Professional Documents

Culture Documents

Accede PR-162 1-2

Uploaded by

Massimo FumarolaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accede PR-162 1-2

Uploaded by

Massimo FumarolaCopyright:

Available Formats

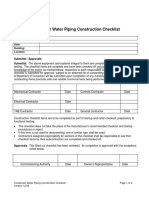

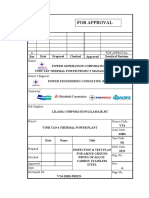

Form N°: PR – 162

Piping Completion Inspection Record Rev: 00

Date: February 2016

(Pre Test Checklist) Page 1 of 2

Client: Location: Project: Test Pack N:

MAJNOON CPF 2 PROJECT ACD-CP2-F-50701A

PETROFAC LOMMEL CPF-2-50701A/B RADIANT

Description of Activities Punch ACD QC Date Contractor Date Remarks

List Items Checklist, Not Limited Initials QC Initials

To

Welding Complete.

PWHT / HT Complete.

NDE (and Alloy Verification if applicable)

Complete.

Released By QC Welding Department.

Line Installed To Drawing.

Line Size Correct.

Line Correct To Pipe Specification.

Flanges/Fittings Correct.

Branch Connection & Location Correct.

Reinforcing Pads Installed and Tested

Weep Holes Installed and Threaded (if

applicable).

Reducers Installed Correctly.

Piping Straight and Plumb.

Verify all Lines Stress Free Connected.

Line Slope As Per Drawing.

Spades and Blinds Installed Correctly. (see Marking by yellow paint all temporary

note). items (e.g. test blinds) installed.

High Point Vents and Low Point Drains

Installed Correctly.

Flange Joints Aligned Correctly.

Verify Bore Dimensions and Cleanliness of

Drilled Tapings on Orifice Flange.

Verify Orifice Flange Internal Weld Root

Ground Flush With Internal Bore of Pipe

Studs / Bolts Correct.

Gaskets / Type / Rating Correct. Verify that any temporary gaskets are

identified as such.

Valve TAG Numbers Correct.

Valve Stem Orientation Correct.

Valve Locked Open/Closed (as applicable). Verify fluid direction through valves

(globe valves, flexible wedge gate

valve) as per P&ID.

You might also like

- Testing & Commissioning Checklist For Fire PumpDocument2 pagesTesting & Commissioning Checklist For Fire PumpOanh Nguyen86% (7)

- Piping Field Inspection Checklist DikonversiDocument3 pagesPiping Field Inspection Checklist DikonversiJo Francesc100% (2)

- Pre Start Up Safety ReviewDocument8 pagesPre Start Up Safety ReviewAhmed MorsyNo ratings yet

- Astm A234 PDFDocument8 pagesAstm A234 PDFhans30No ratings yet

- SP PI PP 001 (General Piping System)Document49 pagesSP PI PP 001 (General Piping System)Ari IndrajayaNo ratings yet

- Accede PR-162P 2 - 2Document1 pageAccede PR-162P 2 - 2Massimo FumarolaNo ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- Qr-Me-013a (Pre - Test Checklist)Document1 pageQr-Me-013a (Pre - Test Checklist)syedahmad39No ratings yet

- Overhead Crane - FunctionTestProcedureDocument15 pagesOverhead Crane - FunctionTestProcedurepetazNo ratings yet

- Itp FGP 2Document21 pagesItp FGP 2fusionndtNo ratings yet

- Air Handling Unit QC Checklist: AHU InformationDocument5 pagesAir Handling Unit QC Checklist: AHU InformationRaheel AhmedNo ratings yet

- Material Receiving ReportDocument15 pagesMaterial Receiving ReportGomathyselvi100% (1)

- Punch List For Fire Water Pump & Foam Pump PackageDocument4 pagesPunch List For Fire Water Pump & Foam Pump PackageGomathyselviNo ratings yet

- Asorc-Qcp 1652 ModifiedDocument22 pagesAsorc-Qcp 1652 ModifiedalkhiatNo ratings yet

- B15 PCH 50 SP 004 CDocument134 pagesB15 PCH 50 SP 004 CWarlexNo ratings yet

- Underground Drainage Pipes - Installation & TestingDocument1 pageUnderground Drainage Pipes - Installation & TestingBharathraj RajNo ratings yet

- Form Test PacketDocument24 pagesForm Test PacketYudha Andrie Sasi ZenNo ratings yet

- Inspection and Test Plan For SwitchgearDocument12 pagesInspection and Test Plan For SwitchgearShahadat HossainNo ratings yet

- PUNCH LIST - PipingDocument1 pagePUNCH LIST - PipingtalhaNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Indicative Inspection & Test Plan : Project: - Iocl PanipatDocument2 pagesIndicative Inspection & Test Plan : Project: - Iocl PanipatAshish DhokNo ratings yet

- Plant Inspector: Company Nameoryx GTLDocument4 pagesPlant Inspector: Company Nameoryx GTLsanketNo ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Testing & Commissioning Checklist For Fire PumpDocument1 pageTesting & Commissioning Checklist For Fire PumpAmie GTunedNo ratings yet

- PTC Inspector Training Manual Spark MindaDocument20 pagesPTC Inspector Training Manual Spark MindaYogiNo ratings yet

- ACDEDE PR-136 Test Pack HT Dossier Front CoverDocument1 pageACDEDE PR-136 Test Pack HT Dossier Front CoverMassimo FumarolaNo ratings yet

- Std-Insp-0127 Procedure For Commissioning ProcedureDocument54 pagesStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraNo ratings yet

- Eil FormatDocument1 pageEil Formatsales.aquavalvesNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- SER-CUR-CSI-033 Pressure Testing of PipelinesDocument1 pageSER-CUR-CSI-033 Pressure Testing of Pipelinesroraima.salazarNo ratings yet

- EMI Marco Antonio Serrano Bazán Bolivia 6945986 Quote NumberDocument1 pageEMI Marco Antonio Serrano Bazán Bolivia 6945986 Quote NumberMarcoAntonioSerranoBazanNo ratings yet

- QC Surveillance Report: As Per P.OrderDocument3 pagesQC Surveillance Report: As Per P.OrderRahul MoottolikandyNo ratings yet

- Pressure Test Report For Water Supply PipingDocument1 pagePressure Test Report For Water Supply PipingBelal Alrwadieh100% (1)

- Daily QAQC Check SheetsDocument1 pageDaily QAQC Check Sheetsfhairuz.wahidNo ratings yet

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocument4 pages2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNo ratings yet

- Liquid Penetrant Examination Report: PO No.&Document2 pagesLiquid Penetrant Examination Report: PO No.&Samir Chaudhary100% (2)

- Spool HT EPCMD 2 QM00 FMT PP 028 - 01Document1 pageSpool HT EPCMD 2 QM00 FMT PP 028 - 01Muthu AlaguRajNo ratings yet

- Condenser Water Piping Construction Checklist: Project: Date: Building: LocationDocument4 pagesCondenser Water Piping Construction Checklist: Project: Date: Building: LocationGopinath GopiNo ratings yet

- ITP Modofication RF To RTJ BALL VALVE 6 INCH ID-BKP-SOME-2009-550318-P-BKP-19-001 - rev0.1-RSDocument2 pagesITP Modofication RF To RTJ BALL VALVE 6 INCH ID-BKP-SOME-2009-550318-P-BKP-19-001 - rev0.1-RSFerdie OSNo ratings yet

- Nozzle OrientationDocument2 pagesNozzle OrientationArindom KunduNo ratings yet

- Testing & Commissioning For Fire PumpDocument1 pageTesting & Commissioning For Fire PumpSalim BakhshNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- CHK PH 0002Document4 pagesCHK PH 0002jvfcvNo ratings yet

- QCQF04-Concrete Pre-Pour Inspection ChecklistDocument2 pagesQCQF04-Concrete Pre-Pour Inspection ChecklistPrasanthCsadasivanNo ratings yet

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Document4 pagesInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNo ratings yet

- G2W0142006 3.5 PUP DP 5FT 中英文质证书Document11 pagesG2W0142006 3.5 PUP DP 5FT 中英文质证书JoseMi Vacaflor IllanesNo ratings yet

- Electrical ConduitingDocument1 pageElectrical ConduitingGabriel GabeNo ratings yet

- Qar-Qd#413-11 Outlet TC d11rDocument1 pageQar-Qd#413-11 Outlet TC d11rkipak.s.at.uNo ratings yet

- Resume An Welding InspectorDocument7 pagesResume An Welding InspectorspearboraNo ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Installation of Flow Meter Check ListDocument1 pageInstallation of Flow Meter Check ListZulfequar R. Ali Khan100% (2)

- Ecc Mech Sharq 22 016 Rev 01Document6 pagesEcc Mech Sharq 22 016 Rev 01Muthu SaravananNo ratings yet

- Chilled Water Piping Construction Checklist: Project: Date: Building: LocationDocument4 pagesChilled Water Piping Construction Checklist: Project: Date: Building: LocationGopinath Gopi100% (1)

- TIPL-ES-CL-001 - P&ID ChecklistDocument7 pagesTIPL-ES-CL-001 - P&ID ChecklistAshwin PathakNo ratings yet

- PlumbingDocument1 pagePlumbingGabriel GabeNo ratings yet

- Test Pack SampleDocument12 pagesTest Pack SampleGomathyselviNo ratings yet

- Desmet Ballestra India PVT LTD: Inspection Test PlanDocument2 pagesDesmet Ballestra India PVT LTD: Inspection Test Plansameer patilNo ratings yet

- ECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportDocument6 pagesECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportJorge LemusNo ratings yet

- JXN ITR-A Piping PDFDocument21 pagesJXN ITR-A Piping PDFAmyNo ratings yet

- QAR-QD#419-2 Single PartsDocument2 pagesQAR-QD#419-2 Single PartsIrwanto ManafNo ratings yet

- A-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksDocument25 pagesA-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksUnna Malai50% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- COVID 19 Risk RegisterDocument3 pagesCOVID 19 Risk RegisterMassimo FumarolaNo ratings yet

- Dry Film Thickness Based On SSPCDocument4 pagesDry Film Thickness Based On SSPCMassimo FumarolaNo ratings yet

- Ruths Ut 01 Rev 0 Uni en Iso 11666lev 2Document13 pagesRuths Ut 01 Rev 0 Uni en Iso 11666lev 2Massimo FumarolaNo ratings yet

- Emergency Plan SiteDocument10 pagesEmergency Plan SiteMassimo FumarolaNo ratings yet

- Module A - (Internal Production Control)Document2 pagesModule A - (Internal Production Control)Massimo FumarolaNo ratings yet

- pchb02 Hardness ProcedureDocument7 pagespchb02 Hardness ProcedureMassimo FumarolaNo ratings yet

- Method Statement of Hydrostatic TestDocument28 pagesMethod Statement of Hydrostatic TestMassimo FumarolaNo ratings yet

- INOUE Quality Control ManualDocument43 pagesINOUE Quality Control ManualMassimo FumarolaNo ratings yet

- C-1-30 - Radiographic Examination Procedure (O1220-SP-TUY-40130-00)Document15 pagesC-1-30 - Radiographic Examination Procedure (O1220-SP-TUY-40130-00)Massimo FumarolaNo ratings yet

- Paut Total ProcedureDocument25 pagesPaut Total ProcedureMassimo Fumarola100% (1)

- WI 28.008 Taakrisicoanalyse OPTARA LOT 2A ENGELS R2 Voor VGM PlanDocument17 pagesWI 28.008 Taakrisicoanalyse OPTARA LOT 2A ENGELS R2 Voor VGM PlanMassimo FumarolaNo ratings yet

- C-1-29 - Dye Peneterant Inspection Procedure (O1220-SP-TUY-40129-00)Document10 pagesC-1-29 - Dye Peneterant Inspection Procedure (O1220-SP-TUY-40129-00)Massimo FumarolaNo ratings yet

- ACDEDE PR-136 Test Pack HT Dossier Front CoverDocument1 pageACDEDE PR-136 Test Pack HT Dossier Front CoverMassimo FumarolaNo ratings yet

- Accede Test Pressure Record Circuit 2Document1 pageAccede Test Pressure Record Circuit 2Massimo FumarolaNo ratings yet

- Acd Si 004Document6 pagesAcd Si 004Massimo FumarolaNo ratings yet

- Acd Si 005Document13 pagesAcd Si 005Massimo FumarolaNo ratings yet

- Accede Test Pressure Record Circuit 1Document1 pageAccede Test Pressure Record Circuit 1Massimo FumarolaNo ratings yet

- Painting Inspection ProcedureDocument22 pagesPainting Inspection ProcedureMassimo FumarolaNo ratings yet

- Majnoon CPF 2 Project: Fired Heater CP2-F-50701 A/B Coil Prefabrication Hydrostatic Test ProcedureDocument14 pagesMajnoon CPF 2 Project: Fired Heater CP2-F-50701 A/B Coil Prefabrication Hydrostatic Test ProcedureMassimo FumarolaNo ratings yet

- Aco 001Document21 pagesAco 001Massimo FumarolaNo ratings yet

- HSE 28.002er4 EmergencyProcedureTechniciansDocument6 pagesHSE 28.002er4 EmergencyProcedureTechniciansMassimo FumarolaNo ratings yet

- Corrosion Detection and ControlDocument47 pagesCorrosion Detection and ControlMassimo FumarolaNo ratings yet

- Field Radiography Emergency PlanDocument12 pagesField Radiography Emergency PlanMassimo FumarolaNo ratings yet

- Remote Visual InspectionDocument209 pagesRemote Visual InspectionMassimo FumarolaNo ratings yet

- Native-Quality-Management-Xray ManualDocument28 pagesNative-Quality-Management-Xray ManualMassimo FumarolaNo ratings yet

- Borealis Kallo Scan Plan - Shear + DMA L On 9.52mmt Austenitic Weld (Rev 0.0)Document7 pagesBorealis Kallo Scan Plan - Shear + DMA L On 9.52mmt Austenitic Weld (Rev 0.0)Massimo FumarolaNo ratings yet

- Branch and Socket RT Method StatementDocument30 pagesBranch and Socket RT Method StatementMassimo FumarolaNo ratings yet

- SP-P-005 - Rev 1 - Specification For Underground PipingDocument12 pagesSP-P-005 - Rev 1 - Specification For Underground Pipingvishal bhamreNo ratings yet

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionssgopalkn7559No ratings yet

- EVR BrochureDocument6 pagesEVR BrochurekicsnerNo ratings yet

- Ring Joint Flanges: ANSI B16.5, ANSI B16.20Document1 pageRing Joint Flanges: ANSI B16.5, ANSI B16.20QC RegianNo ratings yet

- Latham Steel Open Top Step InstallDocument7 pagesLatham Steel Open Top Step InstallAdrian LeonNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- ASME B16 5 Flange Facing FinishDocument4 pagesASME B16 5 Flange Facing FinishMilton RamirezNo ratings yet

- 5 Material and Traceability RecordDocument6 pages5 Material and Traceability RecordEdha Ali100% (1)

- VMS 1Document121 pagesVMS 1Subash ChandraboseNo ratings yet

- Unit 1 - FPSDocument3 pagesUnit 1 - FPSGreen MichaelsNo ratings yet

- Hydril - GK BOP PDFDocument66 pagesHydril - GK BOP PDFBoris Zaslichko67% (3)

- SPX PLENTY Filters and StrainersDocument7 pagesSPX PLENTY Filters and StrainersniqutomoNo ratings yet

- Installation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Document4 pagesInstallation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Camilo CorreaNo ratings yet

- The Modular Pipework System: No. 1 in Pipework SystemsDocument5 pagesThe Modular Pipework System: No. 1 in Pipework Systemssrikandi marketingNo ratings yet

- Transformer 7Document1 pageTransformer 7KhajaBurhanNo ratings yet

- PricelistDocument80 pagesPricelistCrisanto CajulisNo ratings yet

- Rigid PVC Pressure Pipes and Fittings: Jeevan Bhar Ka Saath..Document8 pagesRigid PVC Pressure Pipes and Fittings: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Mirillas Rectangulares LumiglasDocument2 pagesMirillas Rectangulares Lumiglasluis fernando veraNo ratings yet

- EMR 3 Guia de InstalacionDocument68 pagesEMR 3 Guia de InstalacionChristian Alberto Soto MullerNo ratings yet

- Doneldson Air Breather FilterDocument14 pagesDoneldson Air Breather FilterParinpa KetarNo ratings yet

- Ralph C. Whitley SR.: From: Sent: To: CCDocument7 pagesRalph C. Whitley SR.: From: Sent: To: CCRalph Charles Whitley, Sr.No ratings yet

- 34 Samss 118Document9 pages34 Samss 118naruto256No ratings yet

- 8992 0113 35 List of PartsDocument69 pages8992 0113 35 List of PartsJuan Carlos Galarza CastilloNo ratings yet

- Cafco Blaze Shield Ii HP PDFDocument3 pagesCafco Blaze Shield Ii HP PDFcuestajmNo ratings yet

- Valve PDFDocument100 pagesValve PDF86tejasNo ratings yet

- Walworth Safety Steel Catalog2012 1 PDFDocument76 pagesWalworth Safety Steel Catalog2012 1 PDFJibrain MazariegoNo ratings yet

- RN510 515 520 525 M039215CBDocument44 pagesRN510 515 520 525 M039215CBdavid ciroNo ratings yet