Professional Documents

Culture Documents

WMS Painting PDF

Uploaded by

CamlockOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WMS Painting PDF

Uploaded by

CamlockCopyright:

Available Formats

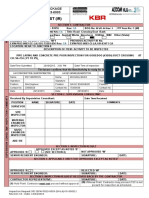

WORK METHOD STATEMENT PAINTING

ORGANISATION DETAILS

Organisation Name: Gedoun Constructions Pty Ltd Contact Name: Joe Gedoun

ACN/ABN: 52 284 873 581 Contact Position: Director

Address: PO Box 1138, Townsville QLD 4810 Contact Phone Number: 0412 968 974

PROJECT DETAILS

Project: Gedoun Construction Sites Project Address: Gedoun Construction Sites

Project No: This WMS has been developed in consultation with: Joe Gedoun

Reviewed by: Stacy Jacobsen

Activity: PAINTING Position: Contract Administrator

Training/Instructions to be Site Induction Training Task Specific Training, Manual Handling Training

provided: OHS Induction Card Training Training Specified in any MSDS

Manual Handling Training Other (Specify): __________________________

Resources/Trades Involved: Qualified Painter and Decorator Engineering Nil

Details/Certificates/EPA/QLD Work

Place Health & Safety Approvals:

Plant/Equipment Used: Powered and manual hand tools, ladders and work Warning Signs and Controls As per Displayed Signage

platforms Measures:

Details of Emergency Procedures: As per Site Safety Plan

Personal Protective High Visibility Clothing and Safety Footwear (Steel Safety Data Sheets Required: NIL

Equipment (PPE) to be used: Capped Boots) are to be worn by ALL worksites. Fire

retardant material long sleeve shirt, trousers, safety

helmet, safety glasses, rescue kit, low voltage insulating

gloves.

WMS: PAINTING Page 1 of 10

WORK METHOD STATEMENT PAINTING

PROJECT DETAILS

Occupational Health Safety • Queensland Acts & Regulations Codes and/or Standards Applicable Building Code of Australia 2010

or Environmental Legislation: • Workplace Health & Safety Act 2011, Workplace to the Works: Queensland & National Codes of

Health & Safety Regulations 2011 Practice:

• Electrical Safety Act 2015, Electrical Safety • Building and Construction 2000

Regulations 2013 Updated 2011

• Building and Construction Industry Improvement • Noise 2004

Acts 2005 • Scaffold 2009

• Electrical 2013

• Manual Tasks 2010

• Plant 2013

• First Aid 2015

• Hazardous Substances 2011

• Prevention of Falls in Housing

Construction 2012

• Construction Work 2013

• Building Code of Australia 2015

• Hazardous Substance Code of

Practice 2003

National Standards:

• Risk Management AS/NZS150

31000:2009

• National Standard for

Construction Work NOSHC:1

016 (2005)

• National Standard for Manual

Tasks 2007

WMS: PAINTING Page 2 of 10

WORK METHOD STATEMENT PAINTING

HIGH RISK ACTIVITY: WORKING ON OR NEAR EXPOSED ENERGISED ELECTRICAL EQUIPMENT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Unloading Hazard: 1 3 3 - Conduct a site-specific risk assessment using a 1 2 2 Painter

Equipment - Manual handling generic checklist and apply controls as necessary

- Confirm workers are properly trained in correct

Risk: bending and lifting techniques

- Impact and crush injuries - Wear PPE of gloves, safety footwear and eyewear

- Cuts and abrasions - Seek assistance. Use another person to assist with

- Lacerations the lift

- Bruising - Use mechanical means to left and move where

- Broken bones needed or available

- Stresses and strains - Have the supplier/principal contractor deliver the

product to the work area to reduce the need for

manual handling

Sanding and Hazard: 4 2 8 - Use dust mask and safety goggles where necessary 1 2 2 Painter

Preparing Surface - Dust from sanding - Sand away from body

for Painting using - Incorrect use of hand tools - Site should be well ventilated. If it is not, then

Hand Tools and respiratory mask should be worn

Hand Sanders Risk: Warning: when sanding MDF a respiratory mask

- Eye irritations and protective clothing should always be worn.

- Impact injuries to hands, MDF dust may cause cancer.

arms and legs - Use tools with guarding fitted

- Move tools away from the body

- Wear protective gloves

Electrical Hazard: 1 5 5 - Ensure power leads are located to minimize risk 1 4 4 Painter

- Electrocution - Ensure leads are kept out of puddles and plugs are

kept dry

Risk: - Ensure electrical equipment and power leads are

- Shock maintained in a safe working condition

- Death

WMS: PAINTING Page 3 of 10

WORK METHOD STATEMENT PAINTING

HIGH RISK ACTIVITY: WORKING ON OR NEAR EXPOSED ENERGISED ELECTRICAL EQUIPMENT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Moving Paint and Hazard: 1 2 2 - Check tools regularly and maintain them in good 1 2 2 Painter

Related Products - Manual handling working order

around the Work - Check route to be travelled is removed of all trips

Site Risk: and fall hazards and provides a clear way for you

- Impact and crush injuries to move around the work site

- Cuts and abrasions - Store materials as close as practicable to the work

- Lacerations area to reduce effort required

- Bruising - Check workers are properly trained in correct

- Stresses and strains bending and lifting techniques

- Pinching injuries - Wear PPE

- Rotate workers’ activities to alternate their

exposure to hazards

Using Paint Brushes Hazard: 3 2 6 - Paint in a well ventilated area 1 2 2 Painter

and Rollers to Apply - Paint fumes - If the area is not well ventilated, then use

(Textured) Paint appropriate half face respiration in accordance

Risk: with AS 1716

- Respiratory problem - Wear a hat and safety goggles. Safety footwear

- Eye and skin irritation should be worn at all times

Mixing Paint Hazard: 1 4 4 - Read the MSDS supplied with product 1 2 2 Painter

Products - Paint splashing in workers’ - If using power tools to mix paint, check they are in

eyes good working order and powered by appropriate

- Inhalation of paint fumes means

- Ingestion of paint See WMS for power tools and use of electrical

leads for further controls

Risk: - Ensure tools used are regularly maintained and

- See specific MSDS for risks that all guarding is fitted and working correctly

associated with the various - Use required PPE which should include protective

paints clothing, gloves, safety glasses and where

WMS: PAINTING Page 4 of 10

WORK METHOD STATEMENT PAINTING

HIGH RISK ACTIVITY: WORKING ON OR NEAR EXPOSED ENERGISED ELECTRICAL EQUIPMENT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Mixing Paint recommended by MSDS, respiratory masks. Where

Product (Continued) power tools are used to mix the paint, hearing

protection may need to be considered

- Mix paint in a well ventilated area. Where

appropriate levels of ventilation are not available,

respiratory masks must be worn

- Remove all excess chemicals/paints from exposed

skin

- Provide material on safe manual handling work

practices and correct bending and lifting

techniques

- Include regular safety reminders during toolbox

meetings

Washing Up Tools Hazard: 3 2 6 - Check workers are trained in correct procedures to 1 2 2 Painter

and Brushes - Chemical fumes clean brushes and rollers

- Direct contact with chemicals - Clean brushes and rollers in the designated Wash

Down are only

Risk: Warning: do not wash the residue down drains and

- Risks are dependent on the into the waterways system

chemicals used - Wear safety glasses and hand protection

See relevant MSDS

Using Chemicals to Hazard: 3 2 6 - All appropriate MSDS must be available on site and 1 2 2 Painter

Clean, Bond or Fill - Chemical fumes all workers must be aware of their location

- Direct contact with chemicals - Apply controls in accordance with the relevant

MSDS

Risk: - Wear PPE and have adequate ventilation. Where

- Risks are dependent on the ventilation is poor, respiratory masks may be

chemicals used required to ensure chemical fumes do not cause

WMS: PAINTING Page 5 of 10

WORK METHOD STATEMENT PAINTING

HIGH RISK ACTIVITY: WORKING ON OR NEAR EXPOSED ENERGISED ELECTRICAL EQUIPMENT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Using Chemicals to See relevant MSDS adverse health effects

Clean, Bond or Fill - Where necessary, display signage advising of risks

(Continued) and work activity

Using a Small Step Hazard: 1 4 4 - Check the ladder is suitable for the intended 1 2 2 Painter

Ladder to reach - Slips, trips and falls purpose and that it is not overloaded

Ceiling Height - Ensuring ladders are of an industrial standard

Risk: - Place the ladder on an even surface

- Minor impact injuries - Use a commercial grade ladder with non-slip feet

- Ensure rungs and stiles are in good condition

- Use non-slip footwear to access the ladder

- Do not stand on the top rung of the ladder

Trestle Hazard: 3 5 15 - Ensuring trestles are erected in accordance with 1 5 5 Painter

Ladders/Scaffold - Falls from heights suppliers instructions

- Confirm the scaffold was erected by a certified

Risk: Scaffolder

- Impact and crush injuries - Ensuring platforms are in good and sound

- Impalement injuries condition

- Cuts and abrasions - Check the completed scaffold has been accepted

- Lacerations by the Principal Contractor and inspected for

- Broken bones compliance.

- Serious head injuries Check also that it has been signed off before using

- death it

- Check scaffold is stable and properly erected at the

correct heights and fitted with top and mid rails,

kick/toe boards or mesh to stop items from falling

off the scaffold

- Check any incomplete scaffold is clearly marked

with displayed signage

WMS: PAINTING Page 6 of 10

WORK METHOD STATEMENT PAINTING

HIGH RISK ACTIVITY: WORKING ON OR NEAR EXPOSED ENERGISED ELECTRICAL EQUIPMENT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Using Scissor Lifts, Hazard: 3 5 15 - Conduct a risk assessment of the work are and of 1 5 5 Painter

Mobile Scaffold and - Falls from heights the equipment to confirm its suitability and to

Cherry Pickers identify the correct configuration of the elevating

(Both owned and Risk: work platform

hires as needed) - Impact and crush injuries - Persons operating the work platforms should be

- Impalement injuries properly trained in their operations. Check the hire

- Cuts and abrasions company provides effective and comprehensive

- Lacerations training so that operators can be competent

- Broken bones - Self-propelled platforms should only be used on

- Serious head injuries firm level surfaces unless otherwise designed by

- Death the manufacturer

- Confirm all equipment has been regularly

maintained and is in good condition

- Check all equipment is functioning properly with

audible alarms and visual flashing lights when is

use

- Check the area is appropriate for suing this

equipment and the platforms are stable and will

not overbalance

Warning: do not use the equipment during high

wind

- Check electrical equipment used is in good

condition and tested and tagged to avoid potential

electrocution of all persons in and on this

equipment

- Before using the equipment confirm all electrical

overhead wiring and other such hazards have been

identified

WMS: PAINTING Page 7 of 10

WORK METHOD STATEMENT PAINTING

HIGH RISK ACTIVITY: WORKING ON OR NEAR EXPOSED ENERGISED ELECTRICAL EQUIPMENT

JOB STEP POTENTIAL HAZARDS RISK SCORE CONTROLS RESIDUAL PERSON

(Before Control RISK RESPONSIBLE

Measures) (After Control

Measures)

L C R L C R

Warning: do not work within 8m of this wiring.

Check all persons are aware of any existing wiring

WMS: PAINTING Page 8 of 10

WORK METHOD STATEMENT PAINTING

RISK MATRIX

CONSEQUENCES

LIKELIHOOD

INSIGNIFICANT (1) MINOR (2) MODERATE (3) MAJOR (4) CATASTROPHIC (5)

RARE (1) Low (1) Low (2) Low (3) Moderate (4) Moderate (4)

UNLIKELY (2) Low (2) Moderate (4) Moderate (6) Moderate (8) High (10)

POSSIBLE (3) Low (3) Moderate (6) Moderate (9) High (12) High (15)

LIKELY (4) Moderate (4) Moderate (8) High (12) Catastrophic (16) Catastrophic (20)

ALMOST CERTAIN (5) Moderate (5) High (10) High (15) Catastrophic (20) Catastrophic (25)

Catastrophic (16+) Then Work is unable to proceed. Seek other methods (Significant)

High (10 – 15) Then Permission from High Level Management for work to proceed (Significant)

If the residual risk is

Moderate (4 – 9) Then Permission from Worker in Charge for work to proceed (Insignificant)

Low (1 – 3) Then Work able to proceed (Insignificant)

1. Eliminate 2. Substitute 3. Isolate 4. Redesign 5. Administrative 6. PPE (Last Resort)

Substitute with a less

Redesign equipment or Introduce administrative

Eliminate the hazard hazardous material, Isolate the hazard Use appropriate PPE

work process controls

process or equipment

C= Consequence L= Likelihood

5= Catastrophic = Fatality, permanent disability, long term widespread 5= Almost Certain = It is almost certain that the risk will occur in most

impacts, huge financial loss circumstances

4= Major = Permanent disability or extensive injuries, medium to long term 4= Likely = The risk is likely to occur in most circumstances

widespread impact, major financial loss

3= Moderate = Lost time injury, reversible medium term local impact, high 3= Possible = There is uncertainty that the risk could occur

financial loss

2= Minor = Medical treatment, reversible short – medium term impact to local 2= Unlikely = The risk could occur at some time but there is confidence that it

area, medium financial loss will not

1= Insignificant = First aid, limited impact to minimal area, low financial loss 1= Rare = The impact/risk may occur only in exceptional circumstances

WMS: PAINTING Page 9 of 10

WORK METHOD STATEMENT PAINTING

I HAVE BEEN CONSULTED AND I ASSISTED IN DEVELOPPING THE WORK METHOS STATEMENTS THAT APPLY TO MY WORK ACTIVITIES.

I WILL COMPLY WITH ITS SAFE WORK PRACTICE.

PRINT NAMES POSITION/TRADE SIGNATURE DATE

JOE GEDOUN DIRECTOR/SITE MANAGER 16 October 2017

MATTHEW CARROLL SITE SUPERVISOR 16 October 2017

CRAIG PENSINI SITE SUPERVISOR 16 October 2017

BOYD TURNER SITE SUPERVISOR 16 October 2017

MONITORING AND REVIEWING OF WMS USE AND EFFECTIVENESS

NAME SIGNATURE DATE

STACY JACOBSEN 16 October 2017

WMS: PAINTING Page 10 of 10

You might also like

- Osh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakFrom EverandOsh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakRating: 5 out of 5 stars5/5 (1)

- WMS Electrical Working On or Near Exposed Energised Electrical EquipmentDocument7 pagesWMS Electrical Working On or Near Exposed Energised Electrical EquipmentFresly PatriaNo ratings yet

- 02 Contractor Daily Report - CDRDocument1 page02 Contractor Daily Report - CDRPERVEZ AHMAD KHANNo ratings yet

- 2338 - Rev 0 - Binladin Group PDFDocument5 pages2338 - Rev 0 - Binladin Group PDFVishnuNo ratings yet

- Viking - Qr. Concealed Pendent Sprinkler K5.6 - VK462, VK463Document2 pagesViking - Qr. Concealed Pendent Sprinkler K5.6 - VK462, VK463mohammadNo ratings yet

- RA - 18 - For Concrete Topping On Hollow Core SlabDocument14 pagesRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatNo ratings yet

- LQ Form 1 Extension of Time V3 June 2015 PDFDocument1 pageLQ Form 1 Extension of Time V3 June 2015 PDFShowki WaniNo ratings yet

- 00-Site InstructionDocument7 pages00-Site InstructionSyed Munawar AliNo ratings yet

- NSCR-EX Precast Yard Daily ReportDocument4 pagesNSCR-EX Precast Yard Daily ReportjackcoolsNo ratings yet

- Doha Expressway Pipe Laying InspectionDocument1 pageDoha Expressway Pipe Laying InspectionraghebomNo ratings yet

- Project Mobilisation PlanDocument72 pagesProject Mobilisation PlanDel Tok100% (1)

- CMSB FP003 - Daily Site Report Rev 01Document2 pagesCMSB FP003 - Daily Site Report Rev 01leo edenNo ratings yet

- L019 - OHSE Shaft Work Permit FormatDocument1 pageL019 - OHSE Shaft Work Permit FormatRajib MondalNo ratings yet

- State Radio Project Contractor'S Daily Construction Report: Site Conditions, Resources and InspectionsDocument3 pagesState Radio Project Contractor'S Daily Construction Report: Site Conditions, Resources and InspectionsMr. Sambath LimNo ratings yet

- HSE Documents-Fit-Out Work-Ris AssessmentDocument3 pagesHSE Documents-Fit-Out Work-Ris AssessmentTom BobanNo ratings yet

- Daily Progress Report NewDocument1 pageDaily Progress Report Newkhalil AlwastiNo ratings yet

- 2012-12-17 Demobilization Plan For Piling Barge - JC-FinalDocument20 pages2012-12-17 Demobilization Plan For Piling Barge - JC-FinalDale WearpackNo ratings yet

- Construction Incident Report PDFDocument1 pageConstruction Incident Report PDFalfieNo ratings yet

- Corrective Action ReportDocument1 pageCorrective Action ReportTito GarciaNo ratings yet

- Attn: Proj: HODP-PR-5002 - Hotel 1 at City Walk Subj: Epoxy & Car Park Coating Works Package Delays To Contract Programme Dear SirDocument2 pagesAttn: Proj: HODP-PR-5002 - Hotel 1 at City Walk Subj: Epoxy & Car Park Coating Works Package Delays To Contract Programme Dear SirkrvprasadNo ratings yet

- Daily Diary Reports-02Document1 pageDaily Diary Reports-02OBERT MASALILANo ratings yet

- 3 RN Sop PDFDocument4 pages3 RN Sop PDFDwitikrushna RoutNo ratings yet

- NCR Log SheetDocument12 pagesNCR Log Sheetakram husseinNo ratings yet

- PRO422 Safety SignageDocument7 pagesPRO422 Safety SignageAsyraf HakeemNo ratings yet

- Method Statement For Hume Pipe CulvertDocument6 pagesMethod Statement For Hume Pipe CulvertRabnawaz Imam0% (1)

- Risk Assessment: Job:Control Blasting For Wagon TipplerDocument1 pageRisk Assessment: Job:Control Blasting For Wagon Tipplerali rezaNo ratings yet

- Near Miss ReportDocument1 pageNear Miss ReportSaravana KumarNo ratings yet

- Construction Site Dengue PreventionDocument27 pagesConstruction Site Dengue PreventionparthNo ratings yet

- 10 662153 1100001342 Mag CPM PQD 000004 - 01Document83 pages10 662153 1100001342 Mag CPM PQD 000004 - 01Bassam KhairyNo ratings yet

- Stars - BoH Nomination FormDocument1 pageStars - BoH Nomination FormRafael-Cheryl Tupas-LimboNo ratings yet

- RFA FormDocument2 pagesRFA FormRitche Lim BragaisNo ratings yet

- 02 MAO Monthly Report Apr 20 PDFDocument80 pages02 MAO Monthly Report Apr 20 PDFjonesNo ratings yet

- Work Permit 2.13Document14 pagesWork Permit 2.13Oliva Del Rosario Sagpao100% (1)

- (Green) Sunny Place Safety PlanDocument40 pages(Green) Sunny Place Safety PlanMatt BermattNo ratings yet

- Project Cash FlowDocument14 pagesProject Cash FlowTejas DesaiNo ratings yet

- Weekly Report of Construction ActivitesDocument4 pagesWeekly Report of Construction ActivitesVijay JamadarNo ratings yet

- Material List (Sultaco)Document2 pagesMaterial List (Sultaco)sui1981No ratings yet

- RA Termite PDFDocument1 pageRA Termite PDFMohammad Arif RasheedNo ratings yet

- QFFS Deliverables - Responsibility MatrixDocument6 pagesQFFS Deliverables - Responsibility MatrixnishadNo ratings yet

- Budget Monitoring DashboardDocument1 pageBudget Monitoring DashboardapurvajahagirdarNo ratings yet

- Daily Site ProgressDocument1 pageDaily Site ProgressyoushabkNo ratings yet

- Daily Labour Output FormDocument2 pagesDaily Labour Output FormJaneshaNo ratings yet

- Install Beacon ChecklistDocument1 pageInstall Beacon ChecklistZulfequar R. Ali Khan100% (1)

- Section 03 Site Clearance N Demolition PDFDocument11 pagesSection 03 Site Clearance N Demolition PDFlakmalperera1986100% (1)

- As Built ReportDocument1 pageAs Built ReportWakil AhmadNo ratings yet

- Clarification on Encashment of Earned Leave in connection with Leave Travel ConcessionDocument4 pagesClarification on Encashment of Earned Leave in connection with Leave Travel ConcessionvijayNo ratings yet

- 3.6.2 Fire Dril - Evacuation Practice ReportDocument2 pages3.6.2 Fire Dril - Evacuation Practice ReportKarim KachourNo ratings yet

- Sika Seal 105Document2 pagesSika Seal 105Gabo Tellez100% (1)

- Demolition Work Audit Checklist: Los Angeles Community College DistrictDocument6 pagesDemolition Work Audit Checklist: Los Angeles Community College DistrictJaycee PagadorNo ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Ipc 1Document2 pagesIpc 1mohammad hmidanNo ratings yet

- Site Logistics and Construction Plan TemplateDocument2 pagesSite Logistics and Construction Plan TemplatekapsarcNo ratings yet

- Work Inspection Request Sample FormatDocument6 pagesWork Inspection Request Sample FormatgregNo ratings yet

- Construction Planning & ManagementDocument39 pagesConstruction Planning & ManagementAnkur SrivastavaNo ratings yet

- FRA 18-57B Weekly Progress Report 76 Weekly Ending 17-07-22Document4 pagesFRA 18-57B Weekly Progress Report 76 Weekly Ending 17-07-22Rahul DeoNo ratings yet

- Sr. Manager Weekly H&S Walkthrough Report 005Document11 pagesSr. Manager Weekly H&S Walkthrough Report 005abdelaziz.a.zakariaNo ratings yet

- Aily Onstruction Eport: Ompany AME EREDocument3 pagesAily Onstruction Eport: Ompany AME EREdedovedoNo ratings yet

- Permit To Load UnloadDocument2 pagesPermit To Load UnloadSarah HaiderNo ratings yet

- WMS PaintingDocument10 pagesWMS PaintingAnonymous 3VAQ9SNxl7No ratings yet

- Camlock Painting Work Method Statement for BuildingsDocument4 pagesCamlock Painting Work Method Statement for BuildingsCamlockNo ratings yet

- MOS Glass Window WorksDocument5 pagesMOS Glass Window WorksCamlockNo ratings yet

- Mos For Gypsum PartitionsDocument8 pagesMos For Gypsum PartitionsCamlockNo ratings yet

- 20171025124222869Document2 pages20171025124222869CamlockNo ratings yet

- Camlock Electrical Maintenance ServicesDocument3 pagesCamlock Electrical Maintenance ServicesCamlock0% (1)

- Decorative Grilles and Diffusers Models FTDG5-FTDG8Document1 pageDecorative Grilles and Diffusers Models FTDG5-FTDG8CamlockNo ratings yet

- TECHNICAL PROPOSAL ADAC RFQ - 6183Document1 pageTECHNICAL PROPOSAL ADAC RFQ - 6183CamlockNo ratings yet

- MK Switches Sockets DATA SHEETDocument9 pagesMK Switches Sockets DATA SHEETCamlockNo ratings yet

- Decorati VE GRI Lles & DI Ffusers Decorati VE GRI Lles: Model No. Ftdg9Document1 pageDecorati VE GRI Lles & DI Ffusers Decorati VE GRI Lles: Model No. Ftdg9CamlockNo ratings yet

- TECHNICAL PROPOSAL FCHS 21549 - Diesel Tank FoundationDocument2 pagesTECHNICAL PROPOSAL FCHS 21549 - Diesel Tank FoundationCamlockNo ratings yet

- Decorati VE GRI Lles & DI Ffusers Decorati VE GRI Lles: Model No. Ftdg1Document1 pageDecorati VE GRI Lles & DI Ffusers Decorati VE GRI Lles: Model No. Ftdg1CamlockNo ratings yet

- TECHNICAL PROPOSAL ADAC RFQ - 6183 PDFDocument2 pagesTECHNICAL PROPOSAL ADAC RFQ - 6183 PDFCamlockNo ratings yet

- Decorati VE GRI Lles & DI Ffusers Decorati VE DI Ffuser: Model No. Ftdd8 Model No. Ftdd7Document1 pageDecorati VE GRI Lles & DI Ffusers Decorati VE DI Ffuser: Model No. Ftdd8 Model No. Ftdd7CamlockNo ratings yet

- Camlock General Maintenance Services Est - P.O Box - 8596 - M-09 - ABU DHABI, UAE - WebDocument3 pagesCamlock General Maintenance Services Est - P.O Box - 8596 - M-09 - ABU DHABI, UAE - WebCamlockNo ratings yet

- 039-2018 - Construction of Two Commercial Buildings - Phase 2Document6 pages039-2018 - Construction of Two Commercial Buildings - Phase 2CamlockNo ratings yet

- C42 AssignmentDocument1 pageC42 AssignmentCamlockNo ratings yet

- Decorati VE GRI Lles & DI Ffusers Decorati VE DI Ffuser: Model No. Ftdd2 Model No. Ftdd1Document1 pageDecorati VE GRI Lles & DI Ffusers Decorati VE DI Ffuser: Model No. Ftdd2 Model No. Ftdd1CamlockNo ratings yet

- Camlock General Maintenance Completes Freezer InstallationDocument1 pageCamlock General Maintenance Completes Freezer InstallationCamlockNo ratings yet

- CAM - Home Renovation INVDocument1 pageCAM - Home Renovation INVCamlockNo ratings yet

- 55210Document2 pages55210whah11No ratings yet

- PREQUALIFICATION Civil DivisionDocument62 pagesPREQUALIFICATION Civil DivisionCamlockNo ratings yet

- Drain Line Channel Maintenance ProposalDocument2 pagesDrain Line Channel Maintenance ProposalCamlockNo ratings yet

- Multi Lizer 4 PDFDocument1 pageMulti Lizer 4 PDFBridgett AllenNo ratings yet

- Owners Assignment C27Document1 pageOwners Assignment C27CamlockNo ratings yet

- Knauf Regular Gypsum Board (RG) PDFDocument2 pagesKnauf Regular Gypsum Board (RG) PDFNithin KumarNo ratings yet

- Camlock - Audit Report 2016Document15 pagesCamlock - Audit Report 2016CamlockNo ratings yet

- 5KW 750RPM PMG - GreefDocument2 pages5KW 750RPM PMG - GreefCamlockNo ratings yet

- Technical Proposal FCHS 21512Document1 pageTechnical Proposal FCHS 21512CamlockNo ratings yet

- MK Switches Sockets DATA SHEETDocument9 pagesMK Switches Sockets DATA SHEETCamlockNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument8 pagesSafety Data Sheet: Section 1. IdentificationSafwan ZuberNo ratings yet

- Fire Triangle & NfpaDocument11 pagesFire Triangle & NfpaluckshimiNo ratings yet

- Alum Oxide A1203Document9 pagesAlum Oxide A1203Sharin Bin Ab GhaniNo ratings yet

- Safety Data Sheet SikaBond NVDocument5 pagesSafety Data Sheet SikaBond NVAshadi AmirNo ratings yet

- 2.4 WP-XXX XX-XX PPE Policy (Final)Document5 pages2.4 WP-XXX XX-XX PPE Policy (Final)MarwotoNo ratings yet

- Essay DRR RJDocument1 pageEssay DRR RJGenevieve C. BaelNo ratings yet

- Division of Safety Regulation Revision: 0: Tanzania Civil Aviation AuthorityDocument13 pagesDivision of Safety Regulation Revision: 0: Tanzania Civil Aviation AuthorityMik AeilNo ratings yet

- Confused by NFPA70EDocument4 pagesConfused by NFPA70Ecperalta_4No ratings yet

- Hotel Safety and Security FeaturesDocument4 pagesHotel Safety and Security FeaturesmunyekiNo ratings yet

- Risk Assessment Photoshoot 2Document5 pagesRisk Assessment Photoshoot 2Jude CarterNo ratings yet

- Commercial Cooking 7 8Document6 pagesCommercial Cooking 7 8billy jane ramos0% (1)

- Guidance For The Topic Assessment of The Major Accident Hazard Aspects of Safety CasesDocument309 pagesGuidance For The Topic Assessment of The Major Accident Hazard Aspects of Safety CasesromeshmoreyNo ratings yet

- CematrixDocument379 pagesCematrixAHNo ratings yet

- Candidate Report - SAMPLEDocument10 pagesCandidate Report - SAMPLEaitzaz561No ratings yet

- Erie Scientific LLC: Globally Harmonized Safety Data Sheet (GHSDS)Document7 pagesErie Scientific LLC: Globally Harmonized Safety Data Sheet (GHSDS)Leni MeifitaNo ratings yet

- Work at Height ChecklistDocument3 pagesWork at Height ChecklistThillai8975No ratings yet

- Employee Orientation Checklist Areas To Be Covered Description CompletedDocument2 pagesEmployee Orientation Checklist Areas To Be Covered Description Completedeast100% (1)

- 1 Presentation Sime DarbyDocument39 pages1 Presentation Sime DarbyPirun Sirimangkalo100% (1)

- H&S Rules With Minimum Safe Behaviour EngDocument1 pageH&S Rules With Minimum Safe Behaviour EngVijay KulkarniNo ratings yet

- Nebosh Element - 1 AnswersDocument4 pagesNebosh Element - 1 AnswersSatish KumarNo ratings yet

- Hammer Mill Job Hazard Assessment PDFDocument2 pagesHammer Mill Job Hazard Assessment PDFIfa FafaNo ratings yet

- Capability Statement: Safety EngineeringDocument25 pagesCapability Statement: Safety EngineeringSDP02No ratings yet

- Safety Data Sheet: AluminumDocument8 pagesSafety Data Sheet: AluminumClaudio BiaginiNo ratings yet

- Day 2-5 Personal Protective EquipmentDocument28 pagesDay 2-5 Personal Protective EquipmentMegaNo ratings yet

- (OHS) Procedure For Hazard IdentificationDocument6 pages(OHS) Procedure For Hazard IdentificationTuan AnhNo ratings yet

- Evidencia 4Document5 pagesEvidencia 4Leonardo NavasNo ratings yet

- Job Safety Analysis (JSADocument2 pagesJob Safety Analysis (JSAGanubio KhottobNo ratings yet

- Kinds of Hazard and Risk ManagementDocument8 pagesKinds of Hazard and Risk ManagementShahid HussainNo ratings yet

- ASCO National - Electrical - Code - Requirements - For - Emergency - Power - Transfer - Switching - 147492 - 0 PDFDocument6 pagesASCO National - Electrical - Code - Requirements - For - Emergency - Power - Transfer - Switching - 147492 - 0 PDFFadi Mohd ShaherNo ratings yet

- 01 HIRA Lifting & RiggingDocument3 pages01 HIRA Lifting & RiggingMudhyn MI75% (4)