Professional Documents

Culture Documents

Method Statement for Pipeline Drying Operations

Uploaded by

Naveed Ahmed Get-InfoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement for Pipeline Drying Operations

Uploaded by

Naveed Ahmed Get-InfoCopyright:

Available Formats

(St) Prodi Unit Type Dev.

Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Method Statement for Drying Operations

IQ022-00-2001-SI-0029

00 Issued for Approval Engineering A. Tareq A. Al-Maliki 14/02/2018

Prepared Checked Approved Date

Rev. Description

(name & initials) (name & initials) (name & initials) DD/MM/YYYY

DOCUMENT REVISIONS

This document is the property of SICIM spa who will safeguard its rights according to the civil and penal provisions of the law.

DOCUMENT REVISION HISTORY SHEET

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 1 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Rev. REVISION DATE ISSUED UPDATE / AMENDMENT DETAILS

DESCRIPTION

00 Issued for Approval 14/02/2019 First issue

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 2 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Table of contents

1 Introduction..................................................................................................................................................... 4

1.1 Definitions/Abbreviations 4

1.2 Reference 4

1.3 Summary……………………………………………………………………………………………………………5

2 Scope of work 5

2.1 Mobilization of Personnel and Equipment 5

2.2 Rig-up of Equipment 6

2.3 Drying 6

2.5 Rig-down of equipment 7

2.5 Demobilization 7

3. Dryness Criteria 8

3.1. Initial drying with dry air……………………………………………………………………………………………..8

3.2. Final air drying with air dryer……………………………………………………………………………………...8

3.3. Soak test……………………………………………………………………………………………………………8

4. Appendix…………………………………………………………………………………………………………………..9

4.1. Execution Schedule………………………………………………………………………………………… ...9

4.2. Equipment Certificate…………………………………………………………………………………….…..10

4.3 Risk Assessment…………………………………………………………………………………………….16

4.4 Daily Report ……………………………………………………………………….……………………......22

4.5 soak test Report…………………………………………………………………………………………….23

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 3 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

1 Introduction

The purpose of this document is to establish a detailed method statement for drying operations that Dr.

Concrete Building Material (hereinafter referred to as Subcontractor) will carry out in accordance with Sicim’s

(hereinafter referred to as Contractor) project requirements and specifications.

1.1 Definitions/Abbreviations

Company ENI BV

Contractor Sicim Iraq

Subcontractor Dr. Concrete Building Material Co.

DGS Degassing Station

SOW Scope of Work

1.2 Reference

03526.PLI.MEC.SDS Hydrocarbon Pipelines Pre-Commissioning (Company specification)

IQ022-00-2001-SI-029-0 SOW for Trunk Lines TK-01, 02, 03 & 04 Drying Operation

1.3 Summary

The scope of work includes the application of super dry air blowing technique on the newly installed Multiphase

Interconnecting Trunk Lines (total of four lines: 20” x 2 nos., 26” x 2 nos.).

The Multiphase Trunk Lines interconnect the oil manifolds headers of nearest DGS’s. The DGS’s interested by

the works are:

- Hammar Mishrif New DGS (DGS North)

- Hammar existing DGS

- Zubair Mishrif existing DGS

- Zubair existing DGS

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 4 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

The Trunk Lines and DGS scheme is per following:

Figure 1: Overall Connection Scheme between the entire plants

Dr. Concrete Building Material as subcontractor scope of work do include the following:

- Mobilization of equipment and personnel

- Rig-up of equipment

- Drying operations

- Rig-down of equipment

- Demobilization of personnel and equipment

2 Scope of work

Drying operation for the Trunk line TK-01, Trunk lineTK-02, Trunk line TK-03, Trunk line TK04..

2.1 Mobilization of Personnel and Equipment

Subcontractor will mobilize all of equipment and personnel needed to work site, 48 hours prior to start of

activities. Please find be the list of personnel to be mobilized to site:

- 1 X Supervisor

- 2 X Operator

- 2 X Technician

- 3 X Driver

All of the communication with regards to the activities will be maintained with supervisor.

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 5 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

For the equipment list, below the list of major equipment list (equipment certification can be found in the

appendix)

- 2 X Diesel Operated Air Compressor (1000 CFM)

- 1 X Pneumatic Air Dryer

- Manifold, hoses fittings and Gauges (adequate quantity)

- 1 X Dew point meter

- 2 X Trailer

- 1 X Crane

- 1 X Pickup

- 1 X Light tower

- 1 X office Cabin and Toilet

2.2 Rig-up of Equipment

Equipment rig-up will commence after mobilization and offloading of all equipment at work site, below

equipment set-up diagram:

Please refer to appendix for equipment certificates, equipment certificates will include the pressure gauges and

hoses certificates as well.

For the receiver side, there are no connections are needed except the following:

- Pressure gauge

- Dew point measurement sampling connection

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 6 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

2.3 Drying

Once residual dewatering and swabbing operations have been completed and approved, drying operations will

be carried out. Each pipeline will be dried using dry air.

When the dew point of the air at the pipeline end is 5°C lower than ambient temperature and does not fluctuate

by more than 3 °C whilst replacing the content of the line by dry air, drying can be accepted.

Air introduced into the pipeline during dry air drying shall have a dew point of at least 15 °C below the final dew

point of the pipeline (i.e., 20 °C below the ambient temperature).

The pipeline dew point is to be monitored at both ends to ensure the required dew point is achieved throughout

the pipeline. For final acceptance, the specified dew point in the pipeline is to be maintained for a minimum

period of 48 hours (soak test). All opening during this period will remain closed.

Following the minimum 48 hours hold period and if the Contractor requirements are fulfilled, final acceptance

will be obtained through signing the Drying Report by Contractor to terminate the drying operation.

The pipeline shall then be pressurized using super dry air to 1.5 barg and maintained at this pressure until start

of commissioning.

Below the expected drying time for each pipeline:

Expected

Length

Support Type diameter Volume drying

meters

time (hrs)

Trunk Line TK-01 4760 26" 1,404 40

Trunk Line TK-02 11946 20" 2072 70

Trunk Line TK-03 7580 26" 2236 45

Trunk Line TK-04 11946 20" 2072 94

2.4 Rig-down of equipment

When drying operation is complete, shall be disconnect and remove the pipeline drying equipment and

cap all open pipe ends. Equipment typically must be disconnected from power sources, decoupled from

pressurized systems, disassembled and moved off the rig floor or even off location.

2.5 Demobilization

Demobilization shall start after completion the all activities. A letter shall be submitted to the contractor

on completion of activity for the approval .DCBM shall carefully manage demobilization plans. DCBM

will assign the skilled workforce for demobilization requisite plant, equipment and materials on

completion.

Demobilization Including the compressor, air dryer, truck, manpower, instrument, crane, Removal, and

site clean-up , monitoring caravan, WC and other facilities on the site.

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 7 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

3 Dryness Criteria

For natural gas pipelines, the generally accepted moisture limit is a dew point of –

4°F (-20°C). The sequence of air drying activities

Initial drying with dry air

Final drying with dry air

Soak test

3.1 Initial drying with dry air

Initial drying will be done with dry air compressor. The facilitating evaporation into the

dry air stream. The pipeline dries from the launch end and gradually progresses in a

front down the pipeline.

The executer must make sure pressure at receiver side is just above the atmospheric

pressure throughout the drying, by this lower the pressure more water vapour the air

can absorb and the quicker the pipeline will dry.

In addition to measuring the outlet dew point, the appearance of dust gives strong visual

indication that the line is beginning to dry.

3.2 Final drying with dry air

If further reductions in the dew point required, it can be achieved by simply continuing to blow air

through the line until the desired dew point is achieved.

3.3 Soak test

After reaching desired dew point, all the opening to the pipeline should be closed for minimum of

48 hours at a pressure of 0.5 bar above the ambient pressure at all point along the pipeline.

After 48 hours of soak test pipeline dew point shall be monitored at both ends to ensure the

required dew point is achieved throughout the pipeline. During starting and finishing time dew

point, ambient temperature and pipe temperature must be checked and recorded.

On acceptance, the pipeline drying campaign is complete. The pipeline shall then be nitrogen

purged and packed with nitrogen at pressure 2 bar. This positive pressure shall be maintained

until start of commissioning.

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 8 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

4 Execution Schedule

Air drying Instruments, materials and equipment’s required to undertake the test shall include oil- free

compressors with dryer, instrumentation recorders, all essential equipment.

Drying materials manifolds shall incorporate end enclosures, by-pass pipe work and valves for

Continuous drying activity.

All equipment’s shall be inspected to ensure that it meets all safety requirements. All calibration certificates of

pressure gauges, dew point meter shall be available at the point of use.

Below the expected drying time for each pipeline:

Appendix 01

Location Responsible Start date Complete date

Trunk Line TK-02 Adnan Abbas Oday 25/02/2019 03/03/2019

Trunk Line TK-04 Adnan Abbas Oday 04/03/2019 12/03/2019

Trunk LineTK-03 Adnan Abbas Oday 13/03/2019 20/03/2019

Trunk Line TK-01 Adnan Abbas Oday 21/03/2019 30/03/2019

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 9 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

3.1. Equipment Certificate

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 10 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

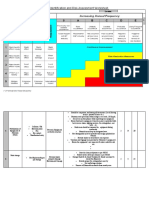

3.2. Risk Assessment

Project Name Zubair Oil Field Development Project Location:

Work Activity Preparation of Air Drying during Pre-commissioning Activity Date:

Proce

Severi Likelih Risk

No Job Steps Potential Hazards Harm Control Measures ty ood Level

dure

No.

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 12 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Project Name Zubair Oil Field Development Project Location:

Unauthorized work Obtain valid operation permit approved by commissioning/operation

Unskilled and untrained authorized personnel

personnel starting the job Allow only trained and qualified workers to assign jobs.

leading to incident / Operatives shall receive Commissioning/operation Safety Induction.

accident. Emergency Response Procedure shall be discussed with the crew.

Emergency situations Employees are not allowed to leave their job site without informing the

Asphyxiation hazards job supervisor.

High noise areas Equipment Explain the work sequence clearly by job supervisor.

Unauthorized tampering or damage Ensure all assign crew participated and attend group TBM.

Preparation triggering any field control

1. Personal Injury Always use mandatory PPE and Job specific PPE if required. 2 B 2B

works panels, devices, sensors Smoking is strictly prohibited in the work place use designated

and fire alarm system and smoking shelter.

removing of LOTO without Ear protection required on high noise areas exceeding 85 db noise

approval. level.

Failure to identify correct Never remove LOTO, touch or tamper any energized field control

isolations. panels, devices, sensors or triggering device for fire alarm system

Release of N2 gas, Parts of unless approved by commissioning authorized person.

system untested, over Barricade system to be leak tested and provide signage on work area

pressurise system.

DCBM shall describe the policies and practices for managing risk and a summary of the risk analysis results. Risk management shall be addressed in the PEP. The

preliminary shall summarize the key project risks. Key risks or “critical risks” are those estimated to have the most impact on cost and schedule and could include

project, technical, internal, external, and other sub-categories.

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 13 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Site

Mobilization,

line checking

and installation

Site speed limit of 20 KPH shall be observed at all times.

of barricade

Equipment Failure Ensure pre-use inspection of vehicle and equipment’s conducted prior

and signage,

Traffic Hazard to use.

Connection of Vehicular Accident Only authorized drivers shall be allowed to drive the vehicle. Site traffic

temporary hose Collision with vehicle,

Personal Injury regulation shall be adhered at all times.

2. equipment and personnel Verify system lines to be leak tested on P and ID drawings 2 C 2C

Damage to

Wrong system System line should be marked up for easy identification.

Property

identification Defective and home-made tool shall not be used on site.

Hand Injuries Wear proper PPE for the task

Slip and trips Ensure access and work area free from obstructions

Material Fall Vehicle shall be parked at dedicated parking area only.

Obstruction

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 14 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 15 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Should be obtain Permit and need to add all relevant information

(Drawings, Connection Joint, Mark up P&ID).

Tool box meeting for all personals involved in the activity should be

conducted, discussion include hazards and precaution for particular

activity.

Allowed only competent and qualified worker to do the activity.

Should be barricade the area properly and Provide signages atleast 5mtr

surrounded.

Notification Protocol shall be followed and confirmed prior to start flushing,

blowing.

Noise – Ear Impact, Should be wear proper PPE – Ear Plug, duct Mask, Face Shield etc…..

Should be maintain safe distance between equipments like Air

Flying Objects, Hit,

Compressor 3mtr – Manifold 3 Mtr – Pipe 3 Mtr approx.

Injury, Failure of

Personnal Should be Maintain Safe Distance at Air Blowing/Venting Area.

Piping, cause by

Injury Proper support at Blowing point to reduce thrust effect.

Air Drying using over pressure,

3 Property Proper communication between team members. 2 C 2C

Air Compressor Improper

Damaged Warning Signages and Information of the hazard to neighbor using

bolting/gasket at

megaphone and whistle.

Flange joint area Inspection of Equipments, Tools, Connection of hoses and Provide

Equipment Failure

inspection Sticker and Apporved TPI certification for Manifold, Guages

and Hoses.

Provide PSV to avoid over pressuring.

Shuold be provide whiplash arrestor for both end of the connected hoses.

Should be provide Shield or vent to prevent

All the temporary connectionn should be pressure rated and Inspected for

damage/defects prior to use.

Notify all personal working within the vicinity of air blowing.

Should be wear earplug when start the blowing out.

Double Check the each re bolting point.

Watch man to be organized for access control.

Proper Ergonomics.

Should be inspect the Equipment and Color Coded by competent Person.

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 16 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Site inductions for personnel.

Inadequate Access & Follow site Safety rules & regulation.

Maintain speed limits. Reverse with a banks man.

Egress

Ensure vehicles are serviced. Ensure loads are secure.

Insufficient turning

Heavy items to be lifted by two or more persons. Personnel to be trained in

circle.

‘Manual Handling.

Movement of

Personnel trained in the correct selection and use of hand tools.

vehicles in and out of Site Supervisor to check rig up and routing of hoses.

site Hoses to be rigged up away from access points and above head height

Manual handling of where possible.

heavy equipment Harness to be worn by personnel working at height1.8m

items. Suitable scaffolding/ladders to be provided.

Incorrect lifting of All hosing to be used is of suitable pressure rating and carries appropriate

equipment items. certification.

Inadequate pressure Supervisor and Client representative to check equipment rig up.

Assess work rating or is damaged. Check test certificates for all pipe work.

area Access Over pressurise or Personnal Check unit, sling and crane Lifting Certification.

and Weather rupture hosing. injury Property Attach guide rope during lift.

Rig up hosing onto Damage Do not lift over personnel or sensitive equipment. Use trained banks man

condition

wrong injection point Equipment during lifting operation. Slings to be attached by a qualified person.

4 Rig up and onto an adjacent Damage Plan and schedule vehicle movements. If required liase with local personnel. 2 C 2C

Equipment Environmental Valve checklist checked and signed by Authorize Person Double block and

system.

and Fall of unit from Effect bleeds where possible. Secondary vent paths identified and aligned.

Alignment of Personnel System walked and alignment checked by Authorized Person Pre ops

height o

system and Failure of slings or involved with checklist completed and signed. OPP connection as close as possible to

Isolation attachments operation. injection point.

System incorrectly Make sure all access ladders, steps and ramps are safe and secure.

Make sure edge protection and handrails are in place and secure where

isolated.

System internal required.

Immediately cease work in hazardous weather conditions such as:

valves closed.

o Thunderstorms and strong winds that may cause loss of

Public (pedestrians /

balance;

others) o Rain is causing a slippery work surface;

Hit by falling objects o Excessive glare is being emitted from work surfaces and/or

Slips, trips and falls

poor lighting affects visibility;

Lighting Remove any items that may obstruct the work activity; and

Eye injury Check for any items that may cause slips, trips and falls and remove or

secure them as required

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 17 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 18 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Wrong system Verify system and lines on approved P and ID

System line and equipment not included on the purging must be

identification

Damage to other isolated by valves or positive blinds and follow LOTO procedures

Ensure hose connection and fittings tight and secured with whiplash

equipment and pipes

Hose dislodge from arrestor

Check hose and fittings for any defects

connection

Ensure all pressure gauge and relief valves properly calibrated and

Rupture of hose

Over pressurization inspected.

Only authorized person to enter the test area.

resulting to rupture of

Always use mandatory PPE and Job specific PPE if required.

Opening of pipes and equipment’s Defective and home-made tool shall not be used on site.

Asphyxiation hazards from Close supervision and monitoring at all times

5 valve and Personal Injury

Nitrogen purged lines or Provide proper communication means . 3 C 3C

purging of Damage to

equipment Emergency Contact Numbers available on work area

nitrogen to gas Property

Unauthorized entry on leak Ear protection required on high noise areas exceeding 85 db noise

line test area level

Hand Injuries Ensure access and work area free from obstructions

Lack of supervision and Ensure all personnel attend work at height training.

monitoring Use full body harness above 1.8 meters of height.

Lack of communication Always hook above the shoulders.

Emergency situations 100% TIE-OFF at all times whenever required.

High noise areas All tools and materials should be tied and secured.

Slip and trips Ensure close supervision by supervisor

Fall from heights Work only in green tag scaffolding and approved steel structure

Falling objects platforms

Never work alone on elevated areas, maintain buddy-buddy system

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 19 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

Un necessary materials and scrap materials must be removed from

Hand injury Personal Injury elevated areas

Completion of Slip and trips Damage to Materials that could easily fall or slip on gratings to be place inside

6 work and house Falling objects Property secured containers. 2 B 2B

keeping Waste accumulation Wear proper PPE for the task given.

Environmental

Conduct housekeeping and proper material segregation.

effect Dispose waste on proper waste disposal area.

Prepared by: Subcontractor Name Position Signature

SICIM

Reviewed by: Name Position Signature

Department/SI

SICIM

Approved by: Name Position Signature

HSE Department

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 20 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

3.3. Daily report

PIPELINE DRYING REPORT

Test Package No.

Pipeline No.

Pipeline Size (inch)

Location

Ambient Dew Point at

S/N Time Remarks

Temp. °C Pipeline End °C

Remarks.

SUBCONTRACTOR CONTRACTOR COMPANY

NAME

SIGNATURE

DATE

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 22 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

ZUBAIR OIL FIELD DEVELOPMENT

PROJECT

SICIM CONTRACT ID:IQ022-2001-SI-029-0

Dr.Concrete Building Material

PIPELINE SWABBING AND DRYING RECORD

TEST PACK No TEST SECTION TEST SECTION

WALL

PIPE SIZE : THICKNESS :

PIG TYPES :

RECEIVING AVERAGE WEIGHT

DATE PIG TYPE LAUNCHING TIME DEW POINT REMARKS

TIME PRESSURE LAUNCHING TIME RECEIVING TIME

REMARKS : ACCEPTABLE □ NOT ACCEPTABLE □

DCBM SICIM Eni Iraq BV ZFOD

NAME

SIGNATURE

DATE

Annex-01 Pipeline Swabbing and drying Record

Annex - 02 Soak Test Record

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 24 of 25

(St) Prodi Unit Type Dev. Serial Rev

(2) IQ22 00 2001 SI 029 0

Contact N°:

IQ022-00-2001-SI-029-0

Document ID:

SICIM DOCUMENT

Method Statement for Drying Operations

TITLE:

IRAQ - ZUBAR OIL FIELD DEVELOPMENT PROJECT – MULTIPHASE PIPELINES BETWEEN DGS

ZUBAIR OIL FIELD DEVELOPMENT PROJECT

CONTRACT ID:IQ022-2001-SI-029-0

Dr.Concrete Building Material

Soak Test Record

Test Pack no.: Line No.:

Test Limit: From: To : Date :

From Chainage: To Chainage :

Section Length: Pipeline Section no.:

Diameter: Thickness:

Dew point Reading

Ambient temperature Remarks

Date Time Pipe temperature measured from

Launcher Receiver measured from

thermocouples.

Thermocouples.

TP(Launcher TP2(Receiver side) TP TP

side) 1 2

REMARKS : ACCEPTABLE □ NOT ACCEPTABLE □

Remarks :

DCBM SICIM Eni Iraq ZFOD

BV

Name

Signature

Date

METHOD STATEMENT FOR DRYING OPERATIONS Sheet 25 of 25

You might also like

- Insulation Method for Zubair Oil Field PipingDocument14 pagesInsulation Method for Zubair Oil Field PipingSaleem AkhtarNo ratings yet

- Work Procedure For Change Out Activity v-1002 ADocument11 pagesWork Procedure For Change Out Activity v-1002 AFaiz ZainudinNo ratings yet

- 7105 JHRA 008 12 Pneumatic Testing ActivitiesDocument7 pages7105 JHRA 008 12 Pneumatic Testing Activitiesarnel sungkipNo ratings yet

- Risk Assement: Welding & CuttingDocument3 pagesRisk Assement: Welding & CuttingAli Naveed FarookiNo ratings yet

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoNo ratings yet

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDocument3 pagesR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalNo ratings yet

- Jms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 ADocument14 pagesJms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 Aamir hakimNo ratings yet

- JSA-Replacement of GD, FD & MCP - Rev.00Document7 pagesJSA-Replacement of GD, FD & MCP - Rev.00Muhammad Umar GondalNo ratings yet

- Method Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteDocument10 pagesMethod Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteJethin SurendranNo ratings yet

- Engineering Standard for Refractory SystemsDocument25 pagesEngineering Standard for Refractory SystemsAkhil GeorgeNo ratings yet

- JOB SAFETY ANALYSIS FOR CONFINED SPACE CLEANINGDocument18 pagesJOB SAFETY ANALYSIS FOR CONFINED SPACE CLEANINGThái Đạo Phạm LêNo ratings yet

- Method Statement For Lifting Cryognic TankDocument5 pagesMethod Statement For Lifting Cryognic TankYawar QureshiNo ratings yet

- FR 002 Pressure Testing Inspection ChecklistDocument6 pagesFR 002 Pressure Testing Inspection Checklistum er100% (1)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- Risk Assessment Tables GuidanceDocument6 pagesRisk Assessment Tables GuidanceBhargav BbvsNo ratings yet

- Cold Cutting PDFDocument9 pagesCold Cutting PDFAshraf BottaniNo ratings yet

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Jsa Nitrogen Purging PDFDocument2 pagesJsa Nitrogen Purging PDFBISWA RANJAN SAHOONo ratings yet

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteDocument3 pagesJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteganeshkanthNo ratings yet

- Hazard Identification and Risk Assessment Worksheet for Degassing Station ProjectDocument8 pagesHazard Identification and Risk Assessment Worksheet for Degassing Station Projectsudeesh kumarNo ratings yet

- Permit To Work ProcedureDocument18 pagesPermit To Work ProcedureRaghavendra Kiran100% (1)

- Offshore Grating Removal Safety TipsDocument1 pageOffshore Grating Removal Safety TipsKishor KoshyNo ratings yet

- Unloading Wheel Loader Sub-Rigging PlanDocument4 pagesUnloading Wheel Loader Sub-Rigging PlanGyanendra Narayan NayakNo ratings yet

- JHA Valve Leak Test and RepairDocument16 pagesJHA Valve Leak Test and Repairrosevelvet100% (1)

- Safe Work Pipes DemolitionDocument5 pagesSafe Work Pipes DemolitionahmadNo ratings yet

- Fire Hose Rack & Reel Testing ProcedureDocument2 pagesFire Hose Rack & Reel Testing ProcedureDong VanraNo ratings yet

- Method Statement - Shoring and Excavation For Soakaway Tank - Hub Park RevisedDocument13 pagesMethod Statement - Shoring and Excavation For Soakaway Tank - Hub Park Revisedyaswanth reddy mummadiNo ratings yet

- Temporary Work AuditDocument2 pagesTemporary Work AuditArunKumar GanesanNo ratings yet

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- Clean Pipes with Cardboard Bursting and Air BlowingDocument3 pagesClean Pipes with Cardboard Bursting and Air BlowingParthiban Karuna100% (1)

- Flange Weld Testers (FWT)Document1 pageFlange Weld Testers (FWT)moonstar_dmeNo ratings yet

- Hot Work Permit 2Document3 pagesHot Work Permit 2prabu lingamNo ratings yet

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- Hazard Task Risk Control MeasuresDocument5 pagesHazard Task Risk Control MeasuresIshan DankharaNo ratings yet

- Confined Space Rescue Plan: Description of The WorkDocument2 pagesConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- Template-Post Shutdown ReportDocument3 pagesTemplate-Post Shutdown Reportarief bayuNo ratings yet

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNo ratings yet

- Checklist Before Hydrotest HEAVY SLOPEDocument10 pagesChecklist Before Hydrotest HEAVY SLOPEcahyaNo ratings yet

- Air Compressor Operation SafetyDocument10 pagesAir Compressor Operation SafetyKelvin TanNo ratings yet

- Job Hazard Analysis Worksheet: Cold Cutting in Open AreaDocument2 pagesJob Hazard Analysis Worksheet: Cold Cutting in Open AreaAbdul Hakam Mohamed Yusof0% (1)

- 03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineDocument6 pages03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineHimanshu NiveriyaNo ratings yet

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- Method Statement For Hydraulic JackingDocument22 pagesMethod Statement For Hydraulic Jackinghwen.hh100% (1)

- JHA ANALYSIS SCALE REMOVAL VESSELDocument2 pagesJHA ANALYSIS SCALE REMOVAL VESSELRiyadh SalehNo ratings yet

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocument23 pagesJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDNo ratings yet

- Chemical Cleaning and Steam Blowing Application Sheet Rev.1Document12 pagesChemical Cleaning and Steam Blowing Application Sheet Rev.1Eslam ShiblNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- Welding Procedure PIPE HDPE - Rev.03Document29 pagesWelding Procedure PIPE HDPE - Rev.03DORBANI NedjmeddineNo ratings yet

- HSE-OCP-013. Cold CuttingDocument4 pagesHSE-OCP-013. Cold Cuttingibrahim0% (1)

- PTW MatrixDocument1 pagePTW Matrixjinyuan74100% (1)

- Removing and Installing Underground Storage TanksDocument7 pagesRemoving and Installing Underground Storage TanksM Waqas Habib100% (1)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamNo ratings yet

- 43 Equipment Erection (Static and Rotary)Document5 pages43 Equipment Erection (Static and Rotary)Hamza DhariwalNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Mechanical Isolation Methods and ProceduresDocument13 pagesMechanical Isolation Methods and ProceduresHse RiyazNo ratings yet

- 23.plumbing Method Statement GN23Document4 pages23.plumbing Method Statement GN23m_salah20202000No ratings yet

- EPC EXPANSION OF PRODUCED WATER TREATMENT FACILITIESDocument6 pagesEPC EXPANSION OF PRODUCED WATER TREATMENT FACILITIESVittorio FacchettiNo ratings yet

- Sub-Contractor Project HSE Plan-Rev. 2Document64 pagesSub-Contractor Project HSE Plan-Rev. 2shumailapreiousNo ratings yet

- Paint Calculation WorkbookDocument1 pagePaint Calculation WorkbookNaveed Ahmed Get-InfoNo ratings yet

- Hazard Identification and Risk Assessment WorksheetDocument4 pagesHazard Identification and Risk Assessment WorksheetNaveed Ahmed Get-InfoNo ratings yet

- EppsDocument8 pagesEppsJulio CesarNo ratings yet

- PM Blasting and Painting ActivitiesDocument2 pagesPM Blasting and Painting ActivitiesNaveed Ahmed Get-InfoNo ratings yet

- ClemcoCMS-3 Carbon Monoxide Monitor - Alarm - Clemco Abrasive Blasting EquipmentDocument2 pagesClemcoCMS-3 Carbon Monoxide Monitor - Alarm - Clemco Abrasive Blasting EquipmentNaveed Ahmed Get-InfoNo ratings yet

- Sand Blasting & Painting Risk AssessmentDocument6 pagesSand Blasting & Painting Risk AssessmentNaveed Ahmed Get-Info100% (1)

- Dr. Concrete IntroductionDocument5 pagesDr. Concrete IntroductionNaveed Ahmed Get-InfoNo ratings yet

- Framework for Safe Night WorkDocument8 pagesFramework for Safe Night WorkNaveed Ahmed Get-InfoNo ratings yet

- CO Monitor 2Document2 pagesCO Monitor 2Naveed Ahmed Get-InfoNo ratings yet

- Daily Component and Work Area Checklist: Company Name: Date: Job Details: Completed byDocument2 pagesDaily Component and Work Area Checklist: Company Name: Date: Job Details: Completed byNaveed Ahmed Get-InfoNo ratings yet

- CO Monitor ManualDocument15 pagesCO Monitor ManualNaveed Ahmed Get-InfoNo ratings yet

- The Frequency of Various TestsDocument3 pagesThe Frequency of Various TestsNaveed Ahmed Get-InfoNo ratings yet

- Pulmon Ficha Técnica PDFDocument2 pagesPulmon Ficha Técnica PDFderlingNo ratings yet

- Quality Management: Quality Management System Campaigns To Establish A Quality CultureDocument1 pageQuality Management: Quality Management System Campaigns To Establish A Quality CultureNaveed Ahmed Get-InfoNo ratings yet

- Explain For Quantity InquiryDocument10 pagesExplain For Quantity InquiryNaveed Ahmed Get-InfoNo ratings yet

- Method Statement For Application of GRP Lining Inside Water TankDocument5 pagesMethod Statement For Application of GRP Lining Inside Water TankNaveed Ahmed Get-InfoNo ratings yet

- Manual HandlingDocument11 pagesManual HandlingNaveed Ahmed Get-InfoNo ratings yet

- Method Statement for Pipeline Drying OperationsDocument22 pagesMethod Statement for Pipeline Drying OperationsNaveed Ahmed Get-InfoNo ratings yet

- Code of ConductDocument27 pagesCode of ConductNaveed Ahmed Get-InfoNo ratings yet

- GRP Lining Installation for Underground Water TankDocument5 pagesGRP Lining Installation for Underground Water TankNaveed Ahmed Get-InfoNo ratings yet

- He Frequency of Various TestsDocument3 pagesHe Frequency of Various TestsNaveed Ahmed Get-InfoNo ratings yet

- Dr. Concrete IntroductionDocument5 pagesDr. Concrete IntroductionNaveed Ahmed Get-InfoNo ratings yet

- QHSE Dashboard TemplateDocument8 pagesQHSE Dashboard TemplateIvàn Gòmez AlfaroNo ratings yet

- Adhesion TestingDocument4 pagesAdhesion TestingNestramiNo ratings yet

- Piping Specs PDFDocument48 pagesPiping Specs PDFabbas1368No ratings yet

- Procurement ProcedureDocument6 pagesProcurement ProcedureNaveed Ahmed Get-InfoNo ratings yet

- Code of ConductDocument27 pagesCode of ConductNaveed Ahmed Get-InfoNo ratings yet

- QHSE Dashboard TemplateDocument8 pagesQHSE Dashboard TemplateIvàn Gòmez AlfaroNo ratings yet

- Reference Note: Incorrect Spec NumberDocument17 pagesReference Note: Incorrect Spec NumberNaveed Ahmed Get-InfoNo ratings yet