Professional Documents

Culture Documents

Inspection & Testing Plan For Sub Base Laying Material: INF-AP-QUA-ITP-06 Rev. 0 Date: 03.07.2018

Uploaded by

jerin sam kurianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection & Testing Plan For Sub Base Laying Material: INF-AP-QUA-ITP-06 Rev. 0 Date: 03.07.2018

Uploaded by

jerin sam kurianCopyright:

Available Formats

INF-AP-QUA-ITP-06 Rev.

0

Inspection & Testing Plan for Sub Base Laying Material Date: 03.07.2018

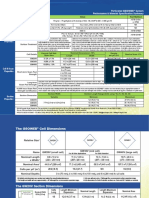

Fine Aggregates

Inspection & Test Details

Parameter Standard

Specification Limits Frequency

Liqiud Limit ASTM D4318 25% Max. Each Source

Plasticity Index ASTM D4318 6% Max. Visible Changes in Material

Sand Equivalent ASTM D2419 25% Min.

1 Test every 1000 m3

Organic Content BS 1377 Part 3 0.5% Max.

Coarse Aggregates

Inspection & Test Details

Parameter Standard

Specification Limits Frequency

One or More Fractured Faces ASTM D5821 50% Min. Each Source

Flat & Elongated Particles (5:1) ASTM D4791 15% Max.

Visible Changes in Material

Soundness ASTM C88 20% Max.

Los Angeles Abrasion ASTM C131, ASTM C535 40% Max. 1 Test every 3000m3

Combined Aggregate Gradation

Parameter Specification Limits

Sieve Analysis (ASTM D6913)

Inspection & Test Details

ASTM Sieve Sizes

Percentage Passing (By Weight) Frequency

50.0 mm 100

Each Source

37.5 mm 90 - 100

19.0 mm 70 - 90

Visible Changes in Material 1 Test Daily

9.5 mm 45 - 75

4.75 mm 30 - 60

600 µm 10 - 30a

75 µm 0 - 12

1 Test every 1000m3

Maximum Dry Density ASTM D1557 2.05 mg/m3 Min.

California Bearing Ratio & Swelling ASTM D1883 (Soaked) CBR- 70% Min. Swelling- 1.0% Max.

ASTM 6938, ASTM D1556 MDD- 100% 1 per 200 m2 per layer

Field Density & Moisture Content

ASTM D4944, ASTM D6938 OMC- ±2% 1 every 75m per lane per layer

In-situ CBR ASTM D4429 70% Min. 1 per 2000 m2

Acid Soluble Chloride Content BS 1377 Part 3 2% Max.

1 per 3000 m3

Acid Soluble Sulphate Content BS 1377 Part 3 3% Max.

ITP Name Position Date

Prepared By Jerin Sam Kurian QA/QC Inspector

INF-AP-QUA-SF-ITP-06-01 Rev. 0 Date 03.07.2018

Reviewed By Alfredo Marques QA/QC Manager

Approved By Alfredo Marques QA/QC Manager

INF-AP-QUA-SF-ITP-06-01 Rev. 0 Date 03.07.2018

You might also like

- ITP For Road Base MaterialDocument2 pagesITP For Road Base Materialjerin sam kurian100% (1)

- Inspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018Document2 pagesInspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018jerin sam kurianNo ratings yet

- Inspection & Testing Plan For AggregatesDocument2 pagesInspection & Testing Plan For Aggregatesjerin sam kurianNo ratings yet

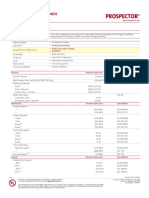

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Inspection & Testing Plan For Asphalt MixturesDocument2 pagesInspection & Testing Plan For Asphalt Mixturesjerin sam kurianNo ratings yet

- PP GF15 - Hifill PP Co GF15 CCDocument1 pagePP GF15 - Hifill PP Co GF15 CCarmandoNo ratings yet

- Ficha Tecnica Mirafi RS580iDocument2 pagesFicha Tecnica Mirafi RS580idaniel trejoNo ratings yet

- Technical Data Sheet: Ptfe + 20% PeekDocument1 pageTechnical Data Sheet: Ptfe + 20% PeekRohan KulkarniNo ratings yet

- Esd 800 HBDocument3 pagesEsd 800 HBsrinivasaNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- Certificado de Calidad GeomallaDocument4 pagesCertificado de Calidad GeomallaAlberto Hernández MartinezNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetSilversnape00No ratings yet

- Mirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueDocument2 pagesMirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueLuis Angel Criollo DivertidoNo ratings yet

- Inspection & Testing Plan For Asphalt Mixtures During ConstructionDocument2 pagesInspection & Testing Plan For Asphalt Mixtures During Constructionjerin sam kurianNo ratings yet

- MONEL 8in OD X 3.5IDDocument1 pageMONEL 8in OD X 3.5IDCAMILO ALFONSO VIVEROS BRICEÑONo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- GM9071P Tape Adhesion Test For Paint FinishesDocument6 pagesGM9071P Tape Adhesion Test For Paint FinishesPNG ApollohxNo ratings yet

- Product Technical Sheet - Saflex Structural 092618 0Document5 pagesProduct Technical Sheet - Saflex Structural 092618 0J RogerNo ratings yet

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersDocument2 pagesAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Vistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore ADocument2 pagesVistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore AShalom JohnNo ratings yet

- Presto: Property Value Test MethodDocument2 pagesPresto: Property Value Test MethodledagoNo ratings yet

- QAP Test Frequency CONCRETEDocument17 pagesQAP Test Frequency CONCRETEfevahe756No ratings yet

- XENOY™ Resin X2300WX - AmericasDocument3 pagesXENOY™ Resin X2300WX - AmericasWellington C. de AraujoNo ratings yet

- R.E Wall Test SummaryDocument1 pageR.E Wall Test SummaryBiplab dattaNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocument2 pagesPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsNo ratings yet

- Survey No:33/3A1B, 11th Main Road, Sidco Industrial Estate, Thirumudivakkam, Chennai - 600044Document4 pagesSurvey No:33/3A1B, 11th Main Road, Sidco Industrial Estate, Thirumudivakkam, Chennai - 600044Tumbin DilseNo ratings yet

- TDS ASIA MACLINE TMH Rev7 Mar 2015Document1 pageTDS ASIA MACLINE TMH Rev7 Mar 2015Andrew Zapanta Jr.No ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- 9SMNPB28K-14.00 Hex Tc.Document1 page9SMNPB28K-14.00 Hex Tc.Mechtek LabNo ratings yet

- ABS-M30: Real Production-Grade ThermoplasticDocument2 pagesABS-M30: Real Production-Grade ThermoplasticqualityfreekNo ratings yet

- PQAGT250 Signed-1Document1 pagePQAGT250 Signed-1Roger Vila RojasNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- Product PDF 210710Document1 pageProduct PDF 210710vaibhav ShindeNo ratings yet

- TWT M50 Mix DesignDocument6 pagesTWT M50 Mix DesignStupidity TalksNo ratings yet

- Natural Sand (Jarboo) For Block MortarDocument7 pagesNatural Sand (Jarboo) For Block MortarMGNo ratings yet

- F0118-i1STF (1HL) (17.05.23) (R-613)Document1 pageF0118-i1STF (1HL) (17.05.23) (R-613)Beximco Denim LabNo ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- ASTM 210cDocument1 pageASTM 210cDodi SuhendraNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- Nonoriented Electrical Steel Fully Processed Types: Standard Specification ForDocument6 pagesNonoriented Electrical Steel Fully Processed Types: Standard Specification Forbenjaminverduzco4No ratings yet

- LS 15 (19012021)Document1 pageLS 15 (19012021)Maskur EfendiNo ratings yet

- LS 15 (19012021)Document1 pageLS 15 (19012021)Maskur EfendiNo ratings yet

- Lldpe Series 1.50MM Black TexturedDocument2 pagesLldpe Series 1.50MM Black TexturedBexy Nathaly DiazNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- En GJS 500 7CDocument1 pageEn GJS 500 7CMatias OnateNo ratings yet

- COQ Exxon-Intertek Maret 19Document1 pageCOQ Exxon-Intertek Maret 19satriasinagaNo ratings yet

- Nexeo Plastics InStruc™ PPAIMDocument1 pageNexeo Plastics InStruc™ PPAIMMax SalogniNo ratings yet

- Driscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetDocument2 pagesDriscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetmariannyNo ratings yet

- 170-10S-Green TapeDocument1 page170-10S-Green Taperondulf goNo ratings yet

- Hand Book On Road PDFDocument56 pagesHand Book On Road PDFrajan sharma100% (1)

- Technical Note PM10 FiltersDocument1 pageTechnical Note PM10 Filtersvisa.tasicNo ratings yet

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- BS EN ISO 10319 2015 - Geosynthetics - Wide Width Tensile Test PDFDocument23 pagesBS EN ISO 10319 2015 - Geosynthetics - Wide Width Tensile Test PDFjerin sam kurianNo ratings yet

- BS en 12697-13-2017 - (2019-07-30 - 02-19-04 PM) PDFDocument10 pagesBS en 12697-13-2017 - (2019-07-30 - 02-19-04 PM) PDFjerin sam kurian100% (1)

- BS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFDocument13 pagesBS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFjerin sam kurianNo ratings yet

- BS en 12697-27-2017 - (2018-07-07 - 01-37-13 PM) PDFDocument22 pagesBS en 12697-27-2017 - (2018-07-07 - 01-37-13 PM) PDFjerin sam kurianNo ratings yet

- BS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary BlocksDocument10 pagesBS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary Blocksjerin sam kurianNo ratings yet

- ASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFDocument7 pagesASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFjerin sam kurianNo ratings yet

- ASTM C305 - 20 - Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistancy PDFDocument3 pagesASTM C305 - 20 - Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistancy PDFjerin sam kurian100% (1)

- Laboratory Work Sheet Test: Soundness of Coarse Aggregate - Mgso Method: ASTM C 88-05Document1 pageLaboratory Work Sheet Test: Soundness of Coarse Aggregate - Mgso Method: ASTM C 88-05jerin sam kurianNo ratings yet

- ASTM A931-18 - Tension Testing of Wire Strand PDFDocument4 pagesASTM A931-18 - Tension Testing of Wire Strand PDFjerin sam kurianNo ratings yet

- ASTM A1061 A1061M-09 - Testing Multi Wire Steel Strand PDFDocument3 pagesASTM A1061 A1061M-09 - Testing Multi Wire Steel Strand PDFjerin sam kurianNo ratings yet

- Water Test Training RecordDocument2 pagesWater Test Training Recordjerin sam kurianNo ratings yet

- ASTM C511 - 19 - Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and Concretes PDFDocument3 pagesASTM C511 - 19 - Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and Concretes PDFjerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Specific Gravity & Water Absorption of Coarse Aggregate Method: ASTM C 127-07Document1 pageLaboratory Work Sheet Test: Specific Gravity & Water Absorption of Coarse Aggregate Method: ASTM C 127-07jerin sam kurianNo ratings yet

- Sieve Hyundai Q5Document1 pageSieve Hyundai Q5jerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Material Passing 75 M (No. 200) Sieve Method: ASTM C117-04 Test: 8Document1 pageLaboratory Work Sheet Test: Material Passing 75 M (No. 200) Sieve Method: ASTM C117-04 Test: 8jerin sam kurian100% (1)

- Plate Load Test - Equipment, Procedure, CalculationDocument5 pagesPlate Load Test - Equipment, Procedure, Calculationjerin sam kurianNo ratings yet

- Pending Review 28 Sieve Analysis - Dry Subbase BS 812-103.1-7.2 Rev1 8jun10Document1 pagePending Review 28 Sieve Analysis - Dry Subbase BS 812-103.1-7.2 Rev1 8jun10jerin sam kurianNo ratings yet

- x02 Sieve Analysis - Dry BS 812-103.1-1985rev3 6.01Document1 pagex02 Sieve Analysis - Dry BS 812-103.1-1985rev3 6.01jerin sam kurianNo ratings yet

- Pending 29 Soundness-BS812P121 For NDPP OnlyDocument1 pagePending 29 Soundness-BS812P121 For NDPP Onlyjerin sam kurianNo ratings yet

- OHS Checklist 2015Document8 pagesOHS Checklist 2015jerin sam kurianNo ratings yet

- Gulf Laboratories Co. W.L.L.: Project Villa at Maed Mohammed Aj Al HebabiDocument3 pagesGulf Laboratories Co. W.L.L.: Project Villa at Maed Mohammed Aj Al Hebabijerin sam kurianNo ratings yet

- Separate: Dr. Richard James Ellis Beng PH.D Ceng Fciht Fiat Miq Deputy General Manager / Laboratory ManagerDocument1 pageSeparate: Dr. Richard James Ellis Beng PH.D Ceng Fciht Fiat Miq Deputy General Manager / Laboratory Managerjerin sam kurianNo ratings yet

- Penetration of Bituminous Material - Method ASTM D5/D5M-19a: Sample Identification Water Bath Temperature 2 3 1Document1 pagePenetration of Bituminous Material - Method ASTM D5/D5M-19a: Sample Identification Water Bath Temperature 2 3 1jerin sam kurianNo ratings yet

- D027B OmronDocument141 pagesD027B OmronirfanWPKNo ratings yet

- The Iron Warrior: Volume 25, Issue 11Document8 pagesThe Iron Warrior: Volume 25, Issue 11The Iron WarriorNo ratings yet

- Gender InequalityDocument9 pagesGender InequalityRhzNo ratings yet

- Reserach MethoodolgyDocument38 pagesReserach MethoodolgyShubashPoojariNo ratings yet

- HS ĐỀ CƯƠNG KIỂM TRA GIỮA KỲ I KHOI 10 NH 23 24Document6 pagesHS ĐỀ CƯƠNG KIỂM TRA GIỮA KỲ I KHOI 10 NH 23 24Ngô Hiểu NhiênNo ratings yet

- Integrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelDocument4 pagesIntegrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelPavlos Vardoulakis0% (1)

- #Stopableism: Reduksi Stigma Kepada Penyandang Disabilitas Melalui Intervensi Bias ImplisitDocument15 pages#Stopableism: Reduksi Stigma Kepada Penyandang Disabilitas Melalui Intervensi Bias ImplisitDennis SuhardiniNo ratings yet

- TRB CatalogDocument836 pagesTRB CatalogDiana LazariNo ratings yet

- MAK Halliday The Language of ScienceDocument268 pagesMAK Halliday The Language of ScienceJeneiGabriellaOfő100% (4)

- Chapter 17Document78 pagesChapter 17Romar PanopioNo ratings yet

- Practice Problems in ADSORPTION and ION EXCHANGE - SolutionsDocument8 pagesPractice Problems in ADSORPTION and ION EXCHANGE - SolutionsJenna Brasz100% (2)

- Research QuestionDocument6 pagesResearch QuestionAlfian Ardhiyana PutraNo ratings yet

- Artificial Intelligence Is Branch of Computer Science Dealing With The Simulation of Intelligent Behavior in ComputersDocument2 pagesArtificial Intelligence Is Branch of Computer Science Dealing With The Simulation of Intelligent Behavior in ComputersMuhammad Zaheer AnwarNo ratings yet

- The Seven Perceptual Learning StylesDocument3 pagesThe Seven Perceptual Learning StylesRamona FloreaNo ratings yet

- 1st Grading Exam Perdev With TosDocument4 pages1st Grading Exam Perdev With Toshazel malaga67% (3)

- IRJES 2017 Vol. 1 Special Issue 2 English Full Paper 038Document6 pagesIRJES 2017 Vol. 1 Special Issue 2 English Full Paper 038liew wei keongNo ratings yet

- My Publications and Workshops ListDocument4 pagesMy Publications and Workshops Listraviteja tankalaNo ratings yet

- EnglishFile4e Intermediate Plus TG PCM Vocab 1BDocument1 pageEnglishFile4e Intermediate Plus TG PCM Vocab 1Bayşe adaliNo ratings yet

- Information Sharing QuestionnaireDocument7 pagesInformation Sharing Questionnairesheelasahoo0% (1)

- Federal Register / Vol. 72, No. 108 / Wednesday, June 6, 2007 / Proposed RulesDocument1 pageFederal Register / Vol. 72, No. 108 / Wednesday, June 6, 2007 / Proposed RulesJustia.comNo ratings yet

- Shadow Volume in Real-Time Rendering: Abdelmouméne Zerari Mohamed Chaouki BabaheniniDocument6 pagesShadow Volume in Real-Time Rendering: Abdelmouméne Zerari Mohamed Chaouki BabaheniniRizqiy Bryan McfaddenNo ratings yet

- Biodiversity EssayDocument6 pagesBiodiversity Essayapi-279100094No ratings yet

- Mutants & Masterminds 1st Ed Character Generater (Xls Spreadsheet)Document89 pagesMutants & Masterminds 1st Ed Character Generater (Xls Spreadsheet)WesleyNo ratings yet

- WMS WIP PickDocument14 pagesWMS WIP PickAvinash RoutrayNo ratings yet

- The Structure of Deception: Validation of The Lying Profile QuestionnaireDocument16 pagesThe Structure of Deception: Validation of The Lying Profile QuestionnaireNancy DrewNo ratings yet

- SN Conceptual & Strategic SellingDocument34 pagesSN Conceptual & Strategic Sellingayushdixit100% (1)

- Leadership Competencies Paper 2Document5 pagesLeadership Competencies Paper 2api-297379255No ratings yet

- Niagara AX Browser Access GuideDocument84 pagesNiagara AX Browser Access GuideccitarellaNo ratings yet

- DataStage Interview QuestionsDocument3 pagesDataStage Interview QuestionsvrkesariNo ratings yet

- Fichas Slate HoneywellDocument1 pageFichas Slate HoneywellING CARLOS RAMOSNo ratings yet