Professional Documents

Culture Documents

FrontLine™ Motor With HyperPulse™ MWD System Sidetracks J Type Well, Saves 2A Days of Rig Time PDF

Uploaded by

Anonymous PQt5zLNnCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FrontLine™ Motor With HyperPulse™ MWD System Sidetracks J Type Well, Saves 2A Days of Rig Time PDF

Uploaded by

Anonymous PQt5zLNnCCopyright:

Available Formats

DRILLING SERVICES REAL RESULTS

FrontLine™ Motor with HyperPulse™

MWD System Sidetracks J-Type Well,

Saves 2 Days of Rig Time

Objectives

• Sidetrack a well at 9,439 ft (2,877 m), above the top of a fish (stuck casing)

at 9,613 ft (2,930 m). The poor hole profile previously drilled by another

service company caused the casing to stick.

• Drill a vertical section of 6,855 ft (2,089.5 m) with a true vertical depth

(TVD) of 9,665 ft (2,946.1 m) to the top of the pay zone at 12,041 ft

(3,670 m).

• Drill an 8.5-in. hole section with a horizontal drift of 7,024 ft (2,141 m) and

a TVD of 9,885 ft (3,013 m) to a total depth (TD) of 12,319 ft (3,755 m).

Our Approach

• The Weatherford crew began drilling through the top of the cement at

9,108 ft (2,776 m). Upon reaching 9,216 ft (2,809 m), they observed that Most drilling applications—including vertical, horizontal,

the cement was soft. They waited for the cement to harden and then and directional wells—can use the robust and reliable

resumed drilling from 9,216 to 9,439 ft (2,809 to 2,877 m). Although the FrontLine drilling motor.

cement did not seem hard enough for a successful sidetrack, the client

insisted on running a Weatherford directional bottomhole assembly (BHA)

to continue the operation. LOCATION

Ankaleshwar, India

• Weatherford designed a BHA—comprised of the FrontLine drilling motor

and the HyperPulse measurement-while-drilling (MWD) system—to avoid WELL TYPE

the sticking situations that the client had encountered previously. Onshore, sidetrack, J-profile

• The crew deployed the BHA and drilled the sidetrack window from 9,439 FORMATION

to 9,521 ft (2,877 to 2,902 m) in 18 hr. Shale, sand, and claystone

• The crew then drilled the sidetrack from 9,521 to 12,320 ft (2,902 to CASING SIZE

3,755 m) with a 38° inclination and a 294.5° azimuth. The motor achieved 7 in.

an average rate of penetration (ROP) of 23 ft/hr (7 m/hr), and drilling was

completed with zero nonproductive time (NPT). HOLE SIZE AND ANGLE

8.5 in., 38° inclination, 294.5° azimuth

• Surveys to avoid sticking situations lasted only 45 sec at each designated

station. TEMPERATURE

212°F (100°C)

• The HyperPulse system provided gamma ray and tool face measurements

while drilling more than 95% of the section. DEPTH

• Sidetrack window: 9,439 to 9,613 ft

Value to Client (2,877 m to 2,930 m)

• Sidetrack: 9,521 ft (2,902 m)

• Using the FrontLine drilling motor and the HyperPulse MWD system saved • Top of fish: 9,613 ft (2,930 m)

the client more than 2 days of drilling time compared to the time required • Total: 12,320 ft (3,755 m)

to drill the mother well to the same depths.

PRODUCTS/SERVICES

• Drilling with the Weatherford BHA resulted in a clean wellbore profile that • FrontLine drilling motor

enabled the client to lower the 7-in. casing on the first attempt without • HyperPulse MWD system

any problems. In the original well, the client had been unable to lower

even the 5.5-in. casing in the 8.5-in. section.

weatherford.com © 2016 Weatherford. All rights reserved. 12383.00

Weatherford products and services are subject to the Company’s standard terms and conditions, available on request or at weatherford.com. For more information contact an authorized Weatherford representative. Unless noted otherwise, trademarks and service marks herein are the property of Weatherford and may be

registered in the United States and/or other countries. Weatherford products named herein may be protected by one or more U.S. and/or foreign patents. Specifications are subject to change without notice. Weatherford sells its products and services in accordance with the terms and conditions set forth in the applicable

contract between Weatherford and the client.

You might also like

- Compact Well Shuttle Facilitates Single Trip Logging in Unstable Fishbone Well With 95° InclineDocument1 pageCompact Well Shuttle Facilitates Single Trip Logging in Unstable Fishbone Well With 95° InclineNairo AlvarezNo ratings yet

- Triple Combo LWD Package Enables High Dogleg Sidetrack, Saves 50 Days and $4 MillionDocument2 pagesTriple Combo LWD Package Enables High Dogleg Sidetrack, Saves 50 Days and $4 MillionPanu PhumtabtimNo ratings yet

- 18DC - PPT - Tech - Sess - 16x9 Rev2Document18 pages18DC - PPT - Tech - Sess - 16x9 Rev2ZIANINo ratings yet

- Increases Production of Offshore Oil Well by More Than 500%: Widepak Deep Gas-Lift SystemDocument1 pageIncreases Production of Offshore Oil Well by More Than 500%: Widepak Deep Gas-Lift SystemvyshakhNo ratings yet

- Nitrified Pressurized Mud Cap Drilling Enables Continued Drilling With Zero NPT Through HighlyDocument1 pageNitrified Pressurized Mud Cap Drilling Enables Continued Drilling With Zero NPT Through HighlyCARLOS RODRIGUEZNo ratings yet

- Sova (Lanzadoras)Document2 pagesSova (Lanzadoras)baq_169513No ratings yet

- National Crane 900H Series: Product GuideDocument16 pagesNational Crane 900H Series: Product GuideGILMAR NIETONo ratings yet

- Casing and Conductor Removal Solution Enables Recovering 24 Joints From 4 Offshore Wells in 48 HoursDocument1 pageCasing and Conductor Removal Solution Enables Recovering 24 Joints From 4 Offshore Wells in 48 HoursabcNo ratings yet

- Rotary Drilling Hoses & SwivelsDocument8 pagesRotary Drilling Hoses & SwivelsRaina GhobadiNo ratings yet

- SK200XDL 10Document2 pagesSK200XDL 10AsrinNo ratings yet

- Technical Specification in Brief: Sandvik Dt912DDocument2 pagesTechnical Specification in Brief: Sandvik Dt912DNico CRa Valenzuela MartínezNo ratings yet

- Final DeviationDocument1 pageFinal DeviationHarjeetNo ratings yet

- Full 100-Page - 2016 PreMat Catalog-MinDocument100 pagesFull 100-Page - 2016 PreMat Catalog-MinLim Kang HaiNo ratings yet

- Ground Anchor: 348,149.52 Total VO AmountDocument1 pageGround Anchor: 348,149.52 Total VO AmountnurNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedNo ratings yet

- Especificaciones Tecnicas DE712Document7 pagesEspecificaciones Tecnicas DE712andyNo ratings yet

- 680 Kva (544 KW) DoosanDocument1 page680 Kva (544 KW) DoosanMd. Harunor RashidNo ratings yet

- Non-Entry Chamber Tegra 600: Installation GuideDocument7 pagesNon-Entry Chamber Tegra 600: Installation GuideXAVIER RUBIONo ratings yet

- Case Study 9: Bridge Work: Spences Bridge - BC CanadaDocument1 pageCase Study 9: Bridge Work: Spences Bridge - BC Canadaduda_sekaNo ratings yet

- LDocument5 pagesLnarayanaNo ratings yet

- Model 35R68 (14D) Rigid Planetary Axle: Rigorous Structure For Mining Trucks and Mining Load Haul DumpersDocument2 pagesModel 35R68 (14D) Rigid Planetary Axle: Rigorous Structure For Mining Trucks and Mining Load Haul DumpersMarek WyszatyckiNo ratings yet

- Jeppview 3.3.5.0: Terminal Chart NotamsDocument3 pagesJeppview 3.3.5.0: Terminal Chart NotamsRobert FergusonNo ratings yet

- Turbopower EgyptDocument2 pagesTurbopower EgyptReynaldo Navia MendozaNo ratings yet

- STR 137G Specs Sheet MarkDocument7 pagesSTR 137G Specs Sheet MarkSantiago Sangil SanchezNo ratings yet

- Tower Bersama Group: Pt. Telekomunikasi SelularDocument2 pagesTower Bersama Group: Pt. Telekomunikasi SelularResti OktavianiNo ratings yet

- Tesmec-Trenchers Catalogue 2018-1475XL EVO II Gen CS-EnDocument2 pagesTesmec-Trenchers Catalogue 2018-1475XL EVO II Gen CS-EnAhmed ElarabyNo ratings yet

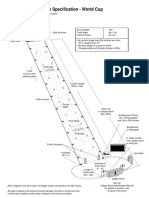

- Moguls Course SpecificationDocument1 pageMoguls Course Specificationfuzzy.logic.2007No ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedNo ratings yet

- BEM-600 Shakers Promote High ROPDocument2 pagesBEM-600 Shakers Promote High ROPnarft narftNo ratings yet

- 12 - Mullakadu - Chainage - 138.8 Tuticorin Gas Pipe Line ProjectDocument21 pages12 - Mullakadu - Chainage - 138.8 Tuticorin Gas Pipe Line ProjectG. BalamuruganNo ratings yet

- Sarojini Nagar Under The Guidance of MR Laksham HansdashDocument37 pagesSarojini Nagar Under The Guidance of MR Laksham HansdashShubhanshu MishraNo ratings yet

- Iron PilesDocument6 pagesIron Pileschino1286No ratings yet

- F-Series Wheel Loaders: 1021F 1121F - SPEC SHEETDocument12 pagesF-Series Wheel Loaders: 1021F 1121F - SPEC SHEETIvanNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- DDMR 03 July 2022Document1 pageDDMR 03 July 2022mohamed gadallahNo ratings yet

- Dug Well (6ft Dia)Document14 pagesDug Well (6ft Dia)AYUSHNo ratings yet

- Ground Treatment For TunnellingDocument22 pagesGround Treatment For Tunnellingthauwui860% (1)

- Product Guide: FeaturesDocument20 pagesProduct Guide: Featuresoscar albertoNo ratings yet

- Gis Installation ProcedureDocument4 pagesGis Installation ProcedurepakistanprotechNo ratings yet

- Manipulador Caterpillar TL 943 Series Spec SheetDocument2 pagesManipulador Caterpillar TL 943 Series Spec SheetKelly RibeiroNo ratings yet

- Cessna Citation Sovereign+ Product CardDocument2 pagesCessna Citation Sovereign+ Product Cardlegoulu21100% (1)

- Scan Mar 30, 2024Document1 pageScan Mar 30, 2024kd10b37No ratings yet

- EnsurSet Offshore Malaysia ExperienceDocument2 pagesEnsurSet Offshore Malaysia ExperienceRoman RyazanovNo ratings yet

- Middle East 2000 HP AC Rig CatalogDocument20 pagesMiddle East 2000 HP AC Rig CatalogM2 XNo ratings yet

- Specifications: TelehandlerDocument2 pagesSpecifications: TelehandlerMarco VelasquezNo ratings yet

- JACK in Foundation PIlesDocument112 pagesJACK in Foundation PIlesVincent ChinNo ratings yet

- BaraECD® Allows Record-Breaking Well Case StudyDocument2 pagesBaraECD® Allows Record-Breaking Well Case Studycarlos14jrNo ratings yet

- MR86L - Drilling MontageDocument1 pageMR86L - Drilling MontageGabriel Plazas100% (1)

- Sample Cost EstimationDocument2,408 pagesSample Cost Estimationarif khanNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedNo ratings yet

- Siemoffshore Specifications SiemahtsDocument8 pagesSiemoffshore Specifications SiemahtsJM MagayanesNo ratings yet

- FeaturesDocument4 pagesFeaturesEduardo MoralesNo ratings yet

- Maersk Intrepid PDFDocument8 pagesMaersk Intrepid PDFMauricio RicardezNo ratings yet

- Maersk Intrepid PDFDocument8 pagesMaersk Intrepid PDFMauricio RicardezNo ratings yet

- Flyer AL-267 A4 en WebDocument2 pagesFlyer AL-267 A4 en WebPhyoe Wai AungNo ratings yet

- Box Hole Borer PDFDocument2 pagesBox Hole Borer PDFnambiiasNo ratings yet

- Paving Surface Tracklane Method - Rev. 1Document23 pagesPaving Surface Tracklane Method - Rev. 1BungaNo ratings yet

- Practical Research RRLDocument6 pagesPractical Research RRLtriciaprivate000No ratings yet

- Contemporary Art Elements and PrinciplesDocument30 pagesContemporary Art Elements and PrinciplesLorraine Joy Zaragoza BalesNo ratings yet

- Install Z2 USB Driver W7 64 Bits V1 0Document12 pagesInstall Z2 USB Driver W7 64 Bits V1 0Juan Tirado Tapia0% (1)

- Roxxane Quimby CaseDocument2 pagesRoxxane Quimby CaseAbdur Rehman Bin Zaheer0% (1)

- ECE 442 Electronic Circuits Homework 1 Due Friday January 25, 2008Document1 pageECE 442 Electronic Circuits Homework 1 Due Friday January 25, 2008Đỗ Minh QuốcNo ratings yet

- Commissioning Manual TM120Document27 pagesCommissioning Manual TM120Josmar peñaNo ratings yet

- Pen - Pal - Application - Form 1 CorrectionsDocument2 pagesPen - Pal - Application - Form 1 CorrectionsValentina SALAZAR MARTINEZNo ratings yet

- Wall Mount EnclosureDocument8 pagesWall Mount Enclosurejfmg1971No ratings yet

- BSBLDR602 Assessment Task 2Document7 pagesBSBLDR602 Assessment Task 2GilsonVenâncioNo ratings yet

- The ABC's of Interviewing: A Is For AttitudeDocument5 pagesThe ABC's of Interviewing: A Is For AttitudeSnehal PatilNo ratings yet

- Oil & Gas New Main Warehouse, Brega, Area 1: Tareq AsiaDocument21 pagesOil & Gas New Main Warehouse, Brega, Area 1: Tareq AsiaDanish mallick100% (1)

- Counting Sample QuestionDocument2 pagesCounting Sample Questionzesrab tanjeel khanNo ratings yet

- Lok 2015Document214 pagesLok 2015JasmineTYPNo ratings yet

- MQB 05 WS 1Document6 pagesMQB 05 WS 1Vincents Genesius EvansNo ratings yet

- 04 Unit 03 Procedure-KCDocument19 pages04 Unit 03 Procedure-KCfitriNo ratings yet

- Detroit Diesel 53 Series Service Manual 439p Abby Sections 1and2Document439 pagesDetroit Diesel 53 Series Service Manual 439p Abby Sections 1and2aviseurNo ratings yet

- New On-Vehicle Brake Lathe: Using The Pro-Cut PFM 9.0Document8 pagesNew On-Vehicle Brake Lathe: Using The Pro-Cut PFM 9.0BBNBGHNo ratings yet

- bkc19 PDFDocument25 pagesbkc19 PDFrohitrgt4uNo ratings yet

- Cisco Access Point Power RequirementsDocument5 pagesCisco Access Point Power RequirementsunivocalNo ratings yet

- Contoh RFP Consulting ServicesDocument156 pagesContoh RFP Consulting ServicesrarasriwindhuNo ratings yet

- Lesson Plan GrammarwhqDocument9 pagesLesson Plan GrammarwhqPrim John MacababbadNo ratings yet

- Lloyd'S Register Integrated Fatigue Design: Assessment SystemDocument17 pagesLloyd'S Register Integrated Fatigue Design: Assessment SystemAna TNo ratings yet

- MSC 184957 Dipamoy BhattacharyyaDocument32 pagesMSC 184957 Dipamoy BhattacharyyaDipamoy BhattacharyyaNo ratings yet

- Features of A Good PresentationDocument5 pagesFeatures of A Good Presentationneelanjan royNo ratings yet

- GEA Lithium Battery Material Drying Spray Tcm11 34880Document10 pagesGEA Lithium Battery Material Drying Spray Tcm11 34880xianghuaokNo ratings yet

- Velocity, Distance & Acceleration 2 QPDocument10 pagesVelocity, Distance & Acceleration 2 QPMisc VidsNo ratings yet

- Statutory Updates BUSY 21Document25 pagesStatutory Updates BUSY 21TapanNo ratings yet

- South African Table of Frequency AllocationsDocument136 pagesSouth African Table of Frequency AllocationsKea MerementsiNo ratings yet

- Bornstein, B. - On LatencyDocument8 pagesBornstein, B. - On LatencycabaretdadaNo ratings yet