Professional Documents

Culture Documents

Optimal stability conditions for beam, slab & staircase design

Uploaded by

ephOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimal stability conditions for beam, slab & staircase design

Uploaded by

ephCopyright:

Available Formats

International Journal of Engineering Research ISSN:2319-6890(online),2347-5013(print)

Volume No.5 Issue: Special 3 pp: 545-548 27-28 Feb. 2016

Approaches to Beam, Slab & Staircase Designing Using Limit State Design

Method for Achieving Optimal Stability Conditions

Utpal Kumar Nandy, Shravani Nandy, Antara Nandy

C.M.D, B.U. Builders & Consultants Pvt. Ltd, ISO 9001:2000 (QMS); Add: ‘NILANJAN’, D1/114, Sector-

IV, Vinay Nagar, Gwalior (M.P.)-474012, INDIA

Email: bubuildersconsultants@gmail.com

Abstract- Building design and construction of multi-story ;

buildings involves a network of highly complex and

meticulous processes. It is imperative to carry out these

processes with great care and concern for achieving

desired levels of stability conditions. Using the ultimate

load values, the designing of essential structural

members have been outlined in the paper. The structural Further,

elements used as a basis for carrying out the design

calculations include beams, slabs and staircase. The

paper presents the various steps of calculations required

for computing the correct values. The necessary

parameters and design criteria have been shown that will

facilitate the design as well as evaluation of the

structures. A base plan has been used as an illustrative

example to conduct the calculations on. Therefore, the final load,

Keywords: Limit State Design, Reinforced beam,

Reinforced Slab, Staircase, Ultimate Load

1. Introduction

1.1 Beams

Load on concrete,

Beams are horizontal structural members constructed below

the slab and are connected to the columns. These members

span along the length of a given edge. Beams are Load on steel,

responsible for carrying the load of the structural elements

built above and then transmitting the load to the columns

The factor is called the equivalent area of the

connected to it. Beams can be constructed using wood, steel,

section.

concrete, reinforced cement concrete and even plastic. The

construction of beams can be carried out in two ways i.e. When the depth and the breadth of a beam needs to follow

cast-in situ and laying of prefabricated beams. Beams are certain restrictions due to various reasons such as enhancing

constructed at an average distance of 3m centre to centre. By the appearance, it becomes essential to provide steel on the

suitably fixing the length and depth of the beam, the compression side of the beam as well. If the permissible

requirement of the number of beams can be reduced and dimension given by the expression, , are greater

hence the overall construction cost can be controlled. than the restricted dimension then the moment of resistance

with respect to compression with smaller than the applied

1.2 Design of Beams bending moment. Steel provided on the compressive side

When a beam is subjected to a bending moment,

increases the capacity of the beam to resist compressive

compressive and tensile stresses are set up in its fibres. The

forces without increasing its size. Beams of such kind are

intensity of stress in any fibre is proportional to its distance

known as doubly reinforced beams (Krishna & Jain, 1977).

from the neutral axis. As long as the stresses in the concrete

Let Asc and At be the areas of steel in the compression and

are within their elastic limits, the stresses in steel and

concrete are in their modular ratio and the beam behaves tension zones of the section respectively. Since plane

homogeneously. The tensile stress in concrete surrounding sections of the beam remain plane after bending, we have:-

the steel is equal to , where is the tensile stress at

any stage of loading (Plain and Reinforced Concrete-Code

of Practice, 2000). Where, N, a and d represent the neutral axis coefficient,

width and depth of the beam section while and are

The equations used for the design of reinforced cement the compressive stresses in the concrete of beam. The value

concrete beams are given below (Plain and Reinforced of the neutral axis coefficient can be calculated using the

Concrete-Code of Practice, 2000).

following equation (Krishna & Jain, 1977).

NCASE@2016 doi : 10.17950/ijer/v5i3/007 Page 545

International Journal of Engineering Research ISSN:2319-6890(online),2347-5013(print)

Volume No.5 Issue: Special 3 pp: 545-548 27-28 Feb. 2016

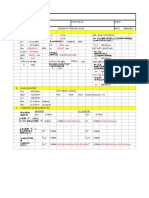

Steps in beam-design are given as follows (Krishna &

Jain, 1977):-

1. Calculation of the minimum depth required with

respect to the safe compression for the given

bending moment

Here B stands for the effective length, for the

thickness of slab and represents the stress in

concrete. Also, N is the co-efficient of neutral axis

and d is the depth of the beam.

2.Calculation of the minimum depth required for the Figure 8: Roof Beam Plan of the multi-storey building

upper limit of shear stress

3. Calculation of the economical depth

Here ‘r’ represents the ratio of the cost of

steel to that of concrete.

4. Calculation of the tensile steel required

5. Provide shear reinforcement if the shear stress

exceeds the safe value for concrete

Figure 9: Slab layout Plan of the multi-storey building

2. Design of Slabs

Reinforced concrete slabs are the horizontal members

acting as a top covering in a building and spans to the entire

length of the floor. In the ground floor, a thick concrete slab

supported on foundations or constructed directly on the

Figure 7: Plinth Beam Plan of a multi-storey building subsoil is used. However, in the case of high rise buildings

or skyscrapers the slabs are connected to the steel frames to

create the floors and ceilings at each level. These slabs are

thinner and are pre-cast concrete slabs. Cast-in situ slabs are

constructed in buildings that are of much smaller scale in

comparison (Krishna & Jain, 1977).

In a rectangular slab with uniformly distributed

load there is only one plane of bending and the load is

transferred to these two supports. However, if a slab is

supported on all the four edges, the load is transferred to all

NCASE@2016 doi : 10.17950/ijer/v5i3/007 Page 546

International Journal of Engineering Research ISSN:2319-6890(online),2347-5013(print)

Volume No.5 Issue: Special 3 pp: 545-548 27-28 Feb. 2016

these supports. Thus the bending moments and the Use 12mm dia. steel bars 10.0 cm apart from centre to

deflection is reduced considerably thereby reducing the need centre. As the steel bars for long span will be placed above

for thicker slabs. The load is carried in two directions to the these bars for short span, effective depth for long span will

respective supports, and the bending moment is much less be 11.4 cm.

than what it would have been if the load was carried in a

single direction only. Area of steel required for long span=

The slabs are designed for the bending moments

WB. B2/8 and WL.L2/8 per unit width along the short and

long spans respectively. The depth is calculated for the

larger of the two values. Since the moment in the short span Use 10mm dia. bars at 12.0 cm centre to centre distance.

is larger therefore the effective depth needs to be higher in

this case. Therefore, the reinforcement parallel to short span Shear force on short edges = 1/2 wB= 1100 kg

should be placed below and parallel to the long span. Hence,

the available effective depth of the slab for long span will be Shear force on long edges =

smaller than that for the shorter span.

In the given project, to design the slab the

following calculations need to be carried out.

Shear stress at long edges

Let the thickness of the slab be 15 cm or 150 mm.

= 0.993 kg/ sq cm

Shear stress at short edges = 1.21 kg/ sq cm

Therefore, the slab is safe at shear. Alternate bars can

Dimensions of slab-1= 5.5m x 10m

be bent up in each span without exceeding the permissible

The effective spans=5.86m and10.36 m limits. The bending of bars can be done at 1/7th span from

centre of supports. The ends of the bars must be provided

with hooks.

3. Design of Staircase

There are several arrangements that can be adopted to

build reinforced concrete staircases. The simplest type of

staircase is the one in which individual R.C. steps can

project out of the wall as cantilevers. If a flat ceiling is

required, an inclined R.C. slab cantilevering from the wall

and supporting the steps can be built. The usual practice in

Maximum bending moment along the short span=

the proportioning of staircase is to keep the rise equal to 15

cm to 20 cm and the tread equal to 23 cm to 25 cm.

exclusive of the nosing that can be about 2 cm (Krishna &

Jain, 1977).

Maximum bending moment along the long span=

Therefore, an effective depth of 13 cm needs to be provided.

Area of steel required along the short span=

Figure 10: Section of the multi-storey building showing the

staircase

NCASE@2016 doi : 10.17950/ijer/v5i3/007 Page 547

International Journal of Engineering Research ISSN:2319-6890(online),2347-5013(print)

Volume No.5 Issue: Special 3 pp: 545-548 27-28 Feb. 2016

Using 12 mm dia. bars, number of bars required in 1.25 m

width =

Spacing of 12 mm steel bars = 125/13 = 9.6 cm.

REFERENCES

i. Analysis and Design of Beams for Bending. (2001).

ii. Baikov, V., & Sigalov, E. (1981). Reinforced Concrete

Structures. Moscow: Mir Publishers.

iii. Design Standards for Architectural Building

Components. (2001). St. Louis : Washington University.

iv. Khanna, P. N. (2001). Civil Engineers' Handbook (1st

ed.). New Delhi: Engineers' Publishers.

v. Krishna, J., & Jain, O. P. (1977). Plain & Reinforced

Concrete (7th ed.). Roorkee: Nemchand & Bros .

vi. Ministry of Water Resources, Central Ground

WaterBoard, Government of India. (2009, August). District

Ground Wter Information Booklet. Retrieved May 13, 2013, from

http://cgwb.gov.in/

vii. Nandy, U. K., & Nandy, A. (2016). Materials, Tools &

Technologies to Enhance Efficiency & the Green-Quotient of Smart

Buildings. International Journal of Engineering Research , 14-17.

viii. Nandy, U. K., Nandy, S., & Nandy, A. (2016). Building

Foundation Engineering. Gwalior: Lulu, Inc.

Figure 11: Detailed Section specifically showing the ix. Plain and Reinforced Concrete-Code of Practice. (2000).

staircase of the multi-storey building New Delhi: Bureau of Indian Standards.

x. Punmia, B. C. (1987). Soil Mechanics & Foundations

To design the staircase, the number of treads and risers need (2nd ed.). Jodhpur: Laxmi Publications Pvt. Ltd.

to be calculated first followed by the weight of the slab xi. Punmia, B. (1973). Soil Mechanics and Foundations.

connected to the stair-case. Depth of the staircase, D = Jodhpur.

xii. Singh, V., & Singh, U. C. (2008). Assessment of

groundwater quality of parts of Gwalior (India) for agricultural

purposes. Indian Journal of Science and Technology , 1 (4), 5.

xiii. SOIL & FOUNDATION TYPES. (n.d.). Retrieved May

13, 2013, from Ironwarrior.org

xiv. Styles, K. (1995). Working Drawings' Handbook. Oxford:

D=16.2 cm Architectural Press.

xv. Welfare and Development Directorate and the

Reinforcement, At = Department of Agriculture. (n.d.). Soil Type Categories and

Districts. Retrieved may 13, 2013, from www.mpkrishi.org

At = 11.5 sq cm

NCASE@2016 doi : 10.17950/ijer/v5i3/007 Page 548

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- BSR553 Report Site Analysis Aap2294bDocument54 pagesBSR553 Report Site Analysis Aap2294bNurazwani AhmadNo ratings yet

- Analysis Design and Comparison of A MultDocument6 pagesAnalysis Design and Comparison of A MultNIHAR SHAHNo ratings yet

- Optimum Design of Reinforced Concrete Flat Slab With Drop PanelDocument3 pagesOptimum Design of Reinforced Concrete Flat Slab With Drop PanelAmit HSNo ratings yet

- Analysis and Design of Flat Slab by Using Etabs Software: 1.1 GeneralDocument8 pagesAnalysis and Design of Flat Slab by Using Etabs Software: 1.1 GeneralPOONAM ABHANGNo ratings yet

- Seismic Analysis of Multi-Storied Building With Shear Walls Using EtabsDocument6 pagesSeismic Analysis of Multi-Storied Building With Shear Walls Using EtabsIsmailNo ratings yet

- Shear Strength of Reinforced Concrete MeDocument10 pagesShear Strength of Reinforced Concrete MeAquila1952No ratings yet

- International Journal of Chemtech Research: Dharanya A, Gayathri S, Deepika MDocument8 pagesInternational Journal of Chemtech Research: Dharanya A, Gayathri S, Deepika MTeja Roop ReddyNo ratings yet

- Comparative Study of RC Building with Flat Slab and Shear Wall under EarthquakeDocument8 pagesComparative Study of RC Building with Flat Slab and Shear Wall under EarthquakeephremNo ratings yet

- NOV151322 (1) For Geometric ND Limit StateDocument11 pagesNOV151322 (1) For Geometric ND Limit StateSrinivas TanigantiNo ratings yet

- 2016 06 IJTRD OptimumPositioningofShearWallsinMultistorey BuildingsDocument7 pages2016 06 IJTRD OptimumPositioningofShearWallsinMultistorey BuildingshemanthsridharaNo ratings yet

- Study On Effective Bracing Systems For High Rise Steel StructuresDocument7 pagesStudy On Effective Bracing Systems For High Rise Steel StructuresSaurabh PednekarNo ratings yet

- Seismic Analysis and Design of ResidentiDocument8 pagesSeismic Analysis and Design of ResidentiMohammad Imran NewazNo ratings yet

- Analysis of Floor Diaphragm in Multi - Storied ReiDocument7 pagesAnalysis of Floor Diaphragm in Multi - Storied ReiNIKHIL SINGH-10No ratings yet

- Zhao 2007Document10 pagesZhao 2007William AvilaNo ratings yet

- RCC vs steel-composite building analysis cost comparisonDocument5 pagesRCC vs steel-composite building analysis cost comparisondarsu NaikNo ratings yet

- IJETR2258Document4 pagesIJETR2258anil kasotNo ratings yet

- Hysteretic Behavior of Conventionally Reinforced Concrete Coupling Beams in Reinforced Concrete Coupled Shear WallDocument18 pagesHysteretic Behavior of Conventionally Reinforced Concrete Coupling Beams in Reinforced Concrete Coupled Shear WallPastor PachecoNo ratings yet

- Revised Finite Element Analysis of Reinforced Concrete Beams With Different Rebar Placements and Tension Anchorage OrientationsDocument47 pagesRevised Finite Element Analysis of Reinforced Concrete Beams With Different Rebar Placements and Tension Anchorage Orientationskairu2506No ratings yet

- Ijm&sv12n1 10Document16 pagesIjm&sv12n1 10chandan naiduNo ratings yet

- Seismic Analysis of Multi-Storied Building With Shear Walls Using ETABS-2013Document11 pagesSeismic Analysis of Multi-Storied Building With Shear Walls Using ETABS-20138790922772No ratings yet

- Seismic Analysis of Flat Slab by Using ETABS: S. Dhana Sree, E. ArunakanthiDocument3 pagesSeismic Analysis of Flat Slab by Using ETABS: S. Dhana Sree, E. ArunakanthiTurnitin ReportNo ratings yet

- MD Samsujjoha NissanDocument7 pagesMD Samsujjoha NissanSamsujjoha NissanNo ratings yet

- JklsDocument8 pagesJklsMilan KarkiNo ratings yet

- Parametric StudyDocument14 pagesParametric StudyAmit Sharma IPS AcademyNo ratings yet

- 2004-Robin Davis, Praseetha Krishnan, Devdas Menon, A. Meher PrasadDocument9 pages2004-Robin Davis, Praseetha Krishnan, Devdas Menon, A. Meher PrasadShivaji SarvadeNo ratings yet

- Analysis and Design of G+5 Residential Building Using EtabsDocument3 pagesAnalysis and Design of G+5 Residential Building Using Etabsinnovative technologies0% (1)

- Numerical Analysis Group 10 (Full Report)Document11 pagesNumerical Analysis Group 10 (Full Report)BruhNo ratings yet

- CE 370-Lecture-20 (Continuous Beams and One Way Slabs) - Theory (Read-Only) PDFDocument39 pagesCE 370-Lecture-20 (Continuous Beams and One Way Slabs) - Theory (Read-Only) PDFJamal RkhNo ratings yet

- Applications of Sustainable Post-Tensioned Concrete SlabsDocument12 pagesApplications of Sustainable Post-Tensioned Concrete Slabsmohamed.s.elsayedNo ratings yet

- In-Elastic Performance of 2D-Two Bay Ordinary Concentrically Braced Steel FrameDocument5 pagesIn-Elastic Performance of 2D-Two Bay Ordinary Concentrically Braced Steel FrameAHMADHUSNIRIZAL97199No ratings yet

- Seismic Behavior of RCC Shear Walls Under Different Soil ConditionsDocument4 pagesSeismic Behavior of RCC Shear Walls Under Different Soil Conditionsdurga mibangNo ratings yet

- Design Loadbearing Masonry StructuresDocument9 pagesDesign Loadbearing Masonry StructuresthushtikaNo ratings yet

- Seismic Behaviour of Tall Building Having In-Plan & Vertical IrregularityDocument8 pagesSeismic Behaviour of Tall Building Having In-Plan & Vertical IrregularityRahul SharmaNo ratings yet

- Analysis and Design of Flat Slab Using ETABSDocument8 pagesAnalysis and Design of Flat Slab Using ETABSMikeNo ratings yet

- (IJETA-V11I1P5) :shubham Mishra, Vikas KumarDocument2 pages(IJETA-V11I1P5) :shubham Mishra, Vikas KumarIJETA - EighthSenseGroupNo ratings yet

- Mitigating Shear Lag in Tall BuildingsDocument11 pagesMitigating Shear Lag in Tall BuildingsAvanish AviNo ratings yet

- Confinementreinforcement RCcolumns ICJAug2011Document10 pagesConfinementreinforcement RCcolumns ICJAug2011joshuaNo ratings yet

- Study of Lateral Load Resisting SystemsDocument11 pagesStudy of Lateral Load Resisting SystemsHema Chandra Reddy KarimireddyNo ratings yet

- 47 (3) 0190Document16 pages47 (3) 0190prisciliano1No ratings yet

- Evaluation of ACI 318 19 Provisions For Special Moment Frames and Special Structural Walls Using Data From The E Defense 10 Story TestsDocument23 pagesEvaluation of ACI 318 19 Provisions For Special Moment Frames and Special Structural Walls Using Data From The E Defense 10 Story TestsSudip ShresthaNo ratings yet

- IJMTES030638Document7 pagesIJMTES030638Bobby LupangoNo ratings yet

- The Role of Reviewing Building Structures To Fulfill Requirements For Stiffness, Stability and Strength of Building StructuresDocument16 pagesThe Role of Reviewing Building Structures To Fulfill Requirements For Stiffness, Stability and Strength of Building Structuresaul nafisNo ratings yet

- Seismic Design of Cold Formed Steel Structures in Residential ApplicationsDocument3 pagesSeismic Design of Cold Formed Steel Structures in Residential ApplicationsKristijanRunevskiNo ratings yet

- Confinementreinforcement RCcolumns ICJAug2011 PDFDocument10 pagesConfinementreinforcement RCcolumns ICJAug2011 PDFSamuel megersaNo ratings yet

- In-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementDocument12 pagesIn-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementPanayioti ZoupantisNo ratings yet

- Design Considerations of Tubular Connections: An Example Through The Singapore Sports Hub National Stadium RoofDocument20 pagesDesign Considerations of Tubular Connections: An Example Through The Singapore Sports Hub National Stadium RoofTed MosbyNo ratings yet

- Reinforced Cement Concrete DesignDocument5 pagesReinforced Cement Concrete DesignKimo KenoNo ratings yet

- CICM 2015 JAHER WASIM Full Paper Infill Wall Seismic ResponseDocument9 pagesCICM 2015 JAHER WASIM Full Paper Infill Wall Seismic ResponseZobair RabbaniNo ratings yet

- Modeling of Strain Penetration Effects in Fiber-Based Analysis of Reinforced Concrete StructuresDocument10 pagesModeling of Strain Penetration Effects in Fiber-Based Analysis of Reinforced Concrete StructuresmgrubisicNo ratings yet

- Study of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingDocument6 pagesStudy of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingAkshay DobleNo ratings yet

- Comparative analysis of zigzag structures with varying column inclination anglesDocument15 pagesComparative analysis of zigzag structures with varying column inclination anglesShaik AakheelNo ratings yet

- Ad. RCSDocument28 pagesAd. RCSThe GLOBENo ratings yet

- R.C.Bush Bush, Anoop I. Shirkol, J.S. Sruthi: Doi:10.38208/acp.v1.610Document7 pagesR.C.Bush Bush, Anoop I. Shirkol, J.S. Sruthi: Doi:10.38208/acp.v1.610Srinivas TanigantiNo ratings yet

- Analysis of Multi Storey Building by UsiDocument5 pagesAnalysis of Multi Storey Building by UsiHero Djoni SNo ratings yet

- Theory of Pre-Stress Concrete: Comparative Analysis of Pre Tension and Post Tension SlabDocument39 pagesTheory of Pre-Stress Concrete: Comparative Analysis of Pre Tension and Post Tension SlabJp NaydaaNo ratings yet

- Lecture Notes 1 in Structural Theory 1: First Semester 2021-2022Document11 pagesLecture Notes 1 in Structural Theory 1: First Semester 2021-2022Pres ButtonNo ratings yet

- V2 I20 10Document7 pagesV2 I20 10Anu PathakNo ratings yet

- Use of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneDocument14 pagesUse of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneZimit SukhadiaNo ratings yet

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Current Changes To The Strength Grading of UK Softwoods-European HarmonisationDocument11 pagesCurrent Changes To The Strength Grading of UK Softwoods-European HarmonisationephNo ratings yet

- Behavior of Piles With Raft Foundation Using Safe Software: Reshma T.V, Bhavya B S, Rashmi Mishra, Sankalpasri S SDocument5 pagesBehavior of Piles With Raft Foundation Using Safe Software: Reshma T.V, Bhavya B S, Rashmi Mishra, Sankalpasri S Sfrog15No ratings yet

- STL-01 SUP 01 Methods of Steel Manufacturing - The Electric PDFDocument6 pagesSTL-01 SUP 01 Methods of Steel Manufacturing - The Electric PDFephNo ratings yet

- Design of Beams in Composite Bridges - SteelConstruction - InfoDocument28 pagesDesign of Beams in Composite Bridges - SteelConstruction - InfoephNo ratings yet

- Chapter 1: Introduction To Basic Terms in Theory of ElasticityDocument2 pagesChapter 1: Introduction To Basic Terms in Theory of ElasticityephNo ratings yet

- STL-01 SUP-02 Rapid - Manufacturing - of - Metallic - Objects PDFDocument14 pagesSTL-01 SUP-02 Rapid - Manufacturing - of - Metallic - Objects PDFephNo ratings yet

- Chapter 1: Introduction To Basic Terms in Theory of ElasticityDocument2 pagesChapter 1: Introduction To Basic Terms in Theory of ElasticityephNo ratings yet

- Chapter 4-Theory-of-Elasticity-PG-Course PDFDocument15 pagesChapter 4-Theory-of-Elasticity-PG-Course PDFephNo ratings yet

- STL-01 Manufacturing and Fabrication of Steel 2020.21 I PDFDocument9 pagesSTL-01 Manufacturing and Fabrication of Steel 2020.21 I PDFephNo ratings yet

- Chapter 2-Theory-of-Elasticity-PG-Course PDFDocument15 pagesChapter 2-Theory-of-Elasticity-PG-Course PDFephNo ratings yet

- AAiT Structural Engineering Postgrad ProgramDocument1 pageAAiT Structural Engineering Postgrad ProgramephNo ratings yet

- One-Way Shear in Wide Concrete Beams With Narrow Supports: AuthorsDocument10 pagesOne-Way Shear in Wide Concrete Beams With Narrow Supports: AuthorsephNo ratings yet

- STL-01 SUP 01 Methods of Steel Manufacturing - The Electric PDFDocument6 pagesSTL-01 SUP 01 Methods of Steel Manufacturing - The Electric PDFephNo ratings yet

- Chapter 3-Theory-of-Elasticity-PG-Course PDFDocument10 pagesChapter 3-Theory-of-Elasticity-PG-Course PDFephNo ratings yet

- STL-01 SUP-02 Rapid - Manufacturing - of - Metallic - Objects PDFDocument14 pagesSTL-01 SUP-02 Rapid - Manufacturing - of - Metallic - Objects PDFephNo ratings yet

- STL-01 Manufacturing and Fabrication of Steel 2020.21 I PDFDocument9 pagesSTL-01 Manufacturing and Fabrication of Steel 2020.21 I PDFephNo ratings yet

- STL-02ii Plastic AnalysisDocument13 pagesSTL-02ii Plastic AnalysisephNo ratings yet

- 1Document47 pages1MqAshladyNo ratings yet

- STL-02ii Plastic AnalysisDocument13 pagesSTL-02ii Plastic AnalysisephNo ratings yet

- STL-01 SUP 01 Methods of Steel Manufacturing - The Electric PDFDocument6 pagesSTL-01 SUP 01 Methods of Steel Manufacturing - The Electric PDFephNo ratings yet

- Prestressed Concrete Design To Eurocodes PDFDocument13 pagesPrestressed Concrete Design To Eurocodes PDFashwini thakurNo ratings yet

- Design of Beams in Composite Bridges - SteelConstruction - InfoDocument28 pagesDesign of Beams in Composite Bridges - SteelConstruction - InfoephNo ratings yet

- Slab Es en 1992-2015 PDFDocument4 pagesSlab Es en 1992-2015 PDFephNo ratings yet

- AAiT Structural Engineering Postgrad ProgramDocument1 pageAAiT Structural Engineering Postgrad ProgramephNo ratings yet

- SR en 10025-04Document8 pagesSR en 10025-04pukla100% (2)

- Concise Drafting Manual DraftDocument39 pagesConcise Drafting Manual DraftAmanuelGirmaNo ratings yet

- A New Formulation For The Geometric Layout Optimisation of Flat S PDFDocument10 pagesA New Formulation For The Geometric Layout Optimisation of Flat S PDFephNo ratings yet

- 62 Effect PDFDocument9 pages62 Effect PDFephNo ratings yet

- Stiffeners - SteelConstruction - InfoDocument12 pagesStiffeners - SteelConstruction - InfoephNo ratings yet

- Watertank GS PDFDocument24 pagesWatertank GS PDFManoj RautNo ratings yet

- Measurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 TotalDocument19 pagesMeasurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 Totaldan12345_007No ratings yet

- EC4 English PDFDocument23 pagesEC4 English PDFSever KawaNo ratings yet

- CALCULATION OF ONE-WAY SLAB PARAMETERSDocument2 pagesCALCULATION OF ONE-WAY SLAB PARAMETERSRal GLNo ratings yet

- Indoor Air Quality TraneDocument45 pagesIndoor Air Quality TraneMuhammad Faheem ShahbazNo ratings yet

- Druk White Lotus School 08.08.2020Document10 pagesDruk White Lotus School 08.08.2020Keshika KsNo ratings yet

- Group 5 - Assignment 2 Green BuildingDocument5 pagesGroup 5 - Assignment 2 Green BuildingDesigan PillayNo ratings yet

- HVAC Budget Pricing Guide for Relocation, New Equipment, and Unit CostsDocument1 pageHVAC Budget Pricing Guide for Relocation, New Equipment, and Unit CostsiwguNo ratings yet

- Formwork For Levelling ConcreteDocument86 pagesFormwork For Levelling ConcreteelfigossNo ratings yet

- Construction notes and schedulesDocument1 pageConstruction notes and schedulesAeron AcioNo ratings yet

- Guidance For Fungus Avoidance in Healthcare Facilities PDFDocument60 pagesGuidance For Fungus Avoidance in Healthcare Facilities PDFSyukri ImranNo ratings yet

- TPE - Bigger Brochure - Newsletter-Type Design v1 2020 RGB - Spreads-View - 72dpi-MinDocument13 pagesTPE - Bigger Brochure - Newsletter-Type Design v1 2020 RGB - Spreads-View - 72dpi-MinfuckoffNo ratings yet

- Checklist 6feb2019Document25 pagesChecklist 6feb2019ngapainNo ratings yet

- AHU ChecklistDocument11 pagesAHU ChecklistHeltonNo ratings yet

- Dense Graded Bitumen Mixes For PavementsDocument4 pagesDense Graded Bitumen Mixes For PavementsPamirNo ratings yet

- AHU Inspection Plan for Saudi AramcoDocument3 pagesAHU Inspection Plan for Saudi AramcoRAMAKRISHNA100% (1)

- Concrete Technology MCQ Civil EngineeringDocument11 pagesConcrete Technology MCQ Civil EngineeringAjay PawarNo ratings yet

- Bim Course ContentsDocument4 pagesBim Course ContentsPavan Kumar M VNo ratings yet

- UntitledDocument28 pagesUntitledUmar YaqoobNo ratings yet

- Laguna Bel AirDocument5 pagesLaguna Bel AirDalawa BenteNo ratings yet

- Elevated Service ReservoirDocument35 pagesElevated Service ReservoirRamachandra SahuNo ratings yet

- Ks Series Vertical Cad Details KSMR KSMMR Ksaz KSMW KSSL NaDocument72 pagesKs Series Vertical Cad Details KSMR KSMMR Ksaz KSMW KSSL NaTaurai ChiwanzaNo ratings yet

- GTG 2.13 Files Exported On 2-2-2017Document1,500 pagesGTG 2.13 Files Exported On 2-2-2017tyaskartikaNo ratings yet

- Final87898-Klaus LanzingerDocument44 pagesFinal87898-Klaus LanzingerAHMAD YAGHINo ratings yet

- Catalog Fatade Ventilate Etem PDFDocument110 pagesCatalog Fatade Ventilate Etem PDFLucian BumbaceaNo ratings yet

- 2015 0526 DWG Fire DDSetDocument16 pages2015 0526 DWG Fire DDSetnadiruuzaman sizanNo ratings yet

- Ufgs 07 05 23Document31 pagesUfgs 07 05 23sharethefilesNo ratings yet

- Self Consolidating High Performance Concrete - SCC Self Consolidation and Highly Flowable ConcreteDocument2 pagesSelf Consolidating High Performance Concrete - SCC Self Consolidation and Highly Flowable ConcreteChitharanjan VishnukripalNo ratings yet

- Acoperis Dublu Faltz VMZINCDocument40 pagesAcoperis Dublu Faltz VMZINCSimona Rotundu100% (1)

- Finalll Report 2022Document23 pagesFinalll Report 2022Alind HasanNo ratings yet