midas Gen Steel Code Checking Result

PROJECT TITLE :

Company Client

Author Tina File Name Main Post.acs

------------------------------------------------------------------------------------------

midas Gen - Steel Code Checking [ AIJ-ASD02 ] Gen 2019

==========================================================================================

+============================================================+

| MIDAS(Modeling, Integrated Design & Analysis Software) |

| midas Gen - Design & checking system for windows |

+============================================================+

| Steel Member Applicable Code Checking |

| Based On Eurocode3:05, Eurocode3, AISC(15th)-LRFD16, |

| AISC(15th)-ASD16, AISC(14th)-LRFD10, |

| AISC(14th)-ASD10, AISC(13th)-LRFD05, |

| AISC(13th)-ASD05, AISC-LRFD2K, AISC-LRFD93, |

| AISC-ASD89, CSA-S16-01, BS5950-90, AIJ-ASD02 |

| |

| |

| |

| |

| (c)SINCE 1989 |

+============================================================+

| MIDAS Information Technology Co.,Ltd. (MIDAS IT) |

| MIDAS IT Design Development Team |

+============================================================+

| HomePage : www.MidasUser.com |

+============================================================+

| Gen 2019 |

+============================================================+

*. DEFINITION OF LOAD COMBINATIONS WITH SCALING UP FACTORS.

--------------------------------------------------------------------------------------

LCB C Loadcase Name(Factor) + Loadcase Name(Factor) + Loadcase Name(Factor)

--------------------------------------------------------------------------------------

1 1 dead( 1.000) + wind( 1.000)

2 1 dead( 1.000) + wind(-1.000)

3 1 dead( 1.000)

--------------------------------------------------------------------------------------

Modeling, Integrated Design & Analysis Software Print Date/Time : 08/31/2020 14:25

http://www.MidasUser.com

Gen 2019 -1/4-

�midas Gen Steel Code Checking Result

PROJECT TITLE :

Company Client

Author Tina File Name Main Post.acs

------------------------------------------------------------------------------------------

midas Gen - Steel Code Checking [ AIJ-ASD02 ] Gen 2019

==========================================================================================

*. PROJECT :

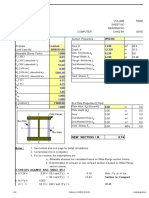

*. MEMBER NO = 1, ELEMENT TYPE = Beam

*. LOADCOMB NO = 1, MATERIAL NO = 1, SECTION NO = 1

*. UNIT SYSTEM : kN, m

*. SECTION PROPERTIES : Designation = C-100x50x5x7.5

Shape = C - Section. (Rolled)

Depth = 0.100, Top F Width = 0.050, Bot.F Width = 0.050

Web Thick = 0.005, Top F Thick = 0.007, Bot.F Thick = 0.007

Area = 1.19200e-003, Asy = 5.00000e-004, Asz = 5.00000e-004

Ybar = 1.54000e-002, Zbar = 5.00000e-002, Qyb = 4.37187e-003, Qzb = 5.98580e-004

Syy = 3.76000e-005, Szz = 7.52000e-006, Zyy = 4.37188e-005, Zzz = 1.59271e-005

Iyy = 1.88000e-006, Izz = 2.60000e-007, Iyz = 0.00000e+000

ry = 3.97000e-002, rz = 1.48000e-002

J = 1.72135e-008, Cwp = 4.39483e-010

*. DESIGN PARAMETERS FOR STRENGTH EVALUATION :

Ly = 5.00000e+000, Lz = 5.00000e-001, Lu = 5.00000e-001

Ky = 1.00000e+000, Kz = 1.00000e+000

*. MATERIAL PROPERTIES :

Fy = 2.35000e+005, Es = 2.05000e+008, MATERIAL NAME = SN400

*. FORCES AND MOMENTS AT (1/2) POINT :

Axial Force Fxx =-7.25000e+000

Shear Forces Fyy = 0.00000e+000, Fzz = 0.00000e+000

Bending Moments My = 8.13750e+000, Mz = 0.00000e+000

End Moments Myi = 0.00000e+000, Myj = 0.00000e+000 (for Lb)

Myi = 0.00000e+000, Myj = 0.00000e+000 (for Ly)

Mzi = 0.00000e+000, Mzj = 0.00000e+000 (for Lz)

======================================================================================

[[[*]]] CHECK AXIAL STRESS.

======================================================================================

( ). Check slenderness ratio of axial compression member (Kl/r).

[ AIJ-ASD02 Specification 11.1 (11.1) ]

-. Lambda = Kl/r = 125.9 < 200.0 ---> O.K.

( ). Check width-thickness ratio of flange of Channel (BTR).

[ AIJ-ASD02 Specification 8.1(1) (8.2) ]

-. BTR = bf/tf = 6.67 < 240/SQRT[Fy] ---> COMPACT SECTION !

( ). Check depth-thickness ratio of web of Channel (DTR).

[ AIJ-ASD02 Specification 8.1(2) (8.3) ]

-. DTR = d/tw = 13.80 < 735/SQRT[Fy] ---> COMPACT SECTION !

Modeling, Integrated Design & Analysis Software Print Date/Time : 08/31/2020 14:25

http://www.MidasUser.com

Gen 2019 -2/4-

�midas Gen Steel Code Checking Result

PROJECT TITLE :

Company Client

Author Tina File Name Main Post.acs

------------------------------------------------------------------------------------------

midas Gen - Steel Code Checking [ AIJ-ASD02 ] Gen 2019

==========================================================================================

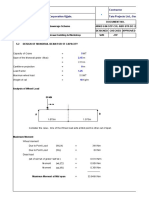

( ). Calculate allowable compressive stress (Fc).

[ AIJ-ASD02 Specification 5.1(3) (5.4) ]

[ Pi^2*Es ]

-. Lambda_p = SQRT [ --------- ] = 119.79

[ 0.6*Fy ]

-. R_Lambda = Lambda/Lambda_p > 1.0

0.277*Fy

-. Fc = ------------ * 1.5 = 88331.253 KPa. (by Short Term).

R_Lambda^2

( ). Calculate axial compressive stress of member (fc).

-. fc = Fxx/Area = -6082.215 KPa.

( ). Check ratio of axial stress (fc/Fc).

fc 6082.215

-. ---- = ------------ = 0.069 < 1.000 ---> O.K.

Fc 88331.253

======================================================================================

[[[*]]] CHECK BENDING STRESSES ABOUT MAJOR AXIS.

======================================================================================

( ). Check width-thickness ratio of flange of Channel (BTR).

[ AIJ-ASD02 Specification 8.1(1) (8.2) ]

-. BTR = bf/tf = 6.67 < 240/SQRT[Fy] ---> COMPACT SECTION !

( ). Check depth-thickness ratio of web of Channel (DTR).

[ AIJ-ASD02 Specification 8.1(2) (8.3) ]

-. DTR = d/tw = 13.80 < 735/SQRT[Fy] ---> COMPACT SECTION !

( ). Calculate allowable bending stresses (FBCy,FBTy).

[ AIJ-ASD02 Specification 5.1(4) (5.8) ]

-. Laterally unbraced length (Lu) = 0.50 m.

-. Section depth (h) = 0.10 m.

-. Area of compression flange (Af) =3.75e-004 m^2.

89000

-. FBCy = ----------- * 1.5 =1001250.000 KPa. (by Short Term).

(Lu*h)/Af

-. FBCy > FBTy ---> FBCy = Fy = 235000.000 KPa. (by Short Term).

-. FBTy = Fy = 235000.000 KPa. (by Short Term).

( ). Calculate actual bending stresses of member (fbcy,fbty).

-. fbcy = (My*Ccom)/Iyy =-216422.872 KPa.

-. fbty = (My*Cten)/Iyy = 216422.872 KPa.

( ). Check ratios of stresses (fbcy/FBCy,fbty/FBTy).

fbcy 216422.872

-. ------ = ------------ = 0.921 < 1.000 ---> O.K.

FBCy 235000.000

Modeling, Integrated Design & Analysis Software Print Date/Time : 08/31/2020 14:25

http://www.MidasUser.com

Gen 2019 -3/4-

�midas Gen Steel Code Checking Result

PROJECT TITLE :

Company Client

Author Tina File Name Main Post.acs

------------------------------------------------------------------------------------------

midas Gen - Steel Code Checking [ AIJ-ASD02 ] Gen 2019

==========================================================================================

fbty 216422.872

-. ------ = ------------ = 0.921 < 1.000 ---> O.K.

FBTy 235000.000

======================================================================================

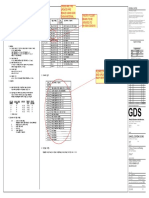

[[[*]]] CHECK COMBINED STRESSES.

======================================================================================

( ). Check interaction ratio of combined stresses (Axial compression + bending).

[ AIJ-ASD02 Specification 6.1 (6.1) ]

fc fbcy fbcz

-. Rmax = ---- + ------ + ------

Fc FBCy FBCz

= 0.990 < 1.000 ---> O.K.

( ). Check combined stresses in accordance with formula (5.16).

[ AIJ-ASD02 Specification 5.5 (5.16) ]

-. Applied shear force : Fzz = 0.00 kN.

-. Applied shear force : Fyy = 0.00 kN.

-. Sxy_y = Fzz / Asz = 0.000 KPa.

-. Sxy_z = Fyy / Asy = 0.000 KPa.

-. Sxcc = | fa + fbcy + fbcz | =-222505.087 KPa.

-. Sxct = | fa + fbcy + fbtz | =-222505.087 KPa.

-. Sxtc = | fa + fbty + fbcz | = 210340.658 KPa.

-. Sxtt = | fa + fbty + fbtz | = 210340.658 KPa.

-. Sx = MAX[ Sxcc,Sxct,Sxtc,Sxtt ] = 222505.087 KPa.

-. Com2y = SQRT[ Sx^2 + 3*Sxy_y^2 ] = 222505.087 KPa.

-. Com2z = SQRT[ Sx^2 + 3*Sxy_z^2 ] = 222505.087 KPa.

-. Ft = Fy = 235000.000 KPa. (by Short Term).

-. Rat2 = MAX[Com2y,Com2z] / Ft = 0.947 < 1.000 ---> O.K.

======================================================================================

[[[*]]] CHECK SHEAR STRESSES.

======================================================================================

( ). Calculate allowable shear stress in local-y direction (Fvy).

[ AIJ-ASD02 Specification 5.1(2) (5.2) ]

-. Fvy = Fy/(1.5*SQRT[3]) = 90451.542 KPa. (by Long Term).

( ). Calculate allowable shear stress in local-z direction (Fvz).

[ AIJ-ASD02 Specification 5.1(2) (5.2) ]

-. Fvz = Fy/SQRT[3] = 135677.313 KPa. (by Short Term).

( ). Calculate shear stress in local-z direction (fvz).

( LCB = 2, POS = J )

-. Applied shear force : Fzz = -6.51 kN.

-. fvz = Fzz / Asz = 13020.000 KPa.

( ). Check ratio of shear stress (fvz/Fvz).

fvz 13020.000

-. ----- = ------------ = 0.096 < 1.000 ---> O.K.

Fvz 135677.313

Modeling, Integrated Design & Analysis Software Print Date/Time : 08/31/2020 14:25

http://www.MidasUser.com

Gen 2019 -4/4-