Professional Documents

Culture Documents

Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint Numbering

Uploaded by

punitg_2Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint Numbering

Uploaded by

punitg_2Copyright:

Available Formats

PAGE NO.

- 1 of 3

LARSEN & TOUBRO LIMITED DATE:-05.11.07

MSQ UP GRADATION (EPCC 1)

REV.NO.- 0

PROJECT

PROCEDURE NO.-

PROCEDURE FOR JOINT NUMBERING LT/MSQ/P/JN/013

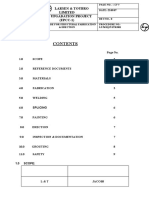

CONTENTS:

1. SCOPE

2. PROCEDURE

APPROVED BY L & T REVIEWED / APPROVED BY JACOBS

PAGE NO.- 2 of 3

LARSEN & TOUBRO LIMITED DATE:-05.11.07

MSQ UP GRADATION (EPCC 1)

REV.NO.- 0

PROJECT

PROCEDURE NO.-

PROCEDURE FOR JOINT NUMBERING LT/MSQ/P/JN/013

1.0 SCOPE

This procedure outlines the method of joint numbering on the isometric drawings.

This procedure is applicable for MSQ Unit .

2.0 PROCEDURE:

After receipt of approved drawing, detailed fabrication & erection scope will be

worked out by planning/ piping engineer based on availability of drawing and

material. The approved Isometric Drg. Shall be marked with all the weld joints

(shop/field) prior to fabrication in the flow direction with a number to identify

each weld in the following sequence and one set of this marked Isometric drawing

shall be submitted to L&T QC & Jacobs for their reference.

2.1 U/G PIPING

2.1.1 Joint Numbering will be marked after receiving of all sheets of individual lines. Butt

joints will be marked as a continuation no. J1, J2, J3…Jn. Shop joint read as 1,2,3,

………. & field joint will have the prefix ‘FJ’ i.e. FJ1, FJ2, FJ3, FJ4…

2.1.2 Branch joints will be marked as a continuation number from BR J1, J2, J3…Jn.

2.1.3 Socket joints will be marked as a continuation number SW J1, J2, J3…Jn.

2.1.4 Miter joints will have prefix MJ.

2.1.5 Re welded joints will have suffix RW to the previous joint number. For example joint

number 1 is re welded then it will be marked as 1RW.

2.1.6 Cut out joints in Radiography will have suffix N to the previous joint number.

2.1.7 Repair joints in radiography will have suffix R1, R2…to the previous joint number

2.1.8 Penalty joints in radiography will have suffix P1, P2…to the previous radiography

number.

2.1.9 Modification joints will have suffix M to the previous joints.

2.1.10 Additional joints will have suffix A, B, C…for example an additional joint is coming in

between joint number 2 & 3, then this additional joint number will be marked as 2A.

APPROVED BY L & T REVIEWED / APPROVED BY JACOBS

PAGE NO.- 3 of 3

LARSEN & TOUBRO LIMITED DATE:-05.11.07

MSQ UP GRADATION (EPCC 1)

REV.NO.- 0

PROJECT

PROCEDURE NO.-

PROCEDURE FOR JOINT NUMBERING LT/MSQ/P/JN/013

2.1.11 This Numbering will be maintained in a welding control database package i.e. ALPS

2.2 A/G PIPING:

2.2.1 Joint Numbering will be marked after receiving of all sheets of individual lines. Butt

joints will be marked as a continuation no. J1, J2, J3…Jn. Shop joint read as 1,2,3,

………. & field joint will have the prefix ‘FJ’ i.e. FJ1, FJ2, FJ3, FJ4…

2.2.2 Branch joints will be marked as a continuation number from BR J1, J2, J3…Jn.

2.2.3 Socket joints will be marked as a continuation number SW J1, J2, J3…Jn.

2.2.4 Miter joints will have prefix MJ.

2.2.5 Re welded joints will have suffix RW to the previous joint number. For example joint

number 1 is re welded then it will be marked as 1RW.

2.2.6 Cut out joints in Radiography will have suffix N to the previous joint number.

2.2.7 Repair joints in radiography will have suffix R1, R2…to the previous joint number.

2.2.8 Penalty joints in radiography will have suffix P1, P2…to the previous radiography

number.

2.2.9 Modification joints will have suffix M to the previous joints.

2.2.10 Additional joints will have suffix A, B, C…for example an additional joint is coming in

between joint number 2 & 3, then this additional joint number will be marked as 2A.

2.2.12 This Numbering will be maintained in a welding control database package i.e. ALPS

Note: No joint number will be repeated in the same line number.

APPROVED BY L & T REVIEWED / APPROVED BY JACOBS

You might also like

- Happiest Refugee Coursework 2013Document10 pagesHappiest Refugee Coursework 2013malcrowe100% (2)

- Comments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseDocument4 pagesComments Resolution Sheet (CRS) : No. QP Comments Contractor Responsemansih457No ratings yet

- Expansion Joint - REJECT PDFDocument34 pagesExpansion Joint - REJECT PDFJuan LubonNo ratings yet

- THE PERFECT DAY Compressed 1 PDFDocument218 pagesTHE PERFECT DAY Compressed 1 PDFMariaNo ratings yet

- Alternatoer Lvsi804s WDG 12 v9 TdsDocument8 pagesAlternatoer Lvsi804s WDG 12 v9 TdsCris_eu09No ratings yet

- NBCC 2015 Seismic Design Examples in S-FRAME AnalysisDocument91 pagesNBCC 2015 Seismic Design Examples in S-FRAME AnalysisMike Smith100% (1)

- Equipment Maintenance and Measuring Equipment ProcedureDocument2 pagesEquipment Maintenance and Measuring Equipment ProcedureRaja Mani100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Ms 33kv Cable LayingDocument11 pagesMs 33kv Cable LayingAhmed Nagy100% (2)

- DA3105-Cable ScheduleDocument14 pagesDA3105-Cable ScheduleCassy AbulenciaNo ratings yet

- Design Basis For 850kVAR 440V 7% CSC APFC PanelDocument10 pagesDesign Basis For 850kVAR 440V 7% CSC APFC Panelchitra rameshNo ratings yet

- Junction BoxDocument11 pagesJunction Boxsugeng wahyudiNo ratings yet

- BOMA - Office Building Standard Methods of Measurement AppendixDocument41 pagesBOMA - Office Building Standard Methods of Measurement Appendixxavest100% (7)

- For Construction: SonatrachDocument69 pagesFor Construction: Sonatrachm.kNo ratings yet

- 01 Procedure For Structural SteelDocument9 pages01 Procedure For Structural Steelpunitg_2No ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingKheireddine AounallahNo ratings yet

- Method Statement FOR Installation of Electrical Earthing System SP-2Document10 pagesMethod Statement FOR Installation of Electrical Earthing System SP-2Mohammad Fazal KhanNo ratings yet

- NG50!3!200-EnG-RP-AB-00-2235 Spools & Jumpers Basis of DesignDocument67 pagesNG50!3!200-EnG-RP-AB-00-2235 Spools & Jumpers Basis of DesignsurNo ratings yet

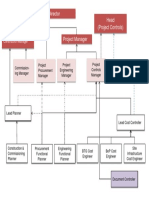

- Project Director Head (Project Controls) Project ManagerDocument1 pageProject Director Head (Project Controls) Project Managerpunitg_2No ratings yet

- Thickness CalculationDocument19 pagesThickness Calculationajiths89No ratings yet

- SCF CalDocument17 pagesSCF CalGanesh SantoshNo ratings yet

- Acsr Stringing of Conductors (Draft)Document18 pagesAcsr Stringing of Conductors (Draft)Anonymous 8xHUWBNo ratings yet

- Pipeline Weld Joint & Ragiograph Film Numbering SystemDocument9 pagesPipeline Weld Joint & Ragiograph Film Numbering Systemgst ajah100% (2)

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Document11 pagesLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011punitg_2No ratings yet

- O2001 DC SCF 001 SCF Cal With 32mtr SpanDocument5 pagesO2001 DC SCF 001 SCF Cal With 32mtr SpanGanesh SantoshNo ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For Under Ground PipingDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For Under Ground PipingBhavani PrasadNo ratings yet

- Design F PSC Pier ArmDocument34 pagesDesign F PSC Pier ArmAmit Rawat100% (1)

- New Org Chart - LNT PowerDocument1 pageNew Org Chart - LNT Powerpunitg_2No ratings yet

- O2 Analyzer - Document - REV-B - 24-03-2018 PDFDocument10 pagesO2 Analyzer - Document - REV-B - 24-03-2018 PDFambeshNo ratings yet

- SW TSP C 001 Rev - 02 Topo PDFDocument10 pagesSW TSP C 001 Rev - 02 Topo PDFramesNo ratings yet

- Contents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) ProjectDocument3 pagesContents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Projectpunitg_2No ratings yet

- Automatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriDocument9 pagesAutomatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriRegistro PersonalNo ratings yet

- Idc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingDocument18 pagesIdc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingJovan Poznan100% (1)

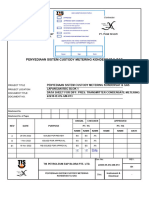

- Metering System Rev 1Document11 pagesMetering System Rev 1sswahyudi100% (1)

- 31 1 Static Equipment Vertical ErectionDocument2 pages31 1 Static Equipment Vertical Erectionpunitg_2No ratings yet

- 30 1 Static Equipment Horizontal ErectionDocument2 pages30 1 Static Equipment Horizontal Erectionpunitg_2No ratings yet

- Action Research in Araling PanlipunanDocument3 pagesAction Research in Araling PanlipunanLotisBlanca94% (17)

- 13 Procedure For Joint NumberingDocument3 pages13 Procedure For Joint NumberingdnbinhNo ratings yet

- Procedure For Joint Numbering: Sepco Iii Project, JharsugudaDocument5 pagesProcedure For Joint Numbering: Sepco Iii Project, JharsugudadiptiNo ratings yet

- TRHT LC Te 00 Oo 202 - 1Document11 pagesTRHT LC Te 00 Oo 202 - 1kerkar mohammedNo ratings yet

- Com PW Mr03 0008 001 04 Js1227 Itt Starter Panel Ga Drawing CrsDocument1 pageCom PW Mr03 0008 001 04 Js1227 Itt Starter Panel Ga Drawing CrsMohammed BrashdiNo ratings yet

- 2 Concrete Works MSDocument7 pages2 Concrete Works MSGaneshNo ratings yet

- Job Procedure For: Job Procedure No.Document5 pagesJob Procedure For: Job Procedure No.venkateshNo ratings yet

- IONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 TransmittalDocument10 pagesIONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 Transmittalyusuf.yuzuakNo ratings yet

- 5063-E-EPC-PTR-DE-D-V-001 - Data Sheet Cat A2Document29 pages5063-E-EPC-PTR-DE-D-V-001 - Data Sheet Cat A2SUSOVAN BISWASNo ratings yet

- Commercial Bid FormDocument68 pagesCommercial Bid FormKasarachi AmadiNo ratings yet

- TTP-1-KSO-SU-5130-M-014-AC Method Statement of Primary Injection Current Transformer SAT ProcedureDocument28 pagesTTP-1-KSO-SU-5130-M-014-AC Method Statement of Primary Injection Current Transformer SAT ProcedurejasonhucetNo ratings yet

- Sonatrach: Project SpecificationDocument23 pagesSonatrach: Project SpecificationAliZenatiNo ratings yet

- CS-383 - Propsed Leg Extn Benching For Lot 1-Locs Q13-1, Q13-2, Q14-0, T2D-0 & Lot 3 - APD6A-0, APD7-0Document3 pagesCS-383 - Propsed Leg Extn Benching For Lot 1-Locs Q13-1, Q13-2, Q14-0, T2D-0 & Lot 3 - APD6A-0, APD7-0Rajesh KrishnanNo ratings yet

- 8 CP-02 - Bill No 2 4 - Electrical - 01-05-16-RDocument377 pages8 CP-02 - Bill No 2 4 - Electrical - 01-05-16-RsaifulNo ratings yet

- Pulapol - Electrical 1Document6 pagesPulapol - Electrical 1Abd RahmanNo ratings yet

- Designs TRD Ur MBNRDocument20 pagesDesigns TRD Ur MBNRarun kumar vermaNo ratings yet

- Datasheet of Analyser - Pe-V0-415-673-A203 R02Document44 pagesDatasheet of Analyser - Pe-V0-415-673-A203 R02ankushbahaleNo ratings yet

- Comment Resolution Sheet: Close Noted Noted. Refer Comment On SHT.2 DETAIL - '11' NotedDocument2 pagesComment Resolution Sheet: Close Noted Noted. Refer Comment On SHT.2 DETAIL - '11' Notedprince francisNo ratings yet

- Draft Spec. No. IRS S 72-88 For Transformer (ABSOLUTE)Document13 pagesDraft Spec. No. IRS S 72-88 For Transformer (ABSOLUTE)Nishant GajiparaNo ratings yet

- Document PDFDocument11 pagesDocument PDFPrakash ChidambaramNo ratings yet

- E84 in TN CMBR GVRD NB 0001 502Document35 pagesE84 in TN CMBR GVRD NB 0001 502Balaji SowrirajanNo ratings yet

- Bn44-00038acb-Ml17, rb17 Inverter PDFDocument11 pagesBn44-00038acb-Ml17, rb17 Inverter PDFodilonsouzaNo ratings yet

- Method Statement: Consolidated Contractors Company & Teyseer Contracting Company J.VDocument7 pagesMethod Statement: Consolidated Contractors Company & Teyseer Contracting Company J.Vrvsreddy1972No ratings yet

- Technical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: ItemDocument9 pagesTechnical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: Itemrafikul123No ratings yet

- CS-350 Propsed Leg Extn & Benching For Lot 3-Locs - APD8-0, APD8A-2Document2 pagesCS-350 Propsed Leg Extn & Benching For Lot 3-Locs - APD8-0, APD8A-2Rajesh KrishnanNo ratings yet

- Revision History Revision History: LGP32-13PL1 LCD TV Power SpecificationDocument1 pageRevision History Revision History: LGP32-13PL1 LCD TV Power SpecificationMaricruz RochaNo ratings yet

- Electrical DocumentsDocument1 pageElectrical Documentssrivatsan boffinsNo ratings yet

- Slon-Gathbnar000-Ele-Lst-Phr-2003-00 - Rev A1Document4 pagesSlon-Gathbnar000-Ele-Lst-Phr-2003-00 - Rev A1StreesNo ratings yet

- Supply Specification For Synthetic Lube Oil Plate Cooler ConsoleDocument11 pagesSupply Specification For Synthetic Lube Oil Plate Cooler ConsoleFazliJaafarNo ratings yet

- TV Control Board Specification: Part Number: MST-13010811 Rev: A0Document12 pagesTV Control Board Specification: Part Number: MST-13010811 Rev: A0Jackeline MosquedaNo ratings yet

- Draft EI Specification RDSO SPN 192Document27 pagesDraft EI Specification RDSO SPN 192Amit srivastavaNo ratings yet

- CS-348 Propsed Leg Extn & Benching For Lot 3-Locs - APD10C-0, APD11-0, APD11A-0, APD11A-1Document3 pagesCS-348 Propsed Leg Extn & Benching For Lot 3-Locs - APD10C-0, APD11-0, APD11A-0, APD11A-1Rajesh KrishnanNo ratings yet

- L&T Hydrocarbon EngineeringDocument43 pagesL&T Hydrocarbon EngineeringRajveer SinghNo ratings yet

- GS-266-MOS-Installation of Method Statement For Installation, Termination & Testing of LV MV, Cables &Wires-REV00Document13 pagesGS-266-MOS-Installation of Method Statement For Installation, Termination & Testing of LV MV, Cables &Wires-REV00Zubair Ahmed KhaskheliNo ratings yet

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionDocument10 pagesProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiNo ratings yet

- 11.tec-Saukem-Loi003-I01-006 V1 R4Document23 pages11.tec-Saukem-Loi003-I01-006 V1 R4Purushothaman SeenuNo ratings yet

- Data Sheet For DPT Condensate Metering Rev.B1Document6 pagesData Sheet For DPT Condensate Metering Rev.B1ariawan habibi.abNo ratings yet

- Customer Drawing List: Revision StatusDocument23 pagesCustomer Drawing List: Revision StatusTukaram PawarNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- 11 TradeDocument3 pages11 Tradepunitg_2No ratings yet

- Project Director: Construction Manager EHS Manager Qa/Qc ManagerDocument1 pageProject Director: Construction Manager EHS Manager Qa/Qc Managerpunitg_2No ratings yet

- Trading Account - ChargesDocument6 pagesTrading Account - Chargespunitg_2No ratings yet

- About Kotak Gold ETF (KGETF) Scheme FactsDocument3 pagesAbout Kotak Gold ETF (KGETF) Scheme Factspunitg_2No ratings yet

- The Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah KhanDocument11 pagesThe Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah Khanpunitg_2No ratings yet

- Larsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: ContentsDocument5 pagesLarsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: Contentspunitg_2No ratings yet

- GEOJIT Equity Trading - Call and Trade Services - Free Online Trading ServicesDocument2 pagesGEOJIT Equity Trading - Call and Trade Services - Free Online Trading Servicespunitg_2No ratings yet

- Trading Holidays For The Calendar Year 2014Document1 pageTrading Holidays For The Calendar Year 2014punitg_2No ratings yet

- Securities Transaction Tax11234Document2 pagesSecurities Transaction Tax11234punitg_2No ratings yet

- Procedure For Installation Static Equipment For MSQ Upgradation UnitDocument7 pagesProcedure For Installation Static Equipment For MSQ Upgradation Unitpunitg_2No ratings yet

- Larsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007Document4 pagesLarsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007punitg_2No ratings yet

- 1 Procedure For Radiography TestingDocument9 pages1 Procedure For Radiography Testingpunitg_2No ratings yet

- NC 306 29JUL2010Document1 pageNC 306 29JUL2010punitg_2No ratings yet

- FRM-OHS-HOT - WORK - PERMIT - Permit & GuidelinesDocument2 pagesFRM-OHS-HOT - WORK - PERMIT - Permit & Guidelinespunitg_2No ratings yet

- PROC-OHS-INCIDENT-REPORTING - Procedure and Corrective ActionDocument6 pagesPROC-OHS-INCIDENT-REPORTING - Procedure and Corrective Actionpunitg_2No ratings yet

- ABRO Company ProfileDocument7 pagesABRO Company Profilepunitg_2No ratings yet

- Udhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTDocument4 pagesUdhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTpunitg_2No ratings yet

- Calculating Staff Strength:: Find Latest Hospitality Resources atDocument8 pagesCalculating Staff Strength:: Find Latest Hospitality Resources atPriyanjali SainiNo ratings yet

- Gita Ananda SDocument10 pagesGita Ananda Srosaanggita76No ratings yet

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Document28 pages2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteNo ratings yet

- High School Physics Rutherford Atom Lesson 27Document4 pagesHigh School Physics Rutherford Atom Lesson 27John JohnsonNo ratings yet

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Document1 pageHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesNo ratings yet

- The Senior High School in The Phillipines: The Way To The WorldDocument5 pagesThe Senior High School in The Phillipines: The Way To The WorldRodel Ramos DaquioagNo ratings yet

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Document2 pagesRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonNo ratings yet

- Digital Control Engineering 2nd Edition Fadali Solutions Manual PDFDocument3 pagesDigital Control Engineering 2nd Edition Fadali Solutions Manual PDFMohammed SalahNo ratings yet

- 2 TolentinoDocument12 pages2 TolentinoMA. ANGELINE GRANADANo ratings yet

- Final ExamDocument2 pagesFinal ExamblacmsNo ratings yet

- CIT 811 TMA 4 Quiz QuestionDocument3 pagesCIT 811 TMA 4 Quiz QuestionjohnNo ratings yet

- Cyanocobalamin Injection Clinical Pharmacology Drug MonographDocument36 pagesCyanocobalamin Injection Clinical Pharmacology Drug MonographLaureyNo ratings yet

- Cisco Nexus 7000 Introduction To NX-OS Lab GuideDocument38 pagesCisco Nexus 7000 Introduction To NX-OS Lab Guiderazzzzzzzzzzz100% (1)

- Zoology LAB Scheme of Work 2023 Hsslive HSSDocument7 pagesZoology LAB Scheme of Work 2023 Hsslive HSSspookyvibee666No ratings yet

- BIOL 2300 Homework 2 Summer2019Document2 pagesBIOL 2300 Homework 2 Summer2019Tanner JohnsonNo ratings yet

- Marshall Mix Design (Nptel - ceTEI - L26 (1) )Document7 pagesMarshall Mix Design (Nptel - ceTEI - L26 (1) )andrewcwng0% (1)

- 10 1 3 RMDDocument5 pages10 1 3 RMDRay GalfianNo ratings yet

- The Roti Canai StoryDocument5 pagesThe Roti Canai StoryDr Bugs TanNo ratings yet

- This Study Resource Was: MCV4U Exam ReviewDocument9 pagesThis Study Resource Was: MCV4U Exam ReviewNathan WaltonNo ratings yet

- Design of A Low Cost Hydrostatic Bearing: Anthony Raymond WongDocument77 pagesDesign of A Low Cost Hydrostatic Bearing: Anthony Raymond WongRogelio DiazNo ratings yet

- Auditing BasicsDocument197 pagesAuditing BasicsMajanja AsheryNo ratings yet

- IRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthDocument32 pagesIRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthbejarhasanNo ratings yet