Professional Documents

Culture Documents

Confined Spaces Monitoring

Confined Spaces Monitoring

Uploaded by

Primelift Safety Resources LimitedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Confined Spaces Monitoring

Confined Spaces Monitoring

Uploaded by

Primelift Safety Resources LimitedCopyright:

Available Formats

Common Mistakes in

CONFINED SPACE MONITORING

A confined space is no place to “learn as you go.”

Learn how to avoid these potentially deadly errors in

the work world’s most dangerous spaces.

by Thomas Suski

L

earning from practical, real-world

experience often requires learning

from your own mistakes. In many

cases, this can be an effective way of de-

veloping greater levels of competence

and understanding in a given subject.

Unfortunately, when mistakes are made

in confined space monitoring, the cost

of this education is often measured in

the number of lives lost.

The deadly nature of confined spaces

leaves little room for error and even less

opportunity to “learn as you go.” Learn-

ing about some common mistakes be-

fore entering a confined space will go a

long way toward establishing a work-

place air monitoring program based on

industry best practices.

Mistake #1 – Not knowing OSHA

standards and recommendations

It all starts here. Understanding what

kind of hazards may be present at your

job site involves familiarity with OSHA

standards and a working knowledge of

its terms and definitions. For example, a

confined space as defined in OSHA’s

confined space standard, 29 CFR

1910.146, is any space that is large

enough and configured so that an em-

PHOTOS: INDUSTRIAL SCIENTIFIC CORP.

ployee can bodily enter and perform as-

signed work, has limited or restricted

means for entry or exit and is not de-

signed for continuous employee occu-

pancy.

When a space meets these criteria, fur-

ther consideration must be given to de-

termine whether it meets OSHA’s defini-

tion of a “permit-required” confined

www.occupationalhazards.com May 2005 / Occupational Hazards 53

ensure that your gas monitors will accu-

rately measure the presence of atmos-

pheric hazards and immediately alert

the user to a dangerous condition. One

common mistake is zeroing the instru-

ment in an environment that contains

any significant concentration of a haz-

ardous substance. Using a less-than-

ideal atmosphere to establish the moni-

tor’s clean-air reference point can lead

to inaccurate or even negative readings

and an increased risk of safety.

Many equipment end-users also are

confused about how – and how often –

to bump-test and calibrate their gas mon-

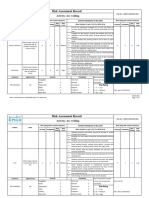

Companies should ensure that attendants know how to call for assistance, ventilate the itors. The confusion typically results in

confined space and be able to operate a non-entry, mechanical retrieval system. ignoring best practices or avoiding the

responsibility altogether. A training pro-

gram can ensure that, at a minimum, a

bump test is performed with a known

space. If a confined space also contains The only way to safely detect a haz- concentration of gas to verify sensor ac-

or has a potential to contain a haz- ardous atmosphere is with a “calibrated curacy before each day’s use and that

ardous atmosphere, contains a material direct reading instrument” as described the instruments are adjusted with a full

that has the potential for engulfing an in OSHA’s confined space standard 29 calibration should they fail the bump

entrant, has an internal configuration CFR 1910.146. test. These minimum recommendations

such that an entrant could be trapped or Mistake #3 – Disregarding the im- were established by the International

asphyxiated or contains any other rec- portance of training Safety Equipment Association (ISEA), a

ognized serious safety or health hazard, A gas monitor is not the only compo- trade association for manufacturers of

then additional measures must be taken nent of an effective gas detection pro- protective equipment, and echoed by

to safely enter and perform any work gram. When workers are trained on the OSHA in a Safety and Health Information

within the space. operation of the instrument and the pro- Bulletin released in 2004.

More than just a glossary of safety terms, cedures for confined space monitoring, Mistake #5 – Not knowing which

OSHA standards also provide a blueprint the risks involved with this type of work toxic gases may be present

for procedures and practices that are at can be greatly diminished. One of the Understanding the work area is essen-

the heart of any safety program. In fact more important benefits of training in- tial not only for the purpose of identify-

many, if not all, mistakes in confined volves an increased awareness of the po- ing areas that should be labeled permit-

space monitoring could be decreased or tential dangers. Familiarity, complacency required confined spaces, but in

eliminated altogether if safety managers and a false sense of security can all lead choosing the type of gas monitor to use.

and workers simply followed OSHA’s stan- to abandoning best practices, especially The most common configuration for a

dards and recommendations. when the time spent working in the space multiple-sensor gas monitor is one that

Mistake #2 – Using your own is expected to be minimal. But trained can read levels of oxygen, combustible

senses workers know that accidents can happen gases, hydrogen sulfide and carbon

While it is common knowledge that a to anybody and that no matter how much monoxide. While monitoring oxygen

number of hazardous gases are both time is spent working in the space, the po- and combustible gas levels is required,

colorless and odorless, many people tential danger remains the same. toxic gas hazards vary with different

think they can easily recognize the pres- A variety of training options from gas types of confined spaces. So, to assume

ence of hydrogen sulfide – one of the monitor manufacturers are available, that the toxic gases present in any con-

more common confined space toxic from video, online and computer-based fined space are limited to only hydrogen

gases. The problem with this deadly gas training to classroom sessions and sulfide and/or carbon monoxide ig-

is that its distinctive “rotten egg” odor is hands-on learning through confined nores the possibility that different or ad-

only perceptible at very low concentra- space simulators. With so many options, ditional toxic sensors must be used.

tions. At higher levels, hydrogen sulfide including sessions that can be held at Many multi-gas monitors now are avail-

has a paralyzing effect on your sense of your facility, there’s no reason that able with several toxic sensor options

smell. Even at low concentrations, pro- proper training in confined space moni- and the flexibility of measuring up to

longed exposure can dull the olfactory toring should be overlooked. five and even six gases simultaneously.

nerves and make it impossible to accu- Mistake #4 – Not implementing a Mistake #6 – Not performing a pre-

rately detect, even if concentrations gas monitor maintenance program entry test

suddenly increase. A sound maintenance program will An extremely dangerous mistake re-

54 Occupational Hazards / May 2005 www.occupationalhazards.com

garding confined space atmospheric Air monitoring does not end with the

testing is not performing or incorrectly pre-entry test. Atmospheric conditions

performing a pre-entry test. Wearing a within a confined space are capable of

gas monitor into a confined space is not changing rapidly, which makes it very

enough to protect from many hazardous important to continuously monitor for

conditions that are immediately harm- gas hazards. Improvements in technol-

ful to the entrant. OSHA’s confined ogy have made it possible to manufac-

space standard 1910.146 states that be- ture gas monitors small and light

fore an employee enters a permit-re- enough to be comfortably worn without

quired confined space, “the internal at- interfering with your work.

mosphere shall be tested, with a Considering this potential of a confined

calibrated direct reading instrument, for space atmosphere to change rapidly,

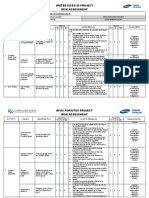

the following conditions in the order OSHA requires conducting a “re-entry” test Atmospheric conditions within a confined

given: (1) oxygen content, (2) flamma- if the confined space has been temporarily space can change rapidly, making it very

ble gases and vapors and (3) potential unoccupied (for more than 20 minutes). important to continuously monitor for gas

toxic air contaminants.” For all practical purposes, re-entry testing hazards.

Why test for oxygen first? Not only is it and pre-entry testing are performed in ex-

essential for the entrant to survive, your actly the same manner and should be con-

monitor may need it as well. Many gas sidered as equally important. emergencies are followed with actions

monitors utilize a catalytic diffusion Mistake #8 – Not assigning an “at- based on impulse rather than a rational

type of sensor that detects combustible tendant” and thoughtful plan.

gas by burning small amounts of it. Do- A large part of safely conducting con- The job of the attendant, in an emer-

ing so requires an oxygen concentration fined space work is to have a designated gency, is not to personally rescue the

of at least 10 percent. Anything less and “attendant” – someone to maintain con- victims, but to implement the rescue

the monitor will not respond to any tact with the entrant while they are in plan. This may involve calling for assis-

amount of combustible gas, let alone the confined space. The attendant must tance, ventilating the confined space

dangerous concentrations. not be involved with any tasks or dis- and/or operating a non-entry, mechani-

Pre-entry testing also involves testing tractions unrelated to the safety of the cal retrieval system. In all cases, the at-

the atmosphere at the top, middle and confined space worker, and must not, tendant must try to maintain contact

bottom of the confined space. Because under any circumstances, enter the con- with the entrant(s) to assure that help is

different gases stratify based on their fined space. If the work is to be per- on the way and to gather information

about the incident that may be helpful

Wearing a gas monitor into a confined space to the rescue.

Reviewing some common mistakes in

is not enough to protect from many confined space monitoring, hopefully,

is an impetus to acquiring further infor-

hazardous conditions that are immediately mation and training. A wealth of infor-

mation is available from OSHA, MSHA

harmful to the entrant. or the training department of your gas

monitor manufacturer. Equip yourself

weight, there is an inconsistency in the formed over an extended period of with the right gas monitors and proper

level of danger if the entrant has to de- time, the attendant may be responsible training to eliminate these common mis-

scend or ascend several feet to get to the for recording additional atmospheric takes ... and the hard lessons that can

work area. Methane, for example, is readings to monitor the safety of the come with them. OH

lighter than air and would be found at the confined space. The attendant should

top of a confined space, while hydrogen also know the gas hazards and the phys- Thomas Suski is marketing communica-

sulfide (heavier than air) would be found ical symptoms of exposure in case of an tions manager for Industrial Scientific

at the bottom. Carbon monoxide is emergency. Corp. He can be reached at

slightly lighter than air, so it will generally Mistake #9 – Not having an emer- tsuski@indsci.com or (800) 338-3287.

stay wherever it is released. To com- gency plan Industrial Scientific Corp. is a leading de-

pletely assess such dangers, OSHA’s stan- Not knowing what to do in an emer- signer, manufacturer and marketer of gas

dards require that testing of the space be gency puts both the worker and the at- monitoring instruments, systems and

performed at 4-foot intervals. The best tendant at greater risk. OSHA statistics of other technical products for

way to test is with a sampling pump and confined space-related deaths show us the preservation of life and

tubing or a probe attachment. what to expect when emergency proce- property. The company has

Mistake #7 – Considering the con- dures are improvised. With would-be headquarters in Oakdale,

fined space safe after pre-entry test- rescuers making up 60 percent of con- Pa., and 30 regional offices

ing fined space fatalities, it’s clear that many throughout the world.

www.occupationalhazards.com May 2005 / Occupational Hazards 55

You might also like

- Full Download Ebook Ebook PDF Managing Human Resources 18th Edition by Scott Snell PDFDocument35 pagesFull Download Ebook Ebook PDF Managing Human Resources 18th Edition by Scott Snell PDFkevin.golden73898% (44)

- Ex63revised 022112SRDocument88 pagesEx63revised 022112SRAlfredd MartinezNo ratings yet

- NFPA 350 Guide For Safe Confined Space Entry and WorkDocument48 pagesNFPA 350 Guide For Safe Confined Space Entry and WorkFatih D. Prasetio100% (1)

- LEEA Correspondence Courses: Assignment 1.2Document3 pagesLEEA Correspondence Courses: Assignment 1.2Primelift Safety Resources Limited0% (1)

- Confined Space EntryDocument40 pagesConfined Space EntryTeknik MarinaNo ratings yet

- Thresholding Multiple Target: Radar CFAR in Clutter and SituationsDocument14 pagesThresholding Multiple Target: Radar CFAR in Clutter and SituationsDivine Grace BurmalNo ratings yet

- Roh Ling 1983Document14 pagesRoh Ling 1983jouini abdelhafidNo ratings yet

- Usage of Hand ToolsDocument4 pagesUsage of Hand ToolsJeffersonDeGuiaNo ratings yet

- 10 1 1 888 137 PDFDocument14 pages10 1 1 888 137 PDFdika franNo ratings yet

- Contractors On Site: Risk Assessment For: Establishment: Assessment By: DateDocument6 pagesContractors On Site: Risk Assessment For: Establishment: Assessment By: Datemuhammad iqbalNo ratings yet

- Physical Distancing ChecklistDocument3 pagesPhysical Distancing ChecklistNikos ZairisNo ratings yet

- Atos GCM Model - EnglishDocument5 pagesAtos GCM Model - Englishpearl042008100% (1)

- Arc WeldingDocument4 pagesArc WeldingJeffersonDeGuiaNo ratings yet

- 9.human ErrorDocument12 pages9.human ErrorUPBU IlagaNo ratings yet

- Harel 10Document9 pagesHarel 10Nilesh GopnarayanNo ratings yet

- Lessons Learned From EPS FailureDocument3 pagesLessons Learned From EPS FailureUmesh PatilNo ratings yet

- Mastermind 2 Unit 6 Wordlist - ChineseDocument3 pagesMastermind 2 Unit 6 Wordlist - ChineseRolando Guzman MartinezNo ratings yet

- A Learning-Based Surface Defect Detection Method For Internal Surfaces of BellowsDocument5 pagesA Learning-Based Surface Defect Detection Method For Internal Surfaces of BellowsJ MrNo ratings yet

- Sample Construction Risk Assessment 3.13.55 PMDocument4 pagesSample Construction Risk Assessment 3.13.55 PMEmmanuelNo ratings yet

- Multiple Attenuation: An Overview of Recent Advances and The Road Ahead (1999)Document5 pagesMultiple Attenuation: An Overview of Recent Advances and The Road Ahead (1999)MaucaNo ratings yet

- The Document Control Tribune Issue31 ConsepsysDocument12 pagesThe Document Control Tribune Issue31 Consepsyskarineee007No ratings yet

- Human Error vs. Work Place Management in Modern OrganizationsDocument5 pagesHuman Error vs. Work Place Management in Modern OrganizationsDede HidajatNo ratings yet

- HomeworkDocument3 pagesHomeworkPhạm Tiến DũngNo ratings yet

- Agtech Eng Job Safety AnalysisDocument4 pagesAgtech Eng Job Safety AnalysisOscar IsingomaNo ratings yet

- Yale University, School of ArchitectureDocument3 pagesYale University, School of ArchitectureRoberto Costa Da MattaNo ratings yet

- Independent Clauses Dependent ClausesDocument2 pagesIndependent Clauses Dependent Clausesbeautifullife never giveupNo ratings yet

- CSE Common MistakesDocument3 pagesCSE Common MistakesDang Minh HuongNo ratings yet

- Learning From Normal Work Professional Safety Journal 1698956321Document8 pagesLearning From Normal Work Professional Safety Journal 16989563210644852788No ratings yet

- Quarter 1Document2 pagesQuarter 1Ken ManalaysayNo ratings yet

- Setting Up A Reinforcement Learning Task With A Real-World RobotDocument6 pagesSetting Up A Reinforcement Learning Task With A Real-World RobotAyman TaniraNo ratings yet

- Implementation DesignDocument5 pagesImplementation DesignAndres LinaresNo ratings yet

- NSQF Level DescriptorsDocument2 pagesNSQF Level DescriptorsKamleshVasavaNo ratings yet

- CHECKLIST: Physical Distancing: One Person Per 4 Square MetresDocument3 pagesCHECKLIST: Physical Distancing: One Person Per 4 Square Metrest04No ratings yet

- Human In: Error Perspectives AviationDocument12 pagesHuman In: Error Perspectives AviationMonica SilalahiNo ratings yet

- Cage John 1969 Choosing Abundance PDFDocument9 pagesCage John 1969 Choosing Abundance PDFElza TolentinoNo ratings yet

- Usage of Power ToolsDocument5 pagesUsage of Power ToolsJeffersonDeGuiaNo ratings yet

- Kevin Chiu - Solving Procrastination v1.1Document2 pagesKevin Chiu - Solving Procrastination v1.1TêteHauteNo ratings yet

- ExpertiseDocument13 pagesExpertiseOlya TsarevNo ratings yet

- HPOG Human Performance Task Check Issue 01Document1 pageHPOG Human Performance Task Check Issue 01gopaNo ratings yet

- Dale's Cone of ExperienceDocument16 pagesDale's Cone of ExperienceKaren Marie Dela PasionNo ratings yet

- Learning From Error: January 1988Document16 pagesLearning From Error: January 1988Sérgio de BastosNo ratings yet

- Apoc Risk Assessment Format - Sesa-Bfim-Ra-Cs-001Document11 pagesApoc Risk Assessment Format - Sesa-Bfim-Ra-Cs-001Abdul WasayNo ratings yet

- Law 2Document6 pagesLaw 2Haze StarNo ratings yet

- This Study Resource Was: Learning Objective in This LessonDocument8 pagesThis Study Resource Was: Learning Objective in This Lessonanshuman sharmaNo ratings yet

- Lynn, Public Management As Art, Science and ProfessionDocument24 pagesLynn, Public Management As Art, Science and ProfessionLuis Alberto Rocha MartinezNo ratings yet

- Harrower 1954Document10 pagesHarrower 1954Flavia ChNo ratings yet

- HSE Interview Q A 1694456104Document6 pagesHSE Interview Q A 1694456104Mahmoud Abdel DayemNo ratings yet

- Motivación A Empleados para Uso EPA ENDocument2 pagesMotivación A Empleados para Uso EPA ENjhonsotoNo ratings yet

- Seven Principles of Software TestingDocument3 pagesSeven Principles of Software TestingpedromoritzNo ratings yet

- The Seven Tools of Causal InferenceDocument7 pagesThe Seven Tools of Causal Inferencesemiring100% (3)

- Mastermind 2 Unit 6 Wordlist - SpanishDocument3 pagesMastermind 2 Unit 6 Wordlist - SpanishRolando Guzman MartinezNo ratings yet

- Cap 3 SPATIAL AGENGY - JEREMY TILLDocument15 pagesCap 3 SPATIAL AGENGY - JEREMY TILLDavid MoralesNo ratings yet

- Visual Ergonomics at Work and Leisure: Paying It ForwardDocument2 pagesVisual Ergonomics at Work and Leisure: Paying It ForwardDiego A Echavarría ANo ratings yet

- A Series of Activities For EportfolioDocument3 pagesA Series of Activities For Eportfolioapi-515804461No ratings yet

- Productive Task TypesDocument7 pagesProductive Task TypesJuan ManuelNo ratings yet

- Restoring Eye Contact To The Virtual Classroom With Machine LearningDocument11 pagesRestoring Eye Contact To The Virtual Classroom With Machine LearningMin PuNo ratings yet

- Mastermind 2 Unit 6 Wordlist - PortugueseDocument3 pagesMastermind 2 Unit 6 Wordlist - PortugueseRolando Guzman MartinezNo ratings yet

- Hsme May June 2014 - Working at Height ArticleDocument6 pagesHsme May June 2014 - Working at Height ArticleMike DaviesNo ratings yet

- Rasmussen and Practical Drift Drift Towards Danger and The Normalization of DevDocument10 pagesRasmussen and Practical Drift Drift Towards Danger and The Normalization of Dev18rosa18No ratings yet

- Operations Research in CommunicationsDocument6 pagesOperations Research in CommunicationsEid CavalcantiNo ratings yet

- HF WK 8 Confirm Correct 85Document5 pagesHF WK 8 Confirm Correct 85Keeve TanNo ratings yet

- Confined Spaces SiDocument3 pagesConfined Spaces SiDita ChannelNo ratings yet

- Robust Processing of Spoken Situated Dialogue: A Study in Human-Robot InteractionFrom EverandRobust Processing of Spoken Situated Dialogue: A Study in Human-Robot InteractionNo ratings yet

- Office Safety TAMUG 12-2014Document9 pagesOffice Safety TAMUG 12-2014Primelift Safety Resources LimitedNo ratings yet

- OSHA 1910.23bDocument2 pagesOSHA 1910.23bPrimelift Safety Resources LimitedNo ratings yet

- Candidate Report SheetDocument1 pageCandidate Report SheetPrimelift Safety Resources LimitedNo ratings yet

- LH 185 DS 0062 6Document6 pagesLH 185 DS 0062 6Primelift Safety Resources LimitedNo ratings yet

- 2020 NCEE Paper 1 Question SampleDocument3 pages2020 NCEE Paper 1 Question SamplePrimelift Safety Resources LimitedNo ratings yet

- IGC Risk Assessment FormDocument1 pageIGC Risk Assessment FormPrimelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.5Document3 pagesLEEA Correspondence Courses: Assignment 1.5Primelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.7Document3 pagesLEEA Correspondence Courses: Assignment 1.7Primelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.6Document3 pagesLEEA Correspondence Courses: Assignment 1.6Primelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.9Document3 pagesLEEA Correspondence Courses: Assignment 1.9Primelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.8Document3 pagesLEEA Correspondence Courses: Assignment 1.8Primelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.3Document3 pagesLEEA Correspondence Courses: Assignment 1.3Primelift Safety Resources LimitedNo ratings yet

- Oil Spill Response Course ContentDocument3 pagesOil Spill Response Course ContentPrimelift Safety Resources LimitedNo ratings yet

- LEEA Correspondence Courses: Assignment 1.4Document3 pagesLEEA Correspondence Courses: Assignment 1.4Primelift Safety Resources LimitedNo ratings yet

- Shackles PDFDocument1 pageShackles PDFPrimelift Safety Resources LimitedNo ratings yet

- Nebosh International General Certificate: Exam Hints and TipsDocument3 pagesNebosh International General Certificate: Exam Hints and TipsPrimelift Safety Resources LimitedNo ratings yet

- Corps Medical & Rescue Services 1Document2 pagesCorps Medical & Rescue Services 1Primelift Safety Resources LimitedNo ratings yet

- Severed Thumb: Health, Safety and EnvironmentDocument1 pageSevered Thumb: Health, Safety and EnvironmentPrimelift Safety Resources LimitedNo ratings yet

- NGC1 Rev NotesDocument56 pagesNGC1 Rev NotesPrimelift Safety Resources LimitedNo ratings yet

- Title: Inspection of Tripoli - Libya Beach Wedding Resort: Children's Play AreaDocument3 pagesTitle: Inspection of Tripoli - Libya Beach Wedding Resort: Children's Play AreaPrimelift Safety Resources LimitedNo ratings yet

- Understanding Action Verbs: DefineDocument4 pagesUnderstanding Action Verbs: DefinePrimelift Safety Resources LimitedNo ratings yet

- Tower Scaffold Site Inspection Checklist v2.01 Dec 2015Document2 pagesTower Scaffold Site Inspection Checklist v2.01 Dec 2015Primelift Safety Resources LimitedNo ratings yet

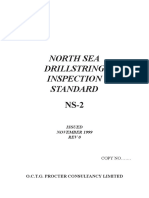

- NS 2 PDFDocument188 pagesNS 2 PDFPrimelift Safety Resources Limited100% (1)

- Paper 1: The Management of Health and Safety - Nebosh Guide April 2007Document4 pagesPaper 1: The Management of Health and Safety - Nebosh Guide April 2007Primelift Safety Resources LimitedNo ratings yet

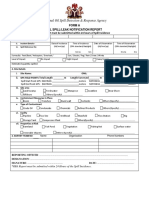

- Oil Spill Report NosdarDocument6 pagesOil Spill Report NosdarPrimelift Safety Resources LimitedNo ratings yet

- Causes of Workplace Attitude: IT Wasn'T MeDocument2 pagesCauses of Workplace Attitude: IT Wasn'T MePrimelift Safety Resources LimitedNo ratings yet

- ISO 45001:2018 Employee Training Overview: Includes Trainer's Guide and Students GuideDocument9 pagesISO 45001:2018 Employee Training Overview: Includes Trainer's Guide and Students GuidePrimelift Safety Resources LimitedNo ratings yet

- Natonal Oil Spill Detection and Response Agency Joint Investigation Visit (Jiv) FormDocument4 pagesNatonal Oil Spill Detection and Response Agency Joint Investigation Visit (Jiv) FormPrimelift Safety Resources LimitedNo ratings yet

- OSHA 1994 - Control of Industrial Major Accident Hazards Regulations 1996Document22 pagesOSHA 1994 - Control of Industrial Major Accident Hazards Regulations 1996NavindranPalasendaramNo ratings yet

- Analytical Skill - UCDocument80 pagesAnalytical Skill - UCashkr5120% (1)

- Fall Protection Program Guide 1apr12Document70 pagesFall Protection Program Guide 1apr12albertmunoz100% (1)

- Se SF Activity HW TRNDocument24 pagesSe SF Activity HW TRNElvyn Fabellore HerreraNo ratings yet

- SWCOEH 2.0 OH Glossary English SpanishDocument1,801 pagesSWCOEH 2.0 OH Glossary English SpanishSB CorinaNo ratings yet

- MODULE 4 - OSH Management System Q & ADocument84 pagesMODULE 4 - OSH Management System Q & AAmirul AmmarNo ratings yet

- Summit Anchor ALG For RDSDocument16 pagesSummit Anchor ALG For RDSMina AdelNo ratings yet

- Work EnvironmentDocument81 pagesWork EnvironmentSudeshPower9494100% (2)

- Human Resources Manager in Fresno CA Resume Josefa PriceDocument2 pagesHuman Resources Manager in Fresno CA Resume Josefa PriceJosefaPriceNo ratings yet

- Eup 222 Fmo 06032017 Elearning OshaDocument39 pagesEup 222 Fmo 06032017 Elearning OshaNur AfiqahNo ratings yet

- Risk Management HotelDocument38 pagesRisk Management Hotellarissa ayumiNo ratings yet

- Non Conformance (NCR)Document3 pagesNon Conformance (NCR)Coby MikeNo ratings yet

- Osha Note Topic 1Document49 pagesOsha Note Topic 1Hasnol HaiqalNo ratings yet

- Fall Protection in ConstructionDocument43 pagesFall Protection in ConstructionArnold AlamaniNo ratings yet

- Safety Committee Operations: An Introduction To Safety Committee Duties and ResponsibilitiesDocument56 pagesSafety Committee Operations: An Introduction To Safety Committee Duties and ResponsibilitiesAndre Ant WilliamsNo ratings yet

- Incident ReportingDocument42 pagesIncident Reportingben100% (1)

- Motorized Cable Reel Owner's Manual: Type Series HFI and HFIIDocument58 pagesMotorized Cable Reel Owner's Manual: Type Series HFI and HFIIMike PoseidonNo ratings yet

- Asbestos Standard For General Industry: U.S. Department of Labor Occupational Safety and Health AdministrationDocument34 pagesAsbestos Standard For General Industry: U.S. Department of Labor Occupational Safety and Health AdministrationJuan CabreraNo ratings yet

- Troubleshooting Erroneous Potassium PDFDocument3 pagesTroubleshooting Erroneous Potassium PDFARIF AHAMMED PNo ratings yet

- 002-Soil Investigation WorkDocument15 pages002-Soil Investigation WorkDon McleanNo ratings yet

- SAP Module 1 EHS OverviewDocument24 pagesSAP Module 1 EHS OverviewParthiban MahalingamNo ratings yet

- Ethics 3Document34 pagesEthics 3Zuhair NadeemNo ratings yet

- Drilling Rigs Inspection ChecklistDocument14 pagesDrilling Rigs Inspection ChecklistRizwan Farid100% (3)

- COSH Crane SafetyDocument44 pagesCOSH Crane SafetyJeffrey Lumba100% (2)

- Safety Training Calendar 2023Document7 pagesSafety Training Calendar 2023Kate PesicNo ratings yet

- 4 - Problems Accident Rate Calculations 1Document7 pages4 - Problems Accident Rate Calculations 1Naeem AshrafNo ratings yet

- Chemicalengineeringmagzinenov2012 PDFDocument77 pagesChemicalengineeringmagzinenov2012 PDF施君儒No ratings yet

- 3.occupational Sefty and Health (OSHA) ActDocument15 pages3.occupational Sefty and Health (OSHA) ActJason MaldonadoNo ratings yet