Professional Documents

Culture Documents

Page 364 of 1305: General 113-FC-0401 (FT-0401, PT-0406, TE-0402)

Uploaded by

jenish parekh0 ratings0% found this document useful (0 votes)

39 views1 pageThe document provides specifications for an electronic gas flow measurement system including a flow computer. Key details include:

- It is used for wet gas measurement in the field at a location on a 10" gas line.

- The flow computer has an accuracy of +/- 0.1% and can store daily and hourly logs of flow data over extended periods.

- Operating parameters include a design flow rate of 3 MMSCMD, maximum temperature of 85°C, and maximum pressure of 58.5 Kg/cm2g.

Original Description:

Original Title

Flow computer

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides specifications for an electronic gas flow measurement system including a flow computer. Key details include:

- It is used for wet gas measurement in the field at a location on a 10" gas line.

- The flow computer has an accuracy of +/- 0.1% and can store daily and hourly logs of flow data over extended periods.

- Operating parameters include a design flow rate of 3 MMSCMD, maximum temperature of 85°C, and maximum pressure of 58.5 Kg/cm2g.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views1 pagePage 364 of 1305: General 113-FC-0401 (FT-0401, PT-0406, TE-0402)

Uploaded by

jenish parekhThe document provides specifications for an electronic gas flow measurement system including a flow computer. Key details include:

- It is used for wet gas measurement in the field at a location on a 10" gas line.

- The flow computer has an accuracy of +/- 0.1% and can store daily and hourly logs of flow data over extended periods.

- Operating parameters include a design flow rate of 3 MMSCMD, maximum temperature of 85°C, and maximum pressure of 58.5 Kg/cm2g.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

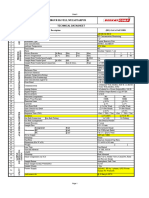

GENERAL 1 Tag Number 113-FC-0401 ( FT-0401, PT-0406, TE-0402)

2 Service RLNG (Wet Gas)

3 Location Field mounted

4 Equipment / Line Number 10"-NG-113-0401-D1A-IH

5 P&ID Number

6 Mounting Direct mounting in the field with mounting bracket

7 Area classification Zone 2 Class-1, Div.-2, Gas Group IIA/IIB, T3 ; ATEX, IEC Exd

8 Gas measurement Standards Meets : API Chapter 21.1 & AGA3/AGA5/AGA7/AGA8(detail,gross1,gross2,NX-19)

GENERAL DETAILS 9 Type Electronic Gas Flow Measurement

10 Operating Principle High accuracy system using USM with integral Pressure and Temp. sensors

11 Enclosure IP66/ NEMA 4X

12 Internal communication options Three serial ports: 2 nos. of RS 232 Port and 1 no of RS 485

LCD, Time & Date, Version I.D., Differential Pressure, Pressure, Temperature, Flow Rate, Volume

13 Display

Today, Volume Yesterday, Volume Totalizer, Mass Flow rate

OPERAING ENVIRONMENT 14 Design flow rate 3 MMSCMD

15 Design temperature 85 deg.C

16 Design pressure 58.5 Kg/CM2g

17 Moisture content 112 Kg / MMSCMD

18 Operating temperature 35 deg.C

19 Operating pressure 45 Kg/cm2g

FLOWMETER DETAILS 20 Power supply 24V DC

21 Accuracy +/- 0.1% of full span

22 Material *

24 End to end dimension of USM *

25 Mounting accessories Required, vendor to provide details

SOFTWARE FUNCTIONS Flow Time, Integrated Flow Extension, Accumulated Volume, Accumulated Energy, Auxiliary Analog

26 Daily log

Input - average

27 Hourly Logs Hourly Log holds 840 Entries or 35 days

Date and Time, Flowing Pressure - average, Flowing Temperature - average, Flow Time,

28 Periodic log

Accumulated Volume, Accumulated Energy

29 Alarms Time Stamped Alarms

PURCHASE 30 Manufacturer *

31 Model *

32 Purchase order Number *

33 Price *

34 Serial Number Item Number * *

NOTES:

1. * - VENDOR to specify / furnish

2. The power supply may be placed in safe area. Supply cabling upto Flow computer is in client's Scope.

3. Original Licensed software for retrieving the stored data, programming the Flow Computer using Laptop, software based on Windows OS shall be offered.

4. When analog input go beyond hi-low value default value shall be taken automatically for calculation.

5. Active barriers shall be provided for all inputs and outputs

6. For RLNG gas composition, refer process design basis P18002-IOCL-BR-PC-DB-1001.

7. Gas shall be reasonably free from dust (max size 10 microns)

DATASHEET FOR FLOW

COMPUTER

0 MG 13.02.2019 Issued For Engineering SHEET : 03 OF 03

REV BY DATE DESCRIPTION DOC.NO. P18002-IOCL-BR-IN-DS-NGS-FC-2004 CODE : REV.0

Page 364 of 1305

You might also like

- TT Data SheetDocument1 pageTT Data Sheetabdelmalek boudjemaaNo ratings yet

- Specification For Pressure TransmitterDocument1 pageSpecification For Pressure TransmitterHarish GundaNo ratings yet

- Datasheet of Gas AnalyserDocument1 pageDatasheet of Gas Analyserk singhNo ratings yet

- Mechanical Datasheet CompressorDocument4 pagesMechanical Datasheet CompressorTaufiq AbdullahNo ratings yet

- FT 04Document2 pagesFT 04trilok corporationNo ratings yet

- Level Instruments Nuclear Belt ScaleDocument2 pagesLevel Instruments Nuclear Belt ScalejosaugustNo ratings yet

- Endress-Hauser Energy Manager RMC621 ENDocument4 pagesEndress-Hauser Energy Manager RMC621 ENGabriel AcuñaNo ratings yet

- DS2422Document1 pageDS2422Generation GenerationNo ratings yet

- FTDocument1 pageFTmanodipNo ratings yet

- Data Sheet For Flow TransmitterDocument1 pageData Sheet For Flow TransmitterNilesh ChavanNo ratings yet

- Professionally Designed Datasheets in Friendly Excel Format. Equipment, Valves, Instrumentation, and SwitchesDocument1 pageProfessionally Designed Datasheets in Friendly Excel Format. Equipment, Valves, Instrumentation, and Switchesdaboo sanatNo ratings yet

- Mass FlowmeterDocument1 pageMass Flowmetervivek mishraNo ratings yet

- Temperature Client Transmitter Project Specification Sheet Unit LocationDocument2 pagesTemperature Client Transmitter Project Specification Sheet Unit LocationFranklin J Talero BNo ratings yet

- EGPM10-PIT-I-DAT-001 Pressure TransmitterDocument2 pagesEGPM10-PIT-I-DAT-001 Pressure TransmitterdrkongalaNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Data Sheet For EVC: ISO 9001-2015 CERITIFIEDDocument1 pageData Sheet For EVC: ISO 9001-2015 CERITIFIEDBrijesh YadavNo ratings yet

- CO AnalyzerDocument1 pageCO AnalyzeruzairNo ratings yet

- Transmisores de Presión y TemperaturaDocument6 pagesTransmisores de Presión y TemperaturaCh LoNo ratings yet

- SGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevADocument1 pageSGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevAاليخاندرو اغيليراNo ratings yet

- PCF2129Document80 pagesPCF2129rajdeepkachaNo ratings yet

- Gas Detector DatasheetDocument1 pageGas Detector Datasheetjenish parekh100% (1)

- RTD Temperature Transmitter Template SmallDocument1 pageRTD Temperature Transmitter Template SmallMohan BabuNo ratings yet

- RTD Temperature Transmitter Datasheet: TAG Number ServiceDocument1 pageRTD Temperature Transmitter Datasheet: TAG Number ServiceEyu100% (1)

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- GPS 12-Channel CorrelatorDocument63 pagesGPS 12-Channel Correlatorkhurram97et11No ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- (Insert Client Logo) : Turbine Flow MeterDocument3 pages(Insert Client Logo) : Turbine Flow MeterrutujaNo ratings yet

- RTD Temperature Transmitter Template SmallDocument1 pageRTD Temperature Transmitter Template SmallMay Rodyn Cuba de la CruzNo ratings yet

- Qalcosonic E1Document4 pagesQalcosonic E1Palaniappan LakshmananNo ratings yet

- Data Sheet For Fire Alam & Gas Detection SystemDocument2 pagesData Sheet For Fire Alam & Gas Detection SystemShabahat Husain100% (1)

- Data Sheet For Electro-Pnuematic Valve Positioners (E/P Positioner)Document2 pagesData Sheet For Electro-Pnuematic Valve Positioners (E/P Positioner)amir kamaliNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- Data Sheet Meter Turbin G.65Document1 pageData Sheet Meter Turbin G.65HerruSetiawanNo ratings yet

- DatasheetDocument8 pagesDatasheetskmrajkumarNo ratings yet

- 16V4000M63L - Heat Exchanger Separate From EngineDocument23 pages16V4000M63L - Heat Exchanger Separate From EngineSarah KirkNo ratings yet

- Datasheet For Pressure Transmitter - Process DataDocument4 pagesDatasheet For Pressure Transmitter - Process DataLai HuynhNo ratings yet

- Temperature Transmitter Specification Sheet: Client Project Unit LocationDocument2 pagesTemperature Transmitter Specification Sheet: Client Project Unit LocationFranklin J Talero BNo ratings yet

- Material List: Produced On 7/04/2022 With Xpress Selection V9.8.0 - Database DIL 17.2.1Document9 pagesMaterial List: Produced On 7/04/2022 With Xpress Selection V9.8.0 - Database DIL 17.2.1Sicologo CimeNo ratings yet

- Hdc3022 Humidity SensorDocument51 pagesHdc3022 Humidity SensorramprabhakarjNo ratings yet

- Data Sheet For Instrument Air Package 15Bv-63-Pk-201: Doc. No.: Engineering Company Rev. No.: DateDocument2 pagesData Sheet For Instrument Air Package 15Bv-63-Pk-201: Doc. No.: Engineering Company Rev. No.: Dateabdeslem mouloudjNo ratings yet

- Technical Document W10Document116 pagesTechnical Document W10namNo ratings yet

- Genius 5+ Control Eng Data - 2016 - v1.0Document55 pagesGenius 5+ Control Eng Data - 2016 - v1.0Kim WongNo ratings yet

- KNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6Document4 pagesKNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6hoapro537817No ratings yet

- SR - 2012-09 Flow IndicatorDocument2 pagesSR - 2012-09 Flow IndicatorHsein WangNo ratings yet

- UNISA Florida Campus Tswelopele Building Block EDocument65 pagesUNISA Florida Campus Tswelopele Building Block ESelloNo ratings yet

- Material List: Produced On 7/12/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Document9 pagesMaterial List: Produced On 7/12/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Sicologo CimeNo ratings yet

- 312-Data Sheet For Pressure TransmitterDocument3 pages312-Data Sheet For Pressure TransmittervyasathNo ratings yet

- DS18B20 Programmable Resolution 1-Wire Digital Thermometer: General Description Benefits and FeaturesDocument22 pagesDS18B20 Programmable Resolution 1-Wire Digital Thermometer: General Description Benefits and FeaturesKill MasterNo ratings yet

- TW DasDocument4 pagesTW DasFershaalNo ratings yet

- SR - 2012-09 Solenoid ValveDocument2 pagesSR - 2012-09 Solenoid ValveHsein WangNo ratings yet

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyenNo ratings yet

- AC ScrollDocument12 pagesAC ScrollKamalMuralikumarNo ratings yet

- Wet Gas MeterDocument4 pagesWet Gas MeterFareez JamaliNo ratings yet

- Digital Temperature Sensor With SPI Interfa: Features General DescriptionDocument28 pagesDigital Temperature Sensor With SPI Interfa: Features General DescriptionRavinder Reddy ANo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- Copeland Discus TechnicalDocument62 pagesCopeland Discus Technicalkhalil.g.semaan100% (2)

- Instrument Design Basis AKPGDocument37 pagesInstrument Design Basis AKPGSameer KapareNo ratings yet

- Flow Transmitter Datasheet: TAG Number ServiceDocument1 pageFlow Transmitter Datasheet: TAG Number Servicejugal ranaNo ratings yet

- TBA SCRUBBER SYSTEM GFL B-15-KGDocument23 pagesTBA SCRUBBER SYSTEM GFL B-15-KGsachin.patelNo ratings yet

- Microcontroller-Based Temperature Monitoring and ControlFrom EverandMicrocontroller-Based Temperature Monitoring and ControlRating: 3.5 out of 5 stars3.5/5 (2)

- Compressed Air Dryers: Recommended Dew PointsDocument11 pagesCompressed Air Dryers: Recommended Dew Pointsjenish parekhNo ratings yet

- Basic Engineering Package: Equipment List Line List Piping Service Index Instrument ListDocument17 pagesBasic Engineering Package: Equipment List Line List Piping Service Index Instrument Listjenish parekhNo ratings yet

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhNo ratings yet

- Gas Detector DatasheetDocument1 pageGas Detector Datasheetjenish parekh100% (1)

- Gas Line Size ResultDocument3 pagesGas Line Size Resultjenish parekhNo ratings yet

- Line Sizing Philosophy Line Sizing PhilosophyDocument21 pagesLine Sizing Philosophy Line Sizing Philosophyjenish parekhNo ratings yet

- HAZOP Worksheet - Case2Document6 pagesHAZOP Worksheet - Case2jenish parekhNo ratings yet

- How Can You Learn English Alone - Self-Study Plan! - EnglishClass101Document6 pagesHow Can You Learn English Alone - Self-Study Plan! - EnglishClass101Neila ArteagaNo ratings yet

- PHD Research Paper SampleDocument6 pagesPHD Research Paper Sampletxnqwcvkg100% (1)

- Safety Data Sheet: Veritas 800 Marine 30Document7 pagesSafety Data Sheet: Veritas 800 Marine 30Om Prakash RajNo ratings yet

- Kagan - 68 Kagan Structures (PDF Ebook) (OPBKS3) Zk6gDocument322 pagesKagan - 68 Kagan Structures (PDF Ebook) (OPBKS3) Zk6gKahlena GeeNo ratings yet

- Sample Paper For Cadet CollageDocument6 pagesSample Paper For Cadet Collageimran safdarNo ratings yet

- Tiếng Anh - Chính Thức - ThiệpDocument7 pagesTiếng Anh - Chính Thức - ThiệpPhung Thanh ThomNo ratings yet

- English Course SyllabusDocument2 pagesEnglish Course SyllabusSrikanthNo ratings yet

- Development of Non-Conventional Instrument Transformers (NCIT) Using Smart MaterialsDocument7 pagesDevelopment of Non-Conventional Instrument Transformers (NCIT) Using Smart Materialsjuanandrea2014No ratings yet

- Indo AryanDocument35 pagesIndo AryanDamith Chandimal100% (1)

- On The Foundations of Gravitation, Inertia and Gravitational WavesDocument9 pagesOn The Foundations of Gravitation, Inertia and Gravitational Wavesgiorgiofontana100% (5)

- Fault Code 471 Engine Oil Level - Data Valid But Below Normal Operational Range - Least Severe LevelDocument4 pagesFault Code 471 Engine Oil Level - Data Valid But Below Normal Operational Range - Least Severe LevelAhmedmahNo ratings yet

- Tutorial 1 Week 3Document2 pagesTutorial 1 Week 3Gaiva MuriNo ratings yet

- WEEK 4 - 15 - Yield - Flow MassDocument11 pagesWEEK 4 - 15 - Yield - Flow MassyeeNo ratings yet

- (M2-MAIN) Rectilinear MotionDocument23 pages(M2-MAIN) Rectilinear MotionJoshua AngelesNo ratings yet

- Future Towers Amanora Park Town, Pune, IndiaDocument12 pagesFuture Towers Amanora Park Town, Pune, IndiaPriya Balaji80% (5)

- Transformation of Plastic Solid Waste Into Liquid Fuel: Scientific Inquiry and Review (SIR)Document13 pagesTransformation of Plastic Solid Waste Into Liquid Fuel: Scientific Inquiry and Review (SIR)UMT JournalsNo ratings yet

- Genesis of PPV & FR ActDocument3 pagesGenesis of PPV & FR ActsdNo ratings yet

- Madisen Jolliffs ResumeDocument1 pageMadisen Jolliffs Resumeapi-532500135No ratings yet

- MRT 2150Document244 pagesMRT 2150jorn kieftenbeldNo ratings yet

- 13.47.1 UnlockedDocument2 pages13.47.1 UnlockedJoseVillanuevaNo ratings yet

- Fundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, IndianDocument35 pagesFundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, Indianyair Enrique Romero OspinoNo ratings yet

- EvalSheet OJTDocument1 pageEvalSheet OJTMarlo QuiachonNo ratings yet

- Estropia, Rhealyn Sanao: Email Add CONTACT NO: 09291694464 Address: 856 Prudencia STDocument2 pagesEstropia, Rhealyn Sanao: Email Add CONTACT NO: 09291694464 Address: 856 Prudencia STAlfred CasicasNo ratings yet

- Lilha Education Centre BST RevisionDocument39 pagesLilha Education Centre BST RevisionAlan walkerNo ratings yet

- History Paper 2 3 BibleDocument4 pagesHistory Paper 2 3 BibleCelia ChirinosNo ratings yet

- Spirtual Sayings of Khalil Gibran PDFDocument10 pagesSpirtual Sayings of Khalil Gibran PDFKedar KelkarNo ratings yet

- LANGUAGE REGISTERS - DraftDocument11 pagesLANGUAGE REGISTERS - DraftTrisha Mae DeveraNo ratings yet

- Module 2 (Concepts in Structural Steel Design)Document16 pagesModule 2 (Concepts in Structural Steel Design)Mervin BiloyNo ratings yet

- The Cropper Foundation - ProposalDocument41 pagesThe Cropper Foundation - ProposalPieceeNo ratings yet

- Kelvin-Helmholtz Instability and Roll-Up - ScholarpediaDocument7 pagesKelvin-Helmholtz Instability and Roll-Up - ScholarpediaSanjay Kumar AdvaniNo ratings yet