY BEAM, CRANE MAINTANANCE CAT WALK

PLATFORM, HAND RAIL, CAT WALK PLATFORM APPROACH CAGE LADDER

ETC ARE IN THE SCOPE OF PEB. PLEASE REFER LATEST ARCHITECTURAL

DRAWING.

2 FASTENERS

All primary members connection bolts shall be approved make with high Strength

Bolts of 8.8 grade, hot dip galvanized and conform to ASTM A 325 M.or equivalent.

All secondary members like purlins, girts and flange braces connection machine

bolts 4.6 grade approved make conform to ASTM A 307 Type A. or equivalent. They

are electro galvanized coating.

3 Flange braces with form of angles are stabilized the interior flanges of the rigid frame

rafters and columns at certain location of purlins and girts.

4 Anchor bolts are manufactured from mild steel rods conform to ASTM A 36 M with a

minimum yield strength of 23.5 KN/sqcm and ultimate strength of 40.2 KN/sqcm.

Supply of anchor bolts, templates for positioning of Anchor bolt with necessary

arrangements to protect the threads from environmental impacts and check the

centerlines, alignment and levels before concreting and after concreting, be present

at the time of concreting by civil contractor, jointly sign the pour card and own

responsibility for the correctness of position of Anchor bolts.

5 FLASHING/TRIM CLOSURE.

Solid or closed cell closures matching the profiles of the panel shall be installed along

the eaves, rake, junction of masonry wall and sheeting and other require locations.

Flashing and / or trim shall be furnished at the rake, corners, eaves, service openings

and framed openings for Rolling shutter, Sectional doors, door, window, louvers and

matching with the color of wall. Material shall match with the physical specifications

of sheeting.

C.R. Narayana Rao

4 Bill Of Quantities- Rev4

(Consultants) Private Limited

GMR Safran, Hyderabad PEB

S.No Description Qty Unit Rate Amount (Rs.)

6 Framed opening structural steel support for Rolling shutter, Doors, Windows,

Louvered ventilator and Utility cutouts frames etc., shall be in PEB Scope

Supply and fixing of lovers and Windows are in the scope of PEB vendor.

Windows shall be fixed DGU with minimum 6mm toughened glass or with

laminated glass of approved shade. Louvers shall be Aluminium anodised with

frame and sub frame all around. All details and specifications as shown in

latest Architectural drawing.

The PEB contractor to design the Girt/Jambs and framed openings to taking the load

of Rolling shutter, Doors, Windows, Louvered ventilator and Utility cutouts frames etc

7 FOAM CLOSURE.

Match the sheet profile. They are made of expanded polyurethane material. This is

used for closing the gap between flashing and wall and roof cladding sheets.

8 SEALER.

Sealer; Sealer for side laps, end laps and windows shall be extruded elastomeric

butyl rubber based sealant or equivalent. The sealer shall be non asphaltic, non

shrinking, non drying, non toxic and shall have adhesion to metals, plastics and

painted surfaces. The vendor shall give the complete technical specifications at the

time of submitting the offer. Special grade silicone sealant shall be used at side laps

and end laps of sheet and wherever required..

9 WALL CLADDING SHEET FIXING SCREWS.

Standard primary manufacturer fasteners shall be metallic polyester coated, heat

treated carbon steel conforming to AS 3566 class 3, hex heads, self drilling screws,

assembled with galvanised steel washers bonded with EPDM seals.

10 FLOWABLE MASTIC.

Flowable mastic shall be neutral cure silicon rubber sealant that is chemically inert

and non corrosive and suitable for exterior applications against weathering and rain

water. When cured it is non-toxic and shrinkage changes in structural movements

joints. It shall be used for standing seam roof sheet end overlap.

11 COLUMN PORTAL BRACINGS.

Portal bracings: Cross bracings are not allowed in the PEB columns. Portal bracings

upto 8 mtr in the external side wall columns and above cross angle bracings are

allowed. For intermediate columns full height Portal bracings are allowed.

Preliminary bracing drawing shall be prepared by the PEB contractor and after getting

approval from Client / PMC then only the contractor can proceed with the work. Tie

beams and cross bracings above 8 mtr level in side wall columns shall not interfere

with any openings such as doors, sectional doors, rolling shutter openings, windows,

etc., The supporting structure / framed openings for Joineries like Rolling shutter,

Windows, Sectional doors, Doors, louver and if any utility services opening should be

provided by PEB contractor as per the latest Architectural drawing and also as

required by Client / PMC wherever required. These supporting structure should be

fixed after coordinating with the Joineries Contractor. Supply and fixing of Rolling

shutter, door, window are in the scope of other vendor. Supply and fixing of louvers

are in PEB contractor scope. Details of louvers as shown in the latest Architectural

drawing.

12 The PEB contractor should position at site during the period of Anchor bolt fixing,

aligning and concreting, using an experienced surveyor while the Anchor bolts are

kept in position by the civil contractor. Required number of MS templates to be

supplied by the PEB contractor along with the Anchor bolts. The surveyor of the PEB

contractor shall be responsible for the clearance of accuracy of centerlines, levels,

verticality etc of the bolts until the pour card is signed and handed over to the civil

contractor. The PEB contractor and the Civil contractor should sign in the pour card

together before and after concreting is done for fixing the Anchor bolts & Base plate.

After concreting the anchor bolts shall be covered properly by PEB vendor for

avoiding damage of threads by others.

13 Micro Schedule to be submitted along with the quote for the entire scope of work

including supplying and erection. Also, Supply of Anchor bolts with templates and

number of templates to be supplied to be mentioned in the schedule. Anchor bolts

and template are to be supplied by the PEB vendor within one week from the date of

approval of the PEB column reaction.

14 The successful Contractor shall be required to submit the entire Structural Design

consisting of the analysis and the design output in support of the design of all primary

and secondary members including bracings, anchor bolts and all other components.

The design shall be submitted in full along with all supportive documents to the

Client / PMC for their scrutiny. In addition, the design by the PEB Contractor shall be

got reviewed, commented upon, revised if required and approved by an independent

approved third party checker, preferably from a recognized Institution like IIT / JNTU

Hyderabad / Anna University/ NIT or other approved by Client / PMC. whose name

should be got cleared prior to submission of design and the cost for the same should

be borne by the PEB vendor. The selection of third party is mutually agreed between

Client / PMC and PEB vendor.

Appropriate structural stability certificates should be submitted by the vendor.

15 The sheet fixing detail for Roof and wall cladding should be submitted for approval.

Seven copies of all the shop drawings ( Soft and hard copies ) shall be prepared in

strict conformity with the approved design duly approved by the Client / PMC. The

design shall strictly conform to the parameters and the required standards stipulated

elsewhere in the tender document. The PEB Contractor shall also submit adequacy

checks and supportive documents, design calculation for rain fall intensity of 150mm

per hour for gutters, down take pipes and such other similar members.

16 PAINTING

C.R. Narayana Rao

5 Bill Of Quantities- Rev4

(Consultants) Private Limited

GMR Safran, Hyderabad PEB

S.No Description Qty Unit Rate Amount (Rs.)

The surface preparation, painting & specifications for the PEB work shall be as below

a) Shot blasting - Sa 21/2 (except secondary members)

b)Two shop coat of epoxy polyimide based red oxide zinc phosphate primer (having

VOC < 250 g/l)- 2 x 35 micron

c) Two coats of epoxy polyamide based enamel paint over primer has to be provided.

One shop coat at factory and one site coat after erection of epoxy polyamide based

enamel paint (having VOC < 250 g/l)- 2 x 35 micron

All the members should be painted in controlled environment away from the factory

premises. But touches work at site should be done with VOC paint as per

specification.

The colour of the finish paint shall be approved by the Client / PMC / Architect. In

case of local weld, fresh treatment shall be repeated with same colour to match with

the original Paint.

All columns and end wall column height has to be minimum 300 mm below the FFL

by considering 50mm clear cover between the top of structural member and floor

finish level of the factory building so that all the baseplates, anchor bolts & stiffeners

are below FFL and also to avoid protrusion of Anchor bolts & Nuts above FFL

17 The design submittals shall be done in three stages as per mutually agreed time

schedule.

The first stage shall be submittal of GA drawings with Anchor bolt and base plate

layout with reactions on columns at foundation level both axial, lateral as well as

moments as applicable.

The Client / PMC will proceed with the Design of foundation based on the column

reactions given initially. However, prior to concreting of the pedestals, approval from

the third party checker shall be submitted for the anchor bolt layout and column

reactions at foundation level.

The second stage will be submittal of full design with supportive drawings to Client /

PMC as well as submittal of the same to the approved third party checker.

The third stage is submittal of the finally approved scheme inclusive of Design and

Drawings with necessary approval certificate from the third party checker.

PEB contractor to make material inspection visit flight ticket arrangement, local

transportation, local accommodation for Client / PMC for material inspection visit to

PEB vendor Plant before dispatch of material to site.

Phase 1

The PEB is factory area is divided into two parts - Phase 1 &2 with Mezzanine in

between. Please refer the latest Architectural layout and sections. Cost to include

necessary structural steel supports, trusses, claddings and roofing sheet as shown in

the latest architectural drawing.

Phase 1 includes the following areas. Please refer the latest drawings.

i) Factory from Gird 13A to Grid 13 La / Gird 30A to Grid 30 La

ii) Mezzanine from Grid 13a to 13 Na / 15a to 15Na

BUILDING -1 - Phase1 -Factory. (Gird 13A to Grid 13 La / Gird 30A to Grid 30

La)

Roof-Double skin insulated system with standing seam with FM compliance

Wall -Double skin insulated with FM compliance.

Refer roof and wall sheet Specifications are given above separately.

Building length - Please refer latest Architectural drawing mentioned above. The roof

slope shall be 1 in 40 and eaves to have rain water gutter with galvalume sheet fascia

cladding as shown in latest architectural drawing.

Loading and unloading bay PEB lean to roof canopy as shown in the latest

Architectural drawing.

Phase 1 - Factory have 3 nos of 1Ton + 1Ton EOT crane Tandem operation to a

maximum longitudinal movement as indicated in drawing. EOT crane (PEB) run way

beams are to be as indicated in latest architectural drawing. Clear height of crane

from FFL shall be as shown in the latest architectural drawing. Please refer the latest

architectural drawings for the location of crane, clear height and longitudinal

movement. Necessary details for the crane to be obtained from crane supplier, before

designing.

Mezzanine at +608.80 Lvl : From Grid 13A to 13 Na / Grid 15A to 15 Na

The location of mezzanine are as mentioned above. Mezzanine to have a under deck

sheet with shear stud mezzanine floor at 5.4 mtr level and mezzanine floor Live

load shall be 1000 Kg/Sqm to a width and length as shown in the latest architectural

drawing. GI Deck panels for the mezzanine floor shall be manufactured from Tata

Blue scope Building Products SMARTDEK-51 Profile structural decking system or

approved equivalent to 1mm thickness, 550 Mpa, 275 GSM galvanised coating

confirming to IS 801/811, having depth of corrugation is 51mm and c/c to distance

between the corrugation as 316mm and effective width of the sheet is 960mm.

The deck panels shall be fixed to the beams/joist by shear stud by shear stud

welding at site. The deck panels shall be designed as permanent shuttering to carry

the dead load and construction loads during concreting. PEB contractor while

concreting the mezzanine floor, Mezzanine floor dead load should be assumed as per

IS 875 (Part - II). Screed concreting including reinforcement is in the scope of the

Civil contractor.

Mezzanine Roof are with double skin insulated system with standing seam. Bare

galvalum sheet + 50mm insulation and liner panel with FM compliance

Wall with double skin insulated - Coated corrugated sheet + 50mm insulation + liner

panel with FM compliance. Refer latest architectural Sections and Plans.

Refer roof and wall sheet Specifications are given above separately.

C.R. Narayana Rao

6 Bill Of Quantities- Rev4

(Consultants) Private Limited

GMR Safran, Hyderabad PEB

S.No Description Qty Unit Rate Amount (Rs.)

Mezzanine for ODU at +614.35 Lvl : From Grid 13L to 15L / Grid 13N to 15L

All specifications same mezzanine at +608.80 Lvl and sizes to be as shown in the

latest architectural drawing.

Phase 2

Phase 2 includes the following areas. Please refer the latest drawings.

i) Factory and Special processing area from Grid 2A to 2 Na / Grid 13a to 13Na

ii) Utility Mezzanine from Grid from 1A to 1D / 2A to 2D

iii) Utility Building - Refer Dwg No - GMR - UTL - AR01 -GR-01-251857

Phase2 -Factory. ( Grid 2A to 2Na / Grid 13a to 13 Na)

Roof-Double skin insulated system with standing seam with FM compliance

Wall -Double skin insulated with FM compliance.

Refer roof and wall sheet Specifications are given above separately.

Building length - Refer latest architectural drawing mentioned above. The roof slope

shall be as shown in the latest architectural drawing and to have rain water gutter with

galvalume sheet fascia cladding as shown in latest architectural drawing.

Loading and unloading bay PEB lean to roof canopy as shown in the latest

architectural drawing.

Factory have 4 nos of 1Ton + 1 Ton EOT crane Tandem operation to a longitudinal

movement as indicated in latest architectural drawings.

Special processing area have 2 nos of 5 Ton EOT crane Tandem operation to a

longitudinal movement as shown in the latest architectural plans.

EOT crane (PEB) run way beams are to be as shown in latest architectural drawings.

Clear height of crane from FFL shall be as shown in the latest Architectural section

drawings.

Utility Mezzanine from Grid from 1A to 1D / 2A to 2D

For Dimensions : Refer latest architectural drawing. Roofing with single skin bare

galvalume sheet with standing seam with FM compliance. Wall with single skin colour

coated corrugated sheet.

Roofing for Electrical panel room from Grid 1K to 1Mb / 2K to 2Mb

Roofing with single skin bare galvalume sheet - standing seam with FM compliance

along with necessary truss works. Refer latest Architectural drawing.

Utility Building - Refer Dwg No - GMR - UTL - AR01 -GR-01-251857:

Sizes as shown in the latest Architectural drawing. Roofing with single skin bare

galvalume sheet with standing seam. Wall with single skin colour coated corrugated

sheet. Height, Dimension and Slope shall be as shown in the latest architectural

drawing.

Total Amount for Phase I and II in Rs………….. LS 1.00 -

C.R. Narayana Rao

7 Bill Of Quantities- Rev4

(Consultants) Private Limited

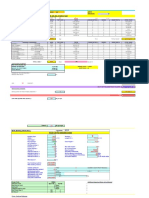

GMR Safran PEB

SAFRAN - PHASE I AND PHASE II

PROPOSED CONSTRUCTION OF FACTORY BUILDINGS AND UTILITY BLOCKS AT GMR

AEROSPACE INDUSTRIAL PARK AT HYDERABAD

Bidders shall furnish their Lump sum Prices strictly in the following format.

1.0 Pre - Engineered Building Rs.

2.0 Details of Taxes and Duties

2.2 Service tax @ % of Base Price Rs.

2.3 Other taxes @ % of Base Price Rs.

2.4 Total taxes Rs.

Total Lump sum price including taxes and

3.0 duties Rs.

Bidders shall indicate various items of materials and its quantities considered in the above L.S. price for

information to the owner. The breakup is only for general information and to get an idea of quantum of

various material considered. This breakup will not be used for evaluating the bids. The total amount

should match with the quoted Lump sum price.

Material

Specification

S.No Item Description as considered Unit Quantity Rate Amount

in the tender

document

1.0 Structural steel Works

Cold formed sections for side runners and

1.1 MT

roof purlins

1.2 Built-up sections for columns and rafters MT

Hot rolled / Built-up sections for crane

1.3 MT

girders

Misc. structural steel works for bracing

1.4 MT

members,

2.0 Sheeting works including its accessories

2.1 Roof sheeting

2.1.1 Double skin standing seam with insulation Sqm

2.1.2 Single skin without insulation Sqm

Canopies for Rolling shutter and Door

2.2

openings

2.2.1 Side cladding sheet Sqm

3.0 Wall

3.1 Double skin wall cladding with insulation Sqm

3.2 Single skin wall cladding without insulation Sqm

Single skin wall cladding sheet for fascia

4.0 Sqm

outer and inner

Polycarbonate/FRP sheets with its

5.0 Sqm

accessories

6.0 Gutter Rm

7.0 Galvalume sheet box type Down pipes Rm

8.0 Insulation with Al foil Sqm

9.0 Powerlon vapour control layer Sqm

10.0 Deck sheet 275gsm and 1mm thick Sqm

11.0 Shear stud and accessories Nos

12.0 Miscellaneous items ( Please specify )

C.R. Narayana Rao

8 Annexure 1 to BOQ - Rev5

(Consultants) Private Limited

GMR Safran PEB

13.1 FASCIA GUTTER

13.1.1 Gutter Wall Facia Builtup 6.2 M.T.

13.1.2 Gutter Wall Facia Cold Form 9.04 M.T.

13.1.3 Gutter Wall Facia sheeting 6.893 M.T.

14.1.1 FASCIA END WALL

End Wall Facia Builtup 6 M.T.

End Wall Facia Cold Form 9.4 M.T.

End Wall Facia sheeting 5.64 M.T.

Cage ladder Nos

Sky light panels (On Roof) Sqm

Louvers Rmt

SS Mesh for Louvers Sqm

Flashing/trim/capping Rmt

Life line system

Roof service walkway

Please add if any missed out items

Erection, Fright, Transportations, Handling

C.R. Narayana Rao

9 Annexure 1 to BOQ - Rev5

(Consultants) Private Limited

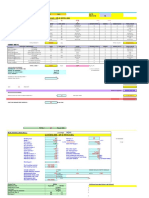

GMR Safran PEB

#REF!

#REF!

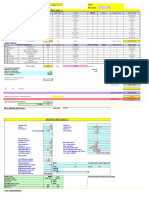

STRUCTURAL ANALYSIS DATA REQUIRED

I. General & Structural Data II. Structural Design Input III. Structural Design Output

1. Building Information 1. Gravity Loads 1. Reactions

Name SAFRAN Roof Load Table containing column reactions

ID Dead Load (kg/sqm) 20+100 (Vx,Vy,Vz, Mx,My,Mz) The various load cases

Footprint Area Live Load (kg/sqm) 100 should not be combined)

Total Area 21280 sqm Floor Load DL

No. of Stories As per drawing Dead Load (kg/sqm) 400 LL

Length 105 m Live Load (kg/sqm) 1000 EQ -EQ Wind -Wind

Width 235 m 2. Earthquake Design Parameters Longitudal

2. Structural System Ss Short period spectral As per IS code Lateral

a. Column Spacing acceleration 2. Periods of Vibration

Longitudinal As per drawing Sl 1 second spectral As per IS code First four periods and associated

Transverse As per drawing acceleration mass participation

b. Story Heights As per drawing Soil type Medium x y

c. Gravity System EQ Reduction Factor, R 3. Location of center of mass 108.335 11.73

Roof Framing As per drawing Longitudinal 4 4. Location of center of rigidity

Beams As per drawing Transverse 5 5. Displacements

Girders As per drawing Total Mass of the Building 52703.67 KN Table with EQ displacement

Columns As per drawing Total Earthquake Base Shear Center

Corner*

Foundation Longitudinal 773.2 KN of Mass

d. Lateral System Lateral 829.6 KN Longitudinal

Roof As per drawing 3. Structural Analysis Model +EQ

Longitudinal As per drawing Plan View showing column -EQ

Transverse As per drawing locations Transverse

e. Materials Properties Isometric view (more than 1 +EQ

Steel 345 Mpa if complicated) -EQ

Concrete

* Roof point farthest from center of rigidity

Annexure 2 - PEB BOQ - Rev5

C. R. Narayana Rao (Consultants) Pvt Ltd 10

GMR Safran PEB

#REF!

#REF!

III. Structural Design Output

z

46.766

Annexure 2 - PEB BOQ - Rev5

C. R. Narayana Rao (Consultants) Pvt Ltd 11

You might also like

- Technical Specifications & BOQ For PEB at KasnaDocument6 pagesTechnical Specifications & BOQ For PEB at KasnaAbhinav Tewari100% (2)

- PEB Roofing and Cladding WorksDocument22 pagesPEB Roofing and Cladding WorksAman ThakurNo ratings yet

- Boundary Wall Construction IST IslamabadDocument2 pagesBoundary Wall Construction IST IslamabadJan Ali Khan100% (1)

- Construction of Dental Council office building in DelhiDocument120 pagesConstruction of Dental Council office building in DelhiAjay Roy100% (1)

- Schedule of Quantity For Industrial BuildingDocument4 pagesSchedule of Quantity For Industrial BuildingShashankSinghNo ratings yet

- Summary of CostDocument334 pagesSummary of CostSurendra MaharjanNo ratings yet

- Complete - BOQ Format of Highway ProjectDocument53 pagesComplete - BOQ Format of Highway ProjectRajesh SinghalNo ratings yet

- Interior Work Tender BOQ - Revised SummaryDocument1 pageInterior Work Tender BOQ - Revised Summarymisipl00750% (2)

- Measurement Sheet for Excavation, PCC, Kerbstone and Joint Filling WorksDocument2 pagesMeasurement Sheet for Excavation, PCC, Kerbstone and Joint Filling WorksYashashree Group100% (1)

- BOQ For Clubhouse - GulbargaDocument18 pagesBOQ For Clubhouse - GulbargaDatta Pujari0% (1)

- Bill No.7 Metal & Aluminum Works Office Building & WarehouseDocument2 pagesBill No.7 Metal & Aluminum Works Office Building & WarehouseFirst Choice100% (2)

- DAR, 2018 Vol. 1Document902 pagesDAR, 2018 Vol. 1Charan Electricals97% (32)

- Estimate and BoQ for Main Building ConstructionDocument273 pagesEstimate and BoQ for Main Building Constructionsrs_ce05No ratings yet

- Factual Civil Engineering: Cement ReconcilationDocument5 pagesFactual Civil Engineering: Cement ReconcilationDeepak Kaushik100% (1)

- Factory Building Bill of QuantitiesDocument30 pagesFactory Building Bill of Quantitieszakaria200811060100% (3)

- BOQDocument23 pagesBOQEsakkirajan BalakrishnanNo ratings yet

- A Ground To 14th Floor: S. No. Description Unit RateDocument3 pagesA Ground To 14th Floor: S. No. Description Unit RateHarsh SathvaraNo ratings yet

- Apartment BOQDocument13 pagesApartment BOQusman khan50% (2)

- BOQ - BuildingDocument44 pagesBOQ - Buildingmonsur ahmed100% (1)

- 2337 7 Boq Overhead Water Tank Civil (Part Vii) 1Document1 page2337 7 Boq Overhead Water Tank Civil (Part Vii) 1BTENo ratings yet

- Methodology Fo Tapecrete WaterproofDocument3 pagesMethodology Fo Tapecrete Waterproofbeshnu garanaikNo ratings yet

- Township BOQ With CorrigendumDocument40 pagesTownship BOQ With CorrigendumPoornima D GowdaNo ratings yet

- Billing EngineerDocument2 pagesBilling EngineerMahesh KurkundaNo ratings yet

- Painting Rate Analysis 15.10.11Document11 pagesPainting Rate Analysis 15.10.11Suresh Patil79% (34)

- Road and Drainage Works BOQ for Central University of KarnatakaDocument20 pagesRoad and Drainage Works BOQ for Central University of KarnatakaPinak ProjectsNo ratings yet

- Pre-Engineered Steel Buildings Design and ConstructionDocument36 pagesPre-Engineered Steel Buildings Design and ConstructionAnonymous UibQYvc675% (4)

- Bill of Quantities (Boq) - NepalDocument7 pagesBill of Quantities (Boq) - NepalHamza Mami50% (2)

- RATE Analysis MS Steel Staircase WorkDocument10 pagesRATE Analysis MS Steel Staircase WorkMohd Israil KhanNo ratings yet

- Toughened Glass Railing Item With DescriptionDocument1 pageToughened Glass Railing Item With DescriptionDeepak ChandolaNo ratings yet

- Steel Structure Unit RatesDocument8 pagesSteel Structure Unit RatesFoisul Alam100% (1)

- BBS BookDocument82 pagesBBS BookVaibhav BachhavNo ratings yet

- House Construction Cost or Packages in Bangalore Starts at 1670 - Sq. Ft. - Brick&BoltDocument3 pagesHouse Construction Cost or Packages in Bangalore Starts at 1670 - Sq. Ft. - Brick&BoltkrvishwaNo ratings yet

- BOQ Interior (Final)Document27 pagesBOQ Interior (Final)dawitgggNo ratings yet

- Package II Part I.2 Civil BOQ For Service BlockDocument22 pagesPackage II Part I.2 Civil BOQ For Service Blockdox4useNo ratings yet

- VDF-Flooring (Floor-M20 Grade) 75 mm thkDocument3 pagesVDF-Flooring (Floor-M20 Grade) 75 mm thkDeepa Junnarkar DegwekarNo ratings yet

- Rates For Rate Analysis Excel FormatDocument44 pagesRates For Rate Analysis Excel Formatanirbanpwd76No ratings yet

- PA - ID BOQ For L1 Entrance Lobby & L12 Main LobbyDocument116 pagesPA - ID BOQ For L1 Entrance Lobby & L12 Main LobbyHamayet Rasel100% (1)

- Revised BoQ For Landscaping Earthgardens and Window GrillsDocument6 pagesRevised BoQ For Landscaping Earthgardens and Window GrillsEngr Muhammad Asif JavaidNo ratings yet

- Quotation For Industrial BuildingDocument3 pagesQuotation For Industrial BuildingSingh Gurpreet0% (2)

- Project Semester Report on Pre-Engineered Steel BuildingsDocument46 pagesProject Semester Report on Pre-Engineered Steel BuildingsPrathamesh Prathamesh100% (2)

- BoqDocument50 pagesBoqSaid KarimNo ratings yet

- Civil & Finishing Work B.O.QDocument32 pagesCivil & Finishing Work B.O.QSagar SharmaNo ratings yet

- Trimix Flooring AnalysisDocument6 pagesTrimix Flooring AnalysisShashank Hegde75% (8)

- Draft BoqDocument9 pagesDraft BoqDeepa Junnarkar DegwekarNo ratings yet

- Flooring Work Rate AnalysisDocument34 pagesFlooring Work Rate Analysiscinema cinema67% (3)

- Canopy BOQ 16x54m Toll Plazas NH-2Document1 pageCanopy BOQ 16x54m Toll Plazas NH-2jalal100% (1)

- Mivan Shuttering CalculationDocument2 pagesMivan Shuttering Calculationrsandye80% (15)

- BOQ AppartmentDocument78 pagesBOQ AppartmentAbdalah OsamaNo ratings yet

- Rate Analysis and Abstract BOQDocument37 pagesRate Analysis and Abstract BOQThota Revanth78% (41)

- PEB Technical BidDocument119 pagesPEB Technical BidAmjad Pervaz100% (2)

- Mivan Component CodesDocument9 pagesMivan Component Codeskishor150688100% (1)

- BT Road Estimate ModelDocument5 pagesBT Road Estimate Modelsasidharkatari91572No ratings yet

- ECGC Bank Branch Interiors SpecificationsDocument15 pagesECGC Bank Branch Interiors SpecificationsRio Gottes HolleNo ratings yet

- Ref PPT For Rate AnalysisDocument22 pagesRef PPT For Rate AnalysisParth Shah75% (4)

- BWDB 'S Item Description (Volume-I) Updated On 21-10-2014Document110 pagesBWDB 'S Item Description (Volume-I) Updated On 21-10-2014їэasħaŗ ēŗ.ďuηĭyą100% (4)

- Peb Technical SpecificationDocument4 pagesPeb Technical Specificationalankar ambwadeNo ratings yet

- PPPL-21362 (R-0) Techno Commercial OfferDocument8 pagesPPPL-21362 (R-0) Techno Commercial OfferAtul Kumar EngineerNo ratings yet

- Prefab Canopies Technical SpecificationDocument10 pagesPrefab Canopies Technical SpecificationTabish IzharNo ratings yet

- Warehouse & Working Facilities Complex at Sreepur, Gazipur, Bangladesh. 11-07-17 22 LB PER SFT PDFDocument7 pagesWarehouse & Working Facilities Complex at Sreepur, Gazipur, Bangladesh. 11-07-17 22 LB PER SFT PDFAbdullah Omar NasseefNo ratings yet

- Bill of Quantity: Baner Lifespaces LLPDocument7 pagesBill of Quantity: Baner Lifespaces LLPSales AlufacadesNo ratings yet

- Offer 153 - r2Document8 pagesOffer 153 - r2Rakesh SharmaNo ratings yet

- WINNTRA PEB systems proposal for pre-engineered buildingsDocument17 pagesWINNTRA PEB systems proposal for pre-engineered buildingsRakesh SharmaNo ratings yet

- FFSDocument8 pagesFFSRakesh SharmaNo ratings yet

- Costing sheet and weight summary for 1835 die casting buildingDocument3 pagesCosting sheet and weight summary for 1835 die casting buildingRakesh SharmaNo ratings yet

- Basement OfferDocument7 pagesBasement OfferRakesh SharmaNo ratings yet

- Costing 145Document16 pagesCosting 145Rakesh SharmaNo ratings yet

- CS 139 - R1Document10 pagesCS 139 - R1Rakesh SharmaNo ratings yet

- FFSDocument8 pagesFFSRakesh SharmaNo ratings yet

- CS 139 - R1Document10 pagesCS 139 - R1Rakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- Basement OfferDocument7 pagesBasement OfferRakesh SharmaNo ratings yet

- MEZZANINE BEAMS (JOIST) 9.5 DeckDocument4 pagesMEZZANINE BEAMS (JOIST) 9.5 DeckRakesh SharmaNo ratings yet

- Costing 458 - R1-02-03-19Document10 pagesCosting 458 - R1-02-03-19Rakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- COSTING 449 - 3 Ridge in CenterDocument14 pagesCOSTING 449 - 3 Ridge in CenterRakesh SharmaNo ratings yet

- COSTING 449 - 3 Ridge in CenterDocument14 pagesCOSTING 449 - 3 Ridge in CenterRakesh SharmaNo ratings yet

- COSTING 449 - 2 IDocument14 pagesCOSTING 449 - 2 IRakesh SharmaNo ratings yet

- Costing 440Document8 pagesCosting 440Rakesh SharmaNo ratings yet

- Costing calculations for India hall buildingDocument8 pagesCosting calculations for India hall buildingRakesh SharmaNo ratings yet

- Costing 479 - Blok-2Document8 pagesCosting 479 - Blok-2Rakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- Costing 439Document8 pagesCosting 439Rakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- 342 Offer - 24augDocument10 pages342 Offer - 24augRakesh SharmaNo ratings yet

- Cost 262Document28 pagesCost 262Rakesh SharmaNo ratings yet

- Utility BoqDocument1 pageUtility BoqRakesh SharmaNo ratings yet

- 05a1 E70 Central Locking PDFDocument19 pages05a1 E70 Central Locking PDFMozes SimataaNo ratings yet

- Samsung SRF653CDLS 653L French Door Fridge User ManualDocument44 pagesSamsung SRF653CDLS 653L French Door Fridge User ManualMilina VeseliNo ratings yet

- Smartshelter Container - Iso 20': 14 KW / 50Hz All in One Datacenter ModuleDocument29 pagesSmartshelter Container - Iso 20': 14 KW / 50Hz All in One Datacenter ModuleMohamed ArafaNo ratings yet

- ANGELANTONI EKOFRIGOLAB Laboratory Refrigerators and FreezersDocument6 pagesANGELANTONI EKOFRIGOLAB Laboratory Refrigerators and FreezersIan G. WalkerNo ratings yet

- M3 Sill Outer (Front Section)Document120 pagesM3 Sill Outer (Front Section)Đông NguyễnNo ratings yet

- FP Metal Enclosed Switchgear BrochureDocument24 pagesFP Metal Enclosed Switchgear BrochureAlex Jr ApuyaNo ratings yet

- KatalogusStaal2014V1 0 PDFDocument32 pagesKatalogusStaal2014V1 0 PDFAndrew MwambaNo ratings yet

- Technal Product BrochureDocument8 pagesTechnal Product BrochureSaksham AdauliaNo ratings yet

- Swing Door Installation ManualDocument28 pagesSwing Door Installation Manualmararuly biliyantoNo ratings yet

- Renault SCENIC: Vehicle User ManualDocument374 pagesRenault SCENIC: Vehicle User ManualTree SaviourNo ratings yet

- EN81-20 欧洲最新电梯标准解读Document100 pagesEN81-20 欧洲最新电梯标准解读babykiss1986No ratings yet

- Whirlpool Awe 7516-1 PDFDocument48 pagesWhirlpool Awe 7516-1 PDFDennYss DenisaNo ratings yet

- AFCEE Iraq Construction Standards Final-06SEPDocument40 pagesAFCEE Iraq Construction Standards Final-06SEPShannon Hopkins100% (1)

- Sri Ram Engineers: Emailid: Ph. No 044-27660611Document3 pagesSri Ram Engineers: Emailid: Ph. No 044-27660611Karthick KeyanNo ratings yet

- Construction Defects: DefinitionDocument12 pagesConstruction Defects: Definitionzoya mariamNo ratings yet

- Assessment Tool For Day Care Center and Day Care WorkerDocument34 pagesAssessment Tool For Day Care Center and Day Care WorkerMarrah Alora IliganNo ratings yet

- Generator TC350-S Cummins 6LTAA9 PDFDocument7 pagesGenerator TC350-S Cummins 6LTAA9 PDFTiếnNo ratings yet

- Semi-Restricted Corridor: Ergonomic Plan General Operating RoomDocument11 pagesSemi-Restricted Corridor: Ergonomic Plan General Operating RoomCarl CrowNo ratings yet

- The Lines of Ornamental PlanningDocument152 pagesThe Lines of Ornamental PlanningBALLERINO82No ratings yet

- Falcon 50 Checklist PDFDocument402 pagesFalcon 50 Checklist PDFJosé A. Montiel Quirós100% (2)

- To Recalibrate The WindowDocument4 pagesTo Recalibrate The WindowPuican IulianNo ratings yet

- SP-PS-430 Rev 1.01Document7 pagesSP-PS-430 Rev 1.01MeNo ratings yet

- KD Steel DoorsDocument1 pageKD Steel DoorsKuladeep YalamanchiliNo ratings yet

- Winnebago CatalogDocument241 pagesWinnebago Catalogchaput87No ratings yet

- 17 PointTruckTrailerInspection PDFDocument39 pages17 PointTruckTrailerInspection PDFokta_msp100% (1)

- Elevator Control Module User's ManualDocument9 pagesElevator Control Module User's ManualBrahim CherguiNo ratings yet

- Renovation and Repair Works at Pakal Dul HE ProjectDocument63 pagesRenovation and Repair Works at Pakal Dul HE Projectsikandar kumarNo ratings yet

- Research Memorial-ParkDocument30 pagesResearch Memorial-ParkBeiya Mae100% (1)

- Garage Door Opener Model 248735 3/4 HP: Owner's ManualDocument40 pagesGarage Door Opener Model 248735 3/4 HP: Owner's ManualJoeyNo ratings yet

- Catalog RetcoDocument84 pagesCatalog RetcoSORIN_NITANo ratings yet