Professional Documents

Culture Documents

2,3 Point Drill Machine

Uploaded by

Venkatesh Venkat0 ratings0% found this document useful (0 votes)

78 views2 pagesOriginal Title

2,3 POINT DRILL MACHINE.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

78 views2 pages2,3 Point Drill Machine

Uploaded by

Venkatesh VenkatCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

DESIGN AND FABRICATION OF AUTOMATIC TWO,

THREE POINT DRILLING MACHINE

SYNOPSIS

ABSTRACT:

In this world everyone is busy in today life. Everyone is looking automation on them

work because which is reduce the work with less human effort. Our project is also reducing

work in drilling process. An ordinary drilling machine makes only one drilling process in a

time. We waiting for make drilling to another work piece so this system is waste of time.

Hence our project is to implement and makes more than one drilling process in a single time.

So more work can be able to do in same time by using single motor and also we are using

timer sensor for reduce delay and lag time it can be easily controlled machine ideal time also

so we can increase the production quantity.

INTROUCTION:

Any industry’s has its own desire to maintain their ability to provide safe and secure

drilling of their customer’s hazardous materials. Addressing these challenges is an important

task and the efficient delivery of their cargo, play a vital role in the economy of the country.

This system provides the safety and accurately, sensing the plates the automatic drilling

machine comes to the target position through the automatic lift system. The drilling machine

drills the particular position and moving up direction then, the plate will rotate for next

position. The drilling machine drills the next position also like this the machine will drills the

number of plates and different positions also.

OBJECTIVE:

A drilling machine, called a drill press, is used to cut holes into or through metal,

wood, or other materials.

Never make any adjustments while the machine is operating.

Drilling machines may be used to perform other operations.

METHODOLOGY:

Drilling Machine is very simple machine. Job or work piece is fixed on work table.

Tool rotating at high speed, is fed into work piece for operation. It consists of drill machine

which is connected to DC motor, drill machine can be moved up and down automatically.

This system provides the safety and accurately, sensing the indexing plates the automatic

drilling machine comes to the target position through the automatic lift system. The drilling

machine drills the particular position and moving up direction then, the indexing plate will

rotate for next position. The drilling machine drills the next position also like this the

machine will drills the number of plates and different positions also. They can perform

countersinking, boring, counter boring, spot facing, reaming, and tapping. Drill press

operators must know how to set up the work, set speed and feed, and provide for coolant to

get an acceptable finished product.

ADVANTAGES:

To achieve mass production.

To reduce the work load.

To reduce the production time.

To achieve good product quality.

Less Maintenance.

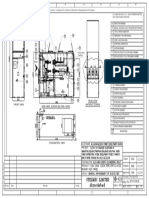

DIAGRAM:

SIGNATURE OF THE GUIDE SIGNATURE OF THE HOD

You might also like

- Universal 3 Motor Drilling MachineDocument6 pagesUniversal 3 Motor Drilling MachineMectrosoft Creative technologyNo ratings yet

- Fabrication of Automatic 2 3 Point Drill MachineDocument3 pagesFabrication of Automatic 2 3 Point Drill MachineNagesh NNo ratings yet

- Mini Drill Press MachineDocument13 pagesMini Drill Press MachineTabish Samar100% (5)

- 3 Directional Flexible Drilling MachineDocument20 pages3 Directional Flexible Drilling Machinedijo krishnanNo ratings yet

- ProjectDocument12 pagesProjectAndrewsNo ratings yet

- Presentation 4Document21 pagesPresentation 4Satish ChavanNo ratings yet

- Auto Feed Drill Machine......................Document47 pagesAuto Feed Drill Machine......................vidyadhar GNo ratings yet

- Report - MillingDocument8 pagesReport - MillingMaarij Anjum50% (2)

- Safety For Motorised Sheet Forming 2018Document3 pagesSafety For Motorised Sheet Forming 2018Chockalingam AthilingamNo ratings yet

- Fabrication of Pneumatic Slotting MachineDocument3 pagesFabrication of Pneumatic Slotting MachineUNITED CADDNo ratings yet

- CNCLATHEDocument13 pagesCNCLATHEMuhd Akmal0% (1)

- Automation in BurnishingDocument3 pagesAutomation in BurnishingdizzilionNo ratings yet

- Mini Milling Machine 7000Document5 pagesMini Milling Machine 7000ஆனந்த் துரைNo ratings yet

- Multi Spindle Drilling Machine Project File - CompressDocument28 pagesMulti Spindle Drilling Machine Project File - CompressSidhesh KalangutkarNo ratings yet

- Note CNC Lathe MachineDocument19 pagesNote CNC Lathe MachineSyafi NafisNo ratings yet

- Saurav S Shrivastav (ME5I04) A Dual Side Shaping Machine For Industrial ApplicationsDocument10 pagesSaurav S Shrivastav (ME5I04) A Dual Side Shaping Machine For Industrial ApplicationsRajratna SonkambleNo ratings yet

- Mqa CepDocument8 pagesMqa Cepfaryad artist100% (1)

- Indexing Drill JigDocument7 pagesIndexing Drill JignkpatilNo ratings yet

- 360 Degree Flexible Drilling MachineDocument7 pages360 Degree Flexible Drilling MachineDnedutcNo ratings yet

- Fine Boring & Jig BoringDocument12 pagesFine Boring & Jig Boringshiva100% (1)

- Mini Milling MachineDocument4 pagesMini Milling Machinekrisbhaskar22No ratings yet

- Spray Painting Robot - Stage1 - ReportDocument71 pagesSpray Painting Robot - Stage1 - ReportwasundesagarNo ratings yet

- SolidCAM 2013 Solid Probe User Guide - WebDocument80 pagesSolidCAM 2013 Solid Probe User Guide - WebTanNguyễnNo ratings yet

- 2.auto Indexing Drilling MachineDocument7 pages2.auto Indexing Drilling Machinesasitharan33No ratings yet

- Design & Fabrication of 360 Flexible DrillingDocument11 pagesDesign & Fabrication of 360 Flexible Drillingjatinshukla431No ratings yet

- Quad Processing MachineDocument6 pagesQuad Processing MachineSulfikkar100% (1)

- Methodology of Special Purpose Spot Facing MachineDocument5 pagesMethodology of Special Purpose Spot Facing MachineInternational Journal of computational Engineering research (IJCER)No ratings yet

- Study of Operational Concepts Of: Conventional and CNC Machines - Lathe & MillingDocument38 pagesStudy of Operational Concepts Of: Conventional and CNC Machines - Lathe & MillingUpender DhullNo ratings yet

- B.TECH. (5 Semester) Production and Industrial Engineering Pi-319 Vocational Training ReportDocument10 pagesB.TECH. (5 Semester) Production and Industrial Engineering Pi-319 Vocational Training ReportPraveen UpadhyayNo ratings yet

- Vertical LatheDocument4 pagesVertical LathevasanthavananNo ratings yet

- Automatic Pipe Cutting MachineDocument7 pagesAutomatic Pipe Cutting MachineMectrosoft Creative technologyNo ratings yet

- "To Dsign and Fabricate 360 Flexible Drilling Machine": Class Room Notes WarmDocument3 pages"To Dsign and Fabricate 360 Flexible Drilling Machine": Class Room Notes Warmnikhil mahaleNo ratings yet

- Study of Engine Overhaul Shop at PIA: Group ADocument29 pagesStudy of Engine Overhaul Shop at PIA: Group Afarkhanda rasheedNo ratings yet

- PD ReportDocument6 pagesPD Reportbitish commectNo ratings yet

- Project Assigmnet 1Document7 pagesProject Assigmnet 1Jaja MangzNo ratings yet

- Fabrication of 3 in 1 Multi Purpose MachineDocument2 pagesFabrication of 3 in 1 Multi Purpose MachineUNITED CADDNo ratings yet

- Satnam Machine Tools OkDocument17 pagesSatnam Machine Tools OkRupinder SinghNo ratings yet

- Sloting MachineDocument5 pagesSloting MachinePatel NikhilNo ratings yet

- Design and Fabrication of Leaf JigDocument9 pagesDesign and Fabrication of Leaf JigAnonymous Clyy9NNo ratings yet

- Manufacturing Secondary Machining Processes DRILLING: This Process Uses A Drill Bit To Cut Into Material As This Works Its Way Into The Material byDocument4 pagesManufacturing Secondary Machining Processes DRILLING: This Process Uses A Drill Bit To Cut Into Material As This Works Its Way Into The Material byIsaiahNo ratings yet

- Final 2Document22 pagesFinal 2prasad moreNo ratings yet

- What Is Lathe Machine - Main Parts, Operations and Working - Mechanical Booster - pdf1Document14 pagesWhat Is Lathe Machine - Main Parts, Operations and Working - Mechanical Booster - pdf1Sk Sajedul100% (1)

- Lab IFDDocument10 pagesLab IFDHashir JAVEDNo ratings yet

- Drilling and Reaming Abstract and Sketch 2012Document4 pagesDrilling and Reaming Abstract and Sketch 2012Chockalingam AthilingamNo ratings yet

- Drilling MachineDocument37 pagesDrilling MachineRavichandran G100% (4)

- Automated Machine ToolsDocument29 pagesAutomated Machine ToolsSyafawati OsmanNo ratings yet

- Xy CoordinatorDocument33 pagesXy Coordinatorsuraj dhulannavarNo ratings yet

- Internship Report EditedDocument28 pagesInternship Report EditedRohanRayNo ratings yet

- Surface GrindingDocument14 pagesSurface GrindingariefNo ratings yet

- Automatic Pneumatic HammerDocument3 pagesAutomatic Pneumatic HammerIyappan40% (5)

- Literature ReviewsDocument7 pagesLiterature ReviewsEngineers Gallery100% (2)

- Multi Purpose MachineDocument14 pagesMulti Purpose MachineKIRSHANT TomerNo ratings yet

- Maintenance Group AssignmentDocument20 pagesMaintenance Group Assignmentdawit gashuNo ratings yet

- Drilling ReportDocument8 pagesDrilling ReportThe white lionNo ratings yet

- Automatic Bar Feeding Mechanism For Power Hacksaw Machine: Mr.N.A.Jadhav, Shubham Shinde, Pradip ThorwatDocument6 pagesAutomatic Bar Feeding Mechanism For Power Hacksaw Machine: Mr.N.A.Jadhav, Shubham Shinde, Pradip ThorwatAnonymous j0aO95fgNo ratings yet

- Automatic Hammering MachineDocument16 pagesAutomatic Hammering MachineErole Technologies Pvt ltd Homemade EngineerNo ratings yet

- ReportDocument44 pagesReportAnindhya VermaNo ratings yet

- Multipurpose Agricultural EquipmentDocument8 pagesMultipurpose Agricultural EquipmentManiranjan KumarNo ratings yet

- Automatic Speed Breaker On Time Demand Using Embedded SystemsDocument4 pagesAutomatic Speed Breaker On Time Demand Using Embedded SystemsMotupatulu RamireddyNo ratings yet

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- 1.manufaturing Technology Lab IIDocument32 pages1.manufaturing Technology Lab IIVenkatesh VenkatNo ratings yet

- 1.manufaturing Technology Lab IIDocument32 pages1.manufaturing Technology Lab IIVenkatesh VenkatNo ratings yet

- 5124-Saraswathi Velu College of Engineering: Time-Table (Even Semester - 2015)Document8 pages5124-Saraswathi Velu College of Engineering: Time-Table (Even Semester - 2015)Venkatesh VenkatNo ratings yet

- Engineering MechanicsDocument37 pagesEngineering Mechanicser_paramjeetgillNo ratings yet

- Manufacturing Technology I 2 MarksDocument69 pagesManufacturing Technology I 2 MarksVenkatesh VenkatNo ratings yet

- Job Reference Ace Model Cv-101wh Di Gate Valves. Resilient Seated. Flange EndsDocument1 pageJob Reference Ace Model Cv-101wh Di Gate Valves. Resilient Seated. Flange EndsSatish Kumar MauryaNo ratings yet

- Coulson & Richardson's Chemical Engineering. Vol. 6, Chemical Engineering Design, 4th Ed-219-223 (1) - 3Document1 pageCoulson & Richardson's Chemical Engineering. Vol. 6, Chemical Engineering Design, 4th Ed-219-223 (1) - 3yeri abatamanNo ratings yet

- MDSP 01Document4 pagesMDSP 01justine sebastianNo ratings yet

- Parts Manual, Chromlite PDFDocument33 pagesParts Manual, Chromlite PDFAgus SantosaNo ratings yet

- Front View Rear View (Without Cover)Document1 pageFront View Rear View (Without Cover)ashraful tanvirNo ratings yet

- Performance Test of Series Centrifugal Pumps With Same CharacteristicsDocument7 pagesPerformance Test of Series Centrifugal Pumps With Same CharacteristicsPrecious Gallardo DerainNo ratings yet

- General Structural NotesDocument5 pagesGeneral Structural NotesreinerNo ratings yet

- Tractor Design & Testing - Lesson 12. Introduction and Selection of Different Components For Steering SystemsDocument7 pagesTractor Design & Testing - Lesson 12. Introduction and Selection of Different Components For Steering SystemsCaio GiarettaNo ratings yet

- CT 126152Document33 pagesCT 126152ZoyasBatalgaatOrchuulgaNo ratings yet

- 811.08 11229979 99999999 05702516 Cylinder HeadDocument10 pages811.08 11229979 99999999 05702516 Cylinder Headeshopmanual EnamNo ratings yet

- ESP3 Vertical Immersion Sump PumpDocument8 pagesESP3 Vertical Immersion Sump PumpAlexander RivillasNo ratings yet

- Fabtech Projects & Engineers LTDDocument17 pagesFabtech Projects & Engineers LTDsaurabhNo ratings yet

- Structural Design Data and SpecificationsDocument6 pagesStructural Design Data and SpecificationsRoland CepedaNo ratings yet

- SM Se 50 ElaDocument2 pagesSM Se 50 ElaKishore GujjarNo ratings yet

- Problem Set MD Day 6Document5 pagesProblem Set MD Day 6WIIGEENNo ratings yet

- Product CatalogDocument40 pagesProduct CatalogAlex Sandro Borges PereiraNo ratings yet

- Operation and Maintenance Manual: COD.: MUM0129 REV. 01Document28 pagesOperation and Maintenance Manual: COD.: MUM0129 REV. 01Laura Camila ManriqueNo ratings yet

- DiagramaDocument1 pageDiagramaCristian CahuatijoNo ratings yet

- Ningbo Hella 2015Document15 pagesNingbo Hella 2015cris.prolineNo ratings yet

- Welcome: A) Types of Layout B) Classification of Industrial Machines and EquipmentDocument23 pagesWelcome: A) Types of Layout B) Classification of Industrial Machines and EquipmentBaldev KumarNo ratings yet

- Subject: Renovation Works at Prayer Room of The Accord Home Owners AssociationDocument2 pagesSubject: Renovation Works at Prayer Room of The Accord Home Owners Associationrumnaz khanNo ratings yet

- JCB JS175W Service Manual PDFDocument270 pagesJCB JS175W Service Manual PDFRicardo Vilca100% (9)

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- Separator Dynamic SealDocument4 pagesSeparator Dynamic SealDilnesa EjiguNo ratings yet

- Prak T 67 Alignment SheavesDocument36 pagesPrak T 67 Alignment SheavesEko Setiawan1PPDNo ratings yet

- Literature Review On Coconut Peeling MachineDocument8 pagesLiterature Review On Coconut Peeling MachineIJRASETPublications100% (1)

- MMPL-PSA-02-Casting Surface Defect Acceptance Standard - Brake - DrumsDocument1 pageMMPL-PSA-02-Casting Surface Defect Acceptance Standard - Brake - DrumsVishal MaliNo ratings yet

- PumpsDocument26 pagesPumpsEyad MasoudNo ratings yet

- Miyano Evolution Line: CNC Turning Center With 2 Spindles, 2 Turrets and 1 Y-Axis SlideDocument8 pagesMiyano Evolution Line: CNC Turning Center With 2 Spindles, 2 Turrets and 1 Y-Axis SlidealdiNo ratings yet

- 1200KV LINE & Substation Materials: A Presentation by Supreme & Co PVT LTDDocument26 pages1200KV LINE & Substation Materials: A Presentation by Supreme & Co PVT LTDraghavendran raghuNo ratings yet