Professional Documents

Culture Documents

12 (3) 8MaizeThreshing PDF

Uploaded by

GuiiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 (3) 8MaizeThreshing PDF

Uploaded by

GuiiCopyright:

Available Formats

AU J.T. 12(3): 199 -206 (Jan.

2009)

The Design and Construction of Maize Threshing Machine

Abdulkadir Baba Hassan, Matthew Sunday Abolarin, Olufemi Ayodeji Olugboji

and Ikechukwu Celestine Ugwuoke

Department of Mechanical Engineering, Federal University of Technology

Minna, Niger State, Nigeria

Email: <abdulkadir_hassan2003@yahoo.com; abolarinmatthew@yahoo.com;

olufem000@yahoo.com; ugwuokeikechukwu@yahoo.com >

Abstract

Many farmers grow maize but could not afford the cost of acquiring some of the

imported threshing machines because of their cost. Such people resort to manual means

of threshing which results into low efficiency, high level of wastage and exerting of

much labor. This machine was constructed to shell maize and separate the cob from the

grains. It was constructed from locally available materials and its cost is very low and

affordable. Its threshing efficiency is 99.2% and breakage is very insignificant, as well

as losses.

Keywords: Hopper, shutter, threshing chamber, breakage, collector, wastage.

unsatisfactory because of their low output,

Introduction tediousness and their requirement of extra

strength. According to Kaul and Egbo (1985),

Grains, according to Okaka (1997) are the performance of a thresher depends upon its

fruits of cultivated grasses belonging to the size, cylinder speed, cylinder concave

monocotyledonous family, Gramineae. The clearance, fan speed and the sieve shaker

principal cereal grains of the world include speed. Oni and Ali (1986) reported that the

wheat, barely, rye, sorghum, rice and maize. factors influencing threshability of maize in

The last has become a popular staple in West Nigeria are field drying, maize varieties, ear

Africa. Maize is another world’s most versatile size cylinder speed and feed rate. The

seed crop. Its cultivation originated from properties of the crop that affect the thresher

Europe but was soon brought to Africa by performance are crop variety, shape and size,

explorers early in the sixteenth century. Within hardness of the seed, the moisture content of

hundreds of years, it was well established as a the seed and the density.

staple food in areas around the north and south

shores of Mediterranean Sea. In later years,

maize cultivation spread widely into Africa Design Analysis

down to Nigeria as well as many parts of Asia

all at the same span of time. Its production in The Hopper

the southern states of the United States of

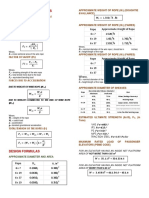

America also expanded greatly just as it was in The hopper (Fig. 1) is designed to be fed

Africa and Asia (Adaokoma 2001). The use of in a vertical position only. The material used

sticks for threshing was predominant in the pre- for the construction is mild steel sheet metal,

historic era. In Egypt, livestock was earlier which is readily available in the market and

employed for threshing out grains after which it relatively affordable. The hopper has the shape

was winnowed. In Palestine, threshing sledge of a frustum of a pyramid truncated at the top,

was used 3,000 years earlier. In Nigeria, maize with top and bottom having rectangular forms.

was threshed originally by bare hands. Other

popular method was the use of pestle and Calculation of the Overall Height

mortar. This method is still used in the rural

areas today. The above methods became Lengths AC and EG are calculated by

Technical Report 199

AU J.T. 12(3): 199 -206 (Jan. 2009)

using the Pythagorean theorem, The Threshing Bars

AC 2 = AB 2 + BC 2. Also, AC = (AB 2 + BC 2)1/2,

and OC = (AB 2 + BC 2)1/2/2, Weight, W, of threshing bar is given by:

EG 2 = EH 2 + HG 2, EG = (EH 2 + HG 2)1/2, W = mg,

and MG = [(EH 2 + HG 2)/2]1/2. where:

P m = mass of threshing bar;

g = acceleration due to gravity.

Mass, m, of threshing bar:

m = ρ x V,

where:

F

ρ = density of mild steel;

V = volume of threshing bar.

E G Volume, V, of threshing bar:

V = l x b x h,

H where:

1 = length;

b = breadth;

D

h = height.

Shaft Design

A C

A shaft is a rotating or stationary

member, usually of circular cross-section

B having such elements as gears, pulleys,

Fig. 1. Schematic diagram of the hopper. flywheels, cranks, sprockets and other power

transmission elements mounted on it Shigley

From the principle of similar triangles, for (1986). The shaft of this machine has a

triangles PMG and POC: threshing tool attached to it (by welding) at two

PM/MG = PO/OC, or PM = PO x MG/OC. opposing sides and a pulley mounted on it. It is

Then the volume of the hopper is given by: supported on bearings. Shaft design consists

Vhopper = [(area of base) x height]/3 primarily of the determination of the correct

= [(AB x BC) x h – (EH x HG) x x]/3, shaft diameter to ensure satisfactory strength

where: and rigidity when the shaft is transmitting

h = overall height; power under various operating and loading

x = height of the truncated top. conditions. Shafts are either solid or hollow.

The following presentation is based on shafts

The Main Frame of ductile materials and circular cross-section.

The length of the shaft has been pre-determined

The main frame supports the entire at 770mm.

weight of the machine. The total weights

carried by the main frame are: Power Delivered By Shaft

- weight of the hopper and housing; Power, P = work done per second:

- weight of the threshing chamber; P = (work done)/time = (force x distance)/time

- the collector and pot; and = force x velocity.

- the bearings and pulleys.

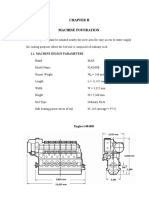

The two design factors considered in Calculation of Reactions RB and RD

determining the material required for the frame From Fig. 2:

are weight and strength. In this work, angle XT = total length of shaft;

steel bar of 11/2” by 11/2” and 2mm thickness is X = distance along the shaft;

used to give the required rigidity. Wp = weight of the pulley;

Technical Report 200

AU J.T. 12(3): 199 -206 (Jan. 2009)

T1 & T2 = tensions of belt. w = angular velocity;

r = radius of the arm of the threshing bar.

To determine the mass, m, of the

threshing bars:

mass (m) = density (ρ) x volume (V), and

volume (V)

= length (L) x breadth (B) x thickness (t).

Determination of Angular Velocity, ω

The angular velocity, ω, is given by:

ω = 2πN/60,

where:

N = speed of the shaft in r.p.m.

The Radius, r, of the Threshing Arm

The radius, r, of the threshing arm

Fig. 2. Distributed weights acting on the shaft increases along the length of the shaft and also

at different sections of the shaft. decreases towards the other end of the shaft,

where:

Taking moment about RB: r = radius of threshing arm and it is given as

sum of clockwise moments equal = sum of rmax = 0.082m (assumed),

anticlockwise moments, i.e., rmin = 0.058m (assumed), so that

(WP + T1 + T2)XT + Hx6 + Gx5 + Ex4 + Dx3 + centripetal force at rmax (F) = mω2rmax,

Cx2 = RDx7, centripetal force at rmin (F) = mω2rmin.

RD = [(WP + T1 + T2)XT + Hx6 + Gx5 + Ex4 +

Dx3 + Cx2]/x7. Determination of Threshing Torque

But sum of upward forces = sum of

downward forces: The torque, T, is given by:

RD + RB = WP + T1 + T2 + C + D + E + G + H, T = F x r,

RB = (WP + T1 + T2 + C + D + E + G + H ) – where:

RD. F = Force available along the threshing bar;

r = threshing radius.

Calculation of the Shearing Force and

Bending Moment of the Shaft at Different Determination of Power Delivered by Shaft

Sections of the Shaft along the Length of Threshing Bars

Here: The power is given by

S.F. = upward forces – downward forces; power = energy/time = (work done)/time =

B.M = forces x perpendicular distances. (force x distance)/time = force x velocity,

velocity = ωr,

Force Required to Thresh Maize along the where:

Length of the Threshing Bars ω = angular velocity;

r = radius.

The threshing bars, which are attached to

Therefore, power = Fωr.

the shaft contained in the threshing chamber,

rotate with the shaft, giving rise to centripetal Determination of Torsional Moment, MT

force:

The torsional moment, MT, is given by

F = m ω2 r,

MT = 9,550 x KW/N,

where:

where:

F = centripetal force;

KW = power delivered;

m = mass of threshing bars;

N = revolutions per minute.

Technical Report 201

AU J.T. 12(3): 199 -206 (Jan. 2009)

Determination of Maximum Bending - the class of V-belt used;

Moment - the configuration of the machine;

- the space available.

The maximum bending moment, Mbmax, is However, the two pulleys must be near to each

given by other.

Mbmax = (MV 2 + MH 2)1/2.

iii. Weight of Pulley: The weight of pulley

on a shaft can be determined as follows:

The Prime Mover

weight of pulley, WP = mg, with

The purpose of an electric motor is to m = ρV,

develop the necessary power required for a V = A x Lp = (πd 2/4) x Lp,

task. m = ρ x (πd2/4) x Lp,

The most common types of motors used WP = ρ x (πd2/4) x Lpg,

for industrial purpose are: the squirrel cage where: Lp = length of pulley.

induction motors where a continuous supply of

power is required: and the split-ring induction Belt Design

motors being used for intermitted supply of

power. The squirrel type motor has its current A belt provides a convenient means of

induced in the motor bars by induction thereby transferring power from one shaft to another.

dispensing with commutators. For the purpose Belts are frequently necessary to reduce the

of this work, a squirrel induction motor is higher rotational speeds of electric motors to

selected. The rating however will be lower values required by mechanical

determined by calculation results. equipments (Spotts 1985). The belt driver relies

on frictional effects for its efficient operation.

Pulley When the belt connecting two pulleys is

stationary, the tensions in the two portions of

i. Driver Pulley: Williams (1953), gives the the belt are equal but when torque is applied to

horse power rating at a maximum pitch the driving pulley, one portion of the belt is

diameter of pulleys and the corresponding stretched and the other portion becomes slack.

speeds. The horsepower rating of the electric The procedure for selecting a V-belt drive is

motor will therefore determine the diameter of dependent on the motor horse power and the

the driver pulley. speed (rpm) rating. V-belts are rated from class

ii. Driven Pulley: The spindle speed and A to E (Table 1).

the speed of the prime mover are related by the The effective pull on belt:

expression: T = T1 – T2,

N1D1 = N2D2, or N1/N2 = D2/D1, i.e., where:

(speed of driver)/(speed of driven) T1 = tension on tight side;

= (diameter of driven)/(diameter of driver). T2 = tension on slack side;

The following factors determined the Torque, Ts, on shaft = F x r, and F = Ts/r.

centre distance of pulleys:

Table 1. V-belt horse power*.

Cross Load of drive Recommended Nominal top Nominal Weight per

section (Kw) min. pulley pitch width, w (mm) thickness, T meter (kg f)

diam., d (mm) (mm)

A 0.75 – 5 75 13 8 0.106

B 2-15 125 17 11 0.189

C 7.5-75 200 22 14 0.343

D 22-50 355 32 19 0.596

E 30-190 500 38 22 —

* Design data (PSG Tech 1989)

Technical Report 202

AU J.T. 12(3): 199 -206 (Jan. 2009)

But T = F and T = Ts/r. Groove Dimension

Also, Ts = TM, and T = TM/r. The groove for pulleys has been

But PM = ωTM, and TM = PM/ω. standardized depending on the type of class of

Therefore, T = PM/(ωr), and MT = (T1 - T2)r1, belt intended for use (Williams 1953). Classes

where: of belts, pitch diameters of pulleys, and the

T = effective pull on bell; groove angles have been listed out by Williams

F = Force on driver pulley; (1953).

TS = torque on shaft;

TM = Torque on the motor; Determination of Minimum Diameter of

r1 = radius of driver pulley; Shaft

T1 - Tension on the tight side of belt; Design of shafts of ductile material based

T2 = Tension on the slack side of belt; on strength is controlled by maximum shear

MT = Torsional moment. theory. Shafting is usually subjected to torsion,

bending and axial loads. For a solid shaft

Power Transmitted by Belt

having little or no axial loading, the ASME

According to Hannah and Stephens code equation is given as (ASME 1995):

(1970), the power transmitted by belt is given d 3 = [16/(πSs)] x [(KbMb)2 + (KtMt)2]1/2,

by P = (T1 – T2)V. where:

But V = (πDN)/60. Also, d = diameter of the shaft;

T1/T2 = exp(μθ cosec β), Mt = torsional moment;

where: Mb = bending moment;

β = groove semi-angle; Kb = combined shock and fatigue factor applied

θ = angle of lap; to bending moment;

α = angle of contact at the smaller pulley; Kt = combined shock and fatigue factor applied

μ = coefficient of friction. to torsional moment;

The coefficient of friction for rubber belt Ss = Allowable Stress.

on cast iron or steel operating on dry surface is For rotating shafts, when load is suddenly

μ = 0.3 (Ogunwede 2003). The angle of lap for applied (minor shock):

open V-belt drive is given as: Kb = 1.5 to 2.0;

θ = (180 – 2α) x π/180 rad. Also, Kt = 1.0 to 1.5.

For shaft without key-way:

sin α = (r2 – r1)/x,

Ss (allowable) = 55MN/m2.

where:

For shaft with key-way:

x = distance between pulleys;

Ss (allowable) = 40MN/m2.

r1 = radius of smaller pulley;

A shaft with key-way was used for this

r2 = radius of bigger pulley.

work.

Centre Distance of Belt Bending Stress

The maximum centre distance of belt in According to Hall et al. (1988), for

use depends on the size of the two pulleys and bending load, bending stress (tension or

is given as: compression) is:

Xmax = 2(D + d). Sb = Mbr/I.

Hence,

Length of Belt

Sb = (32Mb)/(πd 3),

Belt length can be calculated if the where:

diameters of both the bigger pulley and the Sb = bending stress;

smaller pulley and the belt centre distance are Mb = bending moment;

known: d = shaft diameter;

L = 2x + (π/2)(D + d) + (D – d)2/(4x). I = moment of inertia.

Technical Report 203

AU J.T. 12(3): 199 -206 (Jan. 2009)

Also, I = πd4/64, for a cylindrical shaft (PSG T = Torque (Nm);

Tech 1989). d = Shaft diameter (m).

Torsional Stress Bearing Selection

According to Black and Adams (1968), Bearing must be selected based on its

torsional stress is determined using load carrying capacity, life expectancy and

τxy = MT r/J. reliability (PSG Tech 1989). The relationship

But J = πd4/32, hence, τxy = (16MT)/(πd3), between the basic rating life, the basic dynamic

where: rating and the bearing load is:

τxy = Torsional stress N/m2; C = [L/L10]1/KP, or C/P = [L/L10]1/K, i.e.,

MT = torsional moment; [C/P]K = L/L10, or L10 = [C/P]K/L.

r = radius of shaft; But L = 60n/106 million revolutions,

J = Polar moment of area; therefore, L10 = (106/60n) x [C/P]K,

d = diameter of shaft. where:

L10 = life of bearing for 90% survival at one

Torsional Rigidity million revolutions;

Torsional rigidity of a shaft is based on L = required life of bearing in million

permissible angle of twist. The amount of twist revolutions (mr);

permissible depends upon the particular n = rotational speed (rev/min);

application and varies from 0.3 degree/m for a C = basic dynamic load rating (N);

machine tools shaft to about 3 degree/m for P = equivalent dynamic bearing load (N);

line shafting as given by: K = exponent for life equation with:

θ = (584 MTL)/(Gd4), K = 3 for ball bearing;

where: K = 10/3 for roller bearing.

θ = angle of twist (degree); Also, P = radial load + axial load,

L = length of shaft (m); P = (XFr + YFa),

MT = torsional moment (Nm); where:

G = Torsional modulus of rigidity (N/m2); X = radial load factor for the bearing;

d = diameter of shaft (m). Y = axial load factor for the bearing;

Fr = actual radial bearing load (N);

Lateral Rigidity Fa = actual axial bearing load (N).

Table 2 shows the recommended life

The lateral rigidity of a shaft is based

value in operation. It is assumed that this

upon the permissible lateral deflection for

machine is designed to operate for 8 hours per

proper bearing operation, accurate machine

day intermittently and whose breakdown will

tool performance, shaft alignment etc. Amount

have serious consequences.

of deflection can also be calculated by two

The bearing life in operating hours is

successive integrals of the formula:

chosen to be 8,000.

d2y/dx2 = (Mb)/(EI),

where:

Table 2. Recommended life value of bearings.

Mb = bending moment N/m2;

E = Modulus 'of elasticity (N/m2) ; Type of operation Life in operation

I = Moment of inertia (m4). Infrequently operated 500

Brief operation only 4,000-8,000

Shear Stress

Intermittent operation 8,000-15,000

The shear stress on the shaft is One shift operation 15,000-30,000

determined by the formula below (Black and Continuous operation 30,000-60,000

Adams 1968): Continuous operation with 100,000

τ = (16T)/(πd3), high production capacity

where:

τ = Shear stress N/m2; * Design data (PSG Tech 1989)

Technical Report 204

AU J.T. 12(3): 199 -206 (Jan. 2009)

Table 3. Deep groove bearing selection factor.

Bearing Basic dynamic Inner race max. Outside Width, B Max.

load, C (N) diam., d (mm) diameter, D speed, rpm

6,406 3,350 30 90 23 6,300

6,407 4,300 35 100 25 5,600

6,408 5,000 40 110 27 5,000

6,409 5,850 45 120 29 4,500

* Design data (PSG Tech 1989)

A deep grooved bearing will be used for where:

this work due to its ability to withstand heavy T ' = resisting torque;

radial loads at high speed (Table 3). F = resisting force;

d = diameter of shaft;

Screen L = length of key.

Purpose of the screen is to act as a

separator between the threshed maize and the Design Calculation and Results

cobs. Screens are either woven-wire or plate

with perforated round holes. The plate with The average cylinder speed for high and

perforations was selected for this work. This efficient threshing output was estimated as 830

will allow threshed maize grains to escape into rpm. This cylinder speed was used as the basis

collector pot. for the calculation. Then:

volume of hopper, V= 0.004797m3;

Key overall height, H = 0.511m;

mass required to thresh maize along the length

The function of a key is to prevent

of the threshing bars = 0.837 kg;

relative rotation of a shaft and the member to

angular velocity, ω = 86.92 rad/sec;

which it is connected, e.g., hub of a gear,

maximum force available along the threshing

pulley or crank. Different types of keys are

arm, Fmax = 518.88N;

available, the choice of which is dependant on

threshing torque = 42.55Nm;

power requirements, tightness of fit, stability of

power delivered by shaft along the length of

connection and cost. For a light transmission, a

threshing bars = 3.698KW;

set screw may be employed. But for this work,

prime mover (electric motor) = 5Hp.

a flat key was adopted, as this is used where

According to Spotts (1985), for a 5 horse

added stability is desired, e.g. machine tools.

power motor and a speed of 870 rpm, the

recommended minimum sheave pitch diameter

Proportion of a Key

is 3.8", which is equivalent to 96.52mm or

For a good result, the width of a key is 100mm diameter of pulley. For this range of

made one-quarter the diameter of the shaft. The speed, V-belt is the best. Referring to Table 2,

thickness of a key for equal strength of the key a class B V-belt was selected for this work.

in failure by shearing of the key, and According to Williams (1953), a groove angle

compression on the key may be determined by of 38° was chosen for a pulley of 100mm

the corresponding allowable stresses in shear diameter using class B V-belt. Then:

and compressions. weight of pulley, Wp = 10.01N;

The length of the key can be calculated as speed of driver pulley, N1 = 870 r.p.m;

L = πd/2 = 1.57d. speed of driven pulley, N2 = 830 r.p.m;

The forces on the top and bottom of the diameter of driver pulley, D1 = 100mm;

key resist tipping of the key, and the force, F, diameter of driven pulley, D2 = 105mm;

between the side of the key and the key way in effective pull on belt, T = 518.9N;

the hub is due to the resisting torque, T ': tension on tight side, T1 = 550.2N;

T ' = Fd/2 = FL/π, tension on slack side, T2 = 31.33N;

Technical Report 205

AU J.T. 12(3): 199 -206 (Jan. 2009)

maximum centre distance of belt, Xmax = dehauler. M. Eng. Thesis, Department of

102.5mm; Mechanical Engineering, Federal University

length of belt, L = 537mm; of Technology (FUT), Minna, Nigeria.

reaction, RD = 647.9N; ASME. 1995. Design of Transmission

reaction, RB = -79.44, negative sign means one Shafting. American Society of Mechanical

should reverse the direction of RB; Engineering, New York, NY, USA.

maximum bending moment Mbmax = -50.25Nm; Black, P.H.; and Adams, O.E., Jr. 1968.

torsional moment, Mt = 42.55 Nm; Machine design. 3rd ed. McGraw-Hill, New

maximum shear force = -87.43N, York, NY, USA.

negative sign implies the direction of the force; Hall, A.S.; Holowenko, A.R.; and Laughlin,

shock and fatigue factor (bending moment), H.G. 1988. Theory and problems of

Kb = 1.5. machine design. Shaum’s Outline Series,

S.I. (metric) ed. McGraw-Hill, New York,

Performance Test NY, USA. pp. 113-4.

Hannah, J.; and Stephens, R.C. 1970.

The completed work was subjected to test

Mechanics of machines: elementary theory

and it was found to thresh maize very

and examples. Edward Arnold, London,

effectively. Losses and breakages were found

England.

to be very negligible. The efficiency of the

Kaul, R.N.; and Egbo, C.O. 1985. Introduction

machine was found from the equation below to

to agricultural mechanization. Macmillan,

be equal to 99.2%:

London, England, UK. pp. 128-41.

Efficiency = [(W1 – W2)/W1] x 100,

Ogunwede, O.I. 2003. Design and construction

where:

of plastic crushing machine. PGD Thesis,

W1 = weight of unthreshed cobs;

Department of Mechanical Engineering,

W2 = weight of cobs not well threshed.

Federal University of Technology (FUT),

Minna, Nigeria.

Conclusion Okaka, J.C. 1997. Cereals and legumes: storage

and processing technology. Nigeria Data

Self-reliance is the major drive of and Microsystem Publishers, Enugu,

development and vibrant economy. This Nigeria. pp. 47-53.

machine has been fabricated with the use of Oni, K.C.; and Ali, M.A. 1986. Factors

locally available materials. The machine is influencing the threshability of maize in

simple, less bulky and effective with its self- Nigeria. Agricultural Mechanization in

cleaning ability. Grains loss and mechanical Asia, Africa and Latin America (AMA)

visible damage have been very minimal. 17(4): 39-44.

Performance test has revealed that the PSG Tech. 1989. Design data. Faculty of

efficiency of the machine is 99.2%. The Mechanical Engineering, Poolamedu

machine threshes 200kg of maize within an Sathankulam Govindsamy Naidu College of

hour. The machine can either be powered by an Technology (PSG Tech), DPV Printers,

electric motor or engine (diesel or petrol). The Coimbatore, India.

electric motor seat provides adjustment so that Shigley, J.E. 1986. Mechanical engineering

the V-belt can be fixed easily. There is no design. S.I. (metric) ed. McGraw-Hill, New

doubt that the machine will ease the long term York, NY, USA.

scourge of youth unemployment in our land. Spotts, M.F. 1985. Design of machine

elements. 6th ed. Prentice Hall, Englewood

Cliffs, NJ, USA.

References Williams, W.A. 1953. Mechanical power

transmission manual. Conover-Mast Publ.,

Adaokoma, A. 2001. The design and New York, NY, USA.

fabrication of a multi-purpose grain

Technical Report 206

You might also like

- The Design and Construction of Maize Threshing MachineDocument8 pagesThe Design and Construction of Maize Threshing MachineAbiodun GbengaNo ratings yet

- Flywheels: Flywheel - A Heavy Rotating Body That Acts As A Reservoir of Energy. Energy Is Stored inDocument4 pagesFlywheels: Flywheel - A Heavy Rotating Body That Acts As A Reservoir of Energy. Energy Is Stored inNayeon DahyunNo ratings yet

- Design of Grass Briquette Machine: M. U. Ajieh, A. C Igboanugo and T. O. K. AuduDocument4 pagesDesign of Grass Briquette Machine: M. U. Ajieh, A. C Igboanugo and T. O. K. Auducjs_rades8101No ratings yet

- Transmission Line Supports.Document37 pagesTransmission Line Supports.ninadpujara2007No ratings yet

- Pillar DesignDocument51 pagesPillar Designbishal pradhanNo ratings yet

- Methodology To Calculate The Effective RDocument13 pagesMethodology To Calculate The Effective Rcajimenezb8872No ratings yet

- FST1 11101191Document5 pagesFST1 11101191Tamer Hernan Jaramillo LeonNo ratings yet

- The 10xi in The Element Spliced Plus 5 Percent But in Nocase Shouldthe Strength Developed Be Less Than 50percent ofDocument5 pagesThe 10xi in The Element Spliced Plus 5 Percent But in Nocase Shouldthe Strength Developed Be Less Than 50percent ofRaj MeenaNo ratings yet

- Chapter 10Document24 pagesChapter 10Mahesh Theking100% (1)

- Design of Joints, Levers, & Offset Links (12 Marks) : Visit For More Learning ResourcesDocument30 pagesDesign of Joints, Levers, & Offset Links (12 Marks) : Visit For More Learning ResourcesJAY KACHANo ratings yet

- Pillar Design - Concentrating On Room and PillarDocument30 pagesPillar Design - Concentrating On Room and PillarYogi TariuNo ratings yet

- 3.4 Soil-Structure Interaction: U Us 1 2 Ud 3Document9 pages3.4 Soil-Structure Interaction: U Us 1 2 Ud 3Rodrigo Medina AngelNo ratings yet

- 4-Pile FoundationDocument10 pages4-Pile FoundationRajratna MadhaleNo ratings yet

- Flywheels May SulatDocument3 pagesFlywheels May SulatRonnieNo ratings yet

- Cotter and Sleeve JointDocument17 pagesCotter and Sleeve JointNishit Karkar100% (2)

- DMX5532 Tma01-2019 PDFDocument2 pagesDMX5532 Tma01-2019 PDFJasinthaja AsankaNo ratings yet

- Caracteristicas de DragasDocument117 pagesCaracteristicas de DragasRodrigo Ignacio CárcamoNo ratings yet

- Surface Areas and VolumesDocument10 pagesSurface Areas and VolumesBharani SriNo ratings yet

- Me 463-Machine Design 2: Instructor: Engr. Danielle D. Cabana, MengDocument32 pagesMe 463-Machine Design 2: Instructor: Engr. Danielle D. Cabana, MengChristian Breth Burgos50% (2)

- Phase 2.1Document13 pagesPhase 2.1Neil Allison Najorda CabilbilNo ratings yet

- Design of Combined FootingsDocument45 pagesDesign of Combined FootingsAnkit AgrawalNo ratings yet

- Sem RecordDocument37 pagesSem RecordkishoreputhaNo ratings yet

- Bend TestDocument14 pagesBend TestAdasi SamuelNo ratings yet

- Agricultural Engineering-Farm Machinery: Sources of Farm PowerDocument17 pagesAgricultural Engineering-Farm Machinery: Sources of Farm PowerGladys Ruth PaypaNo ratings yet

- Design, Construction and Evaluation of Motorized Okra SlicerDocument8 pagesDesign, Construction and Evaluation of Motorized Okra SlicerBaba shehu Abba kyariNo ratings yet

- Spread Footing DesignDocument12 pagesSpread Footing DesignNikka ToledoNo ratings yet

- Chapter 3 1 ConveyorsDocument49 pagesChapter 3 1 ConveyorsMatthew MhlongoNo ratings yet

- Footing BiaxialDocument28 pagesFooting Biaxialdbircs1981100% (1)

- Chapter 7Document44 pagesChapter 7Nebiyou KorraNo ratings yet

- Design and Fabrication of Groundnut Shelling MachineDocument17 pagesDesign and Fabrication of Groundnut Shelling Machinesasi100% (1)

- Steady Sailing Performance of A Hybrid-Sail Assisted Bulk CarrierDocument16 pagesSteady Sailing Performance of A Hybrid-Sail Assisted Bulk CarrierBoby48007No ratings yet

- 13 An Experimental Study On Uplift Capacity of Plate AnchorsDocument35 pages13 An Experimental Study On Uplift Capacity of Plate AnchorsAna Sofía Arango BermúdezNo ratings yet

- Double Purchase Crab: Objective: TheoryDocument3 pagesDouble Purchase Crab: Objective: TheorydarshanNo ratings yet

- Estimation of Urea in Silo: AuthorDocument8 pagesEstimation of Urea in Silo: AuthorNeyda Flores VasquezNo ratings yet

- Alcorcon Engineering Review Center: I. Machine FoundationDocument5 pagesAlcorcon Engineering Review Center: I. Machine FoundationReinzo GallegoNo ratings yet

- Arch DamsDocument23 pagesArch DamsHannah EsquilloNo ratings yet

- Articulo 5Document4 pagesArticulo 5Xiomara Massiel Criales ValerNo ratings yet

- Unit - Iii Lecture NotesDocument43 pagesUnit - Iii Lecture NotesrajasankarNo ratings yet

- Ore Storage CalculationsDocument24 pagesOre Storage CalculationsmpwemboNo ratings yet

- Vibrations of Vertical Pressure VesselsDocument15 pagesVibrations of Vertical Pressure VesselsNelson RangelNo ratings yet

- управлен судна прак 2Document8 pagesуправлен судна прак 2nwana9975No ratings yet

- Chapter 1 Shaft (Cont'd)Document47 pagesChapter 1 Shaft (Cont'd)Rayuth KEATNo ratings yet

- T / (1000 T+ (M 1) Ash) : Bearing Stresses at BendsDocument2 pagesT / (1000 T+ (M 1) Ash) : Bearing Stresses at BendsZakiQureshiNo ratings yet

- لاب 5Document5 pagesلاب 5osama.ammer2002No ratings yet

- Design and Analysis of Eot Crane Hook For Various Cross SectionsDocument6 pagesDesign and Analysis of Eot Crane Hook For Various Cross SectionsFiroz PawaskarNo ratings yet

- A Review On Design Analysis & Optimization of Screw ConveyorDocument6 pagesA Review On Design Analysis & Optimization of Screw ConveyorFootball TotalityNo ratings yet

- Topic 5 - Pile FootingDocument29 pagesTopic 5 - Pile FootingZxeroNo ratings yet

- Wire Ropes and ChainsDocument3 pagesWire Ropes and ChainsMark CruzNo ratings yet

- L5 Retaining WallDocument43 pagesL5 Retaining WallLAR RAFIUDDIN ROSLANNo ratings yet

- Surface Mine Design and PracticeeeeeeeeeeeeeeeeeeeeDocument56 pagesSurface Mine Design and PracticeeeeeeeeeeeeeeeeeeeeSelamet ErçelebiNo ratings yet

- Board Exam Agri PatDocument35 pagesBoard Exam Agri Patwmcartalaba00233No ratings yet

- Design of Threshing Cylinder For A Combine Paddy Harvester (KUBOTA)Document7 pagesDesign of Threshing Cylinder For A Combine Paddy Harvester (KUBOTA)komyatthu.tt99No ratings yet

- Design of Pile FoundationDocument30 pagesDesign of Pile FoundationAshish Karki100% (1)

- Pier Column Design PDFDocument6 pagesPier Column Design PDFJaycee Bareng PagadorNo ratings yet

- FORMULA Machine DesignDocument11 pagesFORMULA Machine Designnatalie echaviaNo ratings yet

- Lyka Chapter 2 DieselDocument17 pagesLyka Chapter 2 DieselRuby Jane LuchingNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Design and Fabrication of Onion Seed Sowing Machine 1433826027 PDFDocument10 pagesDesign and Fabrication of Onion Seed Sowing Machine 1433826027 PDFGuiiNo ratings yet

- Design, Development and Fabrication of Multi Crop Cutter Powered by Electric MotorDocument9 pagesDesign, Development and Fabrication of Multi Crop Cutter Powered by Electric MotorInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design of Mechanical Tef Harvesting Machine: Thomas Gebre, Jegan Raj, Cheru ZelekeDocument9 pagesDesign of Mechanical Tef Harvesting Machine: Thomas Gebre, Jegan Raj, Cheru ZelekeGuiiNo ratings yet

- 12 (3) 8MaizeThreshing PDFDocument8 pages12 (3) 8MaizeThreshing PDFGuiiNo ratings yet

- Design of Mechanical Tef Harvesting Machine: Thomas Gebre, Jegan Raj, Cheru ZelekeDocument9 pagesDesign of Mechanical Tef Harvesting Machine: Thomas Gebre, Jegan Raj, Cheru ZelekeGuiiNo ratings yet

- Design, Development and Fabrication of Multi Crop Cutter Powered by Electric MotorDocument9 pagesDesign, Development and Fabrication of Multi Crop Cutter Powered by Electric MotorInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Fabrication of Onion Seed Sowing Machine 1433826027 PDFDocument10 pagesDesign and Fabrication of Onion Seed Sowing Machine 1433826027 PDFGuiiNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetAryabhatt ThakurNo ratings yet

- I. Melc.: Perpetual Succour Academy, Inc. National Rd. Poblacion Dos, Malabuyoc, Cebu Science 10Document4 pagesI. Melc.: Perpetual Succour Academy, Inc. National Rd. Poblacion Dos, Malabuyoc, Cebu Science 10Cry BeroNo ratings yet

- Computational Fluid Dynamics Analysis of Greenhouse Solar DryerDocument19 pagesComputational Fluid Dynamics Analysis of Greenhouse Solar DryerPurusothamanManiNo ratings yet

- Physical Science - Semester End Project: The Electromagnetic SpectrumDocument4 pagesPhysical Science - Semester End Project: The Electromagnetic SpectrumBreanna HartNo ratings yet

- Final Exam MA and MBDocument6 pagesFinal Exam MA and MBعبدالله حامد الرفاعيNo ratings yet

- Considerations For Instrument Grounding: TechnicalDocument12 pagesConsiderations For Instrument Grounding: TechnicalmetqalNo ratings yet

- NEW Atlanta Permaline 2019Document2 pagesNEW Atlanta Permaline 2019gregNo ratings yet

- AssignmentDocument3 pagesAssignmentdola indupriyaNo ratings yet

- Science and Health 6Document2 pagesScience and Health 6MA. PATRIA MANDAPNo ratings yet

- Sink CSMDocument2 pagesSink CSMZulfiqar AhmedNo ratings yet

- 16kw ManualDocument48 pages16kw ManualJamesBrionesNo ratings yet

- Night Vision Technology1Document20 pagesNight Vision Technology1Srinivas RaoNo ratings yet

- Third Floor Beam Design CalculationDocument3 pagesThird Floor Beam Design CalculationArnold VercelesNo ratings yet

- Comms 4 - FormulaDocument7 pagesComms 4 - Formulaengineeringbsece2fNo ratings yet

- Book 1Document44 pagesBook 1Soubhik ChoudhuryNo ratings yet

- Achenbach - 1995 - Heat and Flow Characteristics of Packed BedsDocument11 pagesAchenbach - 1995 - Heat and Flow Characteristics of Packed BedsDOUGLAS RAMON RODRIGUEZ ORDOÑEZNo ratings yet

- Aplied Thermodynamics Tutorial 1, Revision of Isentropic Efeciency Advanced Steam Cycles.Document80 pagesAplied Thermodynamics Tutorial 1, Revision of Isentropic Efeciency Advanced Steam Cycles.Moch Bagus BahtiarNo ratings yet

- CHM 101 QuestionsDocument4 pagesCHM 101 QuestionsAbraham BanjoNo ratings yet

- W2manual42 Part2 Theory Rev1Document256 pagesW2manual42 Part2 Theory Rev1Maria Camila Valencia CárdenasNo ratings yet

- Inspire Cast FinalDocument195 pagesInspire Cast Finalamele25100% (1)

- Fully Automatic Current and Voltage Transformer Test SetDocument8 pagesFully Automatic Current and Voltage Transformer Test SetMuhammad ShahidNo ratings yet

- Mech 311 Formula Sheet For Final ExamDocument3 pagesMech 311 Formula Sheet For Final ExamJonathon Raymond-SzewczukNo ratings yet

- Objective PhysicsDocument4 pagesObjective PhysicsleoyodapieNo ratings yet

- Sensors & Sensor Modules: YF-S201 Water Flow SensorDocument2 pagesSensors & Sensor Modules: YF-S201 Water Flow SensorPOOVENDHAN TNo ratings yet

- 2502 Series LeveltrolDocument24 pages2502 Series LeveltrolayoubNo ratings yet

- Electrical Engineering SolutionsDocument14 pagesElectrical Engineering SolutionsJustine Kyla OlivarNo ratings yet

- Flange Management Rev 1 160216081830Document31 pagesFlange Management Rev 1 160216081830Ali100% (1)

- Chapter 4-Behavior Evaluation of Vehicule Materials-Lecture 2Document44 pagesChapter 4-Behavior Evaluation of Vehicule Materials-Lecture 2roy barmoNo ratings yet

- 4270GP PDFDocument1 page4270GP PDFImadNo ratings yet

- St. Paul'S Academy: Purba BardhamanDocument5 pagesSt. Paul'S Academy: Purba BardhamanBHRAMAR DHARANo ratings yet