Professional Documents

Culture Documents

Method Statement for Roof Waterproofing

Uploaded by

beshnu garanaikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement for Roof Waterproofing

Uploaded by

beshnu garanaikCopyright:

Available Formats

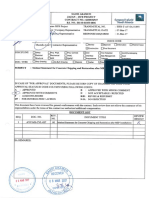

FOR APPROVAL

JUNG WOO

0 09.JUL.2019 C.W.Hyun J. C. PARK FOR APPROVAL

KIM

Rev Date Prepared Checked Approved Details of Revision

Owner JAWAHARPUR VIDYUT UTPADAN NIGAM LIMITED

(A UP Government Undertaking)

Owner’s Engineer DESEIN PRIVATE LIMITED,

Consulting Engineers

Contractor DOOSAN POWER SYSTEMS

INDIA PVT. LTD

METHOD STATEMENT

FOR ROOF WATER PROOFING WORK

DP16003-CC02-P0-UMA-780013

Supplier

Project JAWAHARPUR SUPER THERMAL POWER STATION

(2 X 660 MW)

Date Project Code

Name Title

(08.07.2019) DP16003

UAS Code

JUNG WOO

Prepared

KIM

DD09

Unit Code

Checked C.W.Hyun

METHOD STATEMENT

P0

FOR

KKS Code

Approved J. C. PARK ROOF WATER PROOFING

UMA

Reg. No.

Department Architecture DEPT.

780013

Owner’s Consultant Document No. Rev.

Contractor’s Document No. Page-No.

DP16003 – DD09 - P0 - UMA – 780013 1 of 7

Supplier’s Document No.

JAWAHARPUR THERMAL POWER STATION (2x660 MW) Rev. 0

Page 2 of 7

METHOD STATEMENT

FOR ROOF WATER PROOFING WORK

DP16003-CC02-P0-UMA-780013

Revision History

0 09.JUL.2019 J.W.Kim C.W.Hyun J.C. PARK FOR APPROVAL

Rev Date Prepared Checked Approved Details of Revision

JAWAHARPUR THERMAL POWER STATION (2x660 MW) Rev. 0

Page 3 of 7

METHOD STATEMENT

FOR ROOF WATER PROOFING WORK

DP16003-CC02-P0-UMA-780013

INDEX

ARTICLE DESCRIPTION

COVER PAGE INDEX

1.0 USE

2.0 REFERANCE DRAWINGS

3.0 MATERIAL

4.0 MANPOWER

5.0 TOOLS AND TACKLES

6.0 SURFACE PREPARATION

PROCEDURE FOR APPLICATION OF

7.0

WATERPROOFING

8.0 SAFETY

JAWAHARPUR THERMAL POWER STATION (2x660 MW) Rev. 0

Page 4 of 7

METHOD STATEMENT

FOR ROOF WATER PROOFING WORK

DP16003-CC02-P0-UMA-780013

Work Method Statement for Application of Roof waterproofing

1. USE

Objective of this procedure is to provide a guideline for sequence of operations

pertaining to waterproofing on concrete masonry/roof surface, so as to ensure

that the works are carried out in a systematic manner and to ensure that the

works conform to the drawings and technical specification.

2. Reference

This Procedure is based on the requirements of the Approved Drawings and

Technical Specification.

3. Materials

Cement

Sand

Water

RMC (1:2:4)

IWL Liquithane EMA PU based waterproofing material

Galvanized chicken wire mesh (0.56mm)

4. MAN POWER

Adequate Skilled manpower shall be arranged for laying this type of floor.

5. Tools & Tackles

Surface preparation tools like hand grinder, concrete cutters, industrial

vacuum cleaner etc, measuring tape, electric/pneumatic stirrers, clean

JAWAHARPUR THERMAL POWER STATION (2x660 MW) Rev. 0

Page 5 of 7

METHOD STATEMENT

FOR ROOF WATER PROOFING WORK

DP16003-CC02-P0-UMA-780013

containers, brush, roller, stop watch, weighing scale, cleaning tools,

finishing tools like serrated trowel, spiked roller.

6. Surface preparation

The surface should be free from dust, loose particles, grease, oil or any

other contamination.

Cleaning the area for all debris, mortar and excess water with wire

brush/blower.

7. Procedure for application of waterproofing

Clean the surface to remove dust particles and to receive the waterproofing

coating.

All the depression, pin hole/pot holes & honey combing area to be repaired

with cement and coarse sand.

Application of Liquithane primer to applied at 5-6m2/kg.

Thorough mixing of catalyst with Liquithane EMA in the ratio 20kg: 400

Gms.

First coat applied of mixing material (Catalyst & Liquithane EMA) after one

hrs of primer coat.

Application of Liquithane EMA in two coat maximum within a gap of 24 hrs.

Second coat applied after 24 hours. Liquithane EMA is to be applied with

help of viper/brush.

Water testing as per norms to be done for 72 hrs.

Cement sand mortar

40 mm thick lean concrete (Ratio 1.2.4) lay on waterproofing surface in

JAWAHARPUR THERMAL POWER STATION (2x660 MW) Rev. 0

Page 6 of 7

METHOD STATEMENT

FOR ROOF WATER PROOFING WORK

DP16003-CC02-P0-UMA-780013

panel size 1.2 mtr x1.2 mtr. Chicken wire mess fixed in panel and joint must

be sealed with sealing compound.

Surface should be cured for 5- 7 day.

8. Safety Precautions

Each workman should use all PPEs like hand gloves, nose musk, safety

goggles, safety belt, helmet and safety shoes during waterproofing works.

Area lighting will be provided for night work. Good housekeeping will be

ensured

Safety supervisor shall ensure that safety precautions are taken and safe

work environment is maintained.

Safety precautions for work at height will be taken.

JAWAHARPUR THERMAL POWER STATION (2x660 MW) Rev. 0

Page 7 of 7

You might also like

- DepEd CI GuidebookDocument244 pagesDepEd CI Guidebookasdfg100% (4)

- Form Leak Test Report DD 101005Document5 pagesForm Leak Test Report DD 101005Thiri HtetNo ratings yet

- 115A - Water Proofing Checklist For ToiletDocument1 page115A - Water Proofing Checklist For Toiletbeshnu garanaikNo ratings yet

- Ms - Chipping and Restoration On Mep InstallationsDocument8 pagesMs - Chipping and Restoration On Mep Installationsmoytabura9667% (3)

- Method Statement For Site EstablishmentDocument12 pagesMethod Statement For Site Establishmentmdfahad0047No ratings yet

- Dasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientDocument1 pageDasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientTusarranjan BhuyanNo ratings yet

- Method Statement For Installation of Wooden Flooring PDFDocument18 pagesMethod Statement For Installation of Wooden Flooring PDFChris EnyinnayaNo ratings yet

- QC Check Sheet for Earthworks ExcavationDocument1 pageQC Check Sheet for Earthworks ExcavationPrasanna KumarNo ratings yet

- Structural CommentsDocument3 pagesStructural CommentsMusherib KhanNo ratings yet

- Inspection and Test Plan (ITP) for Suspending Ceiling InstallationDocument2 pagesInspection and Test Plan (ITP) for Suspending Ceiling Installationexia1992No ratings yet

- Installation Method of Statement of HDPE PipeDocument3 pagesInstallation Method of Statement of HDPE Pipebeshnu garanaik100% (2)

- Method Statement Epoxy FloorDocument8 pagesMethod Statement Epoxy Floorbeshnu garanaik67% (3)

- Unit 3 Digital Documentation: Multiple Choice QuestionsDocument7 pagesUnit 3 Digital Documentation: Multiple Choice Questions07tp27652% (21)

- Improving Performance With Goals、Feedback、Reward、and Positive ReinforcementDocument15 pagesImproving Performance With Goals、Feedback、Reward、and Positive ReinforcementMichelle HuwaeNo ratings yet

- DLL in Science 5 Q1 W1Document3 pagesDLL in Science 5 Q1 W1Rhinalyn Andaya Barberan100% (2)

- Socrates 8dDocument8 pagesSocrates 8dcarolinaNo ratings yet

- Teaching Speaking: Daily Activities Lesson PlanDocument3 pagesTeaching Speaking: Daily Activities Lesson PlanMARCELANo ratings yet

- Water Proofing and DPC checklist-Rev-R6Document1 pageWater Proofing and DPC checklist-Rev-R6Guna SekaranNo ratings yet

- Method of Statment CONCRETEDocument7 pagesMethod of Statment CONCRETESyed AtherNo ratings yet

- Install and Test Domestic Water PipingDocument14 pagesInstall and Test Domestic Water PipingBelal AlrwadiehNo ratings yet

- Method Statement & Itp For Waterproofing WorkDocument7 pagesMethod Statement & Itp For Waterproofing WorkRumi ZamNo ratings yet

- Method Statement For Installation of Kerbstone and Pavers in UAEDocument18 pagesMethod Statement For Installation of Kerbstone and Pavers in UAEGhayas JawedNo ratings yet

- Method Statement For Installation of PVC uPVC Drainage Piping Under or Above GroundDocument7 pagesMethod Statement For Installation of PVC uPVC Drainage Piping Under or Above GroundDong VanraNo ratings yet

- Megaadd Wl2: Integral Water Repellent AdmixtureDocument2 pagesMegaadd Wl2: Integral Water Repellent AdmixtureShaik QutubuddinNo ratings yet

- Method Statement Striking FormworkDocument3 pagesMethod Statement Striking FormworkSurya HeriwijayaNo ratings yet

- ITP-Application of PaintingDocument2 pagesITP-Application of PaintingMuthu Saravanan100% (1)

- Construction Permit To Work SystemDocument3 pagesConstruction Permit To Work SystemZubair KhanNo ratings yet

- Method of Statement Template For Marble InstallationDocument6 pagesMethod of Statement Template For Marble InstallationumitNo ratings yet

- P1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BDocument16 pagesP1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BEILA545 QAQCNo ratings yet

- Drainage and Sewage Works Method StatementDocument16 pagesDrainage and Sewage Works Method StatementazrulNo ratings yet

- List of Approved Materials (Civil)Document3 pagesList of Approved Materials (Civil)xyzhynNo ratings yet

- ITP - Plaster WorkDocument1 pageITP - Plaster Workmahmoud ghanemNo ratings yet

- Methodology Statement Civil Works MuntinlupaDocument8 pagesMethodology Statement Civil Works MuntinlupaFrancis GonzalesNo ratings yet

- 7 BOQ For Furnishing Work Bahadurganj BranchDocument1 page7 BOQ For Furnishing Work Bahadurganj BranchRashedNo ratings yet

- Tiling WorksDocument21 pagesTiling WorksGhayas JawedNo ratings yet

- Method Statement For Excavation Works-Eastern Regional Hospital Project-Phase - 1Document9 pagesMethod Statement For Excavation Works-Eastern Regional Hospital Project-Phase - 1NORTSEN ALBERTNo ratings yet

- QCS 2010 Part 6.03 EarthworksDocument21 pagesQCS 2010 Part 6.03 EarthworksRotsapNayrb100% (2)

- Compliance FormatDocument1 pageCompliance FormatDeepak JoyNo ratings yet

- Itp For Gravel Surfacing and Dust PreventionDocument7 pagesItp For Gravel Surfacing and Dust PreventionShewale PravinNo ratings yet

- Checklist For Rebar and Concrete WorkDocument4 pagesChecklist For Rebar and Concrete WorkDwinto RachmadNo ratings yet

- Lavatex 2000...Document2 pagesLavatex 2000...ArifNo ratings yet

- 002-PDS-CON-010 Method Statement For Site Preparation WorksDocument15 pages002-PDS-CON-010 Method Statement For Site Preparation WorksMalik ZamanNo ratings yet

- AluminumDocument291 pagesAluminumAbdul BasithNo ratings yet

- Cavity Wall-Method StatementDocument4 pagesCavity Wall-Method StatementTAHER AMMAR100% (1)

- Method Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneDocument2 pagesMethod Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneParasNo ratings yet

- 2x150mw Dmci CWP 001 EarthworksDocument12 pages2x150mw Dmci CWP 001 EarthworksBenjo FaustoNo ratings yet

- Method Statement for Ceramic Tile InstallationDocument4 pagesMethod Statement for Ceramic Tile InstallationAli SaifNo ratings yet

- WATERPROOFDocument1 pageWATERPROOFKarthick NatrajanNo ratings yet

- Vacuum de - Watered Flooring Method Statement: ActivitiesDocument1 pageVacuum de - Watered Flooring Method Statement: Activitiesவினோத் குமார்No ratings yet

- Method Statement For False Ceiling WorksDocument8 pagesMethod Statement For False Ceiling WorkscdnaveenNo ratings yet

- CONSTRUCTION STANDARD FOR INSTALLING PRECAST CONCRETE MANHOLESDocument9 pagesCONSTRUCTION STANDARD FOR INSTALLING PRECAST CONCRETE MANHOLESgemotorresNo ratings yet

- Method of Statement PCDocument8 pagesMethod of Statement PCAbada SaadNo ratings yet

- Method Statement For Aac BlockworkDocument10 pagesMethod Statement For Aac BlockworkobieNo ratings yet

- National Cyber Security Center Qatar Project DetailsDocument1 pageNational Cyber Security Center Qatar Project Detailsmohamed haniNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- 044 ITP For Installation of Gypsum Board Buildings PDFDocument10 pages044 ITP For Installation of Gypsum Board Buildings PDFHarshvardhan PathakNo ratings yet

- Methodology of Leakage Treatment at Z4-896 PDFDocument2 pagesMethodology of Leakage Treatment at Z4-896 PDFEngr. MahmudNo ratings yet

- Vetonit Spatter Dash-MC SDM212Document2 pagesVetonit Spatter Dash-MC SDM212toni mujiyonoNo ratings yet

- Inspection Checklist Masonry WallDocument3 pagesInspection Checklist Masonry WallJonatan LopezNo ratings yet

- Water Proofing Toilets WorksDocument63 pagesWater Proofing Toilets WorksGhaffar Laghari100% (1)

- Maintaining Flood Mitigation WorksDocument42 pagesMaintaining Flood Mitigation WorksKuang Ngang ENo ratings yet

- Road Construction Method Statement - Method Statement HQDocument19 pagesRoad Construction Method Statement - Method Statement HQaugustine samuelNo ratings yet

- Renovation Works at Al Forsan Sports ResortDocument7 pagesRenovation Works at Al Forsan Sports ResortAshimolowo BabatundeNo ratings yet

- Chain Link Fence Installation MethodDocument8 pagesChain Link Fence Installation MethodAzhar ShaikhNo ratings yet

- Soil Inspection Checklist For BackfillingDocument1 pageSoil Inspection Checklist For BackfillingBasker BaluNo ratings yet

- Large Wall Tile Installation MethodDocument35 pagesLarge Wall Tile Installation Methodlokesh.kukadiyaNo ratings yet

- MS 20.0 Crack Repair Method StatementDocument9 pagesMS 20.0 Crack Repair Method StatementNorhidayah Binti100% (1)

- Method Statement WoodenDocument7 pagesMethod Statement Woodenbeshnu garanaik0% (1)

- Method Statement TileDocument10 pagesMethod Statement Tilebeshnu garanaikNo ratings yet

- ASTM Acceptance CriteriaDocument10 pagesASTM Acceptance Criteriabeshnu garanaikNo ratings yet

- Handbook On Statutory ComplianceDocument62 pagesHandbook On Statutory Compliancebeshnu garanaikNo ratings yet

- 2021 Quality Day - BannerDocument1 page2021 Quality Day - Bannerbeshnu garanaikNo ratings yet

- Site Lab - Field Test Equipment DetailsDocument2 pagesSite Lab - Field Test Equipment Detailsbeshnu garanaikNo ratings yet

- Quality Observation For Hand OverDocument9 pagesQuality Observation For Hand Overbeshnu garanaikNo ratings yet

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocument3 pagesAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specificationbeshnu garanaikNo ratings yet

- CRM CGL Area Audit Report FindingsDocument11 pagesCRM CGL Area Audit Report Findingsbeshnu garanaikNo ratings yet

- 101 DR Fixit Pidiproof LW+Document2 pages101 DR Fixit Pidiproof LW+beshnu garanaikNo ratings yet

- Method Statement WoodenDocument7 pagesMethod Statement Woodenbeshnu garanaik0% (1)

- Method Statement TileDocument10 pagesMethod Statement Tilebeshnu garanaikNo ratings yet

- Method Statement WoodenDocument7 pagesMethod Statement Woodenbeshnu garanaik0% (1)

- Method Statement Non MetallicDocument7 pagesMethod Statement Non Metallicbeshnu garanaikNo ratings yet

- Weekly review meeting TSK PH-II expansion project quality reinforcementDocument4 pagesWeekly review meeting TSK PH-II expansion project quality reinforcementbeshnu garanaikNo ratings yet

- Batch Sheet & IS CodeDocument7 pagesBatch Sheet & IS Codebeshnu garanaikNo ratings yet

- Methodology Fo Tapecrete WaterproofDocument3 pagesMethodology Fo Tapecrete Waterproofbeshnu garanaikNo ratings yet

- Anti-Termite Treatment MethodDocument4 pagesAnti-Termite Treatment Methodbeshnu garanaikNo ratings yet

- Method Statement for False Ceiling WorkDocument7 pagesMethod Statement for False Ceiling Workbeshnu garanaikNo ratings yet

- Method Statement for False Ceiling WorkDocument7 pagesMethod Statement for False Ceiling Workbeshnu garanaikNo ratings yet

- Method Statement Non MetallicDocument7 pagesMethod Statement Non Metallicbeshnu garanaikNo ratings yet

- Cem CreteDocument3 pagesCem CreteMadhukar SMNo ratings yet

- TrackDocument11 pagesTrackBeshnu GaranaikNo ratings yet

- Coordinate & Elevation Inspection Report Anchor BoltDocument2 pagesCoordinate & Elevation Inspection Report Anchor Boltbeshnu garanaikNo ratings yet

- Methodology-TG DECK-rev0 (4feb12)Document11 pagesMethodology-TG DECK-rev0 (4feb12)beshnu garanaik100% (1)

- Method Statement AluminiumDocument7 pagesMethod Statement Aluminiumbeshnu garanaikNo ratings yet

- Is.1498.1970 Soil ClassificationDocument28 pagesIs.1498.1970 Soil Classificationp09tp451No ratings yet

- Shortlisted CandidateDocument1 pageShortlisted Candidatebeshnu garanaikNo ratings yet

- Solid Solution For Catalytic Ammonia Synthesis FromDocument8 pagesSolid Solution For Catalytic Ammonia Synthesis FromAhmad AlShahrourNo ratings yet

- Technical ManualDocument32 pagesTechnical ManualIstvan MadacsyNo ratings yet

- Activity No.1 in GED 103Document2 pagesActivity No.1 in GED 103Kenneth HerreraNo ratings yet

- 11 - Leo Vega Bolt Failure AnalysisDocument35 pages11 - Leo Vega Bolt Failure AnalysissymkimonNo ratings yet

- Basic Vacuum Theory PDFDocument17 pagesBasic Vacuum Theory PDFada guevarraNo ratings yet

- Fireclass: FC503 & FC506Document16 pagesFireclass: FC503 & FC506Mersal AliraqiNo ratings yet

- Netprobe 2000Document351 pagesNetprobe 2000Jordon CampbellNo ratings yet

- AR Ageing FinalDocument13 pagesAR Ageing FinalHAbbunoNo ratings yet

- PTE - Template - Essay All TypesDocument8 pagesPTE - Template - Essay All TypeskajalNo ratings yet

- Using Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Document6 pagesUsing Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Jeko Betguen PalangiNo ratings yet

- Advantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrDocument3 pagesAdvantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrRameshNo ratings yet

- ABB Softstarters, Type PSR, PSS, PST/PSTBDocument50 pagesABB Softstarters, Type PSR, PSS, PST/PSTBElias100% (1)

- Guardian Brand Book - 042019Document15 pagesGuardian Brand Book - 042019FTU.CS2 Nguyễn Việt HưngNo ratings yet

- Professor Barry T Hart - BiographyDocument1 pageProfessor Barry T Hart - BiographyadelNo ratings yet

- Base Case Analysis Best CaseDocument6 pagesBase Case Analysis Best CaseMaphee CastellNo ratings yet

- ICT - 81 - F32A - ISO - 13485 - and - MDD - IVDD - Checklist - Rev1 - 01.05.2020 - ALAMIN (1) (Recovered)Document41 pagesICT - 81 - F32A - ISO - 13485 - and - MDD - IVDD - Checklist - Rev1 - 01.05.2020 - ALAMIN (1) (Recovered)Basma ashrafNo ratings yet

- Limit of Outside Usage Outside Egypt ENDocument1 pageLimit of Outside Usage Outside Egypt ENIbrahem EmamNo ratings yet

- Writing in Bengali - : Past and PresentDocument3 pagesWriting in Bengali - : Past and PresentRanjanNo ratings yet

- BG BG 202102080912862 User Manual - File (Long) BG BG-8Document1 pageBG BG 202102080912862 User Manual - File (Long) BG BG-8hofolo39No ratings yet

- CMO Olympiad Book For Class 3Document13 pagesCMO Olympiad Book For Class 3Srividya BaiNo ratings yet

- Eugene A. Nida - Theories of TranslationDocument15 pagesEugene A. Nida - Theories of TranslationYohanes Eko Portable100% (2)

- Testing Methods for Selectivity Bias in Panel Data ModelsDocument24 pagesTesting Methods for Selectivity Bias in Panel Data Modelsstehta16529No ratings yet

- IEC Developer version 6.n compiler error F1002Document6 pagesIEC Developer version 6.n compiler error F1002AnddyNo ratings yet

- Pressure Variation in Tunnels Sealed Trains PDFDocument258 pagesPressure Variation in Tunnels Sealed Trains PDFsivasankarNo ratings yet