Professional Documents

Culture Documents

Qr-Me-013a (Pre - Test Checklist)

Uploaded by

syedahmad390 ratings0% found this document useful (0 votes)

24 views1 pageThis document is a pre-test checklist for a pipeline at the Ma'aden Phosphate Project. It contains 28 items that must be checked prior to hydrotesting the line, including verifying piping and component materials and dimensions, removal of instruments and valves, installation of blinds and supports, calibration of gauges and relief valves, and ensuring vents and drains are properly configured. The checklist requires sign-off by inspectors from the project contractor, Dragados Industrial, and the project owner, Ma'aden Phosphate Company, once all items are confirmed.

Original Description:

Original Title

QR-ME-013A (PRE -TEST CHECKLIST)

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a pre-test checklist for a pipeline at the Ma'aden Phosphate Project. It contains 28 items that must be checked prior to hydrotesting the line, including verifying piping and component materials and dimensions, removal of instruments and valves, installation of blinds and supports, calibration of gauges and relief valves, and ensuring vents and drains are properly configured. The checklist requires sign-off by inspectors from the project contractor, Dragados Industrial, and the project owner, Ma'aden Phosphate Company, once all items are confirmed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views1 pageQr-Me-013a (Pre - Test Checklist)

Uploaded by

syedahmad39This document is a pre-test checklist for a pipeline at the Ma'aden Phosphate Project. It contains 28 items that must be checked prior to hydrotesting the line, including verifying piping and component materials and dimensions, removal of instruments and valves, installation of blinds and supports, calibration of gauges and relief valves, and ensuring vents and drains are properly configured. The checklist requires sign-off by inspectors from the project contractor, Dragados Industrial, and the project owner, Ma'aden Phosphate Company, once all items are confirmed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

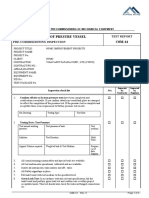

PROJECT: TEST PACKAGE NO.

MA`ADEN PHOSPHATE PROJECT HT-0001

QUALITY RECORD FORM QR/ME/013A CLIENT: MA`ADEN PHOSPHATE COMPANY

CONTRACTOR: DRAGADOS INDUSTRIAL S.A

PRE TEST LINE CHECKLIST CONTRACT NO.: MD-502-8000-CN-PS-CON-0001

NO. ITEM YES NO N/A

1 Check Piping Lay-out, Isometric Drawings and P&ID`s

2 Correct material used. Check Size,Wall Thickness,Dimension,Rating and Material.

3 Check Type & Location of bend,tee,reducer & other fittings.

4 Check if Piping & components & Attachments are clean internally & externally.

5 All weld joints are uninsulated and expose for hydro test.

6 Weep holes in reinforcing pads.

7 All NDT & PWHT are completed and accepted.

8 Check flow direction of globe/control valves/strainers.

9 Orifice flange record already accepted & attached.

10 Test Blinds Installed and proper thickness are verified.

11 Instruments Removed/Blocked

12 Check Valve Internals Removed (if necessary).

13 Special Piping Items Removed (if necessary)

14 Control Valves, Pressure Safety,Valves,Temperature Safety Valves removed.

15 Expansion Joints Removed.

16 Spring Support Gagged

17 Valves Open Position for Flushing.

18 Ball Valves in Half Open Position for Flushing.

19 Temporary Support Installed (where applicable).

20 Temporary Spool Installed (where applicable).

21 Vents Open for Filling

22 Vents and drains are Closed Testing and properly fitted valves.

23 Correct Gasket and Bolting installed.

24 Test fluid approved.

25 Presure Gauges Calibrated.

26 Presure Relief Valve Calibrated.

27 OSI (On Stream Inspection) points to be verified.

28 Bolts tightness / sequence torqueing and Lubrication for requirements.

29 Correct Flanges / Gasket rating.

INSPECTOR NESMA DRAGADOS OWNER

NAME

SIGNATURE

DATE

You might also like

- Bill Payment Schedule: D Ue O N Pa y On Not Es Ja N Fe B M Ar A PR M AyDocument2 pagesBill Payment Schedule: D Ue O N Pa y On Not Es Ja N Fe B M Ar A PR M Aysyedahmad39No ratings yet

- Shoring Sloping Procedure PDFDocument20 pagesShoring Sloping Procedure PDFsyedahmad39No ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Piping System Hydraulic Test Procedure R0Document6 pagesPiping System Hydraulic Test Procedure R0cmc261185No ratings yet

- Hydrostatic Test Procedure: Salalah Ammonia ProjectDocument6 pagesHydrostatic Test Procedure: Salalah Ammonia ProjectAbdelkhak KhallaNo ratings yet

- Manpower & Equipment Deployment Rev 0Document345 pagesManpower & Equipment Deployment Rev 0syedahmad39100% (1)

- Manpower & Equipment Deployment Rev 0Document345 pagesManpower & Equipment Deployment Rev 0syedahmad39100% (1)

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeeNo ratings yet

- Indicative Inspection & Test Plan : Project: - Iocl PanipatDocument2 pagesIndicative Inspection & Test Plan : Project: - Iocl PanipatAshish DhokNo ratings yet

- JXN ITR-A Piping PDFDocument21 pagesJXN ITR-A Piping PDFAmyNo ratings yet

- 16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Document28 pages16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Fauzan Rusmayadi Reharder100% (1)

- Wellhead Operator - AnandrajDocument4 pagesWellhead Operator - Anandrajjohn M100% (1)

- Piping Reinstatement: Inspection Test Report Form NoDocument2 pagesPiping Reinstatement: Inspection Test Report Form NoFrancisco75% (4)

- 220+ Excel Shortcuts Keys For Windows & Mac - ExcDocument28 pages220+ Excel Shortcuts Keys For Windows & Mac - Excsyedahmad39No ratings yet

- Duties of Welding InspectorDocument4 pagesDuties of Welding InspectorBalakumarNo ratings yet

- MS For Leak Testing of TanksDocument5 pagesMS For Leak Testing of TanksOmar Tocmo100% (1)

- Petronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - A Piping Work Completion P01-ADocument21 pagesPetronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - A Piping Work Completion P01-AWael Chouchani100% (2)

- Piping Hydrostatic Test Procedure Rev0Document8 pagesPiping Hydrostatic Test Procedure Rev0smsunil12345No ratings yet

- Hydrotest Procedure For PipingDocument4 pagesHydrotest Procedure For Pipingsuria qaqcNo ratings yet

- Std-Insp-0127 Procedure For Commissioning ProcedureDocument54 pagesStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraNo ratings yet

- Method Statement For Domestic Water Piping Installation UG & AGDocument14 pagesMethod Statement For Domestic Water Piping Installation UG & AGBelal AlrwadiehNo ratings yet

- Engineering Activities, Man-Hour EstimatesDocument9 pagesEngineering Activities, Man-Hour Estimatessyedahmad39No ratings yet

- Qcf301 Tp05 Pressure Test ChecklistDocument1 pageQcf301 Tp05 Pressure Test ChecklistminhnnNo ratings yet

- VINDAIR SOP.01 Duct Pressure TestDocument3 pagesVINDAIR SOP.01 Duct Pressure TestRamakrishna Agumbe100% (2)

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- Method Statement - Drain PipingDocument17 pagesMethod Statement - Drain PipingAnish KumarNo ratings yet

- 88 D 340 nh3 Storage Tank Sept 10 2014 2Document9 pages88 D 340 nh3 Storage Tank Sept 10 2014 2mohamed abd eldayemNo ratings yet

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- An Article For Piping Design Guide of Reactors - What Is Piping PDFDocument19 pagesAn Article For Piping Design Guide of Reactors - What Is Piping PDFsyedahmad39No ratings yet

- TANK 06 Test PackDocument12 pagesTANK 06 Test PackGomathyselvi100% (3)

- Method Statement - MS PipingDocument13 pagesMethod Statement - MS PipingAnish KumarNo ratings yet

- Benchmarking Project Level Engineering ProductivityDocument10 pagesBenchmarking Project Level Engineering Productivitysyedahmad39No ratings yet

- IRN-8108577716-432-01-RIL-Audco-17 Jan 2014Document1 pageIRN-8108577716-432-01-RIL-Audco-17 Jan 2014MuralitclNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- NS2-DD09-P0ZEN-740027 HDPE Piping Hydrostatic Test ProcedureDocument36 pagesNS2-DD09-P0ZEN-740027 HDPE Piping Hydrostatic Test ProceduretuanphamNo ratings yet

- Cost Estimating Manual For Projects: December 2020Document72 pagesCost Estimating Manual For Projects: December 2020M Al HattanNo ratings yet

- Method Statement For Ss PipingDocument10 pagesMethod Statement For Ss PipingNishar BalkavadeNo ratings yet

- Sa01 Genxxx SDGG PRTS 0107 V00Document7 pagesSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNo ratings yet

- Hydro Test ProcedureDocument6 pagesHydro Test Procedurevijay padaleNo ratings yet

- Pre-Hydrotest Check List-FormatDocument1 pagePre-Hydrotest Check List-FormatHanuman Rao0% (1)

- Method Statement For Refrigerant Piping Installation and Pressure TestingDocument3 pagesMethod Statement For Refrigerant Piping Installation and Pressure TestingDong Vanra100% (1)

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning ChecklistsMuhammad Akram100% (1)

- Material Receiving ReportDocument15 pagesMaterial Receiving ReportGomathyselvi100% (1)

- 10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)Document1 page10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)caovanthien10121992No ratings yet

- Mps SDM 2014 Tp042Document37 pagesMps SDM 2014 Tp042Janardhan Surya100% (1)

- Procedure For Hydro TestDocument5 pagesProcedure For Hydro TestRam ThevarNo ratings yet

- Hydrotest Procedure For PipingDocument4 pagesHydrotest Procedure For Pipingsuria qaqcNo ratings yet

- Testing Preparation and ExecutionDocument2 pagesTesting Preparation and ExecutionCharlie Dela RosaNo ratings yet

- Accede PR-162 1-2Document1 pageAccede PR-162 1-2Massimo FumarolaNo ratings yet

- Pipework Pre-Test Check ListDocument1 pagePipework Pre-Test Check ListJoanrenis SaranyaNo ratings yet

- 08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Document12 pages08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Avak NishanNo ratings yet

- 05 Hyd - Test ProcedureDocument3 pages05 Hyd - Test ProcedureirfanNo ratings yet

- Nitto - MOS Pressure TestDocument6 pagesNitto - MOS Pressure TestNajwa AmirahNo ratings yet

- Post-Test Check List of Piping Work (After Hydrostatic Test)Document1 pagePost-Test Check List of Piping Work (After Hydrostatic Test)Febboy FebriNo ratings yet

- MGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031Document9 pagesMGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031velmurug_balaNo ratings yet

- Hot-Tapping ProceduresDocument2 pagesHot-Tapping ProceduresBensmatNo ratings yet

- Pressure Vessel InspectionDocument3 pagesPressure Vessel InspectionSpectex dubaiNo ratings yet

- Form Test PacketDocument24 pagesForm Test PacketYudha Andrie Sasi ZenNo ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Pressure Vessel - Inspectin CertificateDocument3 pagesPressure Vessel - Inspectin CertificateSpectex dubaiNo ratings yet

- Hydrotest Procedure C 6 23Document19 pagesHydrotest Procedure C 6 23savanth jayaramNo ratings yet

- Akhtar Ansari - TPI - FRT PDFDocument5 pagesAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNo ratings yet

- 2022Document17 pages2022mahdi_g100% (1)

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 pagesC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNo ratings yet

- Construction Check Sheet Piping Installation For Test PI-0021ADocument1 pageConstruction Check Sheet Piping Installation For Test PI-0021AhrimklimNo ratings yet

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- Arun CV PDFDocument5 pagesArun CV PDFArun SidharthNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Excel Shortcut Keys Download .PDF andDocument36 pagesExcel Shortcut Keys Download .PDF andsyedahmad39No ratings yet

- Developing A Framework For Mitigation of Project Delays in Roads and Highways Sector Projects in IndiaDocument10 pagesDeveloping A Framework For Mitigation of Project Delays in Roads and Highways Sector Projects in Indiasyedahmad39No ratings yet

- Duration: 2 Days Audience: Prerequisites:: Project Management ResourcesDocument1 pageDuration: 2 Days Audience: Prerequisites:: Project Management Resourcessyedahmad39No ratings yet

- NATIONAL FITTINGS A PDFDocument102 pagesNATIONAL FITTINGS A PDFsyedahmad39No ratings yet

- Test Pack Flow / Control Log: Punch List / Inspection Prior For Hydro TestDocument2 pagesTest Pack Flow / Control Log: Punch List / Inspection Prior For Hydro Testsyedahmad39No ratings yet

- 0 6394 1 PDFDocument212 pages0 6394 1 PDFsyedahmad39No ratings yet

- 15.1 Safety Management: Contractor Management System: 15.1.1 PurposeDocument13 pages15.1 Safety Management: Contractor Management System: 15.1.1 Purposesyedahmad39No ratings yet