Professional Documents

Culture Documents

INOUE Quality Control Manual

Uploaded by

Massimo FumarolaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

INOUE Quality Control Manual

Uploaded by

Massimo FumarolaCopyright:

Available Formats

INOUE VIETNAM CO., LTD.

Address: Nhon Trach 3 Industrial Park, Phase

2,

Long Tho Commune, Nhon Trach District,

Dong Nai

Province, Viet Nam

QUALITY CONTROL MANUAL

FOR

SHOP CONSTRUCTION AND FIELD ASSEMBLY

STAMP CERTIFICATION MARK WITH U DESIGNATOR

OF

PRESSURE VESSEL AND THEIR PARTS

IN ACCORDANCE WITH

ASME BPV CODE SECTION VIII Division 1

SECTION Cover Page

DOC. No. ASME-QCM-00

EDN. / REV. No. 1/0

CONTROL No.

CONTROLLED COPY UNCONTROLLED COPY

[Type here]

Inoue Vietnam Co., Ltd.

Section I

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Table of Contents

Page 1 of 1

Edn. /

Section Description Date

Rev. No.

Cover Page Cover Page 1/0 Jul 23, 2016

I Table of Contents 1/0 Jul 23, 2016

II Statement of Authority 1/0 Jul 23, 2016

III Glossary 1/0 Jul 23, 2016

1.0 Organization 1/0 Jul 23, 2016

2.0 QCM Control 1/0 Jul 23, 2016

3.0 Drawings, Design Calculations, and Specification Control 1/0 Jul 23, 2016

4.0 Material Control 1/0 Jul 23, 2016

5.0 Examination & Inspection Program 1/0 Jul 23, 2016

6.0 Correction of Nonconformities 1/0 Jul 23, 2016

7.0 Welding 1/0 Jul 23, 2016

8.0 Nondestructive Examination 1/0 Jul 23, 2016

9.0 Heat Treatment 1/0 Jul 23, 2016

10.0 Calibration of Measurement and Test Equipment 1/0 Jul 23, 2016

11.0 Records Retention 1/0 Jul 23, 2016

12.0 Authorized Inspector 1/0 Jul 23, 2016

13.0 Field Assembly 1/0 Jul 23, 2016

14.0 Certification 1/0 Jul 23, 2016

15.0 Index of Sample Form and Exhibit 1/0 Jul 23, 2016

This QCM (1st Edition, Rev.0, and Dated on Jul 23, 2016) has been prepared, reviewed,

approved and accepted as follows:

Prepared By: Reviewed By:

QC Inspector/ Inoue Vietnam QA/QC Manager / Inoue Vietnam

Approved By: Accepted By:

General Manager / Inoue Vietnam Authorized Inspector

INOUE VIETNAM CO., LTD.

Section II

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Statement of Authority

Page 1 of 1

This QCM shall be used for the shop construction and field assembly of Pressure Vessels and

parts (code items) in accordance with the ASME BPV Section VIII Division 1. Local jurisdiction

requirements, where the construction installed shall be mandatory.

All Code items shall be constructed or field assembled in the full compliance with this QCM and

the Code.

No person involved in the implementation of this QCM shall deviate from the provisions set forth

in this QCM.

Managers may delegate their authority to individuals within their respective as appropriate, but

shall retain responsibility for the function.

The QA/QC Manager has the sufficient and well-defined responsibility, authority and

organizational freedom to identify quality problems and to initiate, recommend and provide

solutions to those problems. He also has authority to stop work which, in his opinion, is

nonconforming.

In the event that any problem or difference in opinion concerning quality that cannot be resolved

within the organization, it shall be brought to my attention for final resolution and this resolution

shall be within the limits of Code and this QCM as applicable.

General Director / Inoue Vietnam

INOUE VIETNAM CO., LTD.

Section III

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Glossary

Page 1 of 2

AI Authorized Inspector

AIA ASME Accredited Authorized Inspection Agency

AIS Authorized Inspector Supervisor

ASME The American Society of Mechanical Engineers

BPV Boiler and Pressure Vessel

C of C Certificate of Compliance

ASME Boiler and Pressure Vessel Code unless otherwise described

Code

separately

EL Equipment List

Hold point is a designated inspection stage where the next operation cannot

Hold Point

proceed without sign-off by the party who designate the hold point.

Inoue Vietnam INOUE VIETNAM CO., LTD.

IR Inspection Request

Item Sub-assemblies and completed products in this QCM

MAWP Maximum Allowable Working Pressure

MDR Manufacturer's Data Report or Manufacturer’s Partial Data Report

MO Manufacturing Order

MPR Material Purchase Requisition

MR Material Request

MT Magnetic Particle Examination

MTR Material Test Report

NCR Nonconformance Report

NDE Nondestructive Examination (RT, UT, MT, PT and VT)

PMR Project Material Requisition

PMS Project Material Specification

PO Purchase Order

PQR Procedure Qualification Record

PT Liquid Penetrant Examination

PTR Pressure Test Record

PWHT Post Weld Heat Treatment

INOUE VIETNAM CO., LTD.

Section III

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Glossary

Page 2 of 2

QA Quality Assurance

QC Quality Control

QCM Quality Control Manual

QCP Quality Control Procedure

A Manufacturing step or operation that requires a review of records by AI or

Review Point Customer. The review activity shall be documented by signature and date on

the Traveler and affected document.

RIR Receiving Inspection Report

RT Radiographic Examination

Operation description in the process of fabrication, record all steps and

Traveler

applicable drawings, documents

UT Ultrasonic Examination

VT Visual Examination

WCL Welder Continuity Log

Welder Welders or Welding Operators unless otherwise described separately

Witness point means a designated inspection stage beyond which the next

operation can proceed when the specified party’s presence is not available

Witness Point

after being notified in advance. The waiver by the AI shall be documented on

the Traveler.

WMIL Welding Material Issue Log

WL Welder List

WPQ Record of Welder or Welding Operator Performance Qualification

WPS Welding Procedure Specification

INOUE VIETNAM CO., LTD.

Section 1.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Organization

Page 1 of 4

1.1 Scope

This section describes the interaction, authority and responsibility of each organization within

Inoue Vietnam and the reporting structure is shown on the organizational chart.

The responsibilities and authority of personnel related to the quality not described in this section

are described in other sections of this QCM.

1.2 Responsibility and Authority

1.2.1 General Director

The General Director has the overall responsibility for the management of the shop and field

sites and shall be responsible for delegating the authority to various Managers, and shall be

the arbitrator of any conflicts between QA/QC Manager and other Managers in this

organization.

1.2.2 General Manager

General Manager shall be responsible for assisting the General Director in the management

and he is also responsible for assuring that the provisions set forth in this QCM are effectively

implemented.

He is responsible for the issuance of MO.

He is responsible for monitoring the process planning and approval QCM, MPR, PO.

He reports to the General Director.

1.2.3 Document Controller

Document Controller reports to the General Manager.

She is responsible for distribution all documents between all positions in the Organization

Chart as description in the Sections.

She is responsible for arrange and maintain all original documents of the system.

1.2.4 Engineering Manager

Engineering Manager reports to the General Manager and shall be responsible for

review/approve and issuing the design documents and applicable fabrication and

procurement documents in accordance with the Code, this QCM and customer's documents.

He is responsible for the procurement of the Code materials and services.

He is responsible for the controlling of the material in the warehouse.

INOUE VIETNAM CO., LTD.

Section 1.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Organization

Page 2 of 4

1.2.4.1 Engineer

Engineer is responsible for the preparation of drawings, design calculation, PMR/PMS except

for the welding material, MPR, applicable fabrication documents and MDR.

He is responsible to prepare of PO when received MPR approved.

1.2.5 Manufacturing Manager

Manufacturing Manager reports to the General Manager and he is responsible for the

fabrication activities.

Manufacturing Manager is responsible for:

- The preparation and issuance of fabrication procedures, traveler, specifications and

other related documents, including their subsequent revisions;

- Providing effective supervision instructions during construction in the working area of

the shop;

- Conducting hydrostatic tests as per Code requirements.

1.2.5.1 Foreman

Foreman is responsible to assign Welder, Worker to the job.

He is responsible to receive materials accepted for code items from Engineering

Manager as MR approved.

He is responsible store, issue and control all materials received from Engineering

Manager.

He is responsible record information to Traveler during construction in the working area

of the shop.

1.2.6 QA/QC Manager

QA/QC Manager reports to the General Manager and he has responsible on controlling

QA/QC activity.

QA/QC Manager has direct access to the General Director in the event of a problem, which

cannot be easily resolved.

He shall have the responsibility for the documentation of QC Program and he shall work

closely with all other Managers within Inoue Vietnam towards the goal of producing quality

items.

He is responsible for reviewing and distributing this QCM and its revisions to each Manager

within Inoue Vietnam and outside organization, if necessary.

INOUE VIETNAM CO., LTD.

Section 1.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Organization

Page 3 of 4

He is responsible for assigning QC Inspector to perform examination/tests including receiving

inspection at the shop or field sites controlled by Inoue Vietnam shop.

He is responsible for the approval of WPS and certification of PQR and WPQ.

He is also responsible for the review and certification of MDR.

And he has the responsibility for the appointment of the subcontractor's NDE Level III

personnel as an Inoue Vietnam Level III and for review and verification of the calibration

records for measurement and test equipment.

He is the principal contact with the AI.

1.2.6.1 Welding Engineer

Welding Engineer is responsible for the preparation and issuance of WPS, PQR, WPQ

and Welding Map.

He is also responsible for the preparation of PMR and PMS for welding material.

1.2.6.2 QC Inspector

QC Inspector is responsible for preparing QCM, QCPs.

He is responsible for material inspection, dimension inspection, fitup/visual and

hydrostatic test monitoring.

1.2.7 Site Engineer

Site Engineer is appointed by General Manager takes overall responsibility for the operation

of the field site controlled by the shop.

He is responsible for control of material and documents such as drawing and other fabrication

documents, which are supplied by the shop.

1.2.7.1 Field Foreman

Field Foreman is responsible to assign Welder, Worker to the job.

He is responsible store, issue and control all materials received at the field site.

He is responsible record information to Traveler during construction in the working area

of the field site.

1.2.8 Site QC Inspector

Site QC Inspector shall be designated by QA/QC Manager takes responsibility for the quality

control activity at the field site including in-process inspection, control of NDE subcontractor.

He is the principal contact with AI at the field site.

INOUE VIETNAM CO., LTD.

Section 1.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Organization

Page 4 of 4

1.3 Delegation of Authority

Managers may delegate their authority to individuals within their respective as appropriate, but

shall retain responsibility for the function.

1.4 Organizational Chart

See Figure 1.1.

Figure 1.1. Organizational Chart

General Director

General Manager

Document Controller

Engineering Manufacturing QA/QC

Manager Manager Manager

Engineer Foreman Welding QC NDE Sub-

Engineer Inspector contractor

General QA/QC

Manager Manager

THE SHOP

FIELD SITE

Site Site QC

Engineer Inspector

Field Foreman NDE Sub-

contractor

Administration Line

Communication Line

INOUE VIETNAM CO., LTD.

Section 2.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

QCM Control

Page 1 of 2

2.1 Scope

This section describes the applicability and control of the QC Program for Code / activities.

2.2 Applicability of QC Program

2.2.1 This QCM is the primary documentation of the QC Program.

2.2.2 Detailed requirements not covered by this QCM shall be implemented by the related QCP

which shall not conflict with this QCM.

2.2.3 QC Program set forth in this QCM shall be applied to the Code activities under ASME

Certificate shall be held by Inoue Vietnam. Upon agreement with the customer, the portions

of this QCM may be applied to the fabrication of Non-Code items.

2.3 Control of QCM

2.3.1 The QCM shall be prepared by QC Inspector in English in accordance with the Code, reviewed

by QA/QC Manager and approved by General Manager.

2.3.2 The review and the approval shall be indicated by the QA/QC Manager's and the General

Manager’s signature/date on the Table of Contents.

2.3.3 The QCM shall be submitted to the AI for review and acceptance prior to implementation. The

AI acceptance shall be documented with his signature/date on the Table of Contents.

2.3.4 Distribution

1) Document Controller is responsible for distribution of the QCM approved.

2) Only controlled copies of the QCM shall be distributed by Document Controller to the related

organization in Inoue Vietnam and shall be available to all the personnel concerned.

3) All the controlled copies of QCM to be issued shall be serialized.

4) The QCM and all revisions thereto shall be distributed by hand carry to the related

organizations. The recipient shall sign and date on the QCM / Procedure Distribution Log (A-

02-01) except the recipient of uncontrolled copy.

5) Uncontrolled copy may be issued outside Inoue Vietnam at the discretion of QA/QC

Manager. Uncontrolled copy shall be current at time of issuance but need not be updated.

INOUE VIETNAM CO., LTD.

Section 2.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

QC Manual Control

Page 2 of 2

2.3.5 Revision Control

1) Revisions to the QCM may be requested by Inoue Vietnam personnel, by Code change, by

organizational change, etc. and QA/QC Manager shall be responsible for the final decision

and preparation of the revision to the QCM.

2) The QCM shall be revised by each Section except for Exhibit which is revised by page. The

revised area of the QCM except for typographical correction shall be identified by bold and

italic style letter except the area of pictorial information shall be identified with appropriate

method such as cloud mark and revision level.

3) Revision status of each Section and Exhibit shall be shown on the Table of Contents and

Index of Sample Form and Exhibit, respectively.

4) Addition of information on Exhibit will not require a revision to the QCM, but shall be available

to the AI for review prior to its use and to be included in the next revision of the QCM.

However, deletion of information on Exhibit is considered a revision.

5) Revisions to the QCM shall be controlled in the same manner as the original.

6) The obsolete of controlled copies of the QCM shall be returned to Document Controller and

destroyed by Document Controller. The obsolete original of the QCM with “VOID” stamp shall

be retained by Document Controller for historical record.

2.3.6 Edition Control

At the discretion of the QA/QC Manager such as when the changes effect the majority of the

QCM or in commensurate with ASME Joint Review all revision may be reverted to Rev. 0,

with a new edition number. All revision marks shall be removed when new edition is

introduced.

2.4 Review of Code Edition

QA/QC Manager and other responsibility person shall review ASME Code Edition after issuance

but prior to the effective date for possible revisions of QCM or program. The review result shall be

documented on the Code Edition Review Log (A-02-02).

When revisions are required due to Code Edition, they shall be implemented within 6 months of

the Edition issue date.

INOUE VIETNAM CO., LTD.

Section 3.0

QUALITY CONTROL MANUAL Edn./Rev. No. 3/0

Drawings, Design Calculations, Date Jul 23, 2016

and Specification Control Page 1 of 3

3.1 Scope

This section describes order entry and control of design calculations, drawings and specifications

and revisions thereto.

3.2 Order Entry

3.2.1 Upon awarding of a contract to the Inoue Vietnam, General Manager shall issue the

Manufacturing Order (MO) (A-03-01), which includes assigned MO number for that job with

identification of “ASME” to Engineering Manager, Manufacturing Manager and QA/QC

Manager. The MO number and “ASME” identification shall be shown on all project related

documents. The assignment of the manufacturer’s serial number shall be controlled by

QA/QC Manager.

3.2.2 Documents supplied by Customer shall be transferred to the related Managers with the MO

by Document Controller.

3.2.3 Either SI unit, US Customary unit or local customary units may be used for compliance with

all requirements of the Code, but one system should be used consistently throughout all

phases of construction (e.g. material, design, fabrication and report) unless otherwise

permitted by the Code or Code Case. The system to be used shall be designated on the

drawing and shall be the same as the unit used in the MDRs / Nameplate.

3.3 Customer Specification

Design Specification that is supplied by customer shall be reviewed and accepted by Engineering

Manager in order to verify compliance with applicable Code requirements.

Engineering Manager is responsible for further communication and clarification with the customer

for the requirements that are not clear or not in compliance with the Code.

3.4 Control of Customer Supplied Documents

3.4.1 Customer supplied drawings and calculations may be used directly for fabrication. They shall

be stamped with “CUSTOMER SUPPLIED” and reviewed and approved by Engineering

Manager prior to use.

3.4.2 Customer Supplied Documents shall be return to customer for final revision, when required.

INOUE VIETNAM CO., LTD.

Section 3.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Drawings, Design Calculations, Date Jul 23, 2016

and Specification Control Page 2 of 3

3.5 Control of Documents

3.5.1 Drawings, Design Calculations and Specifications

1) Drawings, calculations and specifications shall be prepared accordance with Code by

Engineer, reviewed for Code compliance and approved by Engineering Manager.

2) Drawings shall contain enough information to ensure proper fabrication. This information shall

consist of, but not be limited to, MO No., design conditions, material specification including

grade and class, NDE requirements, heat treatment, joint number, dimension, tolerances,

hydrostatic test pressure, Code Section Edition, drawing number, weld detail and Code case

if applicable.

3) Design calculation shall include the evaluation whether the impact test is required or

exempted, the applicable Code Section, calculation methods and calculated thickness, etc.

4) Engineering Manager shall verify the Code compliance of inspection openings and corrosion

allowance according to the applicable Code as required to be described on the MDR.

5) Engineering Manager shall submit the design calculations and drawings to the AI for his

verification prior to the start of fabrication so that the Al may place his inspection points on the

Traveler in accordance with Section 5.0 of this QCM.

6) Distribution of approved design documents shall be handled by Document Controller.

Document Controller shall keep a Drawing/Document Distribution List (A-03-02) and record

the latest revision for each contract. Document Controller shall hand deliver new and revised

drawings to the concerned personnel and obtain the signature with date of recipients as

record of receipt on the Drawing / Document Distribution List.

3.5.2 Computer Aided Design Calculation

1) When computer aided design calculations are used for the design of Code items, Engineer is

responsible for the input of the correct design data and for verifying that the correct output

has been obtained and in compliance with Code by alternate methods.

2) Engineering Manager shall review Code Edition to determine whether standard designs and

computer programs are affected or not. All computer program revisions shall be verified in the

same manner as the original prior to use.

3) Computer aided calculations shall be made available to the AI. Engineering Manager

provides the AI with any alternate calculations for review.

INOUE VIETNAM CO., LTD.

Section 3.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Drawings, Design Calculations, Date Jul 23, 2016

and Specification Control Page 3 of 3

3.5.3 Fabrication Documents

1) Manufacturing Manager is responsible for issuing the applicable fabrication documents such

as fabrication procedures, work instructions.

2) Fabrication documents with revision level to be used for fabrication shall be listed on the

Traveler and distributed to ASME working area.

3.5.4 Inspection and Test Documents

1) QA/QC Manager is responsible for issuing the inspection and test documents such as Quality

Control Procedures, Nondestructive Examination Procedures as described in Section 5.0 and

8.0 of this QCM.

2) Inspection and test documents with revision level to be used for fabrication shall be listed on

the Traveler.

3.5.5 Distribution of approved fabrication, inspection and test documents shall be handled by

Document Controller and record of receipt on the Drawing / Document Distribution List.

3.5.6 Quality Control Procedure

QCPs shall be prepared by QC Inspector/Welding Engineer, reviewed by the related

Manager and approved by QA/QC Manager.

3.5.7 Revisions of Drawings/Documents

1) Revisions of drawings/documents shall be prepared, reviewed, approved and distributed in

the same manner as the original.

If the design documents are revised, the Engineer shall verify whether the revisions have on

effect on the design calculation.

2) The revised area of drawings/documents except for typographical correction shall be

identified with a vertical line on the right hand margin and the area of pictorial information

shall be identified with appropriate method such as cloud mark and revision level.

3) The obsolete copies shall be withdrawn from the work area and physically destroyed or

identified with the stamping of “VOID” by the Document Controller. The obsolete original with

“VOID” stamp shall be retained by Document Controller for historical record.

3.6 Availability of Documents to the AI

All the documents related to Code activities shall be made available to the AI.

INOUE VIETNAM CO., LTD.

Section 4.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Material Control

Page 1 of 4

4.1 Scope

This section describes procurement, receiving inspection and control of Code materials including

welding materials to assure that only intended materials are used in Code construction.

4.2 Responsibility

Requisition of materials shall be the responsibility of Engineer except that the requisition of

welding material shall be the responsibility of Welding Engineer.

Purchasing of materials shall be the responsibility of Engineering Manager.

Receiving inspection shall be the responsibility of QA/QC Manager.

4.3 Material Purchase Requisition

The Project Material Requisition (PMR) (A-04-01) shall be prepared by Engineer or Welding

Engineer for each contract, verified by Engineering Manager or QA/QC Manager. By the PMR

verified, Engineer shall be check stock for checking of applicable material availability in stock.

Based on the actual, Engineer shall be prepare the Material Purchase Requisition (MPR) (A-04-

03) included all material not in stock. MPR shall be reviewed by Engineering Manager then

submitted to the General Manager for purchased approval.

The PMR shall contain the material specification, grade/class, quantity, dimension and all

pertinent information.

When these requirements are too numerous to be included on the PMR, Project Material

Specification (PMS) (A-04-02) shall be completed by Engineer or Welding Engineer, approved by

Engineering Manager or QA/QC Manager. The PMS shall be attached to applicable PMR to

become a part of PMR.

Prior to approval of the PMR/PMS, Engineering Manager or QA/QC Manager shall assure that

the PMR/PMS includes all the requirements of the Material Specification of ASME Code Section,

construction Codes and Customer Specifications, including Material Certification documentation

requirements, that the materials are acceptable for Construction and that all the ordering

information as required by the Material Specification is indicated.

No change or substitution of material shall be made without revision of the PMR affected

Drawings and Calculations by Engineer and the approval of Engineering Manager/General

Manager and any other affected documents shall be made available to the AI when requested.

PMR/PMS approved shall be attached to applicable MPR to become a part of MPR.

4.4 Purchase Order

After received the MPR approved by General Manager, Engineer shall prepare the PO using the

information as shown on the MPR without any technical changes. The PO shall contain the MO

No. and reference the PMR No./PMS No.

INOUE VIETNAM CO., LTD.

Section 4.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Material Control

Page 2 of 4

Engineering Manager shall check and, when acceptable, signs and date the PO and then submit

to General Manager for approval.

Engineer shall send the PO approved to the proper vendor with the applicable MPR/PMR/PMS

for purchasing the material.

All materials shall be ordered to SA or SB specification for which allowable stresses are listed in

the Section II Part D for the applicable construction Code, and to SFA specification for welding

material, or other specifications allowed by the Code.

A copy of the approved PO with MPR/PMR/PMS shall be forwarded to QA/QC Manager to be

used during receiving inspection.

When vessel shell sections, heads or other pressure boundary parts are cold formed by a

subcontractor, the required certification for the part shall indicate whether or not the part has been

heat treated as per the requirements of UG-79.

The Coded Marking System used by the subcontractors of formed shape or the processors of

plate and pipe shall be acceptable to QA/QC Manager and to the AI. It shall be specified on the

PMS or PO. This shall be verified at receiving inspection stage. QC Inspector shall perform shop

inspection on all formed heads to witness thickness and dimension check after forming.

4.5 Receiving Inspection

Engineer shall prepare Inspection Request (IR) (A-04-04) for receiving of new material and

including for stock material to the QA/QC Manager. The IR along with the MTR or C of C shall be

forwarded to QA/QC Manager for receiving inspection.

Using the PO with MPR/PMR/PMS and Code as a guide, QC Inspector shall perform receiving

inspection and fill out the Receiving Inspection Report (RIR) (A-04-05). The RIR shall contain

measurement for dimensions, heat No., MO number, MTR number, material identification

marking taken from the materials and all other pertinent information.

QC Inspector shall submit RIR to the QA/QC Manager for approval.

Engineering Manager shall be responsible for handling material based on RIR.

4.6 Identification of the accepted Material

QC Inspector shall indicate the acceptable material by attaching the “ACCEPT” tag/sticker (A-04-

06) on the material. When small parts are received, they may be placed in the bin or tub and the

“ACCEPT” tag/sticker shall be attached on the tub or bin.

For the material from which the “ACCEPT” tag/sticker can be easily defaced during handling i.e.

for plates, pipes, etc. QC Inspector may indicate the acceptance of the material by writing the MO

number and RIR number with signature on the surface of the material with paint.

INOUE VIETNAM CO., LTD.

Section 4.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Material Control

Page 3 of 4

If the material is found to be nonconforming, a “HOLD” tag/sticker (A-04-06) shall be placed upon

the material and an NCR shall be generated per Section 6.0 of this QCM.

4.7 Material Certification

The Material Certification, when required, shall be reviewed by QC Inspector for the traceability of

identification numbers on the material and for the compliance with the requirements of the ASME

Code and PO.

The QC Inspector’s signature and date on the material certificate shall evidence review of the

Material Certificate.

QA/QC Manager shall verify Code compliance and re-certify for the material produced to the

specification listed in “Acceptable ASTM Editions” (A-04-06) of ASME Code Section II Part A or

B.

QA/QC Manager shall approved the RIR with the material certification and he is responsible to

make them available to the AI when requested.

If further material testing is required to be performed at receiving inspection or during

manufacturing operations, the test shall be prepared by QC Inspector with testing specification

and the result shall be reviewed/approved by QA/QC Manager and shall be available to the AI

using either a NCR or a Traveler.

The report shall be referenced and attached to the MTR and form part of the material certification.

4.8 Issuance of Material

Upon completion and acceptance of material at receiving inspection, QC Inspector shall record

the results on the RIR and a copy shall be sent to Engineering Manager for notification of

acceptance.

Engineering Manager shall release only the material accepted and so identified on the RIR.

A copy of the RIR shall be sent to Manufacturing Manager for withdrawal of the accepted material

for fabrication work as described in the Traveler.

Material Request (MR) (A-04-07) shall be prepared by Foreman based on RIR then sent to

Manufacturing Manager for approval.

Engineer shall issue material as required in MR approved to Foreman.

4.9 Storage

Storage of Code material in the shop shall be in the designated areas.

A shop storage area shall be in such a location as to prevent damage to the material.

INOUE VIETNAM CO., LTD.

Section 4.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Material Control

Page 4 of 4

Welding material shall be stored in accordance with manufacturer's recommendation in a clean

and dry area and under the control of Foreman and in a suitable atmosphere when opened.

Welding material shall be stored, issued and controlled in accordance with the Welding Material

Control Procedure (A-QCP-02).

4.10 Customer Supplied Material

For customer supplied materials, MTR or C of C as required by the material specification and

Code shall be provided and Customer supplied material shall receive the same cycle of receiving

inspection, identification, certification and control according to the paragraph 4.5 through 4.9,

except the customer’s PO, and MPR/PMR/PMS shall be prepared according to paragraph 4.3 of

this QCM.

4.11 Stock Material

Stock material shall receive the same cycle of receiving inspection, identification, certification and

control according to the paragraph 4.5 through 4.9 before use.

4.12 Nonconforming Material

If material is found to be nonconforming, it shall be handled in accordance with Section 6.0 of this

QCM.

4.13 Identification Marking

In case the original identification markings are to be cut out or the material is divided into two or

more parts, one set of material identification shall be accurately transferred prior to cutting to the

location where the markings shall be visible on the completed vessel, or a Coded Marking

System shall be used as per Coded Marking Control Procedure (A-QCP-01).

When the Coded Marking System is used it shall be traceable to the original required marking

and accepted by the AI.

Coded marking or material identification markings shall be recorded on the Traveler in the event

of machining or other operations which would cause the identification markings to be removed.

Upon completion of machining or other operation, the markings shall be re-stamped or etched

back onto the material. This shall be verified by QC Inspector.

4.14 Authorized Inspector

All documents for Code material shall be made available to the AI for review.

INOUE VIETNAM CO., LTD.

Section 5.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Examination & Inspection Program

Page 1 of 4

5.1 Scope

This section describes the control measures of examination, test and inspection through

construction process.

5.2 Responsibility

Material processing and handling in the shop shall be the responsibility of Manufacturing

Manager.

The Traveler shall be prepared under the responsibility of Manufacturing Manager.

The planning and performing of examinations and inspections shall be the responsibility of

QA/QC Manager.

5.3 Traveler

5.3.1 The Traveler (A-05-01), which shall contain all applicable processes such as fit-up, welding,

NDE, heat treatment, inspection and test, etc. and all applicable procedures to be used, shall

be prepared by Manufacturing Manager.

5.3.2 The Traveler shall be forwarded to QA/QC Manager for review and the designation of QC

Hold/Witness Points.

When entry to the completed vessel is not provided, an inspection stage shall be identified on

the Traveler for internal examination prior to setting up the final closure weld.

5.3.3 After designation of QC Hold/Witness Points, QA/QC Manager shall submit the Traveler and

drawings and any other documents requested to the AI so that he can assign his

Hold/Witness/Review Points prior to start of fabrication.

5.3.4 The Traveler shall be reviewed by AI with his signature/date shall be given to the Foreman to

place in the working area with the applicable drawings and procedures referenced on the

Traveler for use during fabrication.

5.3.5 The revision to the Traveler shall be prepared, reviewed and approved in the same manner

as for the original including AI review except that the processed page of Traveler shall remain

attached to the revised page.

5.3.6 If additional Hold/Witness/Review Points are requested by AI or Customer, they shall be

included. Hold/Witness/Review Points shall not be deleted without approval of QA/QC

Manager or Customer in concurrent of AI.

5.3.7 Upon the satisfactory completion of the each operation, Foreman shall sign/date on the

applicable column to indicate the completed fabrication operation on the Traveler.

5.3.8 Foreman shall also record the identification number of materials used and any requested

information of the joints on the Traveler.

INOUE VIETNAM CO., LTD.

Section 5.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Examination & Inspection Program

Page 2 of 4

5.4 In-Process Inspection

5.4.1 QC Inspector shall monitor the fabrication, NDE and heat treatment operations, and

document inspection results on the Traveler and appropriate report form. He shall

examination all cut edges during the fit-up inspection.

5.4.2 QA/QC Manager shall notify the AI of all Hold/Witness Points in reasonable advance.

5.4.3 Hold points of any parties shall not be waived. The designated Witness Points shall not be

bypassed without consent of the party who designated the inspection point. In the event that

the AI consents to allow work to proceed through a specified AI Witness Points without his

presence, QA/QC Manager shall be responsible for documenting this agreement on the

Traveler prior to beginning of the work so affected. AI may designate additional Witness

Points in such event.

5.4.4 Upon satisfactory completion of the inspection of the QC Inspector/AI/Customer's

Hold/Witness/Review Points, they shall sign-off on the applicable column of the Traveler to

indicate their acceptance. Related report/record number shall be recorded on the Traveler.

5.4.5 If any nonconformance is found during inspection, they shall be handled in accordance with

Section 6.0 of this QCM and QC Inspector shall record the NCR number on the Traveler.

Nonconforming conditions found by a person other than QC Inspector shall be notified to

QA/QC Manager.

5.4.6 Upon the completion of fabrication operations, the completed Traveler and required reports

shall be submitted to QA/QC Manager for review to assure that all the designated inspections

and tests have been completed and conform to the applicable drawings, procedures and

customer documents.

5.4.7 When the review is acceptable, the Traveler and associated records shall be handled in

accordance with Section 11.0 of this QCM.

5.4.8 The QA/QC Manager is responsible for assuring that all Code required inspections by the AI

have been performed and there is no open NCR.

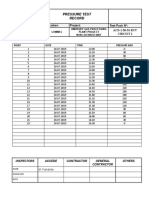

5.5 Final Testing

5.5.1 Manufacturing Manager shall be responsible for conducting the final pressure test.

5.5.2 QC Inspector shall be responsible for monitoring the final pressure test of the Code items.

5.5.3 QC Inspector and AI shall witness and make the examination and inspection on the welded

joints and connections of Code items during the final pressure test and document the result

on Pressure Test Record (PTR) (A-05-02).

INOUE VIETNAM CO., LTD.

Section 5.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Examination & Inspection Program

Page 3 of 4

5.5.4 At least one pressure indicating gauges used in testing shall be calibrated and have dials

graduated over a range as described in the applicable Code section. The gauges shall be

connected to the vessel directly. Hydrostatic test shall be perform in accordance with the

Hydrostatic Test Procedure (A-QCP-??).

5.5.5 In the event of a pneumatic test for Section VIII Div.1 construction, the NDE requirements of

UW-50 shall be followed.

5.6 Manufacturer’s Data Reports and Stamping

5.6.1 Upon successful completion of the final pressure test, Engineer shall prepare a complete

MDR. QA/QC Manager shall review MDR for correctness, and certify the MDR. The MDR

and all documents shall be presented to AI for his review and signature.

5.6.2 QA/QC Manager shall distribute the copy of MDR to the user or his designated agent, AIA

and jurisdiction at the location of installation, as required by the Code.

5.6.3 When providing parts to be assembled by another ASME Certificate Holder, it is the

responsibility of QA/QC Manager to assure that the Partial MDR has been forwarded, in

duplicate, to the manufacturer of the finished item or replacement or repair parts, and to the

user or his designated agent. The scope of the design responsibility shall be indicated in the

“Remarks” of the Partial MDR.

5.6.4 Prior to affixing the Certification Mark with number, QC Inspector shall check the data on the

item or on the name plate with the final drawings and related documents to assure all

specified requirements have been met. Such stamping shall not be used on vessels or parts

constructed of steel material less than 1/4 inch (6mm) thickness or nonferrous material less

than 1/2 inch (13mm) thickness.

5.6.5 The Certification Mark (A-05-04) shall be applied only with the concurrence of AI. He shall

witness and verify the affixing of Stamped Nameplate on code items.

The Certification Mark with the number may be applied to the name plate prior to the

attachment. In this case, the QC Inspector shall ensure AI verified that the name plate with

the correct marking is affixed to the proper code items.

INOUE VIETNAM CO., LTD.

Section 5.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Examination & Inspection Program

Page 4 of 4

5.7 Certification Mark

5.7.1 QA/QC Manager shall safely keep the Certification Mark when not in use.

5.7.2 When the Certification Mark is requested by the shop, QA/QC Manager shall hand carry it to

the location or QC Inspector shall come to QA/QC Manager and pick up to shop. Soonest

after being used, the Certification Mark shall be returned to the custody of QA/QC Manager.

5.8 Retention of Manufacturer's Data Report

The MDR shall be maintained by Document Controller using the Manufacturer's Data Reports

Log (A-05-03), which shows the issued date, type of code item and manufacturer's serial number.

5.9 Authorized Inspector

All documents related to Code activities including material certification, examination reports, test

records and other fabrication records shall be made available to the AI.

INOUE VIETNAM CO., LTD.

Section 6.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Correction of Nonconformities

Page 1 of 3

6.1 Scope

This section describes the system for handling of nonconforming items including identification,

reporting and disposition in order to prevent their in advertent use.

Nonconformity is any condition which does not comply with the applicable rules of the Code, this

QCM or other specified requirements. Nonconformities must be corrected before the completed

component can be considered to comply with the code.

6.2 Identification

6.2.1 When nonconforming conditions are found at any stage of fabrication activity, it shall be

identified by QC Inspector by attaching a “HOLD” Tag/Sticker (A-04-06) to the nonconforming

items. Where attaching the “HOLD” Tag/Sticker is not practical; it shall be attached to the tub

or the bin contained the nonconforming items, and shall be indicated on the Traveler as

appropriate.

6.2.2 QC Inspector shall issue a Nonconformance Report (NCR) (A-06-01).

6.2.3 QC Inspector is responsible to record the NCR number on the Traveler and on the RIR for

receiving inspection.

6.2.4 When an individual other than QC Inspector detects the nonconforming conditions, the

individual shall notify the nonconformance to QA/QC Manager so that the activities described

above shall be accomplished.

6.3 Documentation

6.3.1 QC Inspector documents the nonconforming condition on the NCR with the proposed

dispositions from related departments.

6.3.2 When the NCR is issued it shall be recorded on the Nonconformance Report Log (NCR Log)

(A-06-02) which is maintained by Document Controller.

6.4 Segregation

The nonconforming items shall be segregated, if practical, from similar acceptable items by

Manufacturing Manager or Engineering Manager and further processing shall not be permitted

until the final disposition is accepted by all concerned parties.

INOUE VIETNAM CO., LTD.

Section 6.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Correction of Nonconformities

Page 2 of 3

6.5 Disposition

6.5.1 QA/QC Manager is responsible for providing the final disposition of the nonconforming condition

and when needed, the NCR shall be sent to Engineering Manager to confirm before the final

disposition for the further technical justification or design evaluation.

6.5.2 Manager whom related shall responsible for evaluation of nonconformance and for the

development of the proposed disposition of nonconformance in accordance with the

requirements of Code and Customer documents.

6.5.3 QA/QC Manager shall review the proposed disposition and make final disposition. A copy of the

NCR resulting in a design change shall be distributed to Engineering Manager for information

and use in the reconciliation of the design documents.

6.5.4 All NCR's shall be submitted to AI by QA/QC Manager for his review and concurrence and

designation of addition inspection points prior to the implementation of disposition.

6.5.5 The NCR need not be issued for recurring type welding defects found by NDE or visual

inspection during the fabrication process provided the following conditions are met and

documented on the appropriate NDE report.

1) The welding defects are repaired using the welding repair procedure which has been

accepted by AI in advance and impact testing is not the requirement.

2) The repair shall be completed before final heat treatment or pressure testing whichever is

earlier.

3) The repaired area shall be re-inspected using the original method.

6.5.6 When the final disposition is “Repair”, Manufacturing Manager shall describe the process steps

including required inspection for repair work on the NCR or by using the Traveler.

6.5.7 It is the responsibility of Manufacturing Manager to implement the disposition for the In-Process

items and of Engineering Manager for the received material.

6.5.8 Repaired items shall be examined in accordance with applicable procedures and with the

original acceptance criteria unless the alternate acceptance criteria are established on the

NCR which meets the Code requirements.

6.5.9 Nonconforming items shall be returned for further fabrication process as described on the

original Traveler only after the disposition has been accepted by QA/QC Manager, AI and/or

Customer.

6.5.10 Upon verification of the final activity, QC Inspector shall close it out with his signature and

date on the NCR to obtain QA/QC Manager for approval before AI acceptance. Document

Controller is responsible to record to NCR Log.

INOUE VIETNAM CO., LTD.

Section 6.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Correction of Nonconformities

Page 3 of 3

6.5.11 Use- as- is

When the disposition is “Use-As-Is”, any required revisions to the drawings, calculations and

procurement documentation shall only be done as described in this QCM after consultation

and concurrence with QA/QC Manager and Engineering Manager. “Use-as-is” disposition

requires technical justification and AI’s acceptance.

6.5.12 Repair

For repair of base material, the proposed disposition shall be submitted to AI for his

concurrence of the method, extent of the repair and his designation of required Hold or

Witness points prior to making such repairs.

6.5.13 Replace

When the disposition is “Replace”, QC Inspector shall mark “Reject” on the material and

inform to Foreman to segregate the material. QA/QC Manager and Engineering Manager

shall assign the right material for compliance to the Code.

6.5.14 Scrap/Returned to Suppliers

When the disposition is “Scrap”, QC Inspector shall mark “Reject” on the material and inform

Foreman to segregate the material. When the disposition is “Returned to Suppliers”, QC

Inspector shall mark “Reject” on the material and inform Engineering Manager of the

disposition.

6.6 Repair of Base Materials

When the disposition of a nonconformance requires the repair to base material as defined by the

Code, the acceptance by AI and customer shall be obtained prior to the start of repair work for the

method and extent of repairs. It shall be documented on the NCR.

6.7 Un-Resolved Nonconformity

Material or items that cannot be corrected from the nonconforming condition shall be scrapped.

6.8 Authorized Inspector

All documents related to the NCR activities shall be made available to the AI for his review.

INOUE VIETNAM CO., LTD.

Section 7.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Welding

Page 1 of 4

7.1 Scope

This section describes the control of WPS, PQR, Welder, welding material distribution and

welding processes.

All WPS/Welder qualification and welding activities shall be performed in accordance with Section

IX and with additional requirements of the applicable Code Sections.

7.2 Responsibility

Preparation of all WPS/PQR and WPQ shall be the responsibility of Welding Engineer.

The approval of the WPS and certification of the PQR and WPQ shall be the responsibility of

QA/QC Manager.

Actual issuing and storage of welding material shall be the responsibility of Foreman.

QC Inspector shall monitor all aspects of welding.

It shall be the responsibility of Welding Engineer to provide instructions and assistance to

Welders to assure the full compliance with the Code and WPS.

Welding Engineer is responsible for the full supervision and control of the welding of the test

coupons and recording actual variable used in the welding for the qualification of welding

procedure, Welder and Welding Operator.

In addition to the Traveler, the Welding Engineer is responsible for the preparation of work

instructions for welders and fitters, project specifications and welding sequence, etc.

7.3 Welding Procedure Specification

Welding Engineer shall be responsible for the preparation and qualification of WPS and revisions

to them.

When revisions to a WPS are required and the changes are limited to the nonessential variables

the existing WPS shall either be revised showing a new revision level and date or a new WPS

shall be written.

Any changes in essential or supplementary essential variables (only when impact test is required

by the applicable construction Code), shall require a new qualification test.

INOUE VIETNAM CO., LTD.

Section 7.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Welding

Page 2 of 4

Welding Engineer shall maintain a list of the WPS which have been qualified for ASME Code

activities.

The WPS designated by Welding Engineer and specified on the drawing or weld map shall be

made available to Welders in the work area.

7.4 Welders/Welding Operators (Welder hereafter)

7.4.1 The qualification of Welder shall be witnessed by Welding Engineer in Inoue Vietnam shop.

Only qualified Welders shall be assigned to perform Code welding by Foreman. Foreman is

responsible for assignment and supervision of Welders.

7.4.2 Each Welder shall be assigned a unique identifying number upon successful completion of

first qualification test by Welding Engineer. If a Welder leaves Inoue Vietnam, unique

identifying number shall not be reassign.

7.4.3 All qualified Welder's name, identifying number, qualified position, F-number, pipe diameter,

thickness, process and last welding date in that process, etc. shall be maintained in a Welder

List (WL) (A-07-01) for each project.

7.4.4 Welding Engineer shall update the Welder Continuity Log (WCL) (A-07-03) / WL every three

months using WMIL or other evidences. If the expiration of some Welder's qualification on

WCL is coming prior to the next revision date, Welding Engineer to verify whether the

Welder's qualification can be extended or not. WCL shall indicate at least one report of

welder’s activity within the every three month period for any welding process.

7.4.5 The weld joint shall be stamped with the Welder's unique identification number at intervals of

not more than 3 feet (1 m) of weld which he makes in steel material 1/4 inch (6mm) and over

in thickness and in nonferrous material 1/2 inch (13mm) and over in thickness, or record

Welder's identification number on applicable column of Traveler by Foreman with his

signature.

7.4.6 For identification of Welders on code item in which the wall thickness is less than 1/4 inch

(6mm) for steel material and less than 1/2 inch (13mm) for nonferrous material, suitable

stencil or other surface markings shall be used, or a record of Welder ID shall be indicated on

the Traveler by Foreman for each joint, which shall be available to the AI.

7.5 Documentation of Test Result

The results of the qualification test shall be documented on the PQR or the WPQ as applicable.

When the testing is performed by an outside source laboratory, steps shall be taken to assure

that the test is performed on the correct specimen and these test results shall be documented on

the PQR/WPQ certified by Welding Engineer.

Test reports shall be reviewed and kept on file by Welding Engineer.

INOUE VIETNAM CO., LTD.

Section 7.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Welding

Page 3 of 4

7.6 Expiration and Renewal of Qualification

7.6.1 The performance qualification of Welder shall be affected when one of the following conditions

occurs.

1) When a Welder has not welded with a process during a period of 6 months or more, his

qualifications for that process shall expire; unless, within the six month period, prior to his

expiration of qualification:

A Welder has welded under supervision and control of the Foreman using the manual or

semiautomatic welding process which shall maintain his qualification for manual and

semiautomatic welding with that process.

A Welding Operator under supervision and control of the Foreman has welded with a

machine or automatic welding process which shall maintain his qualification for machine and

automatic welding with that process.

2) When there is a specific reason to question his ability to make welds that meet the

specification, his qualification which support the welding he is doing shall be revoked.

7.6.2 Welding Engineer, QA/QC Manager or AI may require re-qualification of Welder when these

reasons are found. All other qualifications not questioned remain in effect.

7.6.3 Renewal of qualification shall be in accordance with QW-322.2 of the Code Section IX.

7.6.4 Requalification of welders are required when there is change of essential variable in the WPQ

record.

7.7 Welding Material Distribution

7.7.1 Foreman shall be responsible for issuing and returning of welding material in accordance with

the Welding Material Control Procedure (A-QCP-02).

7.7.2 Low hydrogen electrodes shall be properly identified and kept in atmosphere controlled

storage area under conditions complying with the manufacturer's recommendation.

Low hydrogen welding materials shall be dried in the heating oven before being issued for

use in the shop according to the manufacturer's recommended time and temperature.

Electrodes of controlled quantity shall be issued to Welders and recorded to Welding Material

Issue Log (WMIL) (A-07-02) by Foreman. Remained welding materials shall be returned to

the welding material and crib at the end of the shift or after the time specified on the WMIL.

The low hydrogen electrodes returned shall be scrap or re-baked only once time.

7.7.3 Welding materials not requiring heated storage shall be kept in clean and dry storage areas.

7.8 Welding

Foreman shall assign Welder to the job based on WL, Traveler, WPS and drawings.

INOUE VIETNAM CO., LTD.

Section 7.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Welding

Page 4 of 4

Foreman shall maintain the applicable documents to perform the job at the working place of

ASME Code job.

QC Inspector shall record Welder I.D, WPS, Joint No, NDE Method into Welding Summary when

requested by Customer. Fabrication Engineer shall control Traveler based on working

assignment.

7.9 Tack Weld and preparation for welding

Tack welds used to secure alignment shall either be removed completely when they have served

their purpose, or their stopping and starting ends shall be properly prepared by grinding or other

suitable means so that they may be satisfactorily incorporated into the final weld. Tack welds,

whether removed or left in place, shall be made using a qualified WPS.

Tack welds to be left in place shall be made by Welders qualified in accordance with this section

and shall be examined visually for defects by QC Inspector, and if found to be defective, it shall

be removed.

The method of base metal preparation used shall leave the welding groove with reasonably

smooth surfaces and free from deep notches, striations or irregularities.

The surfaces for welding shall be free of all scale, rust, oil, grease or other foreign materials.

7.10 Individual may be contracted by Inoue Vietnam to supply their welding services provided all

the following conditions are met.

All Code construction shall be the responsibility of Inoue Vietnam.

All welding shall be performed in accordance with the Inoue Vietnam’s WPS.

All Welders shall be qualified by Inoue Vietnam in accordance with this QCM and assigned with

an identification number.

Foreman has the authority for complete and exclusive administrative and technical supervision of

all Welders.

Foreman has authority to assign and remove Welders. At his discretion without involvement of

any organization.

QA/QC Manager shall be responsible for Code compliance of the vessel or part, including

Certification Mark and providing Data Report Forms properly executed and countersigned by AI.

The program shall be submitted to the AIA which provides the inspection service.

7.11 Authorized Inspector

AI shall have the right at any time to call for and witness tests of welding procedure qualification

or of the ability of any Welder.

All documentation shall be made available to the AI.

INOUE VIETNAM CO., LTD.

Section 8.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Nondestructive Examination

Page 1 of 3

8.1 Scope

This section describes the requirements for NDE and documentation of the results as required for

Code compliance. When NDE (RT, UT, MT and PT) is needed, it will be subcontracted.

8.2 Responsibility

QA/QC Manager has the overall responsibility for successful performance of nondestructive

examination as required for Code compliance.

Preparation of NDE procedures, calibration of the NDE equipment, qualification of NDE personnel

and implementation of NDE for RT, UT, MT and PT shall be the responsibility of the

subcontractor's NDE Level III who is appointed by QA/QC Manager as a Inoue Vietnam NDE

Level III.

The NDE process shall be conducted by qualified personnel of NDE subcontractor in accordance

with the written procedures which shall be certified by NDE Level III.

The results shall be reviewed and approved by NDE Level III and verified by QA/QC Manager.

Evaluation of NDE results shall be performed by qualified NDE level II or III examinations.

8.3 Appointment of NDE Level III

QA/QC Manager shall review the written practice, qualification and certification records for

intended NDE Level III personnel and, when satisfactory, write a letter to appoint a qualified

representative of an NDE subcontractor as Inoue Vietnam appointed NDE Level III examiner.

This letter shall state the methods (RT, UT, MT and PT) he is qualified for and date of expiration.

8.4 Documentation for the NDE Personnel

The NDE subcontractor shall provide the written practice and qualification and certification

records of personnel in accordance with the Code and using the SNT-TC-1A Code adopted

Edition and Addenda as guide.

QA/QC Manager shall review the Qualification records to accept that they are in accordance with

the Code, this QCM and NDE Subcontractor’s written practice.

INOUE VIETNAM CO., LTD.

Section 8.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Nondestructive Examination

Page 2 of 3

8.5 NDE Procedures

NDE (UT, MT, PT, RT) procedures shall be written and qualified in accordance with Code

requirements and demonstrated to the satisfaction of the AI when required by the construction

Code.

This demonstration shall be certified by the QA/QC Manager documented by the AI's signature

on the cover sheet of the procedure.

NDE (UT, MT, PT, RT) Procedure shall be prequalified when there is any change in the essential

variable.

QA/QC Manager shall verify to accept NDE procedures in accordance with T-150 of Section V

prior to use.

The NDE procedures shall be made available to the NDE operators in the working area.

8.6 Nondestructive Examination

The extent and method of NDE for Code items shall be decided in accordance with the Code and

Customer Specification by Engineering Manager, and it shall be described on the fabrication

drawing.

Engineer, when needed, prepares NDE map showing NDE requirement for weld joints and

materials in accordance with the designated NDE requirements on the drawing.

Additional NDE may be required considering the fabrication process.

The subcontractor shall perform the applicable nondestructive examination based on the drawing

and NDE Map and submit the NDE reports and film to QC Inspector.

NDE results shall be documented on the appropriate subcontractor’s report forms.

QC Inspector shall verify the results of NDE and if a defect is found, he shall notify the results to

Foreman.

Nonconforming conditions shall be handled according to the Section 6.0 of this QCM.

When spot radiographic examination is specified, the AI shall be notify to select the location(s) of

spot or his concurrence shall be obtained.

INOUE VIETNAM CO., LTD.

Section 8.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Nondestructive Examination

Page 3 of 3

8.7 Equipment Control

NDE Subcontractor responsible for the calibration and control of the NDE equipment.

He shall maintain the list of the NDE equipment and calibration records which shall be reviewed

by QA/QC Manager.

8.8 Authorized Inspector

Nondestructive examinations reports including film and interpretation sheets shall be filed by

QA/QC Manager and, after review and acceptance of QC Inspector, made available to the AI for

his review.

All documents including written practice, examination procedures, personnel records, calibration

records, etc. shall be on file with the QA/QC Manager and made available to the AI.

When there is a specific reason to question the qualification of the procedure and personnel, AI

may ask for requalification.

INOUE VIETNAM CO., LTD.

Section 9.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Heat Treatment

Page 1 of 1

9.1 Scope

This section describes the requirements of heat treatment. All heat treatment will be

subcontracted.

9.2 Heat Treatment

9.2.1 QA/QC Manager is responsible to decide the scope of the heat treatment according to the

requirement of Code, standards, and Customer Specifications.

9.2.2 Welding Engineer shall provide the heat treatment procedure which shall be as a minimum

describing the heating and cooling rate, time and temperature, the location and number of

thermocouple, method of thermocouple attachment/removal and Instruction to the

subcontractor. QA/QC Manager shall approve the Instruction. Or, the heat treatment

procedure or instruction shall be submitted by the subcontractor and it shall be reviewed by

Welding Engineer and approved by QA/QC Manager.

9.2.3 QA/QC Manager shall assure the proper performance of the heat treatment by witnessing,

monitoring and document review i.e. furnace loading, method, heating and cooling rate, time

and temperature, the location and number of thermocouple, method of thermocouple

attachment and removal calibration equipment used in the heat treatment, etc.

9.2.4 Before performing the heat treatment, QC Inspector shall make the examination to check the

identification marking, stamping or tagging on the Code item and verify the calibration of

measuring and test equipment to be used.

9.2.5 After completion of the heat treatment, QC Inspector shall make examination to check the

identification marking and to verify that there is no damage or unacceptable deformation on

the item.

9.3 Record

9.3.1 QC Inspector shall review the heat treatment record and Time-Temperature Chart for

conformance with the requirements of the procedure, specification, Code and Customer

Specification. The heat treatment record shall include date, serial number of the equipment

used, procedure, chart speed and furnace loading (including location and number of

thermocouples) as a minimum.

9.3.2 All the heat treatment records shall be made available to the AI.

INOUE VIETNAM CO., LTD.

Section 10.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Calibration of Measurement Date Jul 23, 2016

and Test Equipment Page 1 of 2

10.1 Scope

This Section describes the system for the calibration of examination, measuring and test

equipment used in the fulfillment of Code requirements.

10.2 Responsibility

10.2.1 QA/QC Manager shall have the responsibility to assure that examination, measuring and test

equipment used in the fulfillment of Code requirements have been calibrated and are of

proper type, range and accuracy to accomplish the intended quality of the items.

10.2.2 Calibration of NDE equipment is the responsibility of NDE Subcontractor.

10.2.3 Calibration of equipment shall be accomplished by Inoue Vietnam or government accredited

calibration agency.

10.3 Calibration Standard and Frequency

10.3.1 The measurement and test equipment shall be calibrated and traceable to and controlled in

accordance with the national standards or the manufacturer's standards.

10.3.2 The calibration frequency shall be decided and designated in the Equipment List (EL) (A-10-

01) by QA/QC Manager based on the national standard, the Code, and the manufacturer’s

standard.

10.3.3 Pressure gauges shall be calibrated against a standard dead weight tester or calibrated

master gage. These pressure gauges shall be calibrated at least every 12 months. Two

pressures gauge to be calibrated for test purpose.

10.3.4 The measurement or test equipment shall be replaced or recalibrated at any time when there

is reason to believe that they are in error or there is a doubt in the accuracy due to dropping

or damage.

10.3.5 Impact test machine shall be calibrated using ASTM E23 or ISO 148 (part 1, 2 and 3).

10.4 Calibration Control

10.4.1 Calibration status of equipment shall be recorded on the EL which contains the identification

number, name, range, date calibrated and date to be expired for calibration, etc.

QC Inspector shall calibrate the equipment in accordance to Inoue Vietnam equipment

standard.

EL shall be reviewed every 6 months and updated when necessary by QC Inspector. Only

equipment which calibration date still in validation been used.

INOUE VIETNAM CO., LTD.

Section 10.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Calibration of Measurement Date Jul 23, 2016

and Test Equipment Page 2 of 2

10.4.2 The calibrated equipment shall be identified by the vendor’s number or serial number and by

the Calibration Sticker (A-04-06) or outside agency’s sticker, which identifies the expiration

date. QC Inspector shall review calibration records and verify to acceptance.

10.4.3 When equipment is found to be out of calibration, QC Inspector shall attach a label “Do not

use” and evaluate all inspection records since the previous equipment calibration. Items

affected by the out of calibration condition shall be documented on the NCR for evaluation

and disposition and controlled in accordance with Section 6.0 of this QCM.

10.4.4 Identification number of the measurement and test equipment used shall be recorded on the

applicable blanks of the inspection/test records or Traveler.

10.5 Subcontractor Equipment

Calibration of NDE equipment shall be done by NDE sub-contractor.

QA/QC Manager shall review and verify these calibration records for Code requirement.

10.6 Authorized Inspector

All documents in relation to the calibration shall be made available to the AI.

INOUE VIETNAM CO., LTD.

Section 11.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Record Retention

Page 1 of 1

11.1 Scope

This section describes the requirements for retention of records.

11.2 Responsibility

Document Controller is responsible for the collect of the records from Managers.

Document Controller is responsible for the retention of the records.

11.3 Records

Records for Section VIII Div. 1

All quality related records shall be kept until AI until signs the MDR except that the following

records shall be maintained at least for three (3) years.

1) Manufacturer’s Partial Data Reports

2) Manufacturing drawings

3) Design calculations, including any applicable Proof Test Report

4) Material Test Reports and/or material certifications

5) Pressure parts documentation and certifications

6) WPS and PQR

7) WPQs for each welder who welded on the vessel

8) RT and UT reports

9) Repair procedure and records

10) Travelers

11) Heat treatment records and test results

12) Post weld heat treatment records

13) NCRs and dispositions

14) Hydrostatic test records

The MDR shall be kept at least three (3) years. The RT films shall be kept until AI signs the

MDR.

11.4 Authorized Inspector

When the MDR is presented to AI for his review and signature, all other pertinent documents shall

be presented to him as requested.

11.5 Distribution of MDR

QA/QC Manager shall have the responsibility to distribute the copies of the MDR to the

Jurisdiction, AI (when requested) and/or Customers as required by the Code or Customer

Specification.

INOUE VIETNAM CO., LTD.

Section 12.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Authorized Inspector

Page 1 of 1

12.1 Scope

This Section covers the interface between Inoue Vietnam and AIA.

12.2 Inspection Agreement with AIA

Inoue Vietnam shall maintain a written Inspection Agreement to provide Code inspection and

audit services with an AIA which is accredited by the ASME in accordance with the requirements

of ASME QAI-1 last adopted version.

QA/QC Manager shall notify ASME whenever the agreement is cancelled or changed to another

AIA.

12.3 Authorized Inspector

An AI is a person who is regularly employed by an AIA, holding a valid NB Commission with an

“A” or “AR” endorsement. AI shall monitor Inoue Vietnam’s QC system periodically as required by

the Code.

12.4 Free Access

AI and AIS shall have free access to all areas of the shop and field sites and documents of Inoue

Vietnam including its vendors in order to perform inspection, monitoring and periodic audit as

required by the ASME QAI-1 and Code.

QA/QC Manager shall provide full assistance to the AIS during his audit.

12.5 Documents/QCM

AI shall have free access to all documents and records required by the Code and those other

documents and records requested to assure Code compliance.

The QCM including subsequent revisions shall be acceptable to the AI.

QA/QC Manager shall distribute a controlled copy of the QCM to AI at the shop and field sites

where Code activities are being carried out.

12.6 Interface with AI

QA/QC Manager is the principal contact with AI. He is responsible to present or to make available

to the AI all documents including Design documents, Traveler, NCR, MDR, etc. as required in the

other Sections of this QCM and is responsible for the safekeeping of the AIA’s diary.

QA/QC Manager shall notify the AI for his inspection points reasonably in advance.

INOUE VIETNAM CO., LTD.

Section 13.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Field Assembly

Page 1 of 3

13.1 Scope

This section describes responsibilities and measures to control the field assembly of Code Item.

The quality related activities not described in this section shall be in accordance with the

requirements in the other applicable Sections of this QCM.

13.2 Responsibility

Site Engineer appointed by General Manager takes overall responsibility for the operation of the

field site controlled by the shop.

Site Engineer is responsible for control of material and documents such as drawing and other

fabrication documents, which are supplied by the shop.

Site QC Inspector shall be designated by QA/QC Manager takes responsibility for the quality

control activity at the field site including in-process inspection, control of NDE subcontractor. He is

the principal contact with AI at field site.

13.3 Material Control

Material shall be purchased, inspected and controlled in accordance with Section 4.0 of this

QCM.

All the material including welding material shall be supplied from the shop with related document

at least copies of the RIR or MTR. The parts fabricated in the shop shall be supplied with clear

identification and along with the copies of the processed Travelers or Partial MDR.

The material may be supplied to the field site directly from the vendor. In this case, Site QC

Inspector shall be responsible to perform the receiving inspection accordance with Section 4.0 of

QCM at the field site.

Site Engineer shall designate the material storage area in such a location as to prevent damage

to the material.

13.4 Drawing Control

Drawing, Specifications, etc. shall be supplied by the shop and controlled as specified in Section

3.0 of this QCM. Site Engineer shall control the original or revised drawings supplied by the shop.

INOUE VIETNAM CO., LTD.

Section 13.0

QUALITY CONTROL MANUAL Edn./Rev. No. 1/0

Date Jul 23, 2016

Field Assembly

Page 2 of 3

13.5 Inspection, Examination and Test

The Traveler for field assembly work shall be prepared by Site Engineer, reviewed by Site QC

Inspector for designation of inspection points.

The Traveler shall be submitted to the site AI for the designation of inspection points.

Inspection, Examination and Test shall be carried out according to the Section 5.0 of this QCM