Professional Documents

Culture Documents

MV Power Cable Installation

Uploaded by

Ahmad Dagamseh100%(1)100% found this document useful (1 vote)

90 views3 pagesMV@

Original Title

MV Power cable installation

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMV@

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

90 views3 pagesMV Power Cable Installation

Uploaded by

Ahmad DagamsehMV@

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

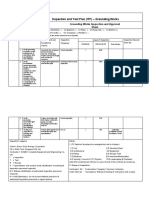

Project: J17082 Employer: ITP Ref No.

ITP-I-04

Engineer: Contractor: Date: August / 23 /2020

PO# 201902600 NEGEMCO Job No.: JV19-016 Rev: 00

Project: Aqaba Screening Project task 5 of APC storing

Inspection test Plan Medium Voltage Power Cable Installation

Inspected By 1- APC Amin Mohammad/Eyad N. Abu Adi

1-Employer APC QCP Approval

2- DAR

MV Cable Installation 2-Engineer DAR

3- Contractor NEGEMCO ( )- Approved without Comment

4- Vendor ( )- Approved With Comment- Proceed

5- Third party ( )- Not Approved-Resubmitted

Control Activity

W: Witness

H: Hold

I: Inspection

Item Activity Description Inspection/Test method Referance standard R: Review Verification Documentation

T: Testing

N/A: Not Applicable

ENG CONT TH.P VEN

1 Documentation

1_1 HSE Plan Document review HSE Policy R H N/A N/A Project requirment

1_2 Related Installation insturuction Document review Vendor Procedure R H N/A N/A Vendor Procedure

1_3 Installation Method of Statement Document review Contractor Procedure R H N/A N/A Method of Statement

1_4 Shop Drawing Document review Contractor Drawing R H N/A N/A Shop Drawing

2 Execution

Check Material Receipt inspection Project Requirement and

2_1 have been done on Delivery Visual inspection specification R+I I N/A N/A Material Receiving Report

Check Cable Drum Position before Project Requirement and

2_2 visual inspection I I N/A N/A Visual Inspection

pulling with drum. specification

Project Requirement and

2_3 Visual Inspection of the Cable visual inspection specification I I N/A N/A Visual Inspection

Inspection of cable trench

2_4 dimesnion and soft sand layer visual inspection Approved shop drawing I I N/A N/A Visual Inspection

below direct burried cable.

Check that route of power cable

2_5 ladder is complete before pulling visual inspection Approved shop drawing I I N/A N/A Visual Report

Mark (well, not same place)

temperary cabel labels 3 pcs to both

2_6 Invoiding cables mixing Cable schedule I I N/A N/A Visual Report

end. Also destination (from --> to) is

marked

Verfy enough number of cable roller

2_7 in open excavation and in cable visual inspection Specification and Drawings I I N/A N/A Visual Report

ladder for pulling.

Check that right size of cable is to be

2_8 pulled for the designated visual inspection Cable schedule I I N/A N/A Visual Report

equipment .

Check that route of cable ladder is

2_9 visual inspection Project Electrical Drawings I I N/A N/A Visual Report

complete before pulling

Cable insulation resistance test 5000 volt insulation Project Requirement and

2_9 before pulling. resistance tester. specification I I N/A N/A Visual Report

Check the cable is fixed with the Shope drawing and

2_10 visual inspection I I N/A N/A Visual Report

specified cable cleat . approved submittal.

Using approved type of cold shrink

2_11 termination on both side with the visual inspection Approved submittal I I N/A N/A Visual Report

use of specified cable gland.

Using specified stainless steel gland

Project requiement and

2_12 on stainless steel instrumet Power visual inspection I I N/A N/A Visual Report

specification

Panel.

Verify that the cable is to be

2_13 terminated in the right equipment visual inspection Cable schedule I I N/A N/A Visual Report

from both ends.

Check the cable is labeled with

specified tag and correct tag no.

2_14 from both ends. And in every 15 m visual inspection Cable schedule I I N/A N/A Visual Report

on cable ladder.

High Potential test for the cable

Project requiement and

2_15 after completion of termination kit High D.C pitential tester. specification I I R N/A Testing Report

not connected from both sides.

Check that colour coding applied Project requiement and

2_16 visual inspection I I N/A N/A Visual Report

the cores of the cable. specification

Check that warning tape, cable ties

Project requiement and

2_17 and propoer backfilling. After final visual inspection I I N/A N/A Visual Report

specification

laying of cable.

You might also like

- Project: Instrument Junction Box InstallationDocument2 pagesProject: Instrument Junction Box InstallationAhmad DagamsehNo ratings yet

- Project: Instrument Junction Box InstallationDocument2 pagesProject: Instrument Junction Box InstallationAhmad DagamsehNo ratings yet

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNo ratings yet

- IQ347-300-EL-CHL-00007 LV Cable Drum Test Report SheetDocument1 pageIQ347-300-EL-CHL-00007 LV Cable Drum Test Report SheetkamilNo ratings yet

- Conduit Installation Check SheetDocument2 pagesConduit Installation Check SheetBinu SulochananNo ratings yet

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanNo ratings yet

- Erection Methodoly Electrical 50 MWPDocument21 pagesErection Methodoly Electrical 50 MWPInaam Ullah MughalNo ratings yet

- Checklist Testing and Inspection Without Interconnection: Shams DubaiDocument26 pagesChecklist Testing and Inspection Without Interconnection: Shams DubaijayapalNo ratings yet

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- Cable Tray Inst in The Concrete-EnDocument15 pagesCable Tray Inst in The Concrete-EngkutNo ratings yet

- IMS 448-EQCL - Transformer Installation Checklist Rev01Document1 pageIMS 448-EQCL - Transformer Installation Checklist Rev01zhangjieNo ratings yet

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocument4 pagesPurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxNo ratings yet

- Electrical Inspection and Test PlanDocument1 pageElectrical Inspection and Test PlanJames Pol JumarangNo ratings yet

- F-Qa-04 General Inspection ReportDocument1 pageF-Qa-04 General Inspection ReportHilal mohamedNo ratings yet

- ITP Transformer Testing and CommissioningDocument1 pageITP Transformer Testing and CommissioningguspriyNo ratings yet

- Earthing and Bonding Method StatementDocument4 pagesEarthing and Bonding Method StatementMusthafa Shaik100% (1)

- Installation Check Sheet For Ahu FahuDocument2 pagesInstallation Check Sheet For Ahu FahuSamer AliNo ratings yet

- CL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00Document9 pagesCL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00MohamedElmahdyNo ratings yet

- Non-Conformance Report (NCR) No 65Document1 pageNon-Conformance Report (NCR) No 65Rosfaizal Mohamad ZainNo ratings yet

- Mechanical Completion Check Sheet for CablesDocument2 pagesMechanical Completion Check Sheet for CablesSourav RanaNo ratings yet

- Visual and Technical Checking of I&C SystemsDocument13 pagesVisual and Technical Checking of I&C SystemszhangyiliNo ratings yet

- Itp Survillance EquipmentsDocument6 pagesItp Survillance Equipmentssyed nadeemNo ratings yet

- Grounding Works ITP Inspection PlanDocument2 pagesGrounding Works ITP Inspection PlanElisco Pher SalmasanNo ratings yet

- Method Statement For Testing & Commissioning of Central Battery SystemDocument6 pagesMethod Statement For Testing & Commissioning of Central Battery SystemBabuNo ratings yet

- ELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Document2 pagesELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Muhammad Irfan100% (1)

- Government of Dubai approves new solar plantDocument32 pagesGovernment of Dubai approves new solar plantjayapalNo ratings yet

- 16950s01 HV Testing ProceduresDocument1 page16950s01 HV Testing ProceduresVICTOR JOSE VILORIANo ratings yet

- KP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationDocument1 pageKP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationUtku Can KılıçNo ratings yet

- MS-006 - MS For Electrical Works - Rev.1 PDFDocument1 pageMS-006 - MS For Electrical Works - Rev.1 PDFJohn Rey PerlasNo ratings yet

- Inspection Requisition / ReportDocument2 pagesInspection Requisition / ReportHanuman RaoNo ratings yet

- ChecklistDocument8 pagesChecklistSrikar Reddy GummadiNo ratings yet

- Ac Panel Test ReportDocument14 pagesAc Panel Test ReportUtku Can KılıçNo ratings yet

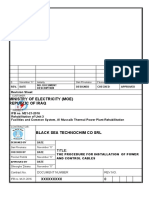

- Verificat Installation of Power and Control Cables - CELIN - Black Sea - IrakDocument8 pagesVerificat Installation of Power and Control Cables - CELIN - Black Sea - IrakAlinaIordacheNo ratings yet

- Commissioning Standard Test FormatsDocument2 pagesCommissioning Standard Test FormatstajudeenNo ratings yet

- Protective Relay Testing ProcedureDocument20 pagesProtective Relay Testing ProceduresathiyaseelanNo ratings yet

- Installation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListDocument1 pageInstallation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListZulfequar R. Ali KhanNo ratings yet

- Global Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelDocument10 pagesGlobal Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelTHULASI RAMNo ratings yet

- ITP For CCTV System Testing & CommissioningDocument1 pageITP For CCTV System Testing & CommissioningTamer EidNo ratings yet

- ITP Electrical New MCCDocument3 pagesITP Electrical New MCCMpuwh 'Riczky Syaputra'No ratings yet

- Qatar Petroleum Construction Co. Ltd Inspection & Test PlanDocument1 pageQatar Petroleum Construction Co. Ltd Inspection & Test PlanmeeNo ratings yet

- Potash Storage Instrument CalibrationDocument13 pagesPotash Storage Instrument CalibrationAhmad DagamsehNo ratings yet

- Current Transformer Testing SWP: 1. Purpose and ScopeDocument9 pagesCurrent Transformer Testing SWP: 1. Purpose and ScopeDEADMANNo ratings yet

- Pgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Document6 pagesPgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Manuel DizonNo ratings yet

- Electrical Works Grounding ITPDocument3 pagesElectrical Works Grounding ITPUtku Can KılıçNo ratings yet

- Form Substation+400V+Switchboard+Test+FormDocument2 pagesForm Substation+400V+Switchboard+Test+Formyudo heruNo ratings yet

- LV Panel ReportDocument71 pagesLV Panel ReportMudassirNo ratings yet

- Cable Testing and Health Monitoring ReportDocument13 pagesCable Testing and Health Monitoring ReportRakesh KumarNo ratings yet

- MS For The Access Control System Installation and TerminationDocument21 pagesMS For The Access Control System Installation and Terminationwaaji snapNo ratings yet

- Field Installation, Inspection & Test PlanDocument2 pagesField Installation, Inspection & Test PlanSaiful Ahda100% (1)

- Air Cooled Condensing Unit Checklist: Mr. Aden LiuDocument45 pagesAir Cooled Condensing Unit Checklist: Mr. Aden LiuADEN LIUNo ratings yet

- MSRA-T&C Electrical SystemDocument18 pagesMSRA-T&C Electrical SystemSharvin NageebNo ratings yet

- Structural Cabling System Inspection & Test PlanDocument1 pageStructural Cabling System Inspection & Test PlanRommel Espinosa ParasNo ratings yet

- Electrical Method Statement GN 8Document5 pagesElectrical Method Statement GN 8Chandree BoonzaaierNo ratings yet

- UPS Junction Box Installation ChecklistDocument1 pageUPS Junction Box Installation ChecklistmeeNo ratings yet

- Checklist For Smoke TestDocument1 pageChecklist For Smoke TestBelal AlrwadiehNo ratings yet

- Record No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesRecord No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDinesh Pitchaivel100% (1)

- QAP ElectricalDocument6 pagesQAP ElectricalFayeemNo ratings yet

- Electrica QC Check ListDocument21 pagesElectrica QC Check Listmakana qc100% (1)

- Saudi Aramco Fence Inspection ChecklistDocument3 pagesSaudi Aramco Fence Inspection ChecklistAbuAhmedQuaziNo ratings yet

- L.V Power Cable Installation 01.09.2020Document7 pagesL.V Power Cable Installation 01.09.2020Ahmad DagamsehNo ratings yet

- Control Panel Bill of MaterialsDocument57 pagesControl Panel Bill of MaterialsAhmad DagamsehNo ratings yet

- Cable Ladders and Trays Installation ManualDocument26 pagesCable Ladders and Trays Installation ManualAhmad DagamsehNo ratings yet

- Coating Inspection Reports for Cable Trays and ConnectorsDocument23 pagesCoating Inspection Reports for Cable Trays and ConnectorsAhmad DagamsehNo ratings yet

- DBHT PHB 0013 CommManShipl Rev0Document35 pagesDBHT PHB 0013 CommManShipl Rev0Ahmad DagamsehNo ratings yet

- 001862-01-0CB-EM-0020 - 01 Instruments Situation-ModelDocument1 page001862-01-0CB-EM-0020 - 01 Instruments Situation-ModelAhmad DagamsehNo ratings yet

- Liebert EXS UM EN EMEA 10H52260UM60Document106 pagesLiebert EXS UM EN EMEA 10H52260UM60Ahmad DagamsehNo ratings yet

- Instrument ListDocument6 pagesInstrument ListAhmad DagamsehNo ratings yet

- Panel Layout and External Mechanical LayoutDocument23 pagesPanel Layout and External Mechanical LayoutAhmad DagamsehNo ratings yet

- DBHT-PHB-3215 TypLight Rev1Document15 pagesDBHT-PHB-3215 TypLight Rev1Ahmad DagamsehNo ratings yet

- Control Panel Bill of MaterialsDocument57 pagesControl Panel Bill of MaterialsAhmad DagamsehNo ratings yet

- HPR Cartridge: Instruction ManualDocument40 pagesHPR Cartridge: Instruction ManualAhmad DagamsehNo ratings yet

- Panel Layout OverviewDocument24 pagesPanel Layout OverviewAhmad DagamsehNo ratings yet

- Cat Rotapuls - Cod 0913 eDocument232 pagesCat Rotapuls - Cod 0913 eAhmad DagamsehNo ratings yet

- Rotary limit switch controls industrial machine movementDocument16 pagesRotary limit switch controls industrial machine movementAhmad DagamsehNo ratings yet

- FSB 809260r2Document48 pagesFSB 809260r2Ahmad DagamsehNo ratings yet

- Man Em58 Pa eDocument60 pagesMan Em58 Pa eAhmad DagamsehNo ratings yet

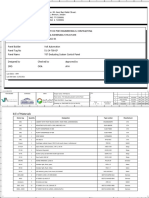

- Instrumentation & Control Cable ScheduleDocument1 pageInstrumentation & Control Cable ScheduleAhmad DagamsehNo ratings yet

- Appl Note 10078817 R0Document20 pagesAppl Note 10078817 R0Ahmad DagamsehNo ratings yet

- ROTACOD Absolute Multi-Turn Encoders GuideDocument3 pagesROTACOD Absolute Multi-Turn Encoders GuideAhmad DagamsehNo ratings yet

- Details: Item Qty ProductDocument1 pageDetails: Item Qty ProductAhmad DagamsehNo ratings yet

- Absolyutnye EnkoedryDocument116 pagesAbsolyutnye EnkoedryAhmad DagamsehNo ratings yet

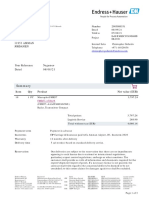

- Quotation: Negemco For Eng. and Contr. Mr. Ahmad Dagamseh Jordan-Amman 11953 AMMAN JordanienDocument3 pagesQuotation: Negemco For Eng. and Contr. Mr. Ahmad Dagamseh Jordan-Amman 11953 AMMAN JordanienAhmad DagamsehNo ratings yet

- Instrumentation & Control Cable ScheduleDocument53 pagesInstrumentation & Control Cable ScheduleAhmad DagamsehNo ratings yet

- Quotation: Negemco For Eng. and Contr. Mr. Ahmad Dagamseh Jordan-Amman 11953 AMMAN JordanienDocument3 pagesQuotation: Negemco For Eng. and Contr. Mr. Ahmad Dagamseh Jordan-Amman 11953 AMMAN JordanienAhmad DagamsehNo ratings yet

- Level Instrument Aqaba Screening Project Volume 2 - SpecsDocument1 pageLevel Instrument Aqaba Screening Project Volume 2 - SpecsAhmad DagamsehNo ratings yet

- Instrumentation & Control Cable ScheduleDocument1 pageInstrumentation & Control Cable ScheduleAhmad DagamsehNo ratings yet

- 0.39020 APC Potash I - O List 200509Document1 page0.39020 APC Potash I - O List 200509Ahmad DagamsehNo ratings yet

- Details: Item Qty ProductDocument2 pagesDetails: Item Qty ProductAhmad DagamsehNo ratings yet

- Technical Information Micropilot FMR56, FMR57: Free Space RadarDocument106 pagesTechnical Information Micropilot FMR56, FMR57: Free Space RadarAhmad DagamsehNo ratings yet

- CMP Brass Gland DataDocument6 pagesCMP Brass Gland DataAhmad DagamsehNo ratings yet

- BHS006-6 - Assessment1 Brief - 23-24Document5 pagesBHS006-6 - Assessment1 Brief - 23-24MJ MathematicsNo ratings yet

- HCIN-552: Clinical Documentation-Electronic Medical Record SystemsDocument20 pagesHCIN-552: Clinical Documentation-Electronic Medical Record SystemssNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Basic Concepts in Item and Test AnaysisDocument11 pagesBasic Concepts in Item and Test AnaysisAkamonwa KalengaNo ratings yet

- Guidelines and Rubric For Oral PresentationDocument3 pagesGuidelines and Rubric For Oral PresentationKileeshaNo ratings yet

- Urban DesignDocument7 pagesUrban DesignSuriyah SivakumarNo ratings yet

- DOE Project Execution Plan Review ModuleDocument16 pagesDOE Project Execution Plan Review ModuleNubergNo ratings yet

- Designing and Evaluating A Humanfactors Investigation Tool (HFIT) For Accident AnalysisDocument25 pagesDesigning and Evaluating A Humanfactors Investigation Tool (HFIT) For Accident AnalysisRauf HuseynovNo ratings yet

- University of Reading Thesis GuidelinesDocument5 pagesUniversity of Reading Thesis GuidelinesWhatIsTheBestPaperWritingServiceSingapore100% (1)

- Edf 621 Syllabus Spring 2020Document18 pagesEdf 621 Syllabus Spring 2020api-488950470No ratings yet

- Chapter 1 Test Bank Aud Internal ControlDocument8 pagesChapter 1 Test Bank Aud Internal ControlAnika BlairNo ratings yet

- Dessler HRM12e PPT 09Document16 pagesDessler HRM12e PPT 09Tamanna AkterNo ratings yet

- PHD Thesis Proposal in ArchitectureDocument5 pagesPHD Thesis Proposal in ArchitectureHelpOnWritingAPaperAlbuquerque100% (2)

- Compliance Audit ProceduresDocument1 pageCompliance Audit ProceduresCabanatuan School of Beauty and wellnessNo ratings yet

- Syllabus - Operations ManagementDocument2 pagesSyllabus - Operations ManagementjvanandhNo ratings yet

- Algorithms and Data Structures Study ManualDocument8 pagesAlgorithms and Data Structures Study ManualSerkan SezinNo ratings yet

- Revision Plan Essay 2Document2 pagesRevision Plan Essay 2api-585385872No ratings yet

- (Guideline) Mid-Year ReviewDocument20 pages(Guideline) Mid-Year ReviewVickiNo ratings yet

- Different Forms of Technical WritingDocument100 pagesDifferent Forms of Technical WritingcheskajelcNo ratings yet

- AEG114 Final Assignment Brief - SU21P1Document4 pagesAEG114 Final Assignment Brief - SU21P1Huỳnh Lê Mỹ Huyền (FGW HCM)No ratings yet

- ALL-IN-ONE Multi-Task LearningDocument8 pagesALL-IN-ONE Multi-Task LearningyaestaNo ratings yet

- James Wright The Impact of Artificial Intelligence Within The Recruitment Industry Defining A New Way of RecruitingDocument40 pagesJames Wright The Impact of Artificial Intelligence Within The Recruitment Industry Defining A New Way of Recruitingsparsh GuptaNo ratings yet

- Abhinandan SahooDocument12 pagesAbhinandan SahooAbhinandan SahooNo ratings yet

- Managing A Successful Computing Project - H and IDocument8 pagesManaging A Successful Computing Project - H and IGautam kumar sahNo ratings yet

- CAE Writing Task 4: of February. of February.: TH THDocument4 pagesCAE Writing Task 4: of February. of February.: TH THМилана ИгоревнаNo ratings yet

- Astm E541Document7 pagesAstm E541AlbertoNo ratings yet

- Manage meetings social activitiesDocument6 pagesManage meetings social activitiesManish UpretyNo ratings yet

- PPAP Risk: MediumDocument8 pagesPPAP Risk: Mediumrajesh sharmaNo ratings yet

- Food SafetyDocument22 pagesFood SafetyMuhammad RehmanNo ratings yet

- A Systematic Review of Green AI: Roberto Verdecchia June Sallou Luís CruzDocument16 pagesA Systematic Review of Green AI: Roberto Verdecchia June Sallou Luís CruzJordan StarNo ratings yet