Professional Documents

Culture Documents

Re 4

Uploaded by

Pankaj BansalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Re 4

Uploaded by

Pankaj BansalCopyright:

Available Formats

1.

Check Suitability of Base Material - The quality of base material before installation should

be inspected. Unless otherwise specified, do not drill holes in concrete until it has achieved

full design strength.

2. Check Installation Condition - Prior to installation, check whether all installation parameters

(e.g. Installation temperature, condition of base material (wet/dry), etc.) are in accordance

with the design and post-installed rebar system being used.

3. Identification of Suitable Installation Location - Identify position of reinforcing steel and

other embedded items prior to drilling holes for rebar using scanning tools. Exercise care in

coring or drilling to avoid damaging existing reinforcing or embedded items. Notify the

Engineer if reinforcing steel or other embedded items are encountered during drilling. Take

precautions as necessary to avoid damaging prestressing tendons, electrical and

telecommunications conduit, and gas lines. Location suitable for rebar installation should be

marked.

4. Drilling of Hole for Rebar Installation - Drilled Holes: Drill holes with rotary impact hammer

drills using carbide-tipped bits, hollow drill bit system and/or core drills using diamond core

bits, as applicable. Drill bits shall be of diameters as specified by the post-installed rebar

system manufacturer. Unless otherwise shown on the drawings, all holes shall be drilled

perpendicular to the concrete surface. Hole if drilled unnecessarily should be filled with a

non-shrink grout of suitable compressive strength. Properly clean cored hole per

manufacturer’s instructions. It is recommended to use roughening tool like Hilti TE-YRT in

case of diamond cored holes.

5. Cleaning of Drilled Hole for Rebar Installation - Clean holes in accordance with

manufacturer instructions. In case, hollow drill bit is used, this step may be skipped [Check

installation instruction]

6. Installation of Post-installed Rebar - Perform rebar installation in accordance with

manufacturer instructions.

Clean all holes per manufacturer instructions to remove loose material and drilling

dust prior to installation of adhesive or use a hollow drilling & vacuum cleaning

system.

Inject adhesive into holes proceeding from the bottom of the hole and progressing

toward the surface in such a manner as to avoid introduction of air pockets in the

adhesive. Use of a battery dispenser is recommended to ensure correct volume of

mortar is dispensed. Piston plugs should be used to avoid formation of air pockets.

Insert rebar as instructed by manufacturer.

You might also like

- B.O.Q For Civil Part Up To Plinth LVL For Shed - Subash JiDocument2 pagesB.O.Q For Civil Part Up To Plinth LVL For Shed - Subash JiPankaj BansalNo ratings yet

- Special Note:-The Responsibility For The Correct and Safe Execution of The Works Lies With The Concerned Engineer in - Charge/ Project ManagerDocument1 pageSpecial Note:-The Responsibility For The Correct and Safe Execution of The Works Lies With The Concerned Engineer in - Charge/ Project ManagerPankaj BansalNo ratings yet

- Bbs (Kapil Ji Ware House)Document8 pagesBbs (Kapil Ji Ware House)Pankaj BansalNo ratings yet

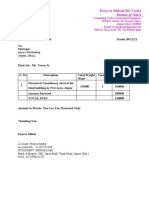

- Poorva Mittal (M-Tech) : Surya Marketing Jaipur, (Raj.)Document1 pagePoorva Mittal (M-Tech) : Surya Marketing Jaipur, (Raj.)Pankaj BansalNo ratings yet

- Method Statement For Post Installed Rebars Hilti India Pvt. LTDDocument1 pageMethod Statement For Post Installed Rebars Hilti India Pvt. LTDPankaj BansalNo ratings yet

- Name of Work:-Design Calculation of Rain Water Harvesting S.No Description Total Area Unit 1 Area Details Project - Ncru (Jamalpur)Document1 pageName of Work:-Design Calculation of Rain Water Harvesting S.No Description Total Area Unit 1 Area Details Project - Ncru (Jamalpur)Pankaj BansalNo ratings yet

- Letetr HeadDocument1 pageLetetr HeadPankaj BansalNo ratings yet

- (Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualDocument59 pages(Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualPankaj BansalNo ratings yet

- Amazon - Ncru: Supplier Wise Status of Key ComponentsDocument2 pagesAmazon - Ncru: Supplier Wise Status of Key ComponentsPankaj BansalNo ratings yet

- Comment On (KIRBY - PEB PROPOSAL)Document4 pagesComment On (KIRBY - PEB PROPOSAL)Pankaj BansalNo ratings yet

- Final Report For Proposed Auditorium at Jhansi Cantt - New-1 PDFDocument9 pagesFinal Report For Proposed Auditorium at Jhansi Cantt - New-1 PDFPankaj BansalNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- RS Construction Company Agreement (Kanak AAngan)Document4 pagesRS Construction Company Agreement (Kanak AAngan)Pankaj BansalNo ratings yet

- (Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualDocument75 pages(Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualPankaj BansalNo ratings yet

- Item No. 12Document80 pagesItem No. 12Pankaj BansalNo ratings yet

- (Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualDocument69 pages(Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualPankaj BansalNo ratings yet

- (Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualDocument57 pages(Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualPankaj BansalNo ratings yet

- Ca No: Cejz/Jslr/ of 2017-2018Document25 pagesCa No: Cejz/Jslr/ of 2017-2018Pankaj BansalNo ratings yet

- (Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualDocument67 pages(Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualPankaj BansalNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NMR Solvents - Unsurpassed Quality For Peak PerformanceDocument12 pagesNMR Solvents - Unsurpassed Quality For Peak PerformanceSigma-Aldrich100% (1)

- AVL Internal Manufacturer 191097Document285 pagesAVL Internal Manufacturer 191097Seyyed Amir MohmmadiNo ratings yet

- IjoiijDocument347 pagesIjoiijpi.314153.4No ratings yet

- M-08 Hull Piping DiagramDocument51 pagesM-08 Hull Piping DiagramĐức Nguyễn ĐìnhNo ratings yet

- Rmi Verif RC Columns 3 2Document76 pagesRmi Verif RC Columns 3 2Fernando MartinezNo ratings yet

- Bche 111l Chemistry For Engineers Weeks 1 9 Self Instructional Manual Rev2Document233 pagesBche 111l Chemistry For Engineers Weeks 1 9 Self Instructional Manual Rev2Rob LunaNo ratings yet

- Method Statement For Painting Works: MS Number Revision Date-IssuedDocument9 pagesMethod Statement For Painting Works: MS Number Revision Date-IssuedKalai ManiNo ratings yet

- Assignment 1Document32 pagesAssignment 1sharifah atiqahNo ratings yet

- A Fatigue Damage Model of Composite Materials PDFDocument5 pagesA Fatigue Damage Model of Composite Materials PDFpanbuNo ratings yet

- Chapt02 PDFDocument21 pagesChapt02 PDFAdi SuwandiNo ratings yet

- Brochure of Dongyang RopesDocument34 pagesBrochure of Dongyang RopesVu Duc Quang100% (1)

- Moles and Empirical FormulaDocument11 pagesMoles and Empirical FormulaZenoxu 7zNo ratings yet

- Quiz 1 InorgDocument5 pagesQuiz 1 InorgDanielle Lois AbagNo ratings yet

- F2 C6: Acids & AlkaliDocument3 pagesF2 C6: Acids & AlkaliJas 408No ratings yet

- ASTM A449 Tech InfoDocument2 pagesASTM A449 Tech InfoBoz Van DuynNo ratings yet

- Windows - Building in - G JamesDocument5 pagesWindows - Building in - G JamesAndrew VincentNo ratings yet

- Inorganic Chemistry Practice Booklet-1Document65 pagesInorganic Chemistry Practice Booklet-1godlanshul32No ratings yet

- Presentation On Utilities & Offsite Iffco, ParadeepDocument22 pagesPresentation On Utilities & Offsite Iffco, ParadeepSOCRATESNo ratings yet

- Sizing & Selection: The Control ValveDocument7 pagesSizing & Selection: The Control ValveJamesTorresPalmaNo ratings yet

- Midas Concrete DamageDocument9 pagesMidas Concrete DamageShishir Kumar Nayak100% (1)

- CH 11Document35 pagesCH 11nur afifahNo ratings yet

- Astm C 1202-97Document6 pagesAstm C 1202-97Vasco Sorte100% (1)

- Enviroline 125LV-LT+ds+engDocument4 pagesEnviroline 125LV-LT+ds+engMohamed NouzerNo ratings yet

- Phosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdDocument7 pagesPhosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdzvjesosNo ratings yet

- Flexural Analysis of BeamsDocument20 pagesFlexural Analysis of BeamsRyle AlavazoNo ratings yet

- Effect of Backstay On 3B+G+20 Storey RC BuildingDocument5 pagesEffect of Backstay On 3B+G+20 Storey RC Buildingdharashah28No ratings yet

- Astm D4759Document7 pagesAstm D4759EfrilaNo ratings yet

- Oilandfat IVDocument28 pagesOilandfat IVARATHI PMPMNo ratings yet

- App 10093Document9 pagesApp 10093Omkar BordeNo ratings yet

- LB Aw Arc SPT - enDocument62 pagesLB Aw Arc SPT - enWaldir Donatti JuniorNo ratings yet