Professional Documents

Culture Documents

Process Overview (1) - Fpso Ruby Ii

Uploaded by

Cao Huu TungOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Overview (1) - Fpso Ruby Ii

Uploaded by

Cao Huu TungCopyright:

Available Formats

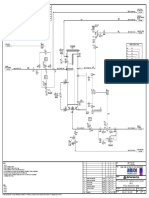

P = 5.

0 barg

o

T = 40 C

TURRET – (GAS LIFT)

P = 7.0 barg

T = 40oC

P = 3.0 barg

o

T = 80 C

DECK BOILER

100t/HR

SLOP

PRODUCED WATER (OVERBOARD)

DEGASSER BLANKET

FUEL GAS

DISTRIBUTION

HEADER (M1) FLARE PILOT GAS

TOTAL CRUDE TANK CAPACITY = 600,000 bbls

OIL PRODUCTION CAPACITY = 039,000 bopd

GAS LIFT CAPACITY = 11.5 MMscfd

TOTAL LIQUID HANDLING = 45,000 bpd

OFFLOADING RATE = 20,000 bbls/hr

HP & LP FLARE HEADER

PRODUCTION CHEMICAL GAS LIFT POWER GENERATION

NITROGEN SUPPLY HEADER

INJECTION LEGEND FPSO RUBY II

NITROGEN BACK-UP RACK PURGING & BLANKETING CA – Antifoam ST M ST

TYP.16 NOS. (MODULE 5)

PROCESS OVERVIEW

CD – Demulsifier

CC – Corrosion Inhibitor GT-6001 A/B MISC DRWG. No.:

INSTRUMENT AIR

K-3001 A/B Steam Turbine Generator

ORIGINAL TANKER: M.T CHERRY II

SUPPLY HEADER CS – Scale Inhibitor CREATOR: MKAS (PROCESS)

AIR COMPRESSOR Reciprocating Compressor Peter Brotherhood

PACKAGE A-8001 A/B

CR – Reverse Demulsifier

CB – Biocide Motor 1.5 MW 5.0 MW each DATE: FEBRUARY 2010 REV 00

(MODULE 5) AIR SUPPLY HEADER BOILER ATOMIZING

You might also like

- Guidelines For Floating Offshore Facilities For LNG/LPG Production, Storage and OffloadingDocument80 pagesGuidelines For Floating Offshore Facilities For LNG/LPG Production, Storage and Offloadingkaspersky2009100% (2)

- Fundamentals of FPSO PDFDocument4 pagesFundamentals of FPSO PDFSamuel Mawutor Gamor25% (4)

- SBM FPSO RecordDocument32 pagesSBM FPSO RecordgpriohardonoNo ratings yet

- Fpso Design and TechnologyDocument57 pagesFpso Design and Technologyjokots100% (1)

- FPSODocument29 pagesFPSOLee Teck WeiNo ratings yet

- FLNG 1500 Kris MartinickDocument100 pagesFLNG 1500 Kris MartinickTracy Evans100% (1)

- FPSO Guide to Floating Production, Storage and Offloading VesselsDocument19 pagesFPSO Guide to Floating Production, Storage and Offloading Vesselsmaz234No ratings yet

- The FPSO Contractors GuidebookDocument20 pagesThe FPSO Contractors Guidebookaarivalagan100% (1)

- 0310-10 Rev 2 CBTA Gas Tester TRAINING PDFDocument16 pages0310-10 Rev 2 CBTA Gas Tester TRAINING PDFfaltekxNo ratings yet

- FPSO Topside Modules DynamacDocument28 pagesFPSO Topside Modules DynamacJames100% (1)

- FPSO ToolkitDocument28 pagesFPSO ToolkitNathachai LeewathanakijNo ratings yet

- Fpso Presentation Technipfmc ShiDocument25 pagesFpso Presentation Technipfmc ShiBharuk Mech100% (2)

- BW Offshore Catcher UK LTD 2017 Environmental StatementDocument18 pagesBW Offshore Catcher UK LTD 2017 Environmental StatementpprabudassNo ratings yet

- Benefits of Cylindrical FPOsDocument40 pagesBenefits of Cylindrical FPOsGaurav SinghalNo ratings yet

- Gas Processing Fundamentals ManualDocument75 pagesGas Processing Fundamentals ManualArjun Shantaram Zope100% (2)

- FPSO Design & Processing SystemsDocument20 pagesFPSO Design & Processing SystemsHtin Lin AungNo ratings yet

- FPSO CSR Field TripDocument44 pagesFPSO CSR Field TripRengaNathanKNo ratings yet

- Hazard Analysis of Turret SystemsDocument23 pagesHazard Analysis of Turret SystemsBali PalNo ratings yet

- General FPSODocument22 pagesGeneral FPSOaravind grandhi100% (2)

- IPTC 14548 FLNG Development: Strategic Approaches To New Growth ChallengesDocument15 pagesIPTC 14548 FLNG Development: Strategic Approaches To New Growth ChallengesIzhamKhairiNo ratings yet

- FPSO InformationDocument24 pagesFPSO Informationzorro21072107No ratings yet

- Crude Oil Processing On Offshore Facilities PDFDocument14 pagesCrude Oil Processing On Offshore Facilities PDFmohit4821No ratings yet

- OTC 16198 Design and Conversion of FPSO MystrasDocument18 pagesOTC 16198 Design and Conversion of FPSO Mystrassegunoyes100% (1)

- FLNGDocument8 pagesFLNGmoiseianNo ratings yet

- 36B - Floating LNG Design & ConceptDocument40 pages36B - Floating LNG Design & ConceptPutu Indra MahatrisnaNo ratings yet

- An Introduction To Floating Production Storage and Offloading (FPSO) VesselsDocument31 pagesAn Introduction To Floating Production Storage and Offloading (FPSO) VesselsGeorge Gougoulidis86% (7)

- 9 Guerrero FLOATERS Master-Ed2013-14Document33 pages9 Guerrero FLOATERS Master-Ed2013-14thlim19078656No ratings yet

- Statoil PPT On Fpso DesignDocument44 pagesStatoil PPT On Fpso Designcxb0716467% (3)

- Turret MooringsDocument3 pagesTurret Mooringsjo0% (1)

- FPSO PresentationDocument30 pagesFPSO Presentationmechmonkey007100% (1)

- FLNG Training Module 1.1 Introduction To FLNG Rev 1Document34 pagesFLNG Training Module 1.1 Introduction To FLNG Rev 1Jay Kanes100% (3)

- Mechanical Engineer Project Manager in Houston TX Resume Patrick OjoDocument5 pagesMechanical Engineer Project Manager in Houston TX Resume Patrick OjoPatrickOjoNo ratings yet

- FpsoDocument8 pagesFpsoJorge HL0% (2)

- 788 TP FPSO ApplicationsDocument23 pages788 TP FPSO ApplicationsRicardo Argentton FicanhaNo ratings yet

- FPSO BrochureDocument12 pagesFPSO BrochuredonyaNo ratings yet

- FPSO Presentation - MODECDocument23 pagesFPSO Presentation - MODECosbianiNo ratings yet

- Zeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaDocument4 pagesZeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaAmirah AqilahNo ratings yet

- Bluewater: First Oil Fpso Information Contract Info. Location InfoDocument6 pagesBluewater: First Oil Fpso Information Contract Info. Location InfoDavid SeowNo ratings yet

- Subsea Control Systems SXGSSC PDFDocument6 pagesSubsea Control Systems SXGSSC PDFLimuel EspirituNo ratings yet

- Deepwater DevelopmentDocument53 pagesDeepwater Developmenthengki wibowoNo ratings yet

- 0711 DSME Lessons Learned FPSO JIP Public Rev.1Document22 pages0711 DSME Lessons Learned FPSO JIP Public Rev.1Anonymous WCG2HjPybJNo ratings yet

- A Guide To FLNGDocument6 pagesA Guide To FLNGRobert WatersNo ratings yet

- Presentation - Ruby II - Fso Bd01 - Fpso Lam SonDocument127 pagesPresentation - Ruby II - Fso Bd01 - Fpso Lam SonRubyNo ratings yet

- Tanker Conversions To FPSODocument32 pagesTanker Conversions To FPSOtambokNo ratings yet

- FLNG FacilitiesDocument30 pagesFLNG FacilitiesSandeep Danta100% (4)

- Golar LNGDocument28 pagesGolar LNGrajee7100% (2)

- L01 - Introduction To SPS PDFDocument39 pagesL01 - Introduction To SPS PDFariful islamNo ratings yet

- Total - FLNG TechnologyDocument14 pagesTotal - FLNG TechnologyRagerishcire KanaalaqNo ratings yet

- DeepC FPSO TutorialDocument33 pagesDeepC FPSO TutorialZou Jiawei100% (1)

- FPSO Facilities: Processing Oil and Gas OffshoreDocument30 pagesFPSO Facilities: Processing Oil and Gas OffshoreJogi100% (1)

- Fpso OtcDocument7 pagesFpso OtcMartinus LuckyantoNo ratings yet

- FPSO Hazard IssuesDocument33 pagesFPSO Hazard IssuesJagan Bose100% (2)

- OE CORP ENG TN 0002 Pre Commissioning Overview Umbilicals Rev C1Document16 pagesOE CORP ENG TN 0002 Pre Commissioning Overview Umbilicals Rev C1hatakerobot100% (1)

- MTU 1163 TB 93 ENGINE LAYOUTDocument52 pagesMTU 1163 TB 93 ENGINE LAYOUTHaritha Haraekrishnan100% (1)

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- Bhel SGDocument17 pagesBhel SGShubham ChaurasiaNo ratings yet

- Chiller and cooling equipment scheduleDocument53 pagesChiller and cooling equipment scheduleRaju KsnNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- Astha: Main Plant Operation Dept. Captive Power Plant-Ii 540MwDocument25 pagesAstha: Main Plant Operation Dept. Captive Power Plant-Ii 540MwRohith KumarNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- 0909-GS-P-XB-00250 - C3 - 3rd Stage Gas Export Compressor Suction Scrubber Train B P&IDDocument1 page0909-GS-P-XB-00250 - C3 - 3rd Stage Gas Export Compressor Suction Scrubber Train B P&IDCao Huu TungNo ratings yet

- 0909-GS-P-XB-00001 - C3 - Process Drawing IndexDocument1 page0909-GS-P-XB-00001 - C3 - Process Drawing IndexCao Huu TungNo ratings yet

- Lva1 App6892Document3 pagesLva1 App6892Cao Huu TungNo ratings yet

- 0909-GS-P-XB-00016 - C3 - Crude Transfer Pumps P&IDDocument1 page0909-GS-P-XB-00016 - C3 - Crude Transfer Pumps P&IDCao Huu TungNo ratings yet

- MTN1229 Transfer Fire & Gas Spare Part To DDWHPDocument3 pagesMTN1229 Transfer Fire & Gas Spare Part To DDWHPCao Huu TungNo ratings yet

- AmeronDocument4 pagesAmerontahatekriNo ratings yet

- Vane Pack SeparatorsDocument2 pagesVane Pack SeparatorsIsaac FloresNo ratings yet

- Site inspection drawing detailsDocument1 pageSite inspection drawing detailsCao Huu TungNo ratings yet

- Toc - Process - Thang Long - Vol 2 - 10-MayDocument4 pagesToc - Process - Thang Long - Vol 2 - 10-MayCao Huu TungNo ratings yet

- Gaslift Choke Valve PDFDocument1 pageGaslift Choke Valve PDFCao Huu TungNo ratings yet

- XCV Fat ReportDocument12 pagesXCV Fat ReportCao Huu TungNo ratings yet

- 0909-GS-P-XA-00001 - C2 - Oil & Gas Processing System PFDDocument1 page0909-GS-P-XA-00001 - C2 - Oil & Gas Processing System PFDCao Huu TungNo ratings yet

- TLDD 0003 1AAG A01 0001 C2 (Basic Design Report)Document152 pagesTLDD 0003 1AAG A01 0001 C2 (Basic Design Report)Cao Huu TungNo ratings yet

- Site inspection drawing detailsDocument1 pageSite inspection drawing detailsCao Huu TungNo ratings yet

- A8 Down Hole Connector PDFDocument4 pagesA8 Down Hole Connector PDFCao Huu TungNo ratings yet

- DD CFT Report Oct-17Document8 pagesDD CFT Report Oct-17Cao Huu TungNo ratings yet

- TLDD-2016-2AAG-D06-0001 - Code 2Document5 pagesTLDD-2016-2AAG-D06-0001 - Code 2Cao Huu Tung100% (1)

- A11 Start Up and Commisioning PDFDocument1 pageA11 Start Up and Commisioning PDFCao Huu TungNo ratings yet

- A2 GE Installation Support PDFDocument3 pagesA2 GE Installation Support PDFCao Huu TungNo ratings yet

- P4E Enhance CV - TL-9PDocument7 pagesP4E Enhance CV - TL-9PCao Huu TungNo ratings yet

- A1 GE JSA Installation PDFDocument7 pagesA1 GE JSA Installation PDFCao Huu TungNo ratings yet

- TEGDocument7 pagesTEGarispriyatmonoNo ratings yet

- 1719 Apl P XD Ag S0015784 - Z - 1Document1 page1719 Apl P XD Ag S0015784 - Z - 1Cao Huu TungNo ratings yet

- Glycol DehydrationDocument25 pagesGlycol DehydrationCao Huu TungNo ratings yet

- Gas DehydrationDocument45 pagesGas DehydrationCao Huu TungNo ratings yet

- Air Compressor PDFDocument11 pagesAir Compressor PDFCao Huu TungNo ratings yet

- Regulator Seat Leakage: American National StandardDocument7 pagesRegulator Seat Leakage: American National StandardThiago Ribeiro da SilvaNo ratings yet

- Reciprocating Compressor TestingDocument24 pagesReciprocating Compressor TestingSh.nasirpurNo ratings yet

- Process Gas CompressorsDocument24 pagesProcess Gas CompressorsMSNo ratings yet

- Refrigeration and Air Conditioning Systems ExplainedDocument260 pagesRefrigeration and Air Conditioning Systems ExplainedYonas AlayuNo ratings yet

- CADE Technologybrochure AccumulatorsDocument24 pagesCADE Technologybrochure AccumulatorsJose francisco Lazo castroNo ratings yet

- The Hydraulic JumpDocument7 pagesThe Hydraulic JumpcynthiaNo ratings yet

- Assignment 1Document5 pagesAssignment 1hussainNo ratings yet

- Gas Turbine Theory and Construction ExplainedDocument29 pagesGas Turbine Theory and Construction ExplainedDee ⎝⏠⏝⏠ DeeNo ratings yet

- HLCP 05 BrochureDocument11 pagesHLCP 05 BrochureResul UygunNo ratings yet

- Advantages of SF6 Gas Insulated TransformerDocument19 pagesAdvantages of SF6 Gas Insulated Transformerkarunamcs67% (3)

- Hydraulics Micro-Project: Topic: Study of Pressure Measuring DevicesDocument18 pagesHydraulics Micro-Project: Topic: Study of Pressure Measuring DevicesGvanNo ratings yet

- Erosional Flow Rate Vs Flowing PressureDocument1 pageErosional Flow Rate Vs Flowing PressureJay SadNo ratings yet

- Hydrogen From BiomassDocument24 pagesHydrogen From BiomassDIPAK VINAYAK SHIRBHATENo ratings yet

- REN5415 - Y19 - Lec5 &6Document76 pagesREN5415 - Y19 - Lec5 &6Abdulla MohammadNo ratings yet

- Flow Meters Butt WeldDocument3 pagesFlow Meters Butt WeldPan GulfNo ratings yet

- CO2 Recovery Plant for DistilleriesDocument2 pagesCO2 Recovery Plant for DistilleriesDimas Eko PrasetyoNo ratings yet

- Heat ExchangersDocument65 pagesHeat ExchangersDionie Wilson Diestro100% (2)

- Capstone Report-FinalDocument91 pagesCapstone Report-FinalBurak GülenNo ratings yet

- Pressure Safety Relief ValveDocument4 pagesPressure Safety Relief ValveGaurav ChovatiyaNo ratings yet

- Atlas Copco Compressed Air Dryers: Refrigerant Dryer F 25-335Document2 pagesAtlas Copco Compressed Air Dryers: Refrigerant Dryer F 25-335farhan adityaNo ratings yet

- Flash Steam Important ArticleDocument14 pagesFlash Steam Important ArticleAhmad Riaz KhanNo ratings yet

- Manual IG5Document36 pagesManual IG5fariboy123No ratings yet

- OMV Kadanwari Plant Gas ProcessingDocument62 pagesOMV Kadanwari Plant Gas ProcessingSyed Haider Abbas Bukhari100% (1)

- Basic Civil and Mechanical Engineering UNIT V Presentation PDFDocument70 pagesBasic Civil and Mechanical Engineering UNIT V Presentation PDFA.R. Pradeep KumarNo ratings yet

- Econoclave Integration FeaturesDocument11 pagesEconoclave Integration FeaturesLuis ArciaNo ratings yet

- Hoja de Datos API-674Document5 pagesHoja de Datos API-674texwan_No ratings yet

- Cooling Circuit With TowerDocument3 pagesCooling Circuit With TowermalarmanicNo ratings yet

- K JetpressuretestsDocument7 pagesK Jetpressuretestshowm782No ratings yet

- Amendment No. 2 February 2021 To Is 11329: 2018 Finned Type Heat Exchanger For Room Air ConditionerDocument8 pagesAmendment No. 2 February 2021 To Is 11329: 2018 Finned Type Heat Exchanger For Room Air ConditionerAMIT VERMANo ratings yet

- Supercritical Fluids ExtractionDocument20 pagesSupercritical Fluids ExtractionSriram HarihararamanNo ratings yet