Professional Documents

Culture Documents

Performance Test of Series Centrifugal Pumps With Same Characteristics

Uploaded by

Precious Gallardo DerainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Test of Series Centrifugal Pumps With Same Characteristics

Uploaded by

Precious Gallardo DerainCopyright:

Available Formats

FEU INSTITUTE OF TECHNOLOGY

DEPARTMENT OF MECHANICAL ENGINEERING

Mechanical Engineering Laboratory Manual

Data Sheet

Name: Angeles, Carl Jeff Andrew

Co, Lorenzo Gerald V.

Derain, Precious

Ilao, John Marc

Tee, Joshua Anthony Experiment No.: 2

Group No.: 5 Date Performed: 10/13/21

Course/ Section: ME Lab 2 (TK41)

Performance Test of Series Centrifugal Pumps with same characteristics:

A. Data:

Pump-1 Speed, n (rev/min): 3000

Pump-2 Speed, n (rev/min): Equal to max. speed of pump 1

z1 = 0mm

z2 = 500mm

Pipe Diameter (d) = ¾”

VR-2 Single Pump Series Pump

position (Pump-1, (AB-1)) (Pump-1(AB-1) and Pump-2 (AB-2 )

P1 P2 T Q Ht Ph Pm Q Ht Ph Pm

(barG) (barG (N.m) (L/hr) (m) (W) (W) (m3/s) (m) (W) (W) Ƞseries

)

Fully opened

(Position 1)

0.75 1.24 1.13 380 5.4949 56.899 356.884 1.056 x 10− 3 10.989 113.799 713.769 15.94%

bars 6 0 7 9 8 4 8

Position 2 0.75 1.25 1.12 300 5.5968 45.753 351.858 8.33 x 10− 4 11.193 91.5076 703.716 13%

0 0 8 4 6 8

Position 3 0.8 1.26 1.11 275 5.1891 38.885 349.345 7.64 x 10 −4 10.378 77.7716 698.690 11.13%

2 0 8 1 2 2

Position 4 0.8 1.5 1.03 200 7.6356 41.614 325.154 5.56 x 10− 4 15.271 83.228 650.309 12.80%

5 0 0 8 2 6

EXPERIMENT 2: Series Coupling of two Pumps with the same characteristics

Fully closed 0.05 2.12 0.63 0 21.600 0 197.920 0 43.201 0 395.840 0%

(Position 5)

0 9 3 8 6

Note: Pump – 2 (AB-2) characteristics is equal to Pump -1(AB-1) characteristics at maximum speed.

EXPERIMENT 2: Series Coupling of two Pumps with the same characteristics

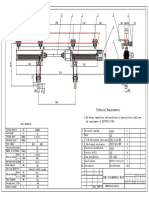

Plot the total head and flow curve of the single pump; ( use the pump curve generated on the PSIM

2)

Plot the pump curve vs. system curve of the series pump; ( use the graph generated on the PSIM 2)

EXPERIMENT 2: Series Coupling of two Pumps with the same characteristics

B. Sample Computation

Single Pump @ Position 1:

100 kpa 100 kpa

P1=0.75 bars ( )= 75 Kpa P2=1.24 bars ( )= 124 Kpa

1 ¯¿ ¿ 1 ¯¿ ¿

liters

T=1.136 N-m, Q=3800

ℎr

Solving for Ht, Pm, and Ph.

(124 − 75) Kpa

Ht= (0.5m-0m)+ KN = 5.4949 meters

9.81 3

m

9.81 KN 3800liters 1 m3 1 ℎr

Ph= ( 3 )( x x )(5.49490316 m) = 56.8997 W

m ℎr 1000liters 3600 seconds

3000rev 1 minute

Pm= (1.136 N-m)(2π x x ) = 356.8849 W

minute 60 seconds

For Series pump:

(124 − 75) Kpa

¿

Ht= 2x((0.5m-0m) + KN = 10.9898 meters

9.81 3

m

9.81 KN 3800liters 1 m3 1 ℎr

Ph= (2) ( 3 )( x x )(5.49490316 m) = 113.7994 W

m ℎr 1000liters 3600 seconds

3000rev 1 minute

Pm= (2) (1.136 N-m) (2π x x ) = 713.7698 W

minute 60 seconds

Pm series= 356.8849 W + 713.7698 W = 1070.6547 W

Ph series = 56.8997 W + 113.7994 W = 170.6691 W

170.6691W

Ƞ= 1070.6547W x 100% =15.94%

EXPERIMENT 2: Series Coupling of two Pumps with the same characteristics

C. Findings/ Analysis

Identify the overall pump power of the series pump system.

The overall power of the series pump based on the results/output from PSIM id at

0.1894 KW.

Identify the operating point of the series pump system.

The operating point of the series pump system is at 150 (liter/hr) units on the x-axis

direction and about 7 (meters) units on the y-axis direction. To simplify it is

approximately at the point (150, 7).

Discuss the pump summary data result.

For the pump summary data results given by the simulator, we can see that our

arrangement showed similar results for both pump 1 and pump 2. For the volume flow

rate it is at 21.57 m^3/hr, 5.98 kg/sec for the mass flow, 100% in speed. But for the

values for the NPSHR for the two pumps are different for pump 1 it is at 17.03 and for

pump 2 it is at 19.90 m. This is probably because for the second pump we need to

consider the first one.

Discuss the pressure characteristic of the series pump system. (Evaluate the pressure

change of all the parts; pipes and junction).

For the pressure characteristics of the pipes in a series pup system, based on the

output given we can see that the pressure change in the pipes gradually decrease from

the first pipe from the reservoir to the last pipe at the P2 discharge. After that we can see

that from the proceeding pipes little to no change in pressure. For the junctions the only

significant change in pressure we can notice is from the pressure change as the fluid

passes through the pumps, wherein we can see that pressure increases as fluid passes

through each pipe at about 0.3 bars in increase for each pump.

D. Conclusion

Draw a conclusion from the simulation test run.

For this experiment where it requires two similar centrifugal pumps in series

connection it is evident that using two pumps with same speed provides an equal volume

EXPERIMENT 2: Series Coupling of two Pumps with the same characteristics

and mass flow rate for both pumps at the discharge. On the other hand, the results shows that

total power have double considering that the efficiency of both pumps is the same. Since the

power has doubled, the total head also doubled with respect for either pump. Therefore, it is

crucial to consider the head and flow in designing a pipe system in order to determine the

power required to deliver the fluid at the required maximum height for the plumbing system.

E. Supplemental Questions:

1) What is pump cavitations?

-Cavitation occurs when the liquid in a pump turns to a vapor at low pressure. It occurs because

there is not enough pressure at the suction end of the pump, or insufficient Net Positive Suction Head

available (NPSHa). When cavitation takes place, air bubbles are created at low pressure.

2) What are the causes of pump cavitations?

-Clogged filters.

-Pipe blockage on the suction side.

-Poor piping design.

-Pump running too far right on the pump curve.

-Conditions not meeting NPSH (net positive suction head) requirements.

3) What is the purpose of connecting centrifugal pump in series?

-Putting your centrifugal pumps in series, or connected along a single line, will let you add the head

from each together and meet your high head, low flow system requirements. This is because the fluid

pressure increases as the continuous flow passes through each pump, much like how a multi-stage pump

works.

4) When the pump connection is in series, what is the effect of the first pump to the second pump?

-When two centrifugal pumps (I and II) are operating in series, the head (HI+II) is the sum of the

individual pumps' heads and the flow rate remains the same.

5) Describe the pump performance curve of series pump.

-As the volumetric flow rate increases, the head rise decreases.

Noted by:

Engr. Tony Rey Escalona

EXPERIMENT 2: Series Coupling of two Pumps with the same characteristics

Instructor

EXPERIMENT 2: Series Coupling of two Pumps with the same characteristics

You might also like

- Mechanical Engineering Lab Manual Series Pump ExperimentDocument7 pagesMechanical Engineering Lab Manual Series Pump ExperimentPrecious Gallardo DerainNo ratings yet

- PeltonDocument10 pagesPeltonNazatul Zuhanis100% (1)

- A. The Following Table Contains Figures OnDocument48 pagesA. The Following Table Contains Figures OnAliNo ratings yet

- Mka-03 Pelton and Francis TurbinesDocument11 pagesMka-03 Pelton and Francis TurbineshasshosNo ratings yet

- Performance Test of Parallel Centrifugal Pump With Same CharacteristicDocument6 pagesPerformance Test of Parallel Centrifugal Pump With Same CharacteristicPrecious Gallardo DerainNo ratings yet

- Pelton Wheel Lab ReportDocument10 pagesPelton Wheel Lab ReportTalhaNo ratings yet

- Wind turbine performance testDocument10 pagesWind turbine performance testthiha soe tunNo ratings yet

- Centrifugal Pump2Document15 pagesCentrifugal Pump2limakupang_matNo ratings yet

- Exp 2 ME LAB 3Document14 pagesExp 2 ME LAB 3q234asdfasdfNo ratings yet

- Simedru - Adrian.acme 2016.Document12 pagesSimedru - Adrian.acme 2016.Simedru Adrian IonNo ratings yet

- Solve Problem of Hydroelectric Power PlantDocument17 pagesSolve Problem of Hydroelectric Power PlantAnonymous 1VhXp188% (26)

- Report 3a Pelton Turbine - HydraulicDocument13 pagesReport 3a Pelton Turbine - HydraulicAin SherinNo ratings yet

- Mathcad - 2Document4 pagesMathcad - 2Desejo SozinandoNo ratings yet

- A2 Logarthmic - DecrementDocument8 pagesA2 Logarthmic - DecrementAkash BargeNo ratings yet

- Powering CalculationDocument11 pagesPowering CalculationIbrahim SameirNo ratings yet

- MELAB3 Experiment 1Document19 pagesMELAB3 Experiment 1Russelle GoNo ratings yet

- SOM Lab EXP6Document7 pagesSOM Lab EXP6Amisha SharonNo ratings yet

- Section 3A - Dynamic StabilityDocument8 pagesSection 3A - Dynamic StabilityAhmad YasserNo ratings yet

- Assignment FluidDocument11 pagesAssignment Fluidadam ishakNo ratings yet

- Mechanical Vibrations Lab. (620415) : Forced Vibration With Negligible DampingDocument8 pagesMechanical Vibrations Lab. (620415) : Forced Vibration With Negligible DampingTamer JafarNo ratings yet

- Position: Experiment 4: Gear Pump Performance TestDocument10 pagesPosition: Experiment 4: Gear Pump Performance TestPrecious Gallardo DerainNo ratings yet

- Pelton & Francis TurbinesDocument37 pagesPelton & Francis TurbinesIkhwan Z.100% (11)

- Pelton Turbine: Experiment - 5Document8 pagesPelton Turbine: Experiment - 5gebremariam birkieNo ratings yet

- Groupwork #5 (Ee108l-A37)Document6 pagesGroupwork #5 (Ee108l-A37)Mark ValduezaNo ratings yet

- PlantasDocument2 pagesPlantasGeorge Daniel Alexsander Morales TorresNo ratings yet

- Hap Ehelp 007Document8 pagesHap Ehelp 007Haji AliNo ratings yet

- Group 4 - F5 pumps performanceDocument16 pagesGroup 4 - F5 pumps performanceParag SinghNo ratings yet

- Modelling and Investigations of Electrohydraulic Servo Valve With Piezo ElementDocument8 pagesModelling and Investigations of Electrohydraulic Servo Valve With Piezo Elementleena175No ratings yet

- Plate and Frame Filter Press AnalysisDocument10 pagesPlate and Frame Filter Press AnalysisDwizky WijayaNo ratings yet

- 1 Logarthmic - DecrementDocument5 pages1 Logarthmic - DecrementAnup PatilNo ratings yet

- Turbine SeatworkDocument14 pagesTurbine SeatworkChoie kun100% (3)

- Pelton Wheel (FINAL) PDFDocument9 pagesPelton Wheel (FINAL) PDFSurendren SurenkkNo ratings yet

- SOM Lab EXP7Document8 pagesSOM Lab EXP7Amisha SharonNo ratings yet

- Experiment No. 1 Centrifugal PumpDocument30 pagesExperiment No. 1 Centrifugal PumpkeaneNo ratings yet

- Mehtodology:: Weight ParametersDocument16 pagesMehtodology:: Weight ParametersWael MotranNo ratings yet

- An Serv 002 PDFDocument20 pagesAn Serv 002 PDFMario TapiaNo ratings yet

- Hydraulics and Water Resources (CEE 340) (Topic 2) : TurbineDocument12 pagesHydraulics and Water Resources (CEE 340) (Topic 2) : TurbineRachel YarasavichNo ratings yet

- Problems 13 1 To 13 17Document39 pagesProblems 13 1 To 13 17Carlos Huete FelixNo ratings yet

- Report 4 Fluid Lab 22Document20 pagesReport 4 Fluid Lab 22Mariam DalloulNo ratings yet

- Coriolli's Component of Acceleration ApparatusDocument7 pagesCoriolli's Component of Acceleration Apparatustinkusk24No ratings yet

- Problems On Hydraulic Turbines (Ch-6)Document8 pagesProblems On Hydraulic Turbines (Ch-6)xan pitchuNo ratings yet

- Ch6 Settling Chamber 2005Document7 pagesCh6 Settling Chamber 2005MutiaKhairunnisaNo ratings yet

- Exp 2 InstroDocument16 pagesExp 2 InstroAbed Alrahman QaddourNo ratings yet

- Performance Test of Pelton TurbineDocument6 pagesPerformance Test of Pelton TurbineMd. Tariqul Islam MunnaNo ratings yet

- Wave Energy Converter ControlDocument97 pagesWave Energy Converter ControlKenneth TanNo ratings yet

- Chap 1 Solutions PDFDocument18 pagesChap 1 Solutions PDFSiva KumarNo ratings yet

- Final GP2 Process Plantfor Aromatic ExtractionDocument81 pagesFinal GP2 Process Plantfor Aromatic ExtractionLuxainne Tremont EchegarayNo ratings yet

- Centrifugal PumpDocument4 pagesCentrifugal PumpHamza SohailNo ratings yet

- Reaction TurbineDocument10 pagesReaction TurbineGokulAgNo ratings yet

- RDCHB2 Tutorial Equipment SizingDocument12 pagesRDCHB2 Tutorial Equipment SizingThabo ThaboNo ratings yet

- Centrifugal Pump Power MeasurementsDocument8 pagesCentrifugal Pump Power MeasurementsMahmoudSehweilNo ratings yet

- BMW M6 Torque SpecsDocument422 pagesBMW M6 Torque Specsstrobachyzoo100% (1)

- Prop Design ExampleDocument7 pagesProp Design Exampleancamardelli100% (1)

- 090443P - Synchronous Generator Transient AnalysisDocument16 pages090443P - Synchronous Generator Transient AnalysisManoj JayaruwanNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsFrom EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNo ratings yet

- Engr Math MCQ - BesavillaDocument3 pagesEngr Math MCQ - BesavillaPrecious Gallardo DerainNo ratings yet

- Math Problem Set 1Document37 pagesMath Problem Set 1Precious Gallardo DerainNo ratings yet

- Instant Center Velocity AnalysisDocument14 pagesInstant Center Velocity AnalysisSuriyagowthamNo ratings yet

- Math Problem Set 1Document37 pagesMath Problem Set 1Precious Gallardo DerainNo ratings yet

- Buma 16 ChannelDocument2 pagesBuma 16 ChannelPrecious Gallardo DerainNo ratings yet

- CCT V Quotation: Attn: Ms. Mary Ann PascuaDocument2 pagesCCT V Quotation: Attn: Ms. Mary Ann PascuaPrecious Gallardo DerainNo ratings yet

- Modifiers of Human ActsDocument2 pagesModifiers of Human ActsJe Rah MaligdongNo ratings yet

- Buma 16 ChannelDocument2 pagesBuma 16 ChannelPrecious Gallardo DerainNo ratings yet

- Reek Philosopher Plato and Aristotle: "An Embodiment of Reason", Whether in The Individual or The Community'Document2 pagesReek Philosopher Plato and Aristotle: "An Embodiment of Reason", Whether in The Individual or The Community'Precious Gallardo DerainNo ratings yet

- Performance Test of Series Centrifugal Pumps With Same CharacteristicsDocument7 pagesPerformance Test of Series Centrifugal Pumps With Same CharacteristicsPrecious Gallardo DerainNo ratings yet

- Performance Test of Parallel Centrifugal Pump With Same CharacteristicDocument14 pagesPerformance Test of Parallel Centrifugal Pump With Same CharacteristicPrecious Gallardo DerainNo ratings yet

- Performance Test of Parallel Centrifugal Pump With Same CharacteristicDocument14 pagesPerformance Test of Parallel Centrifugal Pump With Same CharacteristicPrecious Gallardo DerainNo ratings yet

- Performance Test of Parallel Centrifugal Pump With Same CharacteristicDocument14 pagesPerformance Test of Parallel Centrifugal Pump With Same CharacteristicPrecious Gallardo DerainNo ratings yet

- Refrigeration Engineering: MerefengDocument62 pagesRefrigeration Engineering: MerefengPrecious Gallardo DerainNo ratings yet

- Position: Experiment 4: Gear Pump Performance TestDocument10 pagesPosition: Experiment 4: Gear Pump Performance TestPrecious Gallardo DerainNo ratings yet

- ME Laboratory Report 4-Weight Volume Density and Specific-Gravity-Co Ilao Derain Pabularcon TeeDocument10 pagesME Laboratory Report 4-Weight Volume Density and Specific-Gravity-Co Ilao Derain Pabularcon TeePrecious Gallardo DerainNo ratings yet

- ME-Laboratory 2 Manual: Gear Pump Performance TestDocument18 pagesME-Laboratory 2 Manual: Gear Pump Performance TestPrecious Gallardo DerainNo ratings yet

- Refrigeration Engineering: MerefengDocument62 pagesRefrigeration Engineering: MerefengPrecious Gallardo DerainNo ratings yet

- IsotopesDocument35 pagesIsotopesAddisu Amare Zena 18BML0104No ratings yet

- Cebu Oxygen Acetylene Co., vs. Drilon, G.R. No. 82849, August 2, 1989Document6 pagesCebu Oxygen Acetylene Co., vs. Drilon, G.R. No. 82849, August 2, 1989JemNo ratings yet

- Live Sound 101: Choosing Speakers and Setting Up a Sound SystemDocument14 pagesLive Sound 101: Choosing Speakers and Setting Up a Sound Systemohundper100% (1)

- Moisture Control Guidance For Building Design, Construction and Maintenance (2013)Document144 pagesMoisture Control Guidance For Building Design, Construction and Maintenance (2013)Schreiber_Dieses100% (1)

- Decolonising The FutureDocument20 pagesDecolonising The Futurebybee7207No ratings yet

- Chapter 4 Earth WorkDocument39 pagesChapter 4 Earth WorkYitbarek BayieseNo ratings yet

- NTPC Limited: (A Government of India Enterprise)Document7 pagesNTPC Limited: (A Government of India Enterprise)Yogesh PandeyNo ratings yet

- 2X16-24 Monorail Hoist-04 - 2Document1 page2X16-24 Monorail Hoist-04 - 2RafifNo ratings yet

- Service Driven Logistics System - Basic Service CapabilityDocument12 pagesService Driven Logistics System - Basic Service CapabilityAnusha Sunkara80% (5)

- Local Govt & Public Corp CasesDocument4 pagesLocal Govt & Public Corp CasesAngel OlaNo ratings yet

- The 4 PsDocument7 pagesThe 4 PsJuan Camilo Giorgi MartinezNo ratings yet

- Internship Project Report on MathematicsDocument18 pagesInternship Project Report on MathematicsNancini AVNo ratings yet

- PE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Document6 pagesPE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Prince ImmanuelNo ratings yet

- S3 Unseen PracticeDocument7 pagesS3 Unseen PracticeTanush GoelNo ratings yet

- Collective Fleet Agreement TermsDocument25 pagesCollective Fleet Agreement TermskjdckncknsNo ratings yet

- Baja2018 Unisa Team3 Design ReportDocument23 pagesBaja2018 Unisa Team3 Design ReportDaniel MabengoNo ratings yet

- Robotic Surgery History and SystemsDocument28 pagesRobotic Surgery History and SystemsLidhi DileepNo ratings yet

- Ssnt Question BankDocument32 pagesSsnt Question Bankhowise9476No ratings yet

- Experienced Welder Seeks New OpportunityDocument2 pagesExperienced Welder Seeks New OpportunityLen HebronNo ratings yet

- ELEC 121 - Philippine Popular CultureDocument10 pagesELEC 121 - Philippine Popular CultureMARITONI MEDALLANo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Internship Projects: Rotor Shaft Analysis and DesignDocument19 pagesInternship Projects: Rotor Shaft Analysis and DesignSanjay IraniNo ratings yet

- RCT Methodology ChecklistDocument6 pagesRCT Methodology ChecklistSyahidatul Kautsar NajibNo ratings yet

- MR Khurram Chakwal 6kw Hybrid - 024627Document6 pagesMR Khurram Chakwal 6kw Hybrid - 024627Shahid HussainNo ratings yet

- Bomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceDocument16 pagesBomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceAnonymous Pb39klJNo ratings yet

- Subhra Ranjan IR Updated Notes @upscmaterials PDFDocument216 pagesSubhra Ranjan IR Updated Notes @upscmaterials PDFSachin SrivastavaNo ratings yet

- Joysticks For Hoist & Crane Control SystemsDocument5 pagesJoysticks For Hoist & Crane Control SystemsRunnTechNo ratings yet

- Elizabeth Line When Fully Open PDFDocument1 pageElizabeth Line When Fully Open PDFArmandoNo ratings yet

- Materials Storage and BuildingDocument3 pagesMaterials Storage and BuildingAmit GoyalNo ratings yet

- Designing An AirshipDocument100 pagesDesigning An AirshipFrik van der Merwe100% (2)