Professional Documents

Culture Documents

APCD 55abc

Uploaded by

scribd_anjirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APCD 55abc

Uploaded by

scribd_anjirCopyright:

Available Formats

1 SAN DIEGO AIR POLLUTION CONTROL DISTRICT

2

SUPPLEMENTAL APPLICATION

INFORMATION San Diego APCD Use Only

FEE SCHEDULE Appl. No.:

55 A, B, C ID No.:

DECORATIVE/HARD CHROME PLATING

and

CHROMIC ACID ANODIZING EQUIPMENT

• Attach a Material Safety Data Sheet or a manufacturer’s specification data sheet for each chrome plating solution

and anti-mist additive used.

• If an emission control system is installed, provide a description on a separate sheet which includes the

manufacturer, model, removal efficiency of the equipment, analysis of the basis of the reported removal

efficiency, and copies of any source test data performed on the equipment.

• Please type or print the information requested below.

1Company Name:

2Equipment Address:

3A. EQUIPMENT DESCRIPTION:

4Total number of decorative chrome plating tanks:

5Total number of chrome plating tanks used simultaneously:

6Plating room dimensions: L x W x H.

7Dimensions and operating temperature of each tank:

Tank No. 1 Tank No. 2 Tank No. 3

Length feet Length feet Length feet

Width feet Width feet Width feet

Depth feet Depth feet Depth feet

(inside dimensions) (inside dimensions) (inside dimensions)

Bath Temp. oF Bath Temp. oF Bath Temp. oF

Electric Current Usage: Electric Current Usage: Electric Current Usage:

Min.: Amperes Min.: Amperes Min.: Amperes

Ave.: Amperes Ave.: Amperes Ave.: Amperes

Max.: Amperes Max.: Amperes Max.: Amperes

8B. PROCESS DESCRIPTION:

9Description of Articles Plated:

10

11

12Plating bath agitation? Yes No If yes, type

(Description: air, etc.)

13C. OPERATING SCHEDULE:

14Days equipment is used per week : Su M Tu W Th F S

(check one or more boxes)

15Number of weeks equipment is used per year weeks

16Workload variation by calendar quarter (should total 100%)

3Rev. 4/03 1 of 2 (55A,B,C) OVER

4

17 I. % II. % III. % IV. %

18D. CONTROL EQUIPMENT DESCRIPTION

19Ventilation System

20i. Is plating system equipped with an Emissions Collection System? Yes No

21If yes, please describe

22

23

24ii. Exhaust volumetric flow rate actual cubic ft/min. (if applicable)

25Emissions Control System

26Is ventilation system equipped with an Emissions Control System? Yes No

27Mist Suppressants and Anti-Mist Additives

28i. Is/are tank(s) equipped with Mist Suppressant System? Yes No

29If yes, please describe (include make/model)

30

31

32ii. Is/are District approved Anti-Mist Additive(s) used in the bath? Yes No

33If yes, please describe (include manufacturer/brand name)

34

35

36E. LOCATION BASE MAP

37Attach a location base map, to include the following:

38 • Length, width, and height of building

39 • Length, width, and height of nearby buildings that have a higher vertical profile

40 • Distance from source to nearest offsite boundary

41 • Distance from source to nearby residential and occupational areas (if any)

42Name of Preparer: Title:

43Phone No.: ( ) Date:

NOTE TO APPLICANT:

Before acting on an application for Authority to Construct or Permit to Operate, the District may require further

information, plans, or specifications. Forms with insufficient information may be returned to the applicant for

completion, which will cause a delay in application processing and may increase processing fees. The applicant

should correspond with equipment and material manufacturers to obtain the information requested on this

supplemental form.

5 2 of 2 (55A,B,C)

You might also like

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- CCAC Installation Checklist Page 2Document1 pageCCAC Installation Checklist Page 2Nova CastyNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Draft ABT Spec With TOD & Billing DataDocument51 pagesDraft ABT Spec With TOD & Billing DataSristi MitraNo ratings yet

- Hisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgDocument34 pagesHisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgRajesh SoniNo ratings yet

- Pipeline Survey Questionnaire: Tuboscope Job NumberDocument3 pagesPipeline Survey Questionnaire: Tuboscope Job NumberAnonymous bQsPAALIR6No ratings yet

- Wet Scrubber 21 Info Data SheetDocument2 pagesWet Scrubber 21 Info Data SheetRoberto De RosaNo ratings yet

- CB Testing and Commissioning 76-92Document17 pagesCB Testing and Commissioning 76-92Vijaya KumarNo ratings yet

- CB Testing and Commissioning 76-92 PDFDocument17 pagesCB Testing and Commissioning 76-92 PDFVijaya Kumar100% (2)

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarNo ratings yet

- Paut-Specific Exam Paut SP002Document8 pagesPaut-Specific Exam Paut SP002Tuan Pham Minh82% (11)

- Tech Specs of ABT Meter 25 11 20111Document50 pagesTech Specs of ABT Meter 25 11 20111Ramdas TaloleNo ratings yet

- PFMEA at Wave Soldering-21 Dec 2016Document50 pagesPFMEA at Wave Soldering-21 Dec 2016arum100% (1)

- Getco - r1 Al59 Zebra & MooseDocument27 pagesGetco - r1 Al59 Zebra & Mooseakib javed100% (1)

- TOFD Procedure For VesselDocument12 pagesTOFD Procedure For Vesselmohanraj67% (3)

- 113 83 PFX Troubleshooting DataSheetDocument1 page113 83 PFX Troubleshooting DataSheetJARABA - Jean Luis ReyesNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Prosper® Tutorial 09: Modelling A Water Injection WellDocument49 pagesProsper® Tutorial 09: Modelling A Water Injection WellPedro MarquezNo ratings yet

- Manual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateDocument5 pagesManual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateMohamed IbrahimNo ratings yet

- Electromagnetic Inspection SOPDocument12 pagesElectromagnetic Inspection SOPAsrNo ratings yet

- 7tech Spec ABT As On 12.01.2021 1 PDFDocument59 pages7tech Spec ABT As On 12.01.2021 1 PDFashish kumarNo ratings yet

- 05 Process Datasheet Annexure-PDocument1 page05 Process Datasheet Annexure-PpdilgnfcNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection & Verification of MPT Equipment & Materials SAIC-MPT-2003 3-Jul-18 NdeDocument6 pagesSaudi Aramco Inspection Checklist: Inspection & Verification of MPT Equipment & Materials SAIC-MPT-2003 3-Jul-18 Ndekarthi51289No ratings yet

- PH and Turbidity Transmitter NewDocument5 pagesPH and Turbidity Transmitter NewLaica DelacionNo ratings yet

- Prosper® Tutorial 03: Modelling An Oil Well With Black Oil PVT MatchingDocument62 pagesProsper® Tutorial 03: Modelling An Oil Well With Black Oil PVT MatchingPedro MarquezNo ratings yet

- P&IDDocument23 pagesP&IDmagarciaprieto100% (2)

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- 0040 10 - R1Document39 pages0040 10 - R1tinhNo ratings yet

- Iterview Questions For Design CompanyDocument8 pagesIterview Questions For Design Companyarchanakalyan100% (2)

- What To Do If A Drill String Failure OccursDocument5 pagesWhat To Do If A Drill String Failure Occursislam atifNo ratings yet

- Sationary Equipment InstallationDocument7 pagesSationary Equipment Installationsaif aliNo ratings yet

- Basics of High-Pressure Measuring and Regulating Station DesignDocument8 pagesBasics of High-Pressure Measuring and Regulating Station DesignMelina SbhNo ratings yet

- Section 018923 Site ACMV Utilities Performance RequirementsDocument9 pagesSection 018923 Site ACMV Utilities Performance Requirements刘盘石No ratings yet

- PO1660 (Oil Filtration)Document68 pagesPO1660 (Oil Filtration)anuragpugaliaNo ratings yet

- Switch Gears 134-149Document16 pagesSwitch Gears 134-149Vijaya KumarNo ratings yet

- Section 018919 Site Plumbing Utilities Performance RequirementDocument10 pagesSection 018919 Site Plumbing Utilities Performance Requirement刘盘石No ratings yet

- Commisioning Report-Dx/Package: Project Villa No. & Type Location Report Date Customer Comm. DateDocument1 pageCommisioning Report-Dx/Package: Project Villa No. & Type Location Report Date Customer Comm. DateMohammed JavidNo ratings yet

- Formwork Reinforcement PDFDocument120 pagesFormwork Reinforcement PDFdrpNo ratings yet

- Hydraulic CalDocument22 pagesHydraulic CalSam Hitchens LesenyamotseNo ratings yet

- Well Testing Procedure ExampleDocument15 pagesWell Testing Procedure ExampleMohamed MamdouhNo ratings yet

- Draft 244 Tune Up - Maintenance & Diagnostic CHDocument4 pagesDraft 244 Tune Up - Maintenance & Diagnostic CHMichael DavisNo ratings yet

- Checklist For VRF InstallationDocument14 pagesChecklist For VRF InstallationblahblahNo ratings yet

- 100 PSV 001 AZ Safety Pressure Valve (Design)Document2 pages100 PSV 001 AZ Safety Pressure Valve (Design)magdy salehNo ratings yet

- Cathodic Protection System MMO Grid of Tank Quality Control and Inspection Report FormDocument5 pagesCathodic Protection System MMO Grid of Tank Quality Control and Inspection Report Formjamal2877No ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (1)

- BSEE Production Inspection HandbookDocument71 pagesBSEE Production Inspection HandbookStephanie Burns AyersNo ratings yet

- Kind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hr Softening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Document6 pagesKind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hr Softening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Raol VarshabenNo ratings yet

- Annex 1 Legal Compliance Evaluation SheetDocument130 pagesAnnex 1 Legal Compliance Evaluation SheetChaitanya VamsiNo ratings yet

- Ce - FL - Dealer Resources - Documents - 20180717 - Carrier Bryant Midea VRF Installation Checklist v1Document11 pagesCe - FL - Dealer Resources - Documents - 20180717 - Carrier Bryant Midea VRF Installation Checklist v1mikeNo ratings yet

- Ceiling Fan Laboratory Guidance ManualDocument35 pagesCeiling Fan Laboratory Guidance ManualSsdssddNo ratings yet

- Audit ReportDocument9 pagesAudit ReportVIVEK100% (1)

- BHS-TEPC-SIEVERT-ACFM-2022-001-Rev.01 - ACFM Inspection (Hassyan Power Plant)Document11 pagesBHS-TEPC-SIEVERT-ACFM-2022-001-Rev.01 - ACFM Inspection (Hassyan Power Plant)Saddam HossainNo ratings yet

- Final Wellhead ReportDocument53 pagesFinal Wellhead ReportAli BoubeniaNo ratings yet

- Wind Monitor Series: Product ManualDocument32 pagesWind Monitor Series: Product Manualm89624888No ratings yet

- Sprinkler System Test QCDD FormDocument2 pagesSprinkler System Test QCDD FormMahmoud HassanNo ratings yet

- Maint. SchedulesDocument109 pagesMaint. SchedulesShahriyar Kabir RistaNo ratings yet

- 12.2 Installation Qualification Protocol For Laminar Air Flow UnitDocument10 pages12.2 Installation Qualification Protocol For Laminar Air Flow UnituzairNo ratings yet

- m25 Silencers and Spark Arresters CleanDocument24 pagesm25 Silencers and Spark Arresters CleanKosol KosolkijwongNo ratings yet

- 1 s2.0 S0921509316313041 MainDocument11 pages1 s2.0 S0921509316313041 Mainscribd_anjirNo ratings yet

- 1 s2.0 S0924013617300511 MainDocument8 pages1 s2.0 S0924013617300511 Mainscribd_anjirNo ratings yet

- DFW Paper XalmDocument4 pagesDFW Paper XalmXiomara LópezNo ratings yet

- Riview HVOFDocument4 pagesRiview HVOFscribd_anjirNo ratings yet

- HFOVDocument9 pagesHFOVscribd_anjirNo ratings yet

- Maintenance and Repair Welding On Board (UNITOR)Document1 pageMaintenance and Repair Welding On Board (UNITOR)jok1974100% (1)

- Operating and Maintaining Underground Storage Tank Systems: UPDATED 2016Document59 pagesOperating and Maintaining Underground Storage Tank Systems: UPDATED 2016scribd_anjirNo ratings yet

- Carbohydrates StainsDocument43 pagesCarbohydrates StainssupahvyNo ratings yet

- Chrysler CDS System - Bulletin2Document6 pagesChrysler CDS System - Bulletin2Martin Boiani100% (1)

- God Reproducing Himself in UsDocument6 pagesGod Reproducing Himself in UsLisa100% (1)

- ASTR 323 Homework 4Document2 pagesASTR 323 Homework 4Andrew IvanovNo ratings yet

- The Philippine GovernmentDocument21 pagesThe Philippine GovernmentChristel ChuchipNo ratings yet

- Industrial Motor Control Part IDocument38 pagesIndustrial Motor Control Part Ikibrom atsbha100% (2)

- MCFKTP G3 S2 SC Number Pattern PuzzlesDocument5 pagesMCFKTP G3 S2 SC Number Pattern PuzzlesEric GoNo ratings yet

- Operation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDDocument70 pagesOperation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDManuel ParreñoNo ratings yet

- Arc Hydro - Identifying and Managing SinksDocument35 pagesArc Hydro - Identifying and Managing SinkskbalNo ratings yet

- AN44061A Panasonic Electronic Components Product DetailsDocument3 pagesAN44061A Panasonic Electronic Components Product DetailsAdam StariusNo ratings yet

- Project Report For Tunnel ExcavationDocument19 pagesProject Report For Tunnel ExcavationAbhishek Sarkar50% (2)

- Banin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahDocument4 pagesBanin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahKajen PatiNo ratings yet

- Nails Care: Word Search: Name: - DateDocument1 pageNails Care: Word Search: Name: - DateDeverly Hernandez Balba-AmplayoNo ratings yet

- Te-Chemical Sem5 CPNM-CBCGS Dec19Document2 pagesTe-Chemical Sem5 CPNM-CBCGS Dec19Mayank ShelarNo ratings yet

- PV Power To Methane: Draft Assignment 2Document13 pagesPV Power To Methane: Draft Assignment 2Ardiansyah ARNo ratings yet

- Aircraft Flight Control SystemDocument25 pagesAircraft Flight Control Systemthilina jayasooriyaNo ratings yet

- Richardson ResumeDocument3 pagesRichardson Resumeapi-549248694No ratings yet

- Midterm ReviewerDocument20 pagesMidterm ReviewerJonnafe IgnacioNo ratings yet

- Lecture 7 - Friction - NptelDocument18 pagesLecture 7 - Friction - Nptels_murugan02No ratings yet

- Monster Hunter: World - Canteen IngredientsDocument5 pagesMonster Hunter: World - Canteen IngredientsSong HoeNo ratings yet

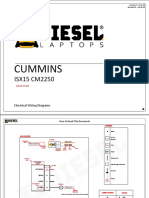

- Cummins: ISX15 CM2250Document17 pagesCummins: ISX15 CM2250haroun100% (4)

- Case Study McsDocument4 pagesCase Study McsManjushree PatilNo ratings yet

- Aman Singh Rathore Prelms Strategy For UPSCDocument26 pagesAman Singh Rathore Prelms Strategy For UPSCNanju NNo ratings yet

- Reinforced Concrete Design PDFDocument1 pageReinforced Concrete Design PDFhallelNo ratings yet

- What Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?Document11 pagesWhat Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?MOHAMED ABD ELGHANYNo ratings yet

- DC Generator - Construction, Working Principle, Types, and Applications PDFDocument1 pageDC Generator - Construction, Working Principle, Types, and Applications PDFGokul GokulNo ratings yet

- Macros and DirectiveDocument7 pagesMacros and DirectiveAbdul MoeedNo ratings yet

- Class 1 KeyDocument3 pagesClass 1 Keyshivamsingh.fscNo ratings yet

- Abdominal Migraine and HomoeopathyDocument17 pagesAbdominal Migraine and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNo ratings yet

- 2017LR72 - SUMMARY REPORT Final 03052020Document72 pages2017LR72 - SUMMARY REPORT Final 03052020Dung PhamNo ratings yet