Professional Documents

Culture Documents

UWP 25418 001 Elevated Water Tank 5000L CR02 PDF

Uploaded by

er.praveenraj30Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UWP 25418 001 Elevated Water Tank 5000L CR02 PDF

Uploaded by

er.praveenraj30Copyright:

Available Formats

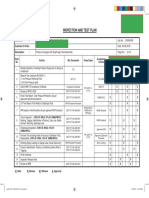

2200 SCHEDULE OF FITTINGS

800 800 TREATMENT

REF ND DESCRIPTION WALL FLANGE GALVA- EPOXY QTY NOTE:

TANK FIXING LUG, ex.: 1 FOUNDATIONS:

2600 't' DRILLING NISED RESIN

50 F 5 x 100 LONG

mm PAINT 1.1 DEPTHS OF ALL BASES SHALL BE DETERMINED AND

POSITION OF 5 000 LITRE H WITH 1-20dia HOLE

WELDED TO 'c' (6x) AFTER ASSEMBLY OF FRAMEWORK 1300 1300

A 63 PVC FLANGE ADAPTOR (CAST IRON) - SABS 11 - - 2no APPROVED ON SITE BY THE ENGINEER PRIOR TO

POLYETHYLENE WATER TANK CONCRETING.

NUTS AND BOLTS TO BE WELDED

(FITTING `W') U 200 TOGHETER WITH 2mm FILLET WELD B 65 GALVANISED STEEL SCREW-ON FLANGE - SABS 11 * - 2no

1.2 SAFE BEARING CAPACITY OF GROUND 200 kPa.

62,5 75 62,5 6

C 65 90 DEGREE MGI MALE/FEMALE BEND - - * - 2no

TANK FIXING LUG, ex.: OVERFLOW PIPE TO DISCHARGE

50 F 5 x 100 LONG ACCORDING TO ENGINEERS B D 65 475mm LONG MGI PIPE PIECE THREADED BOTH ENDS - - * - 2no

2 CONCRETE:

WITH 1-20dia HOLE SITE INSTRUCTION

2.1 PRESCRIBED MIX 10/19 IN BLINDING LAYERS.

WELDED TO 'c' (6x) f

E 65 90 DEGREE MGI FEMALE BEND - - * - 4no

2.2 PRESCRIBED MIX 20/19 IN COLUMN BASES.

Min.25mm

PIPE CLAMP -

SEE DETAIL 2

c F 65 330mm LONG MGI PIPE PIECE THREADED BOTH ENDS - - * - 2no 3 STRUCTURAL STEELWORK:

f f

3.1 ALL STRUCTURAL STEELWORK GRADE 300W

G 65 1020mm LONG MGI PIPE PIECE THREADED BOTH ENDS - - * - 1no

ACCORDING TO SABS 1431.

BOLT DETAIL

1500

H 65 MGI CONICAL SEAT UNION - - * - 1no 3.2 STEELWORK GENERALLY OF WELDED CONSTRUCTION

OUTLET

U WITH SITE CONNECTIONS BOLTED.

1:5 U J 65 MGI BARREL NIPPLE - - * - 1no UNLESS OTHERWISE SHOWN ARE :

c

K 65 BRASS FEMALE THREADED FULLWAY GATE VALVE - - - - 1no

ALL HOLES 12 DIA. FOR M10 BOLTS

ALL BOLTS GRADE 4.8

1350

L 65 2000mm LONG MGI PIPE PIECE THREADED BOTH ENDS - - * - 1no ALL GUSSETS 6mm PLATES

ALL WELDS 6mm FILLET

M 65 65x65x65ND MGI FEMALE EQUAL TEE - - * - 2no

H SECTION H-H LEGEND: N 65x50 65x50ND MGI REDUCING BUSH - - * - 2no

3.3 ALL STEELWORK SHALL BE SUPPLIED, FABRICATED

DELIVERED AND ERECTED IN ACCORDANCE WITH

1:5 SABS-1200H AND SABS-0164 1984.

a : 80 x 80 x 6 HRA (45B/M $)

PIPE CLAMP - O 50 MGI BARREL NIPPLE - - * - 1no 3.4 SITE WELDING OF STEELWORK SHALL NOT BE

b : 40 x 40 x 6 HRA (23B/M $)

2700

SEE DETAIL

PERMITTED WITHOUT THE ENGINEERS APPROVAL.

ELEVATION TYPICAL LUG DETAIL (6x) c : 125 x 75 x 10 HRA (45B/M $)

d : 30 x 6 F (25B/M $) POSITION OF 5000 LITRE

P 50 BRASS FEMALE THREADED FULLWAY GATE VALVE - - - - 1no

3.5 CORROSION PROTECTION:

1:5 1:5 POLYETHYLENE WATER TANK Q 50 50NDx50BSP MALE ADAPTOR COMPRESSION FITTING - - - - 2no 3.5 .1 PAINTWORK IN WORKSHOP:

e : 40 x 40 x 3 HRA (23B/M $) (FITTING `W') EPOXY COATING SHALL BE AN APPROVED

1500

4500

f : 125 x 50 x 20 x 2,5 CRLC R 50 600mm LONG HIGH DENSITY POLYETHYLENE TYPE IV CLASS 6 PIPE

(TO SABS 533) - - - - 2no TWO COMPONENT, POLYAMIDE CURED PIPE

COATING. IT SHALL BE APPLIED IN THE

NOTE:

1350

S 50x40 50NDx40BSP MALE ELBOW COMPRESSION FITTING - - - - 2no WORKSHOP BY SPRAYING TO A FINAL

NM PLUGGED OUTLET FOR

HRA = HOT ROLLED ANGLE O FUTURE EXTENSION THICKNESS OF NOT LESS THAN 300 MICRON.

P T 50 1714mm LONG HIGH DENSITY POLYETHYLENE TYPE IV CLASS 6 PIPE

SUPERIMPOSED POSITION OF QUANTITIES FOR SINGLE TANK STAND F = FLAT BAR 3.5 .2 PAINTWORK AFTER ERECTION:

Y (TO SABS 533) - - - - 1no

TANKSTAND L CRLC = COLD ROLLED LIPPED CHANNEL Q a) AFTER INSTALLATION ANY CHIPS OR

ITEM DESCRIPTION LENGTH No.OFF U E

B/B = BACK TO BACK ( 6 ) 100-500 U 50 90 DEGREE ELBOW COMPRESSION FITTING - - - - 2no SCRATCH MARKS SHALL BE MADE GOOD

BASE PLATE 80 x 80 x 6 HRA 300mm 4 F

COLUMN 80 x 80 x 6 HRA 4000mm 4 B/M = BACKMARK ON SITE WITH BRUSH APPLIED EPOXY

S E V 65 3150mm LONG MGI PIPE PIECE THREADED BOTH ENDS - - * - 1no

STRUT 40 x 40 x 6 HRA 1580mm 10 $ = UNLESS OTHERWISE SHOWN A R A PAINT.

FLOOR BEAM 125 x 75 x 10 HRA 2200mm 2

C B W - 5 000 LITRE POLYETHYLENE WATER TANK (2040mm HIGH x 1800mm b) AN INTERIM LAYER ACCORDING TO

PLANK 125 x 50 x 2 CRLC 2700mm 11 A DIAMETER), COMPLETE WITH 50x40 NOM.DIA NYLON REDUCING

K SABS 681 TYPE I SHALL BE APPLIED

VERT.BRACING 30 x 6 F 2180mm 12 WATER TANK TO BE SUITABLY BUSHES, SEALED INTO ALL INLETS AND OUTLETS, INCLUDING

J VERT.BRACING 30 x 6 F 2150mm 4 HELD IN POSITION ON PLATFORM TO A FINAL THICKNESS OF 25 MICRON.

A 40 NOM.DIA GALV'D PLUG FITTED TO OPENING ABOVE INLET.

H HORI.BRACING 40 x 40 x 3 HRA 2200mm 4 USING MIN. 2 x STRANDS 4,0mm 3.5 .3 FINAL FINISHING LAYER:

PIPE CLAMP 80 x 80 x 6 HRA 100mm 6 GALVANISED STEEL WIRE FIXED

63ND PVC CLASS 6

PIPELINE FROM BOREHOLE

B TANK TO BE SUPPLIED COMPLETE WITH SUFFICIENT

4mm DIA GALVANISED STEEL WIRE FOR ANCHORING A FINAL ENAMEL LAYER ACCORDING TO SABS

1500

PIPE CLAMP M10 U-SHAPED BOLT 125mm 6 TO TANK FIXING LUG AND PUMP STATION TO THE TANKSTAND PLATFORM AS DETAILED ON 630 GRADE 1 SHALL BE APPLIED WITHIN

WOOD BLOCK 140mm 6 PLATFORM SUPPORT BEAMS PLAN NO. 125 826/97ME - - - - 1set

FIXING PLATE 75 PL 6 75 LONG 75mm 8 24 HOURS AFTER THE INTERIM LAYER HAS

BOLTS M10 ST/STL 55mm 64 X 63 PVC CLASS 6 PIPING - - - - 12m BEEN APPLIED, TO A FINAL THICKNESS OF

G D 25 MICRON (COLOUR AS INSTRUCTED).

2600 Y 65 MGI HOLLOW PLUG - - * - 2no

PIPE CLAMP -

SEE DETAIL 37.5 37.5 PLAN MISCELLANEOUS FITTINGS

1) PIPE CLAMPS AS DETAILED ON PLAN No. 125 825/97ME - - - - 6no

4 GENERAL:

4.1 READ THIS PLAN IN CONJUNCTION WITH ALL

125 125 NOTE N.T.S.

THE RELEVANT DRAWINGS.

E ALL FLANGES TO BE DRILLED ACCORDING TO SABS 1123-1977 TABLE 11

1600 4.2 ALL DIMENSIONS IN MILLIMETERS.

300

75 75

(STEEL SCREWED BOSS FLANGES - 1000/4) AND REFERED TO AS SABS

NGL E 1520

11 IN THE SCHEDULE OF FITTINGS

SUPERIMPOSED POSITION

D OF FLOOR AREA

CONCRETE THRUST

15000

BLOCK

590

TANK FIXING LUG

C

TB

OUTLET D SEE DETAIL TWL

b TANK FIXING LUG

V = 0,1 cu m a

GATE POSITION

a SEE DETAIL

CR02

(MAY VARY)

ELEVATED

C 2 C C C TANK

OUTLET e

e f f f f f f f f f f f f f

SECTION A-A

SCALE:1:25

1600

1520

2700

1520

b b 500mm x 600mm

LOCKABLE CAST

13 / FLOOR MEMBERS ex.:

125 x 75 x 20 x 2 CRLC

IRON COVER OVER

U U (10 x 2 700 long + FRAME.

1 x 1 650 long SINGLE TANK)

(13 x 2 700 long

POSITION OF 5 000 LITRE

15000

REST OF MULTIPLE TANKS)

T POLYETHYLENE WATER TANK T ELEVATED TANK

TANK FIXING LUG

(FITTING `W') SEE DETAIL

a a

b

TANK FIXING LUG

D SEE DETAIL

590

2065

FENCE

1032 1032 TO RETICULATION

90

D AND AS INSTRUCTED

LAYOUT PLAN E-E BY ENGINEER

1:25

FENCE

FLOOR LAYOUT

R S M M R 1:25

S

PLAN VIEW CHLORINATOR

NTS MANHOLE

16-05-2014 CHLORINATOR REVISED TO NEW DESIGN S.G.R.

400

45 75 CR02

PIPE CLAMP 50 F 5 x 100 LONG 500

PIPE CLAMP 10 30 5 30 45 WITH 1-12dia HOLE CHLORINATOR ADDED TO DETAILS

FOR 1-M10 BOLT

223 177 100 220mm THICK 04-12-2013 CR01 S.G.R.

50 F 5 x 100 LONG BRICK MANHOLE

f WITH 1-12dia HOLE RISING MAIN 8 BAR GLYCERINE 12-11-2013 CR00 ISSUED FOR CONSTRUCTION S.G.R.

50

b 23 FOR 1-M10 BOLT INLET

10

a FROM BOREHOLE PRESSURE GAUGE

d c 29

B f f f DATE REVISIONS DESCRIPTIONS SIGN

45

1100

b

45

35

30

175

REVISION TABLE

75

23

16

40

BASE SLAB: 1750mm x 1170mm

5

FULLWAY GATE VALVE

80

40

x 150mm 20MPa CONCRETE (TO COMPLY WITH SABS IMPLEMENTING AGENT TECHNICAL SUPPORT

65

e 75 PL 6 x 75 LONG d

A a b c WITH MESH REF 245 776-1975 CLASS 8)

125

125

b FULLY WELDED TO 'a'

17

PLASSON SADDLES WITH

WITH 1-12 DIA. HOLE FOR

79

STAINLESS STEEL BOLTS

60

1-M10 BOLT d

AND NUTS 20mm DIA HDPE

400

(No.REQUIRED : 8x) SEE d a

PIPE CLAMP d FLOOR LAYOUT FOR PIPES TO CHLORINATOR.

PIPE CLAMP - 35 40 POSITIONS 35 45 TOP FLANGE OF HRA TO HAVE

L SEE DETAIL

75 80

11-12dia HOLES, ENDS SPACED AS

DETAILED THE REST AT 200mm

ELEVATED WATER TANK SCHEMATIC

CRS FOR 11- M10 BOLTS FOR SCALE: N.T.S.

d

4500

35 45 FIXING OF 125 x 50 x 20 x 2 CRLC

DETAIL 2 DETAIL 3 80

2600

1:5 1:5

1200

80 100 200 200 200 200 200 200 200 200 200 200 200 200 100 2700

140

VIEW B 10 35 35 550 1600 550 MVULA TRUST UWP CONSULTING (PTY)

V M10 U-SHAPED BOLT HAVING

125mm LONG LEGS OF WHICH THE

1:5 f f f f f f f f f f f f f f P.O. Box 8112 LTD

38 65 38

PIPE CLAMP

PIPE CLAMP

ENDS ARE THREADED FOR A A c c

Nahoon P.O. Box 19276

DISTANCE OF 50mm, COMPLETE 27 86 27 d b

WITH NUTS AND WASHERS c East London TECOMA

80 x 80 x 6 HRA COLUMN R=38 50mm WIDE x 70mm HIGH x 140mm

a

5201 5214

TANKSTAND LONG SHAPED HARD WOOD BLOCK

HAVING 2 x 12mm DIA. HOLES d Tel: (043) 726-2255/6/7 Tel: (043) 721-0186

20

18

DRILLED FOR ANCHOR BOLT Fax: (043) 726-2344 Fax: (043) 721-0288

23

80 x 80 x 6 HRA BASEPLATE TO BE R=38

1500

1500

K WELDED TO THE COLUMN AND b

1320

J 37

70

40

40

b

125

CASTED INTO THE CONCRETE

52

H

FOOTING. SHEET SIZE

105

G NAME SIGNATURE DATE

17

A0

1200 MAX.

25

e

40

a

DESIGNED S.RICHTER 16 MAY 2014

PIPE CLAMP - 80 x 80 x 6 HRA 100mm LONG d

PIPE CLAMP 6 SCALE

SEE DETAIL FULLY WELDED TO 'a' WITH 43 37 b

1-12 DIA. HOLE FOR M10 b b c D.DICKSON

d c DRAWN 16 MAY 2014

300 AS SHOWN

200

U-BOLT (No. REQUIRED : 6x) 80 80 b

E

380

E F E F SEE SECTION B-B FOR

E OVERFLOW PIPE TO

300

DISCHARGE ACCORDING POSITIONS 6 35 39

NGL 75 PL 6 x 75 LONG VERIFIED L.POOK 16 MAY 2014 STATUS LEGEND

TO ENGINEERS SITE

FULLY WELDED TO 'a'

3 I = INFORMATION

63ND PVC CLASS 6 D D INSTRUCTION 80

WITH 1-12 DIA. HOLE d T = TENDER

d

PIPELINE FROM BOREHOLE C = CONSTRUCTION

B B FOR 1-M10 BOLT VALIDATED

PUMP STATION AB = AS BUILT

X (No. REQUIRED : 8x)

C C

1500

1500

SEE FLOOR LAYOUT FOR

INLET

A POSITIONS

250

A

TB

V = 0,1 cu m BASE PLATE DETAIL 1 PIPE CLAMP DETAIL VIEW A

CONCRETE 1:5 CLIENT

THRUST BLOCK (4 OFF REQUIRED) (6 OFF REQUIRED)

500

E E

5700

5700

1:5 1:5

INLET AND OVERFLOW b

b

b b

b

b

SECTION B-B CR02

500

1:25

d

d

STORAGE SUMP AND IN-LINE CHLORINATOR DETAILS d

d

1650

TOP SLAB: (FLOATED FINISH)

1650mm x 1070mm x 150mm WITH 1210 a a a a

1500

1500

375 250 375

600mm x 600mm LOCKABLE

MANHOLE COVER AND FRAME DOSATRON OR SIMILAR 1000 SQUARE

FULLWAY GATE VALVE (TO COMPLY WITH

SABS 776-1975 CLASS 8) APPROVED NON-RETURN VALVE

PROJECT

8 BAR GLYCERINE PRESSURE GAUGE FOOTING DETAIL FOR

FILTER

b SANDY CONDITIONS b

ACCELERATED SCHOOLS INFRASTRUCTURE

RISING MAIN (PIPE DIA. VARIES)

b b

1:25

b b

DELIVERY INITIATIVE (ASIDI)

1070

630

300

300

220mm THICK BRICK MANHOLE (WITH 3 x 20 L CONTAINERS FILLED CONSTRUCTION OF WATER AND SANITATION

250

250

WITH CONCENTRATED ADDITIVE

200

200

WEEPHOLES AT INVERT) (BRICKWORK TO BE VALVE

INFRASTRUCTURE AT SCHOOLS IN THE

1000

1000

PLASTERED INTERNALLY AND EXTERNALLY)

EASTERN CAPE PROVINCE.

20mm HDPE

20mm HDPE

950

950

500

500

20mm OUTLET FROM INLET PIPE

700

700

20mm OUTLET FROM THE

TO THE CHLORINATOR THROUGH DOUBLE DOORS WITH LOCK DRAWING TITLE

CHLORINATOR TO THE INLET CABINET FASTENED TO GALVANISED METAL

PIPE THROUGH A 32mm SLEEVE A 32mm SLEEVE PROTECTION

200

200

FRAME AND FASTENED TO CONCRETE BASE

WITH FOUR STAINLESS STEEL BOLTS AND NUTS 1200 x 1200 x 100 20MPA 4.5m HIGH ELEVATED WATER TANK (5000 l)

CONCRETE BASE

POWDER COATED GALVANISED 20mm OUTLET FROM INLET PIPE TO THE

20mm OUTLET FROM CHLORINATOR TO

275 250 275 300 275 250 275 DETAILS AND SECTIONS

METAL CABINET TO HOUSE CHLORINATOR THROUGH A 32mm SLEEVE

THE INLET PIPE THROUGH A 32mm SLEEVE 800 720 800 800 720 800

CHLORINATOR. DOORS - DOUBLE 1000 x 1000 x 100 CONCRETE

WITH LOCK PROTECTION SIZE - 2320 2320

PLINTH FOR MOUNTING OF

1020(H) x 1000(WIDE) x 600(DEEP) CHLORINATOR

MATERIAL - 1.6mm THICK TYPICAL SECTION THROUGH CHLORINATING UNIT SECTION C-C SECTION D-D DBE DRAWING NUMBER

GALVANISED MILD STEEL 1:25

NTS 1:25

EMS NUMBER DISCIPLANE DRAWING NUMBER STATUS REVISION

TYPICAL ARRANGEMENT FOR INLINE CHLORINATOR

NTS - C UWP-25418-001 C CR02

You might also like

- MQ SP M 4004 PDFDocument17 pagesMQ SP M 4004 PDFjaseelNo ratings yet

- MQ SP M 4011 PDFDocument7 pagesMQ SP M 4011 PDFjaseelNo ratings yet

- Detailed Engineering of Air Seperation Unit - SATORPDocument1 pageDetailed Engineering of Air Seperation Unit - SATORPfarhan yazdaniNo ratings yet

- KANSAI Tank Coating and Piping Material QuoteDocument4 pagesKANSAI Tank Coating and Piping Material QuoteTanveer Rajput EngrNo ratings yet

- MQ SP M 4029 PDFDocument30 pagesMQ SP M 4029 PDFjaseelNo ratings yet

- Nde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTDocument2 pagesNde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTfizanlaminNo ratings yet

- Qap Sa420Document3 pagesQap Sa420Abhishek NagNo ratings yet

- #1 Pedestal Pipe Support PDFDocument3 pages#1 Pedestal Pipe Support PDFBayu Adi DharmaNo ratings yet

- Plant Location Company Doc. No. NADocument8 pagesPlant Location Company Doc. No. NAsivaNo ratings yet

- List Certificates of Werder QualificationDocument2 pagesList Certificates of Werder QualificationMuhammad FajarNo ratings yet

- MS Data Sheet TanqueDocument2 pagesMS Data Sheet TanqueLION_FIRENo ratings yet

- Nominal Size (Inches) Outside Diameter (Inches) Outside Diameter (MM) Wall Thicknes S (Inches) Wall Thicknes S (MM) Weight (LB/FT) Weight (KG/M)Document1 pageNominal Size (Inches) Outside Diameter (Inches) Outside Diameter (MM) Wall Thicknes S (Inches) Wall Thicknes S (MM) Weight (LB/FT) Weight (KG/M)Boj MingiNo ratings yet

- PIPE CLASS SPECIFICATIONDocument138 pagesPIPE CLASS SPECIFICATIONbadelitamariusNo ratings yet

- Tool Fab - WorkshopDocument347 pagesTool Fab - Workshophrdsby100% (1)

- Pipe Wall ThicknessDocument1 pagePipe Wall ThicknessFurkan Burak MuhammedNo ratings yet

- Pipe SpoolDocument2 pagesPipe SpoolMohd Taufiq IsmailNo ratings yet

- 7) - Procedure FRP Tank InstallationDocument34 pages7) - Procedure FRP Tank Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Job Procedure For Hot Insulation Work of Piping & Equipment1Document13 pagesJob Procedure For Hot Insulation Work of Piping & Equipment1ravi00098100% (1)

- SR - No Description QtyDocument12 pagesSR - No Description QtyBoyzannazNo ratings yet

- ITP For Fabrication & Installation of Tensile Fabric ShadesDocument1 pageITP For Fabrication & Installation of Tensile Fabric ShadesSun ShadeNo ratings yet

- GULF ScheduleDocument5 pagesGULF ScheduleKaren OrtizNo ratings yet

- Project Plan and Actuals TrackerDocument5 pagesProject Plan and Actuals TrackerRiaz MohammedNo ratings yet

- Painting Procedure Rev.ADocument12 pagesPainting Procedure Rev.Aคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Costing Calculations:: Date: Revision: 0 Bld-396-R1 With Canopy + Repairing PlatfarmDocument12 pagesCosting Calculations:: Date: Revision: 0 Bld-396-R1 With Canopy + Repairing PlatfarmRakesh SharmaNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- MQ SP M 4003 PDFDocument18 pagesMQ SP M 4003 PDFjaseelNo ratings yet

- MTO For StructureDocument2 pagesMTO For StructureRajnath Rajbhar PanchamNo ratings yet

- Dimensions and Dimensional Tolerances of Straight Tees, NPS 1 - 2 To NPS 48, ASME B16Document4 pagesDimensions and Dimensional Tolerances of Straight Tees, NPS 1 - 2 To NPS 48, ASME B16groshan20No ratings yet

- Inspection and Test Plan for Pressure GaugesDocument1 pageInspection and Test Plan for Pressure GaugesVenkatesh PethurajNo ratings yet

- North Yaran Oil Field Development ClusterDocument4 pagesNorth Yaran Oil Field Development ClustermNo ratings yet

- API 650 Storage Tank Design ReportDocument69 pagesAPI 650 Storage Tank Design Reportshahroze mustafaNo ratings yet

- Anchor bolt schedule documentDocument1 pageAnchor bolt schedule documentvilasfNo ratings yet

- Material Traceability/ Fit Up/ Dimensional & Weld Visual Inspection ReportDocument9 pagesMaterial Traceability/ Fit Up/ Dimensional & Weld Visual Inspection ReportKyNo ratings yet

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFDocument1 pageLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodNo ratings yet

- Inspection and Test Plan FOR Filter Separator/CoalescerDocument6 pagesInspection and Test Plan FOR Filter Separator/Coalescersumit kumarNo ratings yet

- Bondstrand Fiberglass Flanges Assembly Instructions - AmeronDocument8 pagesBondstrand Fiberglass Flanges Assembly Instructions - AmeronFabio SilvaNo ratings yet

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanNo ratings yet

- COPI - Welding Spec For Flowlines To API 1104-1999Document12 pagesCOPI - Welding Spec For Flowlines To API 1104-1999AdvisNo ratings yet

- Daily Progress Report: Client: Adani Gas LTD Contractor: Tolani Projects PVT LTD Tpia: TUV India LocationDocument6 pagesDaily Progress Report: Client: Adani Gas LTD Contractor: Tolani Projects PVT LTD Tpia: TUV India LocationManoranjan sharmaNo ratings yet

- MQ SP M 4038 PDFDocument26 pagesMQ SP M 4038 PDFjaseelNo ratings yet

- Counter Formation Recommendations for Popular FormationsDocument3 pagesCounter Formation Recommendations for Popular FormationsHan Siang KuNo ratings yet

- KNT 001 GE ST3 SP 002 - 0 - Specification For Rubber MaterialDocument13 pagesKNT 001 GE ST3 SP 002 - 0 - Specification For Rubber MaterialvamcodongNo ratings yet

- LINE 100 RFQ CV 004 - Requisition Steel Structure ErectionDocument97 pagesLINE 100 RFQ CV 004 - Requisition Steel Structure ErectionACHMAD.KAMALNo ratings yet

- 10624-Master Index For Pipe SupportsDocument36 pages10624-Master Index For Pipe SupportsSARFRASNo ratings yet

- Welder's Master ListDocument8 pagesWelder's Master ListAnonymous rYZyQQot55No ratings yet

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- FRP Repair of Corrosion-Damaged Concrete BeamsDocument13 pagesFRP Repair of Corrosion-Damaged Concrete BeamsahmadlieNo ratings yet

- Refining Major Projects General ManagementDocument20 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- Power grid network of BangladeshDocument1 pagePower grid network of BangladeshShuhan Mohammad Ariful HoqueNo ratings yet

- MATERIAL TRACKING LISTDocument2 pagesMATERIAL TRACKING LISTgopaltryNo ratings yet

- Et WHP02 0000 Mec TPB 1003 - Ar 0001Document60 pagesEt WHP02 0000 Mec TPB 1003 - Ar 0001orea1No ratings yet

- FORMULA (Coating)Document4 pagesFORMULA (Coating)Ravindra S. JivaniNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- SOP02 - F26 - R00 Pipe Stringing Report 1Document12 pagesSOP02 - F26 - R00 Pipe Stringing Report 1Faiz IshakNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 pagesAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaNo ratings yet

- Work and Financial Plan Template 1Document1 pageWork and Financial Plan Template 1IBP Bohol ChapterNo ratings yet

- NFPC - Oasis Water - Jebel Ali - 2021-09-07 - Proposed Nissei Layout - 2023-05-17Document1 pageNFPC - Oasis Water - Jebel Ali - 2021-09-07 - Proposed Nissei Layout - 2023-05-17Projects DPCSNo ratings yet

- Comp ColumnsDocument2 pagesComp Columnser.praveenraj30No ratings yet

- Kathmandu University Design of Column Section Designed By:: Er. Sudip ShresthaDocument9 pagesKathmandu University Design of Column Section Designed By:: Er. Sudip ShresthaSudip ShresthaNo ratings yet

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Nepal tax rates for employment income FY 2020/21Document3 pagesNepal tax rates for employment income FY 2020/21shankar k.c.No ratings yet

- Income Tax 2058 067 eDocument626 pagesIncome Tax 2058 067 eSujan SinghNo ratings yet

- Column DesignDocument24 pagesColumn DesignSudan ShresthaNo ratings yet

- Steel Column DesignDocument15 pagesSteel Column DesignNitesh Singh100% (6)

- Column Output:: Joints Unique Name (As Shown in Figure Above) Column ID Size (MM) Ground Floor 1st Floor 2 FloorDocument4 pagesColumn Output:: Joints Unique Name (As Shown in Figure Above) Column ID Size (MM) Ground Floor 1st Floor 2 Floorer.praveenraj30No ratings yet

- Plinth Beam Layout Plan (Multipurpose Hall) : VariesDocument1 pagePlinth Beam Layout Plan (Multipurpose Hall) : Varieser.praveenraj30No ratings yet

- Summary ReeeDocument4 pagesSummary Reeeer.praveenraj30No ratings yet

- Gym Hall EstimateDocument3 pagesGym Hall Estimateer.praveenraj30No ratings yet

- Truss section detail with dimensionsDocument1 pageTruss section detail with dimensionser.praveenraj30No ratings yet

- fINAL Aruna Shrestha ANALYSIS REPORTDocument42 pagesfINAL Aruna Shrestha ANALYSIS REPORTer.praveenraj30100% (1)

- Miya FOOTING DETAILS CHARIKOTDocument4 pagesMiya FOOTING DETAILS CHARIKOTer.praveenraj30No ratings yet

- SAP2000 Introductory TutorialDocument62 pagesSAP2000 Introductory Tutorialanon_443224320100% (1)

- Residential Building South and West ElevationsDocument1 pageResidential Building South and West Elevationser.praveenraj30No ratings yet

- Mrs. Ruchila Khanal Residential Building: Structural Analysis Report ofDocument44 pagesMrs. Ruchila Khanal Residential Building: Structural Analysis Report ofer.praveenraj30100% (1)

- Steel Building Structural Analysis and Design ReportDocument34 pagesSteel Building Structural Analysis and Design Reporter.praveenraj30100% (1)

- Ishwari Steel Analysis ReportDocument43 pagesIshwari Steel Analysis Reporter.praveenraj30No ratings yet

- A Report On Structural Analysis of Roof Truss: 1. General Data and Load CalculationDocument56 pagesA Report On Structural Analysis of Roof Truss: 1. General Data and Load Calculationer.praveenraj30No ratings yet

- SAP2000 Introductory TutorialDocument62 pagesSAP2000 Introductory Tutorialanon_443224320100% (1)

- A Report On Structural Analysis of Roof Truss: 1. General Data and Load CalculationDocument56 pagesA Report On Structural Analysis of Roof Truss: 1. General Data and Load Calculationer.praveenraj30No ratings yet

- 2-Combine Report Important Factor 1.5Document47 pages2-Combine Report Important Factor 1.5er.praveenraj30No ratings yet

- Concrete Mix Design M25Document9 pagesConcrete Mix Design M25ramkrishnaNo ratings yet

- Compare Between Manual Calculation and Etabs Done by Eng - Moh.SaadDocument11 pagesCompare Between Manual Calculation and Etabs Done by Eng - Moh.Saader.praveenraj30100% (1)

- NBC 105 Revision - 2019Document108 pagesNBC 105 Revision - 2019er.praveenraj30No ratings yet

- A Report On Structural Analysis of Roof Truss: 1. General Data and Load CalculationDocument31 pagesA Report On Structural Analysis of Roof Truss: 1. General Data and Load Calculationer.praveenraj30No ratings yet

- Some Notes: Changes in Highlighted Rows Is Required As Per DesignDocument3 pagesSome Notes: Changes in Highlighted Rows Is Required As Per Designer.praveenraj30No ratings yet

- Objectives: Instructor Workbook Module M5/ S3Document12 pagesObjectives: Instructor Workbook Module M5/ S3er.praveenraj30No ratings yet

- ETABS 2016 beam designDocument2 pagesETABS 2016 beam designer.praveenraj30No ratings yet

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- Detroit Diesel 6 2 6 5 Repair Manual Bus PDFDocument271 pagesDetroit Diesel 6 2 6 5 Repair Manual Bus PDFAlexander Neyra100% (3)

- Volvo: AT/ATO 2612D AT/ATO 2612E AT/ATO 2612FDocument42 pagesVolvo: AT/ATO 2612D AT/ATO 2612E AT/ATO 2612FDicaf Comercio100% (3)

- Reverse Rinsing Fine Filter With Flanges: Product Specification SheetDocument4 pagesReverse Rinsing Fine Filter With Flanges: Product Specification SheetCiprian BalcanNo ratings yet

- Grundfos CR 15 6 A F A e HqqeDocument11 pagesGrundfos CR 15 6 A F A e HqqeRoat MechNo ratings yet

- Water Control Valve DV-5Document8 pagesWater Control Valve DV-5Christian FherNo ratings yet

- NmaxDocument59 pagesNmaxJayson Verso100% (2)

- GS-Hydro Product Catalogue 2012 PDFDocument504 pagesGS-Hydro Product Catalogue 2012 PDFTAPaolaNo ratings yet

- We Have Something Against Corrosion:: Surface and Corrosion ProtectionDocument6 pagesWe Have Something Against Corrosion:: Surface and Corrosion ProtectionAnibal Aldava CrispinNo ratings yet

- Proporcionador 3, 4, 6 y 8Document2 pagesProporcionador 3, 4, 6 y 8Palomino VergaraNo ratings yet

- PNSMV027Document11 pagesPNSMV027Philippe AlexandreNo ratings yet

- Gate, Globe & Check Valves Technical SpecificationsDocument12 pagesGate, Globe & Check Valves Technical SpecificationsKrunal MahidadiaNo ratings yet

- ASME B16.34 InterpretationsDocument21 pagesASME B16.34 Interpretationsqueretaro75390100% (1)

- ZF MS-B 3025 Diant Cat 416Document25 pagesZF MS-B 3025 Diant Cat 416Ivo Silva100% (3)

- 7200 Series Radar Tank GaugesDocument24 pages7200 Series Radar Tank GaugesJavier E. OtáloraNo ratings yet

- Gen Air TestDocument14 pagesGen Air TestPRINCE SHARMANo ratings yet

- Accumulators Inc Entire CatalogDocument61 pagesAccumulators Inc Entire Catalogoswaldo58No ratings yet

- 8-1285-2 Pipe Class HF-7: Standard SpecificationDocument2 pages8-1285-2 Pipe Class HF-7: Standard SpecificationStuart WickensNo ratings yet

- Umm Lulu Phase II Amine ContactorDocument7 pagesUmm Lulu Phase II Amine ContactorchetanmaleNo ratings yet

- SKUM Over The Top Foam Generators OFG OFGR-0917Document4 pagesSKUM Over The Top Foam Generators OFG OFGR-0917Lee Liang ChenNo ratings yet

- Main Fermenter (F-02&f03) A143951Document1 pageMain Fermenter (F-02&f03) A143951Firdaus AbuNo ratings yet

- Pressure Relief Valve HandbookDocument93 pagesPressure Relief Valve HandbookMohammad Reza Anghaei100% (1)

- 27 Samss 001Document33 pages27 Samss 001nadeem shaikhNo ratings yet

- Steam Explosion During A Re-Injection Into A Leak Sealing Clamp PDFDocument8 pagesSteam Explosion During A Re-Injection Into A Leak Sealing Clamp PDFAPARNA SAWATKARNo ratings yet

- Vectron G 140Document20 pagesVectron G 140josehNo ratings yet

- KRAL Screw Pumps.: Operating InstructionsDocument62 pagesKRAL Screw Pumps.: Operating InstructionsTomislav KorencicNo ratings yet

- Danfoss Orbital Orbitrol OMV OMS OMTDocument117 pagesDanfoss Orbital Orbitrol OMV OMS OMTlucas solon de souza costaNo ratings yet

- Background For P&ID Check (Process) 20090823Document40 pagesBackground For P&ID Check (Process) 20090823akshayNo ratings yet

- CAT BG 12 14c PDFDocument12 pagesCAT BG 12 14c PDFConnor RaeNo ratings yet

- Allweiler Screw PumpDocument20 pagesAllweiler Screw PumpAmit ChourasiaNo ratings yet