Professional Documents

Culture Documents

23-01-24. Comp MTA 6 Plant Sign

Uploaded by

wahyudi140417Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23-01-24. Comp MTA 6 Plant Sign

Uploaded by

wahyudi140417Copyright:

Available Formats

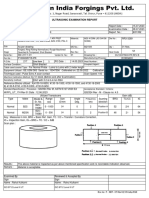

LIQUID PENETRANT EXAMINATION REPORT

USER : PT. PERTAMINA SUBJECT : Comp MTA 6 Project

REQUEST BY : QC ITEM NO. :-

W/O NO. :- SERIAL NO. :-

COST CENTRE :- MATERIAL :

CONTRACT NO. : TEMPERATURE : Ambient

JOB LOCATION : Mta 6 Plant PROCEDURE NO. : PO/AE.MIG-OPS/35

DRAWING NO. : MTA-M-51D-7357 2 of 2 CRITERION : Ansi B 31.3

DATE OF INSP : January 23' 2024 REPORT NO. : /PT-SCI/MTA/Krs/ I /2024

SHEET NO. : 1 of 2

As Welded As Rolled As Forged As Cast

Surface Preparation

Grinding Machining Wire Brushed

Before PWHT Before Hydrostatic Test

Stage of Examination

After PWHT After Hydrastatic Test

Technique Color Contrast Fluorescent

Solvent Removal Water Washable

Type

Post Emulsified

Penetrant Application Spraying Brushing

Material Trade Name Dwell Times

: : 10 minutes

Cleaner Magnaflux SKC-S Penetrant

Penetrant : Magnaflux SKL-SP-1 Developer : 10 minutes

Developer : Magnaflux SKD-S2

Backlight Intensity : uW / CM2

Size (mm) Results

Joint No.

Identification No. Welder

or Part Ind.No.

(ISO Dwg No.) Stamp Round Linear ACC REJ

No.

MTA-M-51D-7357 2 of 2 1 1/2" FW 2 K 105 - - ACC

Comp Mta 6 Project

Interpreted by, Reviewed by, Reviewed by, Reviewed /Approved by

Eddy Agus Wahyudi Hadi S Frans E.Ginting

NDE Level II Client Representative

FOR/SMR.AE.MIG/010 Rev.00 Tgl. Berlaku: 01/08/2019 Hal….. dari …..

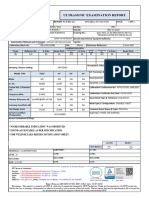

LIQUID PENETRANT EXAMINATION REPORT

USER : PT. PERTAMINA SUBJECT : Comp MTA 6 Project

REQUEST BY : QC ITEM NO. :-

W/O NO. :- SERIAL NO. :-

COST CENTRE :- MATERIAL :

CONTRACT NO. : TEMPERATURE : Ambient

JOB LOCATION : Mta 6 Plant PROCEDURE NO. : PO/AE.MIG-OPS/35

DRAWING NO. : MTA-M-51D-7357 1 of 2 CRITERION : Ansi B 31.3

DATE OF INSP : January 23' 2024 REPORT NO. : /PT-SCI/MTA/Krs/ I /2024

SHEET NO. : 1 of 2

As Welded As Rolled As Forged As Cast

Surface Preparation

Grinding Machining Wire Brushed

Before PWHT Before Hydrostatic Test

Stage of Examination

After PWHT After Hydrastatic Test

Technique Color Contrast Fluorescent

Solvent Removal Water Washable

Type

Post Emulsified

Penetrant Application Spraying Brushing

Material Trade Name Dwell Times

: : 10 minutes

Cleaner Magnaflux SKC-S Penetrant

Penetrant : Magnaflux SKL-SP-1 Developer : 10 minutes

Developer : Magnaflux SKD-S2

Backlight Intensity : uW / CM2

Size (mm) Results

Joint No.

Identification No. Welder

or Part Ind.No.

(ISO Dwg No.) Stamp Round Linear ACC REJ

No.

MTA-M-51D-7357 1 of 2 1 1/2" FW 1 K 105 - - ACC

Comp Mta 6 Project FW 1A K 105 - - ACC

FW 1B K 105 - - ACC

FW 1C K 105 - - ACC

FW 2 K 105 - - ACC

FW 2A K 105 - - ACC

FW 2B K 105 - - ACC

FW 3 K 105 - - ACC

FW 4 K 105 - - ACC

FW 5 k 105 - - ACC

FW 6 k 105 - - ACC

Interpreted by, Reviewed by, Reviewed by, Reviewed /Approved by

Eddy Agus Wahyudi Hadi S Frans E.Ginting

NDE Level II Client Representative

FOR/SMR.AE.MIG/010 Rev.00 Tgl. Berlaku: 01/08/2019 Hal….. dari …..

LIQUID PENETRANT EXAMINATION REPORT

USER : PT. PERTAMINA SUBJECT : Comp MTA 6 Project

REQUEST BY : QC ITEM NO. :-

W/O NO. :- SERIAL NO. :-

COST CENTRE :- MATERIAL :

CONTRACT NO. : TEMPERATURE : Ambient

JOB LOCATION : Mta 6 Plant PROCEDURE NO. : PO/AE.MIG-OPS/35

DRAWING NO. : MTA-M-51D-7350 CRITERION : Ansi B 31.3

DATE OF INSP : January 23' 2024 REPORT NO. : /PT-SCI/MTA/Krs/ I /2024

SHEET NO. : 1 of 2

As Welded As Rolled As Forged As Cast

Surface Preparation

Grinding Machining Wire Brushed

Before PWHT Before Hydrostatic Test

Stage of Examination

After PWHT After Hydrastatic Test

Technique Color Contrast Fluorescent

Solvent Removal Water Washable

Type

Post Emulsified

Penetrant Application Spraying Brushing

Material Trade Name Dwell Times

: : 10 minutes

Cleaner Magnaflux SKC-S Penetrant

Penetrant : Magnaflux SKL-SP-1 Developer : 10 minutes

Developer : Magnaflux SKD-S2

Backlight Intensity : uW / CM2

Size (mm) Results

Joint No.

Identification No. Welder

or Part Ind.No.

(ISO Dwg No.) Stamp Round Linear ACC REJ

No.

MTA-M-51D-7350 1" FW 15 K 99 - - ACC

Comp Mta 6 Project FW 16 K 99 - - ACC

Interpreted by, Reviewed by, Reviewed by, Reviewed /Approved by

Eddy Agus Wahyudi Hadi S Frans E.Ginting

NDE Level II Client Representative

FOR/SMR.AE.MIG/010 Rev.00 Tgl. Berlaku: 01/08/2019 Hal….. dari …..

LIQUID PENETRANT EXAMINATION REPORT

USER : PT. PERTAMINA SUBJECT : Comp MTA 6 Project

REQUEST BY : QC ITEM NO. :-

W/O NO. :- SERIAL NO. :-

COST CENTRE :- MATERIAL :

CONTRACT NO. : TEMPERATURE : Ambient

JOB LOCATION : Mta 6 Plant PROCEDURE NO. : PO/AE.MIG-OPS/35

DRAWING NO. : MTA-M-51D-7296 CRITERION : Ansi B 31.3

DATE OF INSP : January 23' 2024 REPORT NO. : /PT-SCI/MTA/Krs/ I /2024

SHEET NO. : 1 of 2

As Welded As Rolled As Forged As Cast

Surface Preparation

Grinding Machining Wire Brushed

Before PWHT Before Hydrostatic Test

Stage of Examination

After PWHT After Hydrastatic Test

Technique Color Contrast Fluorescent

Solvent Removal Water Washable

Type

Post Emulsified

Penetrant Application Spraying Brushing

Material Trade Name Dwell Times

: : 10 minutes

Cleaner Magnaflux SKC-S Penetrant

Penetrant : Magnaflux SKL-SP-1 Developer : 10 minutes

Developer : Magnaflux SKD-S2

Backlight Intensity : uW / CM2

Size (mm) Results

Joint No.

Identification No. Welder

or Part Ind.No.

(ISO Dwg No.) Stamp Round Linear ACC REJ

No.

MTA-M-51D-7296 2 of 2 1/2" FW 3A K 111 - - ACC

Comp Mta 6 Project FW 3B K 111 - - ACC

Interpreted by, Reviewed by, Reviewed by, Reviewed /Approved by

Eddy Agus Wahyudi Hadi S Frans E.Ginting

NDE Level II Client Representative

FOR/SMR.AE.MIG/010 Rev.00 Tgl. Berlaku: 01/08/2019 Hal….. dari …..

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Corporate Digital LibraryDocument14 pagesCorporate Digital LibraryAnand86% (7)

- Liquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Document4 pagesLiquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Riesky FirdyanNo ratings yet

- D.P. Test ReportDocument1 pageD.P. Test Reportvirendra katkeNo ratings yet

- MIl W 8611.PDF Rev ADocument10 pagesMIl W 8611.PDF Rev ABryan MartinezNo ratings yet

- Four M's Manpower Method Machine MaterialsDocument3 pagesFour M's Manpower Method Machine MaterialsYancie Siaboc100% (6)

- Project List Steel PlantsDocument33 pagesProject List Steel PlantsRoch battousaiNo ratings yet

- BPMS DeckDocument57 pagesBPMS DeckArun ParthasarathyNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- DPT of PropellerDocument3 pagesDPT of Propellersushanto.mtbdNo ratings yet

- Datasheet of Temperature Gauge - 240321Document6 pagesDatasheet of Temperature Gauge - 240321Nikhil KarkeraNo ratings yet

- Dye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuDocument4 pagesDye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuTWI CertificationNo ratings yet

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Document5 pagesIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- Manufacturing Excellence: Excellence, Then, Is Not An Act But A HabitDocument61 pagesManufacturing Excellence: Excellence, Then, Is Not An Act But A HabitVishnu ReddyNo ratings yet

- TQM - Continuous Process ImprovementDocument37 pagesTQM - Continuous Process ImprovementRitik kumar ChourasiyaNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Quality-Requirements-for-Suppliers REV1 Nov2022 v6 Stellantis HarmonizedDocument34 pagesQuality-Requirements-for-Suppliers REV1 Nov2022 v6 Stellantis HarmonizedRoberto S. Inagaki100% (2)

- Implementation Guide For An ISO 55001 Asset Management SystemDocument176 pagesImplementation Guide For An ISO 55001 Asset Management SystemClaudio100% (4)

- Kamlesh Kumar Singh Engineers Pvt. LTDDocument24 pagesKamlesh Kumar Singh Engineers Pvt. LTDAADARSHNo ratings yet

- The Future of Blockchain in Asia Pacific Codex3240 PDFDocument28 pagesThe Future of Blockchain in Asia Pacific Codex3240 PDFEng Eman HannounNo ratings yet

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- Marketing in Digital AgeDocument7 pagesMarketing in Digital AgeLakshya GUptaNo ratings yet

- Quality Assurance QuestionnaireDocument5 pagesQuality Assurance QuestionnaireAbdelkader FattoucheNo ratings yet

- 08-03-24. Water Injection Pump SambojaDocument1 page08-03-24. Water Injection Pump Sambojawahyudi140417No ratings yet

- Liquid PenetrantDocument2 pagesLiquid PenetrantabdiNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- Int Aim 231787 PT 14 1302&03Document1 pageInt Aim 231787 PT 14 1302&03Joshua ClaytonNo ratings yet

- Penetrant Test Report: PT DegremontDocument14 pagesPenetrant Test Report: PT DegremontMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 18-12-23. Gaslift Skid MTA M-23Document4 pages18-12-23. Gaslift Skid MTA M-23Ferdie OSNo ratings yet

- Tndt-frm-ndt-007 Magnetic Particle Inspection ReportDocument2 pagesTndt-frm-ndt-007 Magnetic Particle Inspection ReportKhalid Hidayatullah100% (1)

- Coupler Plate DP TestDocument1 pageCoupler Plate DP Testshindemitesh17No ratings yet

- YS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Document4 pagesYS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Gajendra PatilNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 pagesYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilNo ratings yet

- Liquid Penetrant Test Report: JBM-GA-MMX-08-01, REV. 01 1008.01/03/19-20Document12 pagesLiquid Penetrant Test Report: JBM-GA-MMX-08-01, REV. 01 1008.01/03/19-20virajNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- Hasil Report PT - Intan Giri Abadi IGA 06.06.2023Document6 pagesHasil Report PT - Intan Giri Abadi IGA 06.06.2023Mhd FauziNo ratings yet

- QAR-QD404-1 Liquid Penetrant Testing Report-GeneralDocument1 pageQAR-QD404-1 Liquid Penetrant Testing Report-GeneralIrwanto ManafNo ratings yet

- 518 - Level Switch - Side Mounted - 0Document3 pages518 - Level Switch - Side Mounted - 0Nikhil KarkeraNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Pacific Twelve - LPT - Propeller BladeDocument8 pagesPacific Twelve - LPT - Propeller BladeDolok Joko KenconoNo ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- Dye Penetrant Testing: Surface PreparationDocument2 pagesDye Penetrant Testing: Surface PreparationyuwantoniNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- Inspection Type: Attachmen Photograph: Sketch BlastingDocument8 pagesInspection Type: Attachmen Photograph: Sketch BlastingIndra salehNo ratings yet

- Interloop Satellite Stitching Unit: RecommendationDocument13 pagesInterloop Satellite Stitching Unit: RecommendationFraz AhmadNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- 032 Wire Rope Sling 76.5 TonDocument4 pages032 Wire Rope Sling 76.5 TonHario PramuditoNo ratings yet

- CPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Document14 pagesCPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Vignesh PanchabakesanNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- MT PipaDocument70 pagesMT PipaDani Madrid12No ratings yet

- Reporte Hdpe 2Document2 pagesReporte Hdpe 2Woodrow FoxNo ratings yet

- Liquid Penetrant Examination Report: Asme Sec-Viii 10 Minute Spray 32 CDocument4 pagesLiquid Penetrant Examination Report: Asme Sec-Viii 10 Minute Spray 32 CEngr Saeed AnwarNo ratings yet

- Pallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportDocument1 pagePallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportCharles JacobNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Inspection Report and Leak Test FormatDocument2 pagesInspection Report and Leak Test Formatmujahed_muhammedNo ratings yet

- Pt. Rekayasa Industri: Engineering & ConstructionDocument5 pagesPt. Rekayasa Industri: Engineering & ConstructionandhyirawanNo ratings yet

- Int-Aim-231887 PT 06-15-23Document2 pagesInt-Aim-231887 PT 06-15-23Joshua ClaytonNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- MTPT ReprotDocument3 pagesMTPT Reprotmohd as shahiddin jafriNo ratings yet

- Center Sill 01Document6 pagesCenter Sill 01Bagas Styo Putra PerdanaNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- MRR NO.021 Jetec PO 962922446 PT. Multitek Electrical Pressure Switch PrintDocument3 pagesMRR NO.021 Jetec PO 962922446 PT. Multitek Electrical Pressure Switch PrintSuhendrik Abi NayaNo ratings yet

- DPT Report MBBR U-BDocument15 pagesDPT Report MBBR U-BMuhammad Fitransyah Syamsuar PutraNo ratings yet

- RT ReportDocument4 pagesRT ReportWeldcast Ndt100% (1)

- Sub Y Strainer Apprvd CMNTD 02.02.2019Document1 pageSub Y Strainer Apprvd CMNTD 02.02.2019Gourav SharmaNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Dye Penetrant Test Report: Location: Workshop Pt. Arga Bina GroupDocument6 pagesDye Penetrant Test Report: Location: Workshop Pt. Arga Bina GroupabdiNo ratings yet

- REPORT RT 03 Februari 2024 (SANGA SANGA)Document8 pagesREPORT RT 03 Februari 2024 (SANGA SANGA)wahyudi140417No ratings yet

- Report RT 17 Februari 24 KRS Mta (Tahura)Document13 pagesReport RT 17 Februari 24 KRS Mta (Tahura)wahyudi140417No ratings yet

- Report RT 01 April 24 PR T UnaDocument1 pageReport RT 01 April 24 PR T Unawahyudi140417No ratings yet

- Report RT 08 Maret 24 Rja SambojaDocument4 pagesReport RT 08 Maret 24 Rja Sambojawahyudi140417No ratings yet

- DLP - Final-Demo - Weld DefectsDocument11 pagesDLP - Final-Demo - Weld DefectsTrecita BacoNo ratings yet

- P&GDocument19 pagesP&GVenky PragadaNo ratings yet

- AWS D1.2 at Extent of TestingDocument1 pageAWS D1.2 at Extent of TestingIbrahim shaikNo ratings yet

- 12035PMSP Functional Specification DOA Work Order Approval Rev 1Document18 pages12035PMSP Functional Specification DOA Work Order Approval Rev 1bhupathyraja0% (1)

- Chapter 10 Imc 27.9.21Document37 pagesChapter 10 Imc 27.9.21Chi Linh NguyenNo ratings yet

- ReportDocument19 pagesReportThitinun LekklaNo ratings yet

- We Have Selected Big BazaarDocument20 pagesWe Have Selected Big BazaarMeena TyagiNo ratings yet

- VQCA Guideline For Suppliers Brief SummaryDocument34 pagesVQCA Guideline For Suppliers Brief SummaryYeimy CorredorNo ratings yet

- Internship ReportDocument2 pagesInternship Reportsali0% (1)

- Business Plan For FreshwearDocument4 pagesBusiness Plan For FreshwearUt TAm ThAgunnaNo ratings yet

- Midterm Activity 1: (For Asynchronous) : I. Multiple ChoiceDocument6 pagesMidterm Activity 1: (For Asynchronous) : I. Multiple ChoiceArven FrancoNo ratings yet

- The Times 100 Business Case Studies: Nivea Developing A Marketing PlanDocument9 pagesThe Times 100 Business Case Studies: Nivea Developing A Marketing PlanabdayubNo ratings yet

- 11 - Explain Pricing Under Imperfect CompetitionDocument2 pages11 - Explain Pricing Under Imperfect CompetitionShalini RastogiNo ratings yet

- Shafi BDocument3 pagesShafi BSinan RenjaNo ratings yet

- Table of Content Description Page No 1 DTDC Corporate Introduction 2-7Document65 pagesTable of Content Description Page No 1 DTDC Corporate Introduction 2-7GY PRAJWAL DASNo ratings yet

- A Project Report On Customer Perception Towards Online GroceryDocument52 pagesA Project Report On Customer Perception Towards Online GroceryMuskan GuptaNo ratings yet

- U7 - Lesson 2Document33 pagesU7 - Lesson 2Alejandra HuaytaNo ratings yet

- International Logistics Course OutlineDocument4 pagesInternational Logistics Course OutlinePratikNo ratings yet