Professional Documents

Culture Documents

MSDS N G

Uploaded by

owngauravOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSDS N G

Uploaded by

owngauravCopyright:

Available Formats

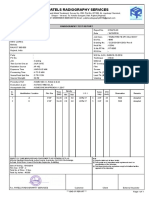

APC AIR SYSTEMS PRIVATE LTD.

13/5, East Patel Nagar, MSDS No. 07/APC/

Below YES Bank ATM, Date .12.2010

N.Delhi – 110 008 Sheet 1 of 3

Customer : Order No. :

Date :

CST No. :

ECC No. :

TIN No. :

Range :

Division :

Phone nos. :

Fax No./mail :

Contact person :

Consignee (in cases other than customer) CST No. :

TIN No. :

LST No. :

Range :

Division :

Phone nos. :

Fax No./ mail :

Contact person :

Manufacturing instructions: Despatch Instructions:

1. Specification : Std./ Special 1. Packing : Only essential/ Special

2. QAP : Std./ Special 2. Despatch : Full truck/ Part/ By Road

3. Painting : Std./ Special 3.Transporter :

4. Inspection : Reqd./ Not reqd. 4. Freight : Prepaid/Recoverable/To pay

5. Certificate : Reqd./ Not reqd. 5. Any spl. :

Instructions

In case of special, the relevant documents to be attached.

DELIVERY REQUIREMENTS:

PROJECT ENGINEER PROJECT IN-CHARGE DIRECTOR IN CHARGE

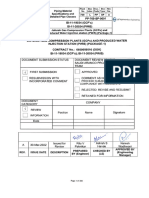

APC AIR SYSTEMS PRIVATE LIMITED MSDS NO. 07/APC/ Sh. 02 of 03

Place of

S. No. Description Size/Model Make/Mtrl. Qty. Mfg./

Proc.

Pressurization & Ventilation System of as per

Drg. No. Comprising Of :-

1. Blower with I/O :-

i) Blower APC/MS

ii) Fan Outlet Damper APC/MS

iii) Flexible Canvass Connection Canvass

iv) VI Rubber Pad 100x100x 10 (M.M.) Rubber

2. Motor & its V-Belt Drive Set :-

i) Electric Motor (Frame size S) Crompton/ABB

ii) Fan Pulley Fenner

iii) Motor Pulley Fenner

iv) No. of Belts Fenner

v) Belt Protection Guard APC/MS

vi) Common Base Frame cum slide rail MS-Channel

3. Filtration Area :-

i) Fine Filter holding frame of 40 M.M. Tee MS

ii) Pre Filter holding frame of 40 M.M. Tee GI

iii) Pre Filter 610 x 610 x 50 (M.M.) HDPE

iv) Fine Filter 610 x 610 x 150 (M.M.) HDPE

v) Auto Viscous Filter in Std. construction :- APC/MS

a) Direct unit (R.H.S.)

b) Indirect unit

4. Air Washer Unit :-

i) Water recirculating monoblock pump (3 Phase) Crompton/ABB

ii) Base frame for pump MS

iii) Paper fill with box frame Munters

iv) Mist Eliminator PVC(Fill)

v) Suction Screen HDPE

5. Air Louvers n Supply Grills :-

i) Air Intake Louver with Frame GI

ii) Exhaust air gravity louvers Frame-MS-

18G/Blade-Al-22G

iii) Double louvre double deflection supply air grilles MS powder coated

with damper

iv) Double louvre double deflection supply air grilles MS powder coated

with damper

6. Piping & Valves as per below details :-

i) GI Overflow & Drain connection with 1 No. of Gate GM(Valve)

Valve.

ii) GI Make up & Quick fill connection with 1 No. Gate GM(Valve)

Valve.

iii) Y Strainer CI/GM

PROJECT ENGINEER PROJECT IN-CHARGE DIRECTOR IN CHARGE

APC AIR SYSTEMS PRIVATE LIMITED MSDS NO. 07/APC/ Sh. 03 of 03

iv) GI Gate Valve GM

v) GI Gate Valve GM

vi) Non Return Valve Vertical GM

vii) Float Valve GM

viii) GI Socket GI

ix) GI tee GI

x) GI Tee GI

xi) GI Union GI

xii) GI Pipe - B Class GI

xiii) GI nipple GI

xiv) GI nipple GI

xv) GI Nipple GI

xvi) GI Elbow GI

xvii) GI Elbow GI

xviii) GI Reducer GI

7. Air Tight Door 850 x 1850 (M.M.) MS

8. Ducting materials with supports

i) GI Sheet of 24 G Sheet size of 2.5 x 1.00 (M) GI

ii) GI Sheet of 22 G Sheet size of 2.5 x 1.00 (M) GI

iii) GI Sheet of 20 G Sheet size of 2.5 x 1.00 (M) GI

iv) MS Angle 40 x 40 x 3 (M.M) MS

v) MS Angle 40 x 40 x 5 (M.M) MS

vi) MS Rod 10 M.M. Dia. MS

vii) GI nut and Bolt M – 6 x 25 (M.M.) GI

viii) GI nut M – 10 M.M. GI

ix) Rubber Gasket 4 M.M. thick Foam Type

x) Rubber Adhesive

xi) Anchor Fasteners M - 8 X 75 (M.M.) I type

Note : M.M. Stands for Milli Meters ; M Stands for Meters & R.M.T. Stands for Running Meters

If any clarification is needed the same should be referred back immediately.

PROJECT ENGINEER PROJECT IN-CHARGE DIRECTOR IN CHARGE

You might also like

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- NDT Request FormDocument1 pageNDT Request FormSHANENo ratings yet

- Lhs Epcmd 2 Qm00 FMT PP 002 - 03Document1 pageLhs Epcmd 2 Qm00 FMT PP 002 - 03Muthu AlaguRajNo ratings yet

- NDT Request FormDocument1 pageNDT Request FormSHANENo ratings yet

- SIMO Research Engineers Pvt. LTDDocument7 pagesSIMO Research Engineers Pvt. LTDunicorn pressure vasselsNo ratings yet

- Gom STP Ins Pid 01012 3Document8 pagesGom STP Ins Pid 01012 3Nikhil PatilNo ratings yet

- CCAC Installation Checklist Page 2Document1 pageCCAC Installation Checklist Page 2Nova CastyNo ratings yet

- Utm - 1Document2 pagesUtm - 1Kaushal GandhiNo ratings yet

- Centrale À Cycle Combiné Bi-Arbres Rades C 1 X 450MW: Specification For FinalDocument7 pagesCentrale À Cycle Combiné Bi-Arbres Rades C 1 X 450MW: Specification For FinalHaythem Ben ZidNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- 29.3 - A33760US-01-VDS - Rev 1Document3 pages29.3 - A33760US-01-VDS - Rev 1manuelarranoNo ratings yet

- FISHERDocument3 pagesFISHERPower Booster Sdn BhdNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- 3c SynopsisDocument2 pages3c SynopsisCharlie MendozaNo ratings yet

- Gagemaker Tdwin Taper Sample ReportsDocument3 pagesGagemaker Tdwin Taper Sample ReportsRosendo Rizo100% (1)

- QC Form 5Document2 pagesQC Form 5rashid ahmadiNo ratings yet

- Pipe Finished Painting: Site Inspection & Test ReportDocument2 pagesPipe Finished Painting: Site Inspection & Test ReporteliiiiiiNo ratings yet

- E 001B1 MotorDocument2 pagesE 001B1 MotorBhihi RajaNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- QC Form 4Document2 pagesQC Form 4rashid ahmadiNo ratings yet

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- CPF2-PAUT-2023-636-20'' CO Header From 1st Stage Separator Skid (SK-21740) To Oil-Oil HE Inlet HeaderDocument199 pagesCPF2-PAUT-2023-636-20'' CO Header From 1st Stage Separator Skid (SK-21740) To Oil-Oil HE Inlet HeaderVignesh PanchabakesanNo ratings yet

- Untitled. - Complete PDFDocument5 pagesUntitled. - Complete PDFDrMahmoud AbbasNo ratings yet

- Idabb PSSS: Inspection and Test Record 1WATPSF0-019 Diesel Generators 1Document2 pagesIdabb PSSS: Inspection and Test Record 1WATPSF0-019 Diesel Generators 1nana arya sumardjaNo ratings yet

- QC Form 3Document4 pagesQC Form 3rashid ahmadiNo ratings yet

- Rfi Request FormDocument1 pageRfi Request Formvishnu300022No ratings yet

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarNo ratings yet

- SA MP LE: Company NameDocument4 pagesSA MP LE: Company NameAnonymous P8XHEXyIZLNo ratings yet

- Tndt-frm-ndt-007 Magnetic Particle Inspection ReportDocument2 pagesTndt-frm-ndt-007 Magnetic Particle Inspection ReportKhalid Hidayatullah100% (1)

- Inspection DishendDocument5 pagesInspection DishendVarun MalhotraNo ratings yet

- Pipe Sandblasting &: Priming Inspection Report Qa/Qc FormDocument4 pagesPipe Sandblasting &: Priming Inspection Report Qa/Qc FormeliiiiiiNo ratings yet

- IMIR - 107 of Rectangle Hollow Section For Group IIDocument1 pageIMIR - 107 of Rectangle Hollow Section For Group IIFredin FrancisNo ratings yet

- Material Testing Consignment NoteDocument1 pageMaterial Testing Consignment NoteSymoky SymokyNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- QC Form 6Document1 pageQC Form 6rashid ahmadiNo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- CPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Document14 pagesCPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Vignesh PanchabakesanNo ratings yet

- FESR - Field Engineer Service Report v-2Document1 pageFESR - Field Engineer Service Report v-2suryadtp suryadtpNo ratings yet

- Report of Wet Fluorescent Magnatic Particle Test of Weld JointDocument1 pageReport of Wet Fluorescent Magnatic Particle Test of Weld Jointkevin desaiNo ratings yet

- Prathna Alloys WC6 Page-2Document1 pagePrathna Alloys WC6 Page-2Kishan ChauhanNo ratings yet

- IECEx MSC 20.0002 00-SignedDocument7 pagesIECEx MSC 20.0002 00-Signedwaylon simsNo ratings yet

- APCD 55abcDocument2 pagesAPCD 55abcscribd_anjirNo ratings yet

- China Civil Engineering Construction Corperation Form: RQC-UTDocument1 pageChina Civil Engineering Construction Corperation Form: RQC-UTMakamu Max Las MokgaoganyiNo ratings yet

- RFQ End e 24 9508 B1Document1 pageRFQ End e 24 9508 B1mlcfceloobooNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- Condition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)Document4 pagesCondition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)ahmat ramadani100% (1)

- Surge ArresterDocument3 pagesSurge Arresterوليد موسىNo ratings yet

- RADES-56-GCD-MC-TS-MTT-3003 - REV. 0 - Painting SpecificationsDocument14 pagesRADES-56-GCD-MC-TS-MTT-3003 - REV. 0 - Painting SpecificationsHaythem Ben ZidNo ratings yet

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaNo ratings yet

- GPM NotificationDocument4 pagesGPM NotificationAffan QureshiNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- Specification For Limit SwitchesDocument2 pagesSpecification For Limit SwitchesHarish GundaNo ratings yet

- 4 RFQ - DSPM000576Document6 pages4 RFQ - DSPM000576GigiNo ratings yet

- SECL-CV240-A4 Post-Pouring InspectionDocument1 pageSECL-CV240-A4 Post-Pouring InspectionhadefNo ratings yet

- MDSReport 6799005210A4Document3 pagesMDSReport 6799005210A4abinayaNo ratings yet

- Hydrostatic - Pneumatic Test Inspection ReportDocument1 pageHydrostatic - Pneumatic Test Inspection ReportGabriel GabeNo ratings yet

- Liquid Penetrant Test Report: JBM-GA-MMX-08-01, REV. 01 1008.01/03/19-20Document12 pagesLiquid Penetrant Test Report: JBM-GA-MMX-08-01, REV. 01 1008.01/03/19-20virajNo ratings yet

- TMA-M-02 Winch Request Form Rev.1 (ENG)Document2 pagesTMA-M-02 Winch Request Form Rev.1 (ENG)RICARDO VILLAMIZARNo ratings yet

- 23-01-24. Comp MTA 6 Plant SignDocument4 pages23-01-24. Comp MTA 6 Plant Signwahyudi140417No ratings yet

- Checklist SkkpiDocument27 pagesChecklist SkkpiarisNo ratings yet

- Format: Proforma For Submission of Monthly Environmental Data (For Coal/Lignite Thermal Power Plants)Document4 pagesFormat: Proforma For Submission of Monthly Environmental Data (For Coal/Lignite Thermal Power Plants)owngauravNo ratings yet

- 1 MR Garg Final Presentation For Cfp-Workshop-2017Document19 pages1 MR Garg Final Presentation For Cfp-Workshop-2017owngauravNo ratings yet

- Using Iso 9001 To Improve Sales Operation Performance: A Case Study of Implementationf ISO 9001Document7 pagesUsing Iso 9001 To Improve Sales Operation Performance: A Case Study of Implementationf ISO 9001owngauravNo ratings yet

- 1607278664goagro 20190401 Mosl Ic PG038 PDFDocument38 pages1607278664goagro 20190401 Mosl Ic PG038 PDFFocused EquityNo ratings yet

- Cargill Feed Safety and RegulatoryDocument19 pagesCargill Feed Safety and RegulatoryowngauravNo ratings yet

- 1 MR Garg Final Presentation For Cfp-Workshop-2017Document19 pages1 MR Garg Final Presentation For Cfp-Workshop-2017owngauravNo ratings yet

- FGD Dual Alkali Data Sheet FilledDocument5 pagesFGD Dual Alkali Data Sheet FilledowngauravNo ratings yet

- 0 - Cover Page-Index (Section II A)Document3 pages0 - Cover Page-Index (Section II A)owngauravNo ratings yet

- Form 26Document2 pagesForm 26Rohit JainNo ratings yet

- Price Schedule of DeSOx Project ACPPDocument4 pagesPrice Schedule of DeSOx Project ACPPowngauravNo ratings yet

- DynaWave Cement Kilns ApplicationDocument1 pageDynaWave Cement Kilns ApplicationowngauravNo ratings yet

- Latest 185 Guidelines On CEMS 02.08.2017Document100 pagesLatest 185 Guidelines On CEMS 02.08.2017రామకృష్ణ పాశలNo ratings yet

- Energy-from-Waste 2006 Statistics 5th EdDocument232 pagesEnergy-from-Waste 2006 Statistics 5th EdowngauravNo ratings yet

- Howe India Company ProfileDocument62 pagesHowe India Company ProfileowngauravNo ratings yet

- 4.1.3 Properties of Coals PDFDocument7 pages4.1.3 Properties of Coals PDFJaco KotzeNo ratings yet

- 4.1.3 Properties of Coals PDFDocument7 pages4.1.3 Properties of Coals PDFJaco KotzeNo ratings yet

- Sparepart ManualDocument364 pagesSparepart ManualEkoNo ratings yet

- 0700P - CompleteFittingsTubing - ParkerDocument60 pages0700P - CompleteFittingsTubing - ParkerJuanPabloBerarducciNo ratings yet

- Column Pipes Broacher English FinalDocument4 pagesColumn Pipes Broacher English FinalBuli VaiNo ratings yet

- Cast Cat 2013Document360 pagesCast Cat 2013megatornadoNo ratings yet

- Post Installation - Troubleshooting GuideDocument18 pagesPost Installation - Troubleshooting GuideandywanderNo ratings yet

- Acoples/Fittings Kq2Document57 pagesAcoples/Fittings Kq2Ever RiveraNo ratings yet

- TCR User Manual TCR Part 3 Iss3 15.01.19Document21 pagesTCR User Manual TCR Part 3 Iss3 15.01.19ASEM NjadatNo ratings yet

- JC70DB Draw Works Parts ListDocument22 pagesJC70DB Draw Works Parts ListLakshmi Kishore100% (1)

- JGCP Pms PP 769 SP 0001Document398 pagesJGCP Pms PP 769 SP 0001Ahmed BoraeyNo ratings yet

- IndexDocument47 pagesIndexJuan Carlos RNo ratings yet

- Disc Brake Manual - BHELDocument49 pagesDisc Brake Manual - BHELAnil Kumar Jha100% (1)

- SAES-L-108 Selection of ValvesDocument26 pagesSAES-L-108 Selection of ValvesMohammed HilalNo ratings yet

- 117T6809 Module Specification & Test InstructionDocument30 pages117T6809 Module Specification & Test InstructionRaziel Mini AtksNo ratings yet

- Overview of CPWD Specifications Part-IIDocument65 pagesOverview of CPWD Specifications Part-IINarendra Kumar KumawatNo ratings yet

- Eccentric Reducers: Pumps Pipe FittingsDocument1 pageEccentric Reducers: Pumps Pipe FittingsbdamitaNo ratings yet

- 20090327134609-Meba Steel BrochureDocument4 pages20090327134609-Meba Steel BrochurezhorvatovicNo ratings yet

- Manual On Design Fabrication Erection & Maintenance of Steel PenstockDocument167 pagesManual On Design Fabrication Erection & Maintenance of Steel Penstockrajeevakumar100% (38)

- Charlotte Plastics Tech ManualDocument132 pagesCharlotte Plastics Tech ManualChairul AnwarNo ratings yet

- +GF+ BS en 10242Document45 pages+GF+ BS en 10242stignz100% (2)

- Common Tube Fitting Mistakes Ebook - SSPDocument11 pagesCommon Tube Fitting Mistakes Ebook - SSPAASHIESH PENDSAYNo ratings yet

- 107-b00 - Manual OperacionDocument12 pages107-b00 - Manual OperacionJuan David Triana SalazarNo ratings yet

- S-420i Mechanical Unit Maintenance (B-80505EN - 06)Document212 pagesS-420i Mechanical Unit Maintenance (B-80505EN - 06)Damian Dusiński100% (4)

- Catalog K L Jack AsstDocument44 pagesCatalog K L Jack AsstBillNo ratings yet

- PGRAL-100-ET-C-007 - B - PIPING CLASS - A3 - ASME 150lb PDFDocument7 pagesPGRAL-100-ET-C-007 - B - PIPING CLASS - A3 - ASME 150lb PDFcasandraNo ratings yet

- OSTP Product Catalogue All Fitings 2014 Rev0818Document88 pagesOSTP Product Catalogue All Fitings 2014 Rev0818rock starNo ratings yet

- NPCP Chapter 7Document4 pagesNPCP Chapter 7Cristian OmacNo ratings yet

- Cosasco Niple de InyecciónDocument2 pagesCosasco Niple de InyecciónFrancisco VillaNo ratings yet

- Storage and Handling of Anhydrous Ammonia. - 1910.111 - Occupational Safety and Health AdministrationDocument20 pagesStorage and Handling of Anhydrous Ammonia. - 1910.111 - Occupational Safety and Health AdministrationkaybeeNo ratings yet

- Plumbing EstimateDocument3 pagesPlumbing Estimatepapa oforiNo ratings yet

- DESMI Self-Priming Centrifugal Pump Operation and Maintenance InstructionDocument20 pagesDESMI Self-Priming Centrifugal Pump Operation and Maintenance InstructiontalabizNo ratings yet