Professional Documents

Culture Documents

Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01

Uploaded by

cmrig74Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01

Uploaded by

cmrig74Copyright:

Available Formats

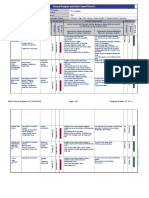

Prepared By: ToolPusher / HSE Advisor

Risk Assessment Register

Reviewed By: Drilling Superintendent

Approved By: HSE Manager Date : 1st November, 2015 Rev. No. 1

INITIAL RISK CONTROL MEASURES RESIDUAL RISK

Risk Number

HAZARDS Effect

Main Activity Sub Activity HAZARDS

Likelihood

Likelihood

Risk Level

Risk Level

( If the Hazard is Released )

Severity

Severity

Class

Class

Prevention & Mitigation Recovery Measures

1 Nipple up / Nipple Nipple up / Moving parts Personnel injury D 4P D H Conduct TBT before starting the job, identify the activity steps hazards and ERP, D 1P D1P L

down BOP Using Nipple down High Pressure Fatality 4P ensure all involved parties are involved in the TBT and aware of the job plan and MEDEVAC,

BOP Hoist BOP Using BOP Heavy objects Equipment damage hazards involved. Medical

Hoist Flying objects Effecting company Raise Permit to Work before starting the task. facilities

Adverse weather reputation effect Inspect all the hydraulic hoses and fittings; ensure that they are in good

Inadequate lighting condition.

Hydraulic Allow only experienced mechanic to operate the BOP winches

equipment Ensure the operation is supervised by unit manager

Loose item at height Barricade the area around the substructure and ensure no one is allowed to

enter the area.

All lifting gear to be inspected and colour coded.

Minimum number of work force present in the area.

Areas to be barricaded and kept clean and clear of obstructions.

Use proper PPE

Proper means of communication to be well known to all involved in the job.

Cover all the openings in the cellar area

Use proper tools, two teams to work at same level. Stay clear, Inspect all tools

and equipment prior to start the job.

Check BOP sling for wear or tear and all shackles and associated equipment for

serviceability and certification.

Preventative maintenance

Drop Inspection

Provision of finger saver tool

Rig weekly inspection

Provision of tower light.

Refer to following documentation

OEM manual (BOP winches).

NDSC PTW procedure

N/U and N/D BOPs

Preventive Maintenance

Hazard Identification STOP SYSTEM.

RA-R9-01-025-01

You might also like

- CHECKLIST FOR LIFTING PLANDocument1 pageCHECKLIST FOR LIFTING PLANAndrianoNo ratings yet

- BOP Nipple Down 17-May-2010Document1 pageBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- IADC Promotes Drilling Safety and Advances TechnologyDocument22 pagesIADC Promotes Drilling Safety and Advances TechnologyHashimi Juni100% (1)

- Change Out Rig Tong DiesDocument1 pageChange Out Rig Tong DiesAbdul Hameed OmarNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- JSA HEMP Well Services Pg11-15Document5 pagesJSA HEMP Well Services Pg11-15Ashok SureshNo ratings yet

- Lay Down Drill PipeDocument2 pagesLay Down Drill PipeAbdul Hameed OmarNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Daily Checks (Floorman)Document1 pageDaily Checks (Floorman)Abdul Hameed OmarNo ratings yet

- Attachment B1 Rig Move Plan ChecklistDocument4 pagesAttachment B1 Rig Move Plan ChecklistJennifer WangNo ratings yet

- Bop Ram ChangeDocument2 pagesBop Ram ChangeAbdul Hameed OmarNo ratings yet

- Install 500 Ton Slips & ElevatorDocument1 pageInstall 500 Ton Slips & ElevatorAbdul Hameed OmarNo ratings yet

- Safety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonsDocument4 pagesSafety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonskhaledNo ratings yet

- Moving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaDocument28 pagesMoving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaHSE PT. GROGOL SARANA TRANSJAYANo ratings yet

- Rig Specific Emergency Response Plan Rev1Document33 pagesRig Specific Emergency Response Plan Rev1bilou100% (1)

- 14a - Joe Hurt-John Auth Rig Pass PresentationDocument36 pages14a - Joe Hurt-John Auth Rig Pass PresentationEduardo Guajardo100% (1)

- Oil Rig Inspection ChecklistDocument17 pagesOil Rig Inspection ChecklistAhmedNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Drilling and Workover Division FinalDocument15 pagesDrilling and Workover Division FinalThem Bui XuanNo ratings yet

- Oil Field Drill Rig Safety (HSE)Document34 pagesOil Field Drill Rig Safety (HSE)omer dafallahNo ratings yet

- Short Fall Results in A FatalityDocument1 pageShort Fall Results in A FatalityAbdul Hameed OmarNo ratings yet

- OIl Rig Safety ChecklistDocument10 pagesOIl Rig Safety ChecklistTom TaoNo ratings yet

- Attachment D Pre Rig Move ChecklistDocument2 pagesAttachment D Pre Rig Move ChecklistJennifer WangNo ratings yet

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- Checklist (For Any Land Rig)Document13 pagesChecklist (For Any Land Rig)Kachur AlekseyNo ratings yet

- Running TubingDocument3 pagesRunning TubingAbdul Hameed OmarNo ratings yet

- Idc 37 Rig Move PlanDocument15 pagesIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- Well Control Incident Report Form TemplateDocument5 pagesWell Control Incident Report Form TemplateJosue Fish100% (1)

- Rig Move Operational Process Flowchart New A4Document1 pageRig Move Operational Process Flowchart New A4aymenmoatazNo ratings yet

- SPE 81130 A Look at Batch Drilling in Trinidad and TobagoDocument4 pagesSPE 81130 A Look at Batch Drilling in Trinidad and TobagoDiego LopezNo ratings yet

- PH C L C 4 - RIG MATRIX TRAININGDocument2 pagesPH C L C 4 - RIG MATRIX TRAININGThem Bui XuanNo ratings yet

- F0810 - Pre-Post Rig Move Meetings FormsDocument18 pagesF0810 - Pre-Post Rig Move Meetings FormsPaulNo ratings yet

- MTL NextGen Rig Move OptimizationDocument13 pagesMTL NextGen Rig Move OptimizationSanjeev MadaviNo ratings yet

- Sinai Field Drilling HSE Survey ChecklistDocument5 pagesSinai Field Drilling HSE Survey ChecklistnadyNo ratings yet

- Rig SafetyDocument1 pageRig Safetymuhammad aldo assaqqafNo ratings yet

- Applying Modified HAZOPs to Well TestingDocument1 pageApplying Modified HAZOPs to Well TestingHakim YahiaouiNo ratings yet

- JSA 115 Slip New Drill-Line On BlocksDocument4 pagesJSA 115 Slip New Drill-Line On BlocksanhlhNo ratings yet

- Table of Contents Iadc Safety Meeting TopicsDocument4 pagesTable of Contents Iadc Safety Meeting TopicsfarisNo ratings yet

- Wellhead Safety GE Oil Gas Pressure ControlDocument20 pagesWellhead Safety GE Oil Gas Pressure ControlCarlos A.No ratings yet

- Precision Drilling International Task Risk Assessment WorksheetDocument1 pagePrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- IADC Incident StatisticsDocument15 pagesIADC Incident StatisticsAnisBelhajAissaNo ratings yet

- Managing Drilling RiskDocument18 pagesManaging Drilling RiskOtnay HaryNo ratings yet

- Viking H Se ManualDocument168 pagesViking H Se ManualAF Dowell MirinNo ratings yet

- Saudi Aramco: RHSEI FindingsDocument2 pagesSaudi Aramco: RHSEI FindingsaswinNo ratings yet

- Cleaning Mud Mixing Tanks JSADocument7 pagesCleaning Mud Mixing Tanks JSAAziz AndriyantoNo ratings yet

- Well Handover DocumentDocument1 pageWell Handover DocumentCadiffNo ratings yet

- Wellsite Leader Checklist Rig # 41Document3 pagesWellsite Leader Checklist Rig # 41IgorCencičNo ratings yet

- Manage High Activity Periods EfficientlyDocument4 pagesManage High Activity Periods EfficientlymashanghNo ratings yet

- Safe Work ManualDocument176 pagesSafe Work ManualAsim JavedNo ratings yet

- Floorman-Tasks & ProjDocument9 pagesFloorman-Tasks & ProjAmeerNo ratings yet

- Dismantling of Concrete Pump TowerDocument1 pageDismantling of Concrete Pump TowerChandruNo ratings yet

- Operation and Maintenance Manual: Triplex Mud Pump - Skid MountedDocument118 pagesOperation and Maintenance Manual: Triplex Mud Pump - Skid MountedrolandNo ratings yet

- Drilling TerminologyDocument75 pagesDrilling TerminologyAshish Kumar JhaNo ratings yet

- Drilling Safety: David Calvert, True Oil Enterprises IncDocument16 pagesDrilling Safety: David Calvert, True Oil Enterprises Inccall_mustafas2361No ratings yet

- JCA Full SetDocument68 pagesJCA Full SetaymenmoatazNo ratings yet

- HSE Manual (Drilling Safety)Document74 pagesHSE Manual (Drilling Safety)Mustafa SaeedNo ratings yet

- Well Plan Checklist GuidanceDocument10 pagesWell Plan Checklist GuidanceWindy MartdianzahNo ratings yet

- Read ItDocument1 pageRead Itcmrig74No ratings yet

- Budgetary Quotation Summary - Rigsense Spectrum Instrumentation SystemDocument16 pagesBudgetary Quotation Summary - Rigsense Spectrum Instrumentation Systemcmrig74No ratings yet

- 155 Clients 0501 27718-0Document5 pages155 Clients 0501 27718-0cmrig74No ratings yet

- Parts List: TYPE 110-UE DrawworksDocument62 pagesParts List: TYPE 110-UE Drawworkscmrig74No ratings yet

- Budgetary Quotation Summary - Sensor Update: M/D TotcoDocument8 pagesBudgetary Quotation Summary - Sensor Update: M/D Totcocmrig74No ratings yet

- MD TrackDocument1 pageMD Trackcmrig74No ratings yet

- Lesson 22: Introduction To Underbalanced Drilling TechnologyDocument65 pagesLesson 22: Introduction To Underbalanced Drilling Technologycmrig74No ratings yet

- Well Control Complications PETE 661Document65 pagesWell Control Complications PETE 661cmrig74No ratings yet

- MD Totco Rig Electricians TrainingDocument1 pageMD Totco Rig Electricians Trainingcmrig74No ratings yet

- PerforatingDocument65 pagesPerforatingdriller22100% (1)

- Assessing Risk Precautionary Approach: and TheDocument24 pagesAssessing Risk Precautionary Approach: and Thecmrig74No ratings yet

- MD Totco Drilling Instrumentation SpecDocument2 pagesMD Totco Drilling Instrumentation Speccmrig74No ratings yet

- Jars and Accelerators.Document10 pagesJars and Accelerators.driller22100% (1)

- Circulation Kill TechniquesDocument71 pagesCirculation Kill Techniquescmrig74No ratings yet

- Kick Detection and ControlDocument63 pagesKick Detection and Controlcmrig74No ratings yet

- PETE 661: Drilling EngineeringDocument50 pagesPETE 661: Drilling Engineeringcmrig74No ratings yet

- Special Well Control Applications UBDDocument63 pagesSpecial Well Control Applications UBDcmrig74No ratings yet

- LinerDocument15 pagesLinerdriller22100% (1)

- Injection and Disposal Wells: - What Is Different - How To Convert Producers To InjectorsDocument49 pagesInjection and Disposal Wells: - What Is Different - How To Convert Producers To Injectorsdriller22No ratings yet

- Remon Ahdy ,: Professional Diplomas in Sales Management and MarketingDocument60 pagesRemon Ahdy ,: Professional Diplomas in Sales Management and Marketingcmrig74No ratings yet

- Injection Wellwork ValueDocument7 pagesInjection Wellwork Valuedriller22No ratings yet

- TAMU - Pemex: Well ControlDocument54 pagesTAMU - Pemex: Well Controldriller22100% (2)

- Injection Well ProblemsDocument12 pagesInjection Well Problemsdriller2250% (2)

- Deepwater Drilling and Well Control Course OutlineDocument2 pagesDeepwater Drilling and Well Control Course Outlinemahdi_esmNo ratings yet

- Tight Gas 2Document59 pagesTight Gas 2cmrig74No ratings yet

- Artificial lift methods overviewDocument11 pagesArtificial lift methods overviewcmrig74No ratings yet

- Wellheads and CasingDocument102 pagesWellheads and Casingdriller22100% (4)

- Motion CompensationDocument39 pagesMotion Compensationdriller22100% (1)

- TAMU - Pemex Offshore DrillingDocument42 pagesTAMU - Pemex Offshore Drillingdriller22100% (1)

- Station KeepingDocument67 pagesStation Keepingdriller22No ratings yet

- How Society Is Organized Chapter 5Document18 pagesHow Society Is Organized Chapter 5Anne MoralesNo ratings yet

- Sysmex XS-500i PDFDocument4 pagesSysmex XS-500i PDFmohamedNo ratings yet

- Mobile and Wireless Communication Complete Lecture Notes #4Document20 pagesMobile and Wireless Communication Complete Lecture Notes #4Student Lecture Notes100% (1)

- Eco Industrial DevelopmentDocument16 pagesEco Industrial DevelopmentSrinivas ThimmaiahNo ratings yet

- ASCO Switch CatalogDocument38 pagesASCO Switch Catalogjohnnie0% (1)

- BBC Learning English 6 Minute English Day-Trip With A DifferenceDocument4 pagesBBC Learning English 6 Minute English Day-Trip With A DifferenceAsefeh KianiNo ratings yet

- Curriculum Vitae Eldy PDFDocument2 pagesCurriculum Vitae Eldy PDFFaza InsanNo ratings yet

- List of Technical Documents: IRB Paint Robots TR-500 / TR-5000Document16 pagesList of Technical Documents: IRB Paint Robots TR-500 / TR-5000Weberth TeixeiraNo ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- 2011 2012 Machinery SubsidyDocument130 pages2011 2012 Machinery SubsidyanbugobiNo ratings yet

- From The Conventional Total Station To The Prospective Image Assisted Photogrammetric Scanning Total Station: Comprehensive ReviewDocument7 pagesFrom The Conventional Total Station To The Prospective Image Assisted Photogrammetric Scanning Total Station: Comprehensive ReviewLeroy Lionel SonfackNo ratings yet

- Chate Junior College Test ResultsDocument5 pagesChate Junior College Test ResultsAna VerdaguerNo ratings yet

- F 09420010120134020 PP T 07Document19 pagesF 09420010120134020 PP T 07Stevia TjioeNo ratings yet

- Mosfet 100 VoltDocument9 pagesMosfet 100 Voltnithinmundackal3623No ratings yet

- Career PlanDocument1 pageCareer Planapi-367263216No ratings yet

- Cc-5 SQL TableDocument5 pagesCc-5 SQL TableK.D. computerNo ratings yet

- V-Qa Full Final (PART-B) PDFDocument104 pagesV-Qa Full Final (PART-B) PDFKoushik DeyNo ratings yet

- MINI R56 N12 Valve Stem Seal ReplacementDocument9 pagesMINI R56 N12 Valve Stem Seal ReplacementJohn DoeNo ratings yet

- Important NoteDocument4 pagesImportant NotemikiNo ratings yet

- Urban Form FactorsDocument56 pagesUrban Form FactorsEarl Schervin CalaguiNo ratings yet

- Pakistan Exams Cie o A Reg Form Oct09Document13 pagesPakistan Exams Cie o A Reg Form Oct09shamsulzamanNo ratings yet

- Ogp1 Pintura PDFDocument19 pagesOgp1 Pintura PDFEl_memito100% (1)

- The 5 Stages of the Design ProcessDocument5 pagesThe 5 Stages of the Design ProcessDacia BarrettNo ratings yet

- Name - Akshay Surange Reg No - 19MCA10049 Software Project Management Assignment 1Document5 pagesName - Akshay Surange Reg No - 19MCA10049 Software Project Management Assignment 1Akshay SurangeNo ratings yet

- Big Data Maturity ModelDocument6 pagesBig Data Maturity Modelkatherine976No ratings yet

- eGr13OM BioResoBookDocument137 pageseGr13OM BioResoBookJanath AnthonyNo ratings yet

- Alayo, M. Internationalization and Entrepreneurial Orientation of Family SMEs The Influence of The Family CharacterArticle 2019Document12 pagesAlayo, M. Internationalization and Entrepreneurial Orientation of Family SMEs The Influence of The Family CharacterArticle 2019Riezz MauladiNo ratings yet

- ) Perational Vlaintena, Nce Manual: I UGRK SeriesDocument22 pages) Perational Vlaintena, Nce Manual: I UGRK Seriessharan kommiNo ratings yet

- 35.4 Uses Principles of Effective Speech Writing Focusing On Facial Expressions, Gestures and MovementsDocument4 pages35.4 Uses Principles of Effective Speech Writing Focusing On Facial Expressions, Gestures and MovementsWayne Dolorico MillamenaNo ratings yet

- StrippingDocument17 pagesStrippingGhavban David0% (1)