Professional Documents

Culture Documents

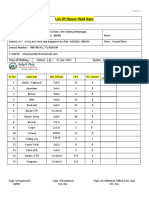

Installation Checklist for Flow Meter Report

Uploaded by

Zulfequar R. Ali KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Checklist for Flow Meter Report

Uploaded by

Zulfequar R. Ali KhanCopyright:

Available Formats

Report No:

INSTALLATION OF FLOW METER

CHECK LIST Date:

Customer : Project: Project Code:

Sub- Contractor : WO No & Amndt, If any.:

Manufacturer : PO No & Amndt, If any.:

Item Description: Identification No.

Location : Sub Location:

Package: Drg No & Rev No :

FQP No. & Rev No. RFIC No.

Total Inspected & Total Inspected &

Total offered Quantity:

Accepted Quantity: Rejected Quantity:

Checked

Sl No Description of Check Points Remarks

Yes No NA

1 Approved Location drawing is available Drg No :

2 Approved P & ID is available Drg No :

3 Approved Data Sheet is available Doc No :

4 Approved Typical drawing is available Drg No :

5 Make & type of Flow Meter is approved by client

6 Sub Contractor is pre qualified and approved

7 Method Statement is approved by client

8 Ensure valid calibartion of Flow Meter

Ensure the Location and tapping point is verified as per approved P&ID &

9

Location Drawing

10 Ensure the Flow Meter is free from damages / defects

11 Ensure Supplied Flow Meter specifications match with approved Data Sheet.

12 Ensure Tag plate is correct as per approved Drawings

Ensure the mechanical clearance is available for installing the metering unit

13

with process pipe flanges

14 Ensure the direction of Flow is verified with respect to flow meter

Ensure the correct type and size of gasket is used in between process line

15

flange and metering unit flange

Ensure the specified type and grade of stud and nut used for tightening the

16

metering unit with process line

Ensure Transmitter stand / stanchion installed as per typical drawing and

17

identified location is having gap /clearance with adjacent pipe/equipment

18 Ensure the Stand is secured on the ground / platform

19 Ensure the grouting is done in between the base plate and ground

Ensure the Flow Meter's Transmitter is installed with mounting bracket and is

20

at operation height as per drawing

Ensure Instrument display orientation is accessible for termination purpose

21

and visible to operator.

Ensure the sensor cable between transmitter and metering unit is laid and

22

without blocking the access way

23 Ensure the Transmitter canopy is installed

Note : This format can also be used for FLOW METER (VORTEX / CORIOLIS /ULTRASONIC /DOPPLER / ROTAMETER / MAGNETIC)

Remarks:

Signature of Sub - Contractor & Date Signature of TPL-FQE & Date Signature of Customer / Inspection Authority & Date

Format No. 08-03-05-FMT-I-FMI-CL-004-R00

Sh:1of1

You might also like

- Check List For Connection BoltsDocument1 pageCheck List For Connection BoltstreyNo ratings yet

- HT Panel & Transmission Line ChecklistDocument1 pageHT Panel & Transmission Line Checklisttango member0% (1)

- Transformer Erection ChecklistDocument2 pagesTransformer Erection Checklistmohan babu100% (2)

- Instrumentation Installation Method of Statement.Document4 pagesInstrumentation Installation Method of Statement.Ahmad Dagamseh100% (4)

- Checklist For Installation of Pressurization UnitDocument1 pageChecklist For Installation of Pressurization Unitvictor100% (3)

- Rsae-Frm-227 Inspection Check List For Motor Solo RunDocument1 pageRsae-Frm-227 Inspection Check List For Motor Solo RunkamilNo ratings yet

- Chemical Dosing Pump SATRDocument2 pagesChemical Dosing Pump SATRDeshan Sing100% (1)

- MV Panel Site Acceptance Test ReportDocument1 pageMV Panel Site Acceptance Test ReportGajendran Sriram100% (1)

- Mech Inspection Checklist PDFDocument11 pagesMech Inspection Checklist PDFDesigner Forever100% (1)

- ITP Inspection-and-Test-Plan-for-Switchgear PDFDocument5 pagesITP Inspection-and-Test-Plan-for-Switchgear PDFHaldirLeao100% (1)

- Valve Actuator ChecklistDocument2 pagesValve Actuator Checklisthamoody_007No ratings yet

- MCC Testing & Commissioning MethodDocument3 pagesMCC Testing & Commissioning MethodHumaid Shaikh75% (4)

- Cable Tray Installation ChecklistDocument2 pagesCable Tray Installation Checklistbaban100% (1)

- JX NIPPON Oil & Gas Low Voltage Cable ITRDocument2 pagesJX NIPPON Oil & Gas Low Voltage Cable ITRAmy100% (1)

- Installation Method for Gas DetectionDocument2 pagesInstallation Method for Gas DetectionvictorNo ratings yet

- 0734 Refrigerant Installation ChecklistDocument1 page0734 Refrigerant Installation ChecklistMubashir KhanNo ratings yet

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad100% (2)

- SEC-EOA Site Test ReportDocument9 pagesSEC-EOA Site Test ReportmaheshknmNo ratings yet

- Attachment 12.7 - QA - QC Checklist - MCC & CBDocument6 pagesAttachment 12.7 - QA - QC Checklist - MCC & CBehteshamNo ratings yet

- SSE-QC-ELE-510 - CT & PT Installation ChecklistDocument2 pagesSSE-QC-ELE-510 - CT & PT Installation ChecklistBhalsingh JangraNo ratings yet

- Checklist For Cable Try Fabrication and EractionDocument2 pagesChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- MV Cable Pulling and Installation Method StatementDocument8 pagesMV Cable Pulling and Installation Method StatementArshad Akhtar KhanNo ratings yet

- Precommissioning Procedures of Testing Commissioning PDFDocument96 pagesPrecommissioning Procedures of Testing Commissioning PDFRatheesh Kumar100% (1)

- 0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)Document2 pages0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)ResearcherNo ratings yet

- Inspection Report For Installation of JB, Juncation BoxDocument1 pageInspection Report For Installation of JB, Juncation BoxnayumNo ratings yet

- Switchgear Inspection Checklist: Section A - Customer DataDocument1 pageSwitchgear Inspection Checklist: Section A - Customer Data20082012No ratings yet

- E&I Quality PlanDocument9 pagesE&I Quality PlanJithuRajNo ratings yet

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 pagesFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoNo ratings yet

- Installation of Transmitter - Pressure - Flow-Level-Temperature Check ListDocument1 pageInstallation of Transmitter - Pressure - Flow-Level-Temperature Check ListZulfequar R. Ali Khan100% (1)

- Installation of Instrument Switches (Pressure - Flow - Temperature - Level) CLDocument1 pageInstallation of Instrument Switches (Pressure - Flow - Temperature - Level) CLZulfequar R. Ali KhanNo ratings yet

- Installation of Instrument Switches (Pressure - Flow - Temperature - Level) CLDocument1 pageInstallation of Instrument Switches (Pressure - Flow - Temperature - Level) CLZulfequar R. Ali KhanNo ratings yet

- Installation Check Sheet For Ahu FahuDocument2 pagesInstallation Check Sheet For Ahu FahuSamer AliNo ratings yet

- MATHEMATICAL ECONOMICSDocument54 pagesMATHEMATICAL ECONOMICSCities Normah0% (1)

- Check List For Installation of Cooling TowersDocument2 pagesCheck List For Installation of Cooling TowersGirithar M Sundaram67% (3)

- Low Voltage Cable - Itr ADocument2 pagesLow Voltage Cable - Itr AHaider HassanNo ratings yet

- Codes InstrumentsDocument5 pagesCodes InstrumentsZulfequar R. Ali KhanNo ratings yet

- The Unbounded MindDocument190 pagesThe Unbounded MindXtof ErNo ratings yet

- Check List For Installation of Local Instruments.Document1 pageCheck List For Installation of Local Instruments.Jaya SeelanNo ratings yet

- Pin-050-Mmd-Pc1-In35-0003 - 01 DCS SpecificationsDocument86 pagesPin-050-Mmd-Pc1-In35-0003 - 01 DCS SpecificationsZulfequar R. Ali KhanNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzania100% (4)

- ITP For Cable Tray - Rev BDocument6 pagesITP For Cable Tray - Rev BDonny Subarja100% (1)

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriNo ratings yet

- 15 ITP Installation of Static EquipmentDocument4 pages15 ITP Installation of Static Equipmenta.hasan670No ratings yet

- Check List LT PanelDocument1 pageCheck List LT PanelAnil PatelNo ratings yet

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla VietorNo ratings yet

- Checklist For LT Cabel JointingDocument3 pagesChecklist For LT Cabel Jointingccsures100% (4)

- Flange Installation ProceduresDocument3 pagesFlange Installation Proceduresgplese0100% (1)

- A1Z5L2 - Appendix VI - Valve Commissioning Checklist - USDocument1 pageA1Z5L2 - Appendix VI - Valve Commissioning Checklist - USAlpesh PatelNo ratings yet

- Pipe installation testing reportDocument1 pagePipe installation testing reportRrgs Bandara100% (1)

- Larsen & Toubro underground piping inspection planDocument4 pagesLarsen & Toubro underground piping inspection planBhavani PrasadNo ratings yet

- Cable Test Sheet On DrumDocument2 pagesCable Test Sheet On DrumAhmad Dagamseh100% (1)

- WSA Line 5 Anchor Bolt Tightening Inspection ReportDocument1 pageWSA Line 5 Anchor Bolt Tightening Inspection ReportMahfudRido'iRonggomaniaNo ratings yet

- Cable Test Sheet After InstallationDocument1 pageCable Test Sheet After InstallationAhmad DagamsehNo ratings yet

- E&I QAP's - Submitted To Contractor HZADocument33 pagesE&I QAP's - Submitted To Contractor HZASuraj ShettyNo ratings yet

- Form No. 102B - Solenoid ValveDocument1 pageForm No. 102B - Solenoid ValveVictor NairNo ratings yet

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 pageInspection & Test Plan for Chilled Water Expansion TanksvictorNo ratings yet

- Check List For DI Pipe InstallationDocument1 pageCheck List For DI Pipe InstallationSaifur Rahman0% (1)

- TR001 Control Cable CFA901-Continuity TestDocument4 pagesTR001 Control Cable CFA901-Continuity TestCharlie MendozaNo ratings yet

- CERTIFICATE NO 2 Electric Welding MachineDocument2 pagesCERTIFICATE NO 2 Electric Welding MachineOwais MalikNo ratings yet

- Visual Inspection ChecklistDocument2 pagesVisual Inspection ChecklistrajuajiNo ratings yet

- Installation checklist for level recorderDocument1 pageInstallation checklist for level recorderZulfequar R. Ali KhanNo ratings yet

- Installation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListDocument1 pageInstallation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListZulfequar R. Ali KhanNo ratings yet

- Installation of Level Transmitter - Ultrasonic - Radar Type Check ListDocument1 pageInstallation of Level Transmitter - Ultrasonic - Radar Type Check ListZulfequar R. Ali KhanNo ratings yet

- IMCC Check ListDocument9 pagesIMCC Check ListZulfequar R. Ali KhanNo ratings yet

- Pin-050-Mmd-Pc1-In02-0001 Design of InstrumentationDocument46 pagesPin-050-Mmd-Pc1-In02-0001 Design of InstrumentationZulfequar R. Ali KhanNo ratings yet

- Installation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListDocument1 pageInstallation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListZulfequar R. Ali KhanNo ratings yet

- Install Beacon ChecklistDocument1 pageInstall Beacon ChecklistZulfequar R. Ali Khan100% (1)

- Installation of Level Transmitter - Ultrasonic - Radar Type Check ListDocument1 pageInstallation of Level Transmitter - Ultrasonic - Radar Type Check ListZulfequar R. Ali KhanNo ratings yet

- Installation of Pressure (PG & DPG) & Level Gauge Check ListDocument2 pagesInstallation of Pressure (PG & DPG) & Level Gauge Check ListZulfequar R. Ali KhanNo ratings yet

- Installation checklist for level recorderDocument1 pageInstallation checklist for level recorderZulfequar R. Ali KhanNo ratings yet

- Ksp-Instrument Impulse Piping & TubingDocument18 pagesKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNo ratings yet

- Installation of Radiation Pyrometer Check ListDocument1 pageInstallation of Radiation Pyrometer Check ListZulfequar R. Ali KhanNo ratings yet

- Installation of Radiation Pyrometer Check ListDocument1 pageInstallation of Radiation Pyrometer Check ListZulfequar R. Ali KhanNo ratings yet

- Flow MeasurementDocument19 pagesFlow MeasurementZulfequar R. Ali KhanNo ratings yet

- Installation of Thermowell & Temperature Elements Check ListDocument1 pageInstallation of Thermowell & Temperature Elements Check ListZulfequar R. Ali KhanNo ratings yet

- KSP Pressure MeasurementDocument15 pagesKSP Pressure MeasurementZulfequar R. Ali KhanNo ratings yet

- KSP Instrument DrawingDocument15 pagesKSP Instrument DrawingZulfequar R. Ali KhanNo ratings yet

- Item Codes & Specification For Instrumentation CableDocument16 pagesItem Codes & Specification For Instrumentation CableZulfequar R. Ali KhanNo ratings yet

- Knowledge Sharing Program: - :by:-Mohammad Zulfequar Ali Khan Dy. Manager - Quality E&IDocument13 pagesKnowledge Sharing Program: - :by:-Mohammad Zulfequar Ali Khan Dy. Manager - Quality E&IkhanzulfiNo ratings yet

- KSP Flow Meter TypesDocument10 pagesKSP Flow Meter TypeskhanzulfiNo ratings yet

- Ksp-Instrument Impulse Piping & TubingDocument18 pagesKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNo ratings yet

- KSP Pressure MeasurementDocument15 pagesKSP Pressure MeasurementZulfequar R. Ali KhanNo ratings yet

- Knowledge Sharing Program: - :by:-Mohammad Zulfequar Ali Khan Dy. Manager - Quality E&IDocument13 pagesKnowledge Sharing Program: - :by:-Mohammad Zulfequar Ali Khan Dy. Manager - Quality E&IkhanzulfiNo ratings yet

- Ksp-Instrument Impulse Piping & TubingDocument18 pagesKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNo ratings yet

- KSP Flow MeasurementDocument19 pagesKSP Flow MeasurementZulfequar R. Ali KhanNo ratings yet

- KSP Pressure MeasurementDocument15 pagesKSP Pressure MeasurementZulfequar R. Ali KhanNo ratings yet

- KSP Flow Meter TypesDocument10 pagesKSP Flow Meter TypeskhanzulfiNo ratings yet

- KSP Instrument DrawingDocument15 pagesKSP Instrument DrawingZulfequar R. Ali KhanNo ratings yet

- Circuit AnalysisDocument98 pagesCircuit Analysisahtisham shahNo ratings yet

- A Summer Internship Project ON " To Study The Supply Chain Management On Amul Fresh Products" AT GCMMF, AmulDocument19 pagesA Summer Internship Project ON " To Study The Supply Chain Management On Amul Fresh Products" AT GCMMF, AmulweetrydhNo ratings yet

- Liquid Analysis v3 Powell-Cumming 2010 StanfordgwDocument28 pagesLiquid Analysis v3 Powell-Cumming 2010 StanfordgwErfanNo ratings yet

- Characteristics and Guidelines of PublicspaceDocument3 pagesCharacteristics and Guidelines of PublicspaceJanani SurenderNo ratings yet

- Organic Facial Remedies Versus Inorganic Facial RemediesDocument13 pagesOrganic Facial Remedies Versus Inorganic Facial Remediesapi-271179911No ratings yet

- Oas Community College: Republic of The Philippines Commission On Higher Education Oas, AlbayDocument22 pagesOas Community College: Republic of The Philippines Commission On Higher Education Oas, AlbayJaycel NepalNo ratings yet

- Service Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42ADocument2 pagesService Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42AAmjad AlQasrawi100% (1)

- Guillermo Estrella TolentinoDocument15 pagesGuillermo Estrella TolentinoJessale JoieNo ratings yet

- Kennedy 1945 Bibliography of Indonesian Peoples and CulturesDocument12 pagesKennedy 1945 Bibliography of Indonesian Peoples and CulturesJennifer Williams NourseNo ratings yet

- Jotrun TDSDocument4 pagesJotrun TDSBiju_PottayilNo ratings yet

- District Wise List of Colleges Under The Juridiction of MRSPTU BathindaDocument13 pagesDistrict Wise List of Colleges Under The Juridiction of MRSPTU BathindaGurpreet SandhuNo ratings yet

- Business StrategiesDocument2 pagesBusiness Strategiesthristanlexter694No ratings yet

- Strategic Flexibility: The Evolving Paradigm of Strategic ManagementDocument3 pagesStrategic Flexibility: The Evolving Paradigm of Strategic Managementnanthini kanasanNo ratings yet

- GD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreDocument1 pageGD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreVinay ManjuNo ratings yet

- List of household items for relocationDocument4 pagesList of household items for relocationMADDYNo ratings yet

- EPISIOTOMYDocument17 pagesEPISIOTOMYKaye Arriane TenorioNo ratings yet

- Telecommunications TechnicianDocument4 pagesTelecommunications Technicianapi-78381064No ratings yet

- Final Annotated BibiliographyDocument4 pagesFinal Annotated Bibiliographyapi-491166748No ratings yet

- 20ME901 Automobile Engineering Unit 3Document74 pages20ME901 Automobile Engineering Unit 36044 sriramNo ratings yet

- Time Table Semester II 2019-2020Document18 pagesTime Table Semester II 2019-2020Shiv Kumar MeenaNo ratings yet

- Admisibility To Object EvidenceDocument168 pagesAdmisibility To Object EvidenceAnonymous 4WA9UcnU2XNo ratings yet

- Komatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646Document26 pagesKomatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646juan santa cruzNo ratings yet

- KingmakerDocument5 pagesKingmakerIan P RiuttaNo ratings yet

- History and Development of the Foodservice IndustryDocument23 pagesHistory and Development of the Foodservice IndustryMaria Athenna MallariNo ratings yet

- GRP Product CatalogueDocument57 pagesGRP Product CatalogueMulyana alcNo ratings yet

- 1 PBDocument11 pages1 PBAnggita Wulan RezkyanaNo ratings yet

- 10 Tips To Support ChildrenDocument20 pages10 Tips To Support ChildrenRhe jane AbucejoNo ratings yet

- Project Report Software and Web Development Company: WWW - Dparksolutions.inDocument12 pagesProject Report Software and Web Development Company: WWW - Dparksolutions.inRavi Kiran Rajbhure100% (1)