Professional Documents

Culture Documents

Validates Turbine Engine Component: High Temperature Spin Testing

Uploaded by

amir moniriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Validates Turbine Engine Component: High Temperature Spin Testing

Uploaded by

amir moniriCopyright:

Available Formats

High Temperature Spin Testing

Validates Turbine Engine Component

T

Rob Murner he demand for more fuel-efficient turbine engines in aircraft is being driven by soaring fuel

Test Devices Inc. prices, unrest in oil-producing nations, global demand to save the environment, and cor-

Hudson, Mass. porate demand to cut costs. While there is immense pressure on design engineers to de-

velop these engines, the “heat” is on test engineers to create new ways to validate component parts

Component that will run, spin, and vibrate in hotter, harsher turbine engine environments that could reach

temperatures over 2000°F.

spin testing

at engine Testing components is critical

temperatures When an engine runs at higher temperatures and pressures, it extracts more energy from the

offers a fuel, making the engine more efficient. However, extreme heat and higher running speeds put

added stress on blades and rotors, which requires new classes of materials having improved per-

method to formance. Engine components are subjected to stress and degradation through thermal interac-

reliably tion, creep, erosion, vibration, and hot corrosion.

evaluate Newer engines will create hotter, harsher environments than those in which their predecessor

components models operated. It is desirable to have testing options that simulate these conditions to validate

in extreme the performance of critical components, especially when performance data for new materials are

lacking. Isolating and controlling

operating test conditions are critical to gather

environments. essential technical data in advance

of the test phase of an engine pro-

gram.

Test engineers and modelers

must simulate what design engi-

neers create to evaluate the per-

formance of materials, coatings,

and parts that will operate in the

new generation of lighter weight,

hotter-running engines. Test De-

vices is developing equipment and

methodologies that better simu-

late real-world engine conditions

(Fig. 1).

Some unique test capabilities

that Test Devices offers are high

cycle fatigue, radial or axial ther-

mal gradient, radial growth, ther-

mal mechanical fatigue, and strain

surveys. The specific range and

control of spin testing includes a

maximum speed of 160,000 rpm

with an accuracy of ±0.01% at max-

imum speed for overspeed testing

and ±1 rpm for vibration mode

(Dynamic Spin Testing). Drives for

speed ranges are 20k, 30k, 40k,

60k, 100k, and 160k.

Need for

material performance data

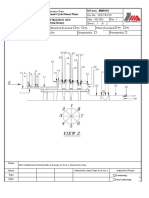

Rotor, damper, and blade configuration of a jet engine.

Development of more fuel efficient jet engines requires tests to

Historically, engineers and sci-

validate component parts that will run, spin, and vibrate in entists have been able to refer in

hotter, harsher turbine engine environments. part to existing bodies of informa-

ADVANCED MATERIALS & PROCESSES • MAY 2011 39

tion, models, test results, and field experiences as they re- terials or designs is through rotational testing.

fine and modify engine parts. But with manufacturers Managing resonant vibration of compressor and turbine

bringing dramatically new components, materials, and blades presents a technical challenge for jet engine and in-

coatings to market, there is a limited body of knowledge dustrial gas turbine (IGT) programs. Under certain condi-

scientists and engineers can rely on to confirm their as- tions of operation, blades vibrate in response to pulsing

sumptions. Some general examples of this are the intro- flow from upstream stages. If common power settings co-

duction of nonmetallic airfoils into the flow path and incide with blade resonant modes, blades can crack and

advanced thermal barrier coatings. As engines run hot- fracture from high-cycle fatigue during operation.

ter and more efficient, different prod-

ucts of combustion and other Spin testing

chemicals are introduced and can be Increasingly, engineers are using Dynamic Spin Test-

increasingly damaging in high-tem- ing to better understand and validate the life and integrity

perature environments. One of the of airfoils and integrally bladed disks (Fig. 2). This testing

best ways for developers to vali- evaluates blade resonance by simultaneously subjecting

date new designs, concepts, or components to the centrifugal, vibratory, and thermal

analytic models of either new ma- stresses of an operating engine. Bladed rotor components

are tested fully assembled or with custom designed scaled

Fig. 1 — Dynamic spin testing

rotors in a manner similar to how they operate in the en-

chamber used to evaluate blade

resonance by simultaneously gine. Rotor assemblies are accelerated to designated engine

subjecting components to the speeds while various excitation methods are used to pro-

centrifugal, vibratory and thermal duce resonant blade vibrations that simulate engine blade-

stresses of an operating engine.

The test can provide critical to-stator interaction, producing of various bending,

performance data to speed torsional, axial, “t-shirt,” and other modes.

up project Blade validation testing under these more realistic end-

completion,reduce use conditions better simulates strain gradients, untwist,

total testing costs,

and lower the risk blade/rotor interaction, etc., when compared to current

of in-service methods such as shaker tables and static tensile testing.

component failure. Tests can be performed in ambient or high temperature

(isothermal or gradient) conditions. This unique capability

is beneficial as manufacturers accelerate research and de-

velopment of high-efficiency engines using new innovative

materials.

Controlled testing parameters

During Dynamic Spin Testing, high-cycle fatigue con-

ditions can be introduced in a very controlled manner and

accurately measured with nonintrusive stress-measure-

ment systems. The test system is designed to dwell at spec-

ified resonant frequencies for 100-million cycles or more to

perform Goodman Validations. By producing realistic res-

onant vibration, Dynamic Spin Testing accurately confirms

expected modal frequencies. Precise speed control allows

for very slow resonance crossings as well. This “slow

sweep” capability helps to initially identify modes, distin-

guish between coupled modes, accurately measure ampli-

fication factors that take time to build, and determine

damping (Q factors), thus allowing for very effective damp-

ing analysis and validation. Finally, the ability to hold res-

onance for long periods of time often results in broken

blades, allowing for blade failure analysis, crack growth

propagation, and validation of surface treatment and vari-

ous repair methods (Fig 3).

Typical approaches to examining blade resonant be-

havior use shaker tables. These bench tests do not include

the effects of centrifugal loads (strain gradients, untwist,

blade/rotor interaction, etc.), a critical driver of blade be-

havior. Separate tests, in addition to shaker tables, are

Fig. 2 — Portion of integrally bladed disk. needed to exert thermal stress, and because each test is

40 ADVANCED MATERIALS & PROCESSES • MAY 2011

Fig. 3 — The ability of dynamic spin testing to hold resonance

for long periods of time often results in broken blades, allowing

for blade failure analysis, crack growth propagation, and

validation of surface treatment and various repair methods.

conducted separately, they deliver isolated information

that does not show the combined effect of heat, vibration,

and centrifugal loads on a rotating part. In contrast, Dy-

namic Spin Testing provides focused data under more re-

alistic engine conditions, offering a more robust, in-depth

solution.

While Dynamic Spin Testing creates precise simula-

tions, live engine testing remains the most comprehen-

sive method of evaluation. However, it is risky and

expensive, costing up to $100,000 per hour in operating

and staffing charges. In addition, given the harsh operat-

ing environment and lack of accessibility, live engine test-

ing may not provide clean data for component evaluation.

An additional problem with engine testing is the danger

of damage to the entire engine if an individual compo-

nent should fail.

Dynamic Spin Testing provides critical performance

data to speed project completion, reduces total testing

costs, and lowers the risk of in-service component failure.

This form of testing is becoming increasingly critical, in www.IpsenUSA.com/titan

the rush to get new engines through certification as quickly

as possible.

Dynamic Spin Testing is a registered trademark

of Test Devices Inc.

For more information: Rob Murner is president of Test De-

vices Inc., 571 Main St., Hudson, MA 01749; tel: 978/562-

4951; fax: 978/562-7939; email: rmurner@testdevices.com;

www.testdevices.com.

ADVANCED MATERIALS & PROCESSES • MAY 2011 41

You might also like

- Testing Facility for Power Transmission UnitsDocument12 pagesTesting Facility for Power Transmission UnitsthisisjineshNo ratings yet

- Spin Testing Capabilities: Test Devices RigsDocument4 pagesSpin Testing Capabilities: Test Devices RigsxmlbioxNo ratings yet

- Testing Modeling of Generator ControlsDocument12 pagesTesting Modeling of Generator Controlskamran1340No ratings yet

- Preglednica A III 2Document10 pagesPreglednica A III 2Ahmed SalemNo ratings yet

- Make Sure The UTM Fits The Application: Materials CharacterizationDocument3 pagesMake Sure The UTM Fits The Application: Materials CharacterizationUti MichaelNo ratings yet

- TTS 138 Field Performance Testing Kurz BrunDocument21 pagesTTS 138 Field Performance Testing Kurz BrunJamalAhmedNo ratings yet

- Turbo adamkiewiczDocument9 pagesTurbo adamkiewiczSam BakkerNo ratings yet

- Fachartikel - Antriebstechnik - Belastungen Messen Und Bewerten - 16 07 2014 - enDocument6 pagesFachartikel - Antriebstechnik - Belastungen Messen Und Bewerten - 16 07 2014 - enGiovanni EsguerraNo ratings yet

- Scale Cavitation TestDocument9 pagesScale Cavitation TestCandy KendeeNo ratings yet

- Ashwa Riders CAE Report Analysis</h1Document15 pagesAshwa Riders CAE Report Analysis</h1Aman AwachatNo ratings yet

- Product Verification Center BrochureDocument12 pagesProduct Verification Center BrochureJoão SaterNo ratings yet

- Guidelines For Generator Stability Model Validation TestingDocument16 pagesGuidelines For Generator Stability Model Validation TestinggabriveragNo ratings yet

- QIMp Tzni MBMWX H0 Ty 6 J WK 2 CDSZ Ci Mez Urdof GMsiyd U7 B Cu VM F7 D IDocument3 pagesQIMp Tzni MBMWX H0 Ty 6 J WK 2 CDSZ Ci Mez Urdof GMsiyd U7 B Cu VM F7 D ILeonardo EntaNo ratings yet

- Vibrationanalysisof PeltonDocument6 pagesVibrationanalysisof PeltonAditya DoyaleNo ratings yet

- 2005-26-037 3W Brakes by TVSDocument10 pages2005-26-037 3W Brakes by TVSSiva ReddyNo ratings yet

- NCCS 2019 1013Document6 pagesNCCS 2019 1013Siddharth BehalNo ratings yet

- Bolt Vibration Machine Tests Fastener LooseningDocument2 pagesBolt Vibration Machine Tests Fastener LooseningSubhasis MallikNo ratings yet

- Test Rig Design and Testing Performance of Linear Ball BearingDocument6 pagesTest Rig Design and Testing Performance of Linear Ball BearingthisisjineshNo ratings yet

- Electric Propulsion System Characterization through ExperimentsDocument9 pagesElectric Propulsion System Characterization through Experiments呂文祺No ratings yet

- FCCU Optimization - A Minimum Capital ApproachDocument6 pagesFCCU Optimization - A Minimum Capital Approachsaleh4060No ratings yet

- AN1013 Rev A0 Brake Kit Module - 2017.078v8Document5 pagesAN1013 Rev A0 Brake Kit Module - 2017.078v8arstjunkNo ratings yet

- Test Cell - SAE-2003-01-1681Document7 pagesTest Cell - SAE-2003-01-1681k8sdkNo ratings yet

- Analysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionDocument19 pagesAnalysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionJOSEPH TinderNo ratings yet

- Jurnal FerografiDocument6 pagesJurnal FerografiPrimawati RahmaniyahNo ratings yet

- Gas Turbine Performance Simulation: GSP HighlightsDocument4 pagesGas Turbine Performance Simulation: GSP HighlightsrezaNo ratings yet

- Relay-Performance - Estados Del SEPDocument3 pagesRelay-Performance - Estados Del SEPquisi123No ratings yet

- Dynamic stiffness of engine mounts comparison test rigsDocument1 pageDynamic stiffness of engine mounts comparison test rigsnkrish21856No ratings yet

- A Methodology For Protective Vibration Monitoringof Hydro Power Units Based On The Mechanical Properties PDFDocument8 pagesA Methodology For Protective Vibration Monitoringof Hydro Power Units Based On The Mechanical Properties PDFHugh cabNo ratings yet

- Article Overall Vibration Values For Reliable Wind Turbines PDFDocument4 pagesArticle Overall Vibration Values For Reliable Wind Turbines PDFrrNo ratings yet

- Mechanical Behavior Evaluation of The Chassis of Mining EquipmentDocument26 pagesMechanical Behavior Evaluation of The Chassis of Mining EquipmentSergio Ricardo ScabarNo ratings yet

- Generator Condition Assessment Rev4Document1 pageGenerator Condition Assessment Rev4Ary SSNo ratings yet

- 75-78 SRAS21 - 72dpiDocument4 pages75-78 SRAS21 - 72dpiLợi Nguyễn VănNo ratings yet

- 1995 Impc Usim Pac Mineral Processing Simulator Supervisor PDFDocument6 pages1995 Impc Usim Pac Mineral Processing Simulator Supervisor PDFLuis Steiler Cespedes CastilloNo ratings yet

- BUILDING ELECTRIC MOTORS WITH REDUNDANCY FOR HIGH RELIABILITY IN SPACEDocument6 pagesBUILDING ELECTRIC MOTORS WITH REDUNDANCY FOR HIGH RELIABILITY IN SPACEdiego peinadoNo ratings yet

- EN25-27_magic_bild_evo205Document3 pagesEN25-27_magic_bild_evo205Michel GuayNo ratings yet

- Too Much Vibration PDFDocument8 pagesToo Much Vibration PDFThanh LuanNo ratings yet

- Camshaft Inspection PDFDocument1 pageCamshaft Inspection PDFDarel DalmassoNo ratings yet

- PadovaDocument12 pagesPadovaSAGI RATHNA PRASAD me14d210No ratings yet

- International Science Index, Mechanical and Mechatronics Engineering Vol:11, No:7, 2017 waset.org/Publication/10007647Document9 pagesInternational Science Index, Mechanical and Mechatronics Engineering Vol:11, No:7, 2017 waset.org/Publication/10007647john georgeNo ratings yet

- Omicron 2Document4 pagesOmicron 2kegiw15659No ratings yet

- DesignGuidelinesfortheSelectionandUseofStainlessSteels 9014Document7 pagesDesignGuidelinesfortheSelectionandUseofStainlessSteels 9014gusiNo ratings yet

- Modeling Parametric Vibration of Multistage Gear Systems As A Tool For Design OptimizationDocument8 pagesModeling Parametric Vibration of Multistage Gear Systems As A Tool For Design OptimizationPunith MlNo ratings yet

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument12 pagesCondition Monitoring of Steam Turbines by Performance AnalysisBao-Phuc NguyenNo ratings yet

- RTS Test Systems For Wind Turbines enDocument12 pagesRTS Test Systems For Wind Turbines enyuanbo0411No ratings yet

- Maxon DC Motormaxon DC MotorDocument88 pagesMaxon DC Motormaxon DC MotorDamien RIGUTTONo ratings yet

- Cummins QSB SpecsDocument6 pagesCummins QSB Specsالتقني للكهرباءNo ratings yet

- ITT Flygt product testing proceduresDocument6 pagesITT Flygt product testing proceduresyutNo ratings yet

- Flotation Circuit Simulation in ModernizationsDocument8 pagesFlotation Circuit Simulation in ModernizationsmecarrascogNo ratings yet

- Engine & Compressor Diagnostic ServicesDocument2 pagesEngine & Compressor Diagnostic ServicesJose RattiaNo ratings yet

- Artikel Specifying Magnetic Bearings PDFDocument2 pagesArtikel Specifying Magnetic Bearings PDFAgustin A.100% (1)

- FYP Part A PresentationDocument22 pagesFYP Part A PresentationNURIN SYAZANA BINTI ABD HAMID / UPMNo ratings yet

- Mitigation of Fatigue Damage and Vibration Severity of Electric Drivetrains by Systematic Selection of Motion ProfilesDocument10 pagesMitigation of Fatigue Damage and Vibration Severity of Electric Drivetrains by Systematic Selection of Motion ProfilesashishNo ratings yet

- Calibration and Verification of Torque Transducers: Standard Practice ForDocument12 pagesCalibration and Verification of Torque Transducers: Standard Practice Forzendaoui amineNo ratings yet

- DC Motor Speed ControlDocument39 pagesDC Motor Speed ControlAnishNo ratings yet

- Hydraulic Unbalance in Oil Injected Twin Rotary Screw Compressor Vibration Analysis (A Case History Related To Iran Oil Industries)Document7 pagesHydraulic Unbalance in Oil Injected Twin Rotary Screw Compressor Vibration Analysis (A Case History Related To Iran Oil Industries)Conifer YuNo ratings yet

- Chapter3 1Document234 pagesChapter3 1mspd2003No ratings yet

- Vibration Analysis & TroubleshootingDocument7 pagesVibration Analysis & TroubleshootingGerardo RosalesNo ratings yet

- Load Simulation For Test Benches: USA IncDocument4 pagesLoad Simulation For Test Benches: USA IncCarlos Muñoz SantibañezNo ratings yet

- The Characteristics of Mechanical Engineering Systems: Pergamon International Library of Science, Technology, Engineering and Social StudiesFrom EverandThe Characteristics of Mechanical Engineering Systems: Pergamon International Library of Science, Technology, Engineering and Social StudiesNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 23Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 23amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 28Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 28amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 26Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 26amir moniriNo ratings yet

- Design theory and practice gas turbine cycle analysisDocument5 pagesDesign theory and practice gas turbine cycle analysisamir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 25Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 25amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 16Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 16amir moniriNo ratings yet

- An Overview of Dry Low Emission CombustorsDocument5 pagesAn Overview of Dry Low Emission Combustorsamir moniriNo ratings yet

- Gas turbine cycle analysis and steam injection benefitsDocument5 pagesGas turbine cycle analysis and steam injection benefitsamir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 24Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 24amir moniriNo ratings yet

- Rotor imbalance, balancing procedures, and multiplane balancing techniquesDocument5 pagesRotor imbalance, balancing procedures, and multiplane balancing techniquesamir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 20Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 20amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 9Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 9amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 8Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 8amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 7Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 7amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 10Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 10amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 6Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 6amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 3Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 3amir moniriNo ratings yet

- The Burns Depression Checklist : Name: D.O.B.: / / F.S.P.#: Medicaid #: Iprs / Lme #Document3 pagesThe Burns Depression Checklist : Name: D.O.B.: / / F.S.P.#: Medicaid #: Iprs / Lme #lettette100% (2)

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 2Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 2amir moniriNo ratings yet

- Ge Til (Bca)Document6 pagesGe Til (Bca)Ascanio Ferreira BarretoNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 5Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 5amir moniriNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 1Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 1amir moniriNo ratings yet

- Din2098 1Document4 pagesDin2098 1amir8100No ratings yet

- Legislation and Type Approval Tests For Vehicles: Test and Research Auto Center Co. (ITRAC)Document12 pagesLegislation and Type Approval Tests For Vehicles: Test and Research Auto Center Co. (ITRAC)amir moniriNo ratings yet

- Proven, Reliable, Versatile PowerDocument15 pagesProven, Reliable, Versatile Poweramir moniriNo ratings yet

- 025-TR-010 - (After Setup by Using 2nd Disc)Document3 pages025-TR-010 - (After Setup by Using 2nd Disc)amir moniriNo ratings yet

- Din2098 2Document4 pagesDin2098 2amir moniriNo ratings yet

- Optimisation of The HVOF Thermal Spray Process For Coating, Forming and Repair of ComponentsDocument229 pagesOptimisation of The HVOF Thermal Spray Process For Coating, Forming and Repair of Componentsamir moniriNo ratings yet

- Course: 141 Tig Welding of Stainless SteelDocument17 pagesCourse: 141 Tig Welding of Stainless Steelamir moniriNo ratings yet

- Modeling of Compressor Blade Behavior Under Tip Rubbing ConditionsDocument21 pagesModeling of Compressor Blade Behavior Under Tip Rubbing Conditionsamir moniriNo ratings yet

- 22 7 BrochureDocument18 pages22 7 BrochureS.Santosh KumarNo ratings yet

- Study of effect of trawl gear on submarine pipelinesDocument11 pagesStudy of effect of trawl gear on submarine pipelinespadmgovi23No ratings yet

- External "Pop-Action" Pressure Relief Valves For ASME Containers and Bulk Plant InstallationsDocument1 pageExternal "Pop-Action" Pressure Relief Valves For ASME Containers and Bulk Plant InstallationsshuzaoNo ratings yet

- Building On Soft Soil PDFDocument401 pagesBuilding On Soft Soil PDFDuong NguyenNo ratings yet

- Sheet Piles (571-607)Document3 pagesSheet Piles (571-607)SSFPLNo ratings yet

- Retaining Wall TypesDocument3 pagesRetaining Wall TypesTarang ChhedaNo ratings yet

- Soil Compaction HandbookDocument20 pagesSoil Compaction HandbookRajeuv Govindan100% (3)

- BabaKhola - Final EstimateDocument95 pagesBabaKhola - Final EstimateBinod ThapaNo ratings yet

- CI - Combine File-69Document1 pageCI - Combine File-69gregorio martinezNo ratings yet

- Manufacturing Tolerances For Profiled MetalDocument8 pagesManufacturing Tolerances For Profiled Metalchaval01No ratings yet

- 2 - Flow in Pipes Closed Conduits (Compatibility Mode)Document28 pages2 - Flow in Pipes Closed Conduits (Compatibility Mode)Eddy BongNo ratings yet

- 04-herrenknecht-ITA TC-slide Format - Herrenknecht AG 20 - 04 - 06Document98 pages04-herrenknecht-ITA TC-slide Format - Herrenknecht AG 20 - 04 - 06Johan EscuderoNo ratings yet

- PCAB 2015 Categorization Classification TableDocument2 pagesPCAB 2015 Categorization Classification TableRotsen Kho Yute100% (2)

- Stability of Curved Bridges During ConstructionDocument129 pagesStability of Curved Bridges During ConstructionAri PranantaNo ratings yet

- Maintenance ManualDocument17 pagesMaintenance ManualSean ChanNo ratings yet

- Embedded Structural Steel Connections PDFDocument9 pagesEmbedded Structural Steel Connections PDFphil brownNo ratings yet

- Mosrth: Code Road Was The Was Code Road Was The WasDocument3 pagesMosrth: Code Road Was The Was Code Road Was The WasAmul KotharkarNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsGANDHILAL mNo ratings yet

- Experimental Study of Tension Stiffening in Reinforced Concrete Under LoadingDocument33 pagesExperimental Study of Tension Stiffening in Reinforced Concrete Under LoadingIsmail MohammedNo ratings yet

- Analytical Research On Ferrocement: Design, Strength and Servicibility AspectsDocument8 pagesAnalytical Research On Ferrocement: Design, Strength and Servicibility AspectsPiyush SharmaNo ratings yet

- 02 - Completion EquipmentDocument44 pages02 - Completion EquipmentIrfan SiddiqueNo ratings yet

- 1611 7220 67 - 37 Retarding ValveDocument2 pages1611 7220 67 - 37 Retarding ValveyangNo ratings yet

- HDB Sor - Jan 2013Document260 pagesHDB Sor - Jan 2013Paul HengNo ratings yet

- Irc DesignDocument48 pagesIrc DesignHasumati Solanki100% (1)

- Report of THERMAL BARRIER COATING OF GAS TURBINE BLADESDocument21 pagesReport of THERMAL BARRIER COATING OF GAS TURBINE BLADESadityanarang1470% (1)

- Channel DesignDocument7 pagesChannel DesignNovianti Sidi Astri100% (3)

- Flat Slab Solution PDFDocument77 pagesFlat Slab Solution PDFjon50% (2)

- CAL - Polished Condensate Tank 14.0 Dia. X 19 HT - R.1 (12-04-2022)Document34 pagesCAL - Polished Condensate Tank 14.0 Dia. X 19 HT - R.1 (12-04-2022)kpsahuNo ratings yet

- Tie-Rod Pre-Stressing - David A. SmithDocument3 pagesTie-Rod Pre-Stressing - David A. Smithwulfgang66No ratings yet

- Tablas VigasDocument17 pagesTablas VigasPatricio Galván EscobarNo ratings yet